Lining is a modern, versatile, environmentally friendly, inexpensive and easy to install and maintain material. Most owners use this material to decorate various surfaces of their households. But few people know that it is possible to make doors from lining and such a panel looks good, is simple to make and lasts a long time. The versatility of the material allows you to create truly unique canvases.

Characteristics and properties of lining

A clapboard door can be made from leftover wood.

Natural material is thin-thick cladding boards that are made from whole natural raw materials or using leftovers from wood processing. The elements are joined using a tongue-and-groove joint.

MDF lining is a facing material that belongs to the group of environmentally friendly coatings. Pressed panels made from small chips are considered as an alternative to natural boards or plastic strips. The adhesive in the mass is legin, a natural component of wood, and phenol and epoxy resins are not used.

The difference between artificial and natural boards:

- have less weight;

- easier to install;

- a greater variety of colors, textures, and options for simulating not only wood, but also stone.

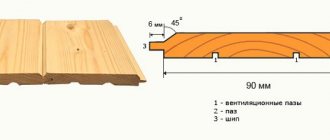

Wooden and synthetic linings are produced in the form of profiles, which differ in locks and cross-sectional shape. The basic profile is the Standard trapezoidal section, in which the edges are cut at 30°. On the reverse side there are grooves to compensate for changes in the size of the part.

Natural lining is treated with an antiseptic against fungus

. There are varieties:

- Calm;

- Europrofile;

- Eurolining;

- American.

The properties of the lining are suitable for covering doors. Resistance to fungus and rot depends on the breed, but all material is treated with antiseptics. Resistance to fire is provided by modifiers in the composition of MDF plates and fire-resistant impregnation of natural wood. All materials are easy to paint, so the door can be designed to suit different interior styles.

What attracts

First of all, you need to figure out: for which specific premises of yours it is best to make doors from eurolining. Entrance doors made of lining look stylish and aesthetically pleasing in country buildings, individual households, and in urban dwellings. We will explain to you the advantages of this material.

- Eurolining has a long service life, it is easy to install and accessible.

- Doors from lining are quite easy to make yourself, which reduces their cost

- This design is perfect for rooms with high humidity. For example, for a bath (see Wooden doors for a bath and their types), because after steaming the wood also releases useful substances.

Rules for choosing material for the door leaf

Making lining on a machine

Before production begins, the wood is selected and unsuitable raw materials are rejected. The selected round timber is fed to the sawmill, where it is cut into individual edged boards, from which the lining is made. They manufacture products in accordance with GOST 8242-1988, and also use European standards DIN 68-126-86. The quality of the material is checked before being sent for sale, and as a result the product is assigned a grade.

Select the material for door cladding according to the following characteristics:

- the humidity of natural wood should not exceed 8 – 12%;

- determine the number of knots and their condition (living, non-living, fallen, staggering), for living ones the color of the color matters;

- find areas affected by the fungus in the form of blue areas;

- check the compliance of the geometry and dimensional parameters of the board, as well as the degree of curvature;

- identify wormholes and cracks;

- determine the direction (tangential, radial) in which the cut was made.

Drying is done during production in heating chambers or an innovative infrared method is used. The correct geometry of the board is obtained on planing machines, where the product is processed simultaneously from four sides. Here the lumber receives a groove and tenon from different sides for perfect joining during installation.

Classic material is produced in 1, 2, 3 grades. The elite types Extra, Elite and others are distinguished by manual screening.

How to choose lumber for sheathing

The choice of lining for finishing a door is not limited to determining the grade, species and shape of the lamella. There are a few more important points.

- Drying degree. The moisture content of lumber should not exceed 12%. It is advisable that it drys under natural conditions. This takes several months, so forced drying is also used. This is also an acceptable option. Damp wood cannot be used. After assembly, it will continue to release moisture and will inevitably become deformed.

- Appearance. It is advisable to inspect the slats before purchasing. An unscrupulous seller may try to sell low-quality products under the guise of high-quality ones. There should be no defects or chips on the planks. Pale blue or greenish spots are not acceptable. This is a sign of developing fungal diseases.

- Quality of locking connections. Experts recommend always checking this circumstance. To do this, you need to take two plates from the pack at random and try to click the lock. The grooves must fit together accurately, without irregularities or difficulties. If you have problems when trying to click the connection, it is better to look for another lumber.

It is advisable to buy material treated with special compounds. It is more expensive, but the factory processing is worth it. It is carried out in special cells where special conditions are created. They cannot be repeated at home. Therefore, treatment with the most expensive compounds will not give the same result as factory treatment. The photo below shows the material processed in the factory.

Required elements and materials

Options for lining layout for making a door leaf

Before starting work, mark the surface of the door leaf, for which you will need a tape measure, a pencil and a square.

Tool list:

- building level for determining the verticality of elements or horizontality in a complex pattern;

- rubber hammer, pliers;

- electric drill, screwdriver;

- circular saw, jigsaw or wood saw.

The materials you will need are jagged clamps of different sizes to fasten the boards, for example, if the sheathing is mounted on a metal sheet. The elements are fixed to the wood with screws, and fastened to the metal with self-tapping screws. It is preferable to take clamps made of galvanized or stainless steel.

You will need an antiseptic and impregnation for fire resistance. This treatment is done independently before cladding, since the material is often sold for sale in its raw form. Only MDF lining, in which modifiers are present in the raw material, can be processed.

If the door is insulated on one or both sides, pieces of insulation will be required. Such material can be polystyrene foam, extruded polystyrene foam, mineral wool, stone wool, glass wool, and foam rubber are used. To install the insulating layer, you will need a lathing made of wooden battens with a cross-section of 20 x 40 mm. It is attached to wood with screws, and for a steel surface, metal screws with fine threads are used.

The rail is leveled using wedges or spacers. You can make the elements yourself or purchase ready-made ones with a corrugated surface in the store.

Method 1: wardrobe on the balcony

I had such a wonderful mezzanine on the balcony, assembled from pine beams. And all sorts of rubbish was stored on it, which frightened everyone with its appearance every time you visited it. It was decided to improve it by hanging doors, which automatically turned the structure into a full-fledged closet on the balcony.

But how to make clapboard doors in a city apartment without routers and a sawmill? The easiest way is to buy ready-made ones in the store.

I wanted an MDF panel

Having taken the measurements, I went to the supermarket, but when I found out the prices for MDF facades, I changed my mind. For the format I needed, I would have to pay about 3,500 rubles for 3 elements, which is too expensive for a little-used cabinet on the balcony.

The idea of making doors from clapboard suggested itself, since the entire balcony was covered with this material.

I decided to use lining

I arm myself with a simple tool:

- Roulette;

- Electric drill;

- Square;

- Hacksaw;

- A pack of wood screws;

- With a hammer.

Let's get started:

- Using a tape measure, I measure the length of the future cabinet door;

- I mark it on the clapboard;

- I cut with a hacksaw;

- I apply it to the opening;

- I calculate the number of slats - I got 7 pieces per door;

- I calculate the number of cross members in the same way - 2 longitudinal and one oblique.

An important point: do not forget that the lining has a tongue and groove. It also needs to be taken into account when calculating the width.

I fasten this whole thing with self-tapping screws. Their length was selected in such a way that when twisted the tip would not pass right through. 32 mm fit (lining thickness 2*20 mm).

Making a door from clapboard with your own hands

Frame for a door made of clapboard

Before installation, the cladding board must lie in the room for about a day so that the material adapts to the microclimate in terms of humidity and temperature. Slats only from the store often burst and crack during installation. For a complex pattern of lining, you need to make a drawing on the surface of the canvas.

Step-by-step procedure for covering a wooden door leaf:

- The canvas is removed from the awnings and its surface is cleaned.

- The hinges and handles are unscrewed from the sash, and the locks are removed;

- The filling of the lining begins from the side of the lock, so the first section is measured.

- The slats are cut into pieces depending on the chosen pattern; sometimes the boards are placed not only vertically and horizontally, but also a stripe is used in a combination or at an angle.

- The first part is placed along the edge, the position is checked with a level and a square, and secured with finishing nails; such hardware is the least noticeable.

- Subsequent elements are joined tenon into groove and fixed in a similar way, the ends are sanded.

The finished surface is coated with varnish, and after hardening, the fittings are fixed in place. If you have to sheathe a steel door, the procedure is similar.

Decorating a door with clapboard on iron:

- Remove the fittings and clean the surface.

- Before installing the strips, clamps are attached to the surface, they are placed on the screws using a screwdriver.

- The slats are fixed to small holders with screws or self-tapping screws.

When insulating, the insulator is cut into pieces and inserted between the slats. It is glued to the surface of the canvas, because in a vertical position the pieces can settle over time.

Initial stage of work

To find out the required amount of material, you first need to decide on the dimensions of the future door. To do this, measure the opening where it should be installed. This is done using a tape measure or metal ruler. Typically, the height of standard structures is two meters with a width of up to 90 cm.

Lining diagram.

But to reduce heat loss, you can move away from these figures and make a structure with dimensions, for example, 180 X 80 cm. It all depends on the size of the opening. You may need to make a small window in the door so you can see into the room from the outside.

Such structures are not sold in construction stores, so you will have to make them yourself. If the frame in the opening is in good condition, then it can be used to hang the door. If it is not there, then you will need to install it. To do this you will need a 100 x 100 mm beam, construction nails and a hammer. After installing the door frame, you will need to take the dimensions of the resulting opening and make a door according to them.

Door surface treatment tips

To hide the heads of the nails, use a metal finisher.

After installing the lamellas, problems arise that can be avoided if you know the intricacies of installation. Sometimes grooves appear between the elements after the boards dry out. During installation, you need to place the lining as tightly as possible, using a rubber mallet for this. The boards are placed with the tenon up and the groove down with the lamellas arranged horizontally.

Tips for processing door panels with clapboard:

- Before installation, they are treated with a special chemical preparation so that mold does not form on the surface of the cladding. The last board is placed at the awnings, so the longitudinal section of the lamella, which is not always even, will be less visible.

- The lining comes in different widths, which must be taken into account when calculating. You need to measure the length of the canvas and its width, count the number of strips so that the material does not remain and there is enough for the covering. If you have to choose slats of a different width in the store, they will recalculate along the way.

- Sometimes nail heads spoil the overall appearance of the canvas. To solve the problem, buy a hammer in the store - the tool will help hide the nails. It is not advisable to push the cap inside by more than 3 mm.

When cutting strips to the desired size, branching fibers spoil the painting and are difficult to remove with sandpaper. Use a hacksaw with fine teeth, for example, for metal, or put a corresponding file on a jigsaw. The inner layer of sheathing at the joints is coated with PVA. The glue will harden, and when it gets colder, it will prevent condensation in the cracks, and the lining will not be deformed.

You can trim the sash using clapboard ornaments; American is more suitable for this. Such a board can be installed overlapping and is suitable for unusual decor, for example, diagonally. You can use old plywood as a backing

Determining the dimensions of the structure

The diagram shows the main dimensions that should not be changed

Openings in self-built baths, as a rule, differ from standard ones. Therefore, before making a door and frame for it, it is worth carrying out basic calculations:

- Using a tape measure, measure the width and height of the opening according to the level to avoid errors due to skew.

- Subtract 6 cm from the resulting width and 3 cm from the height. This way you will get the external parameters of the box without taking into account the threshold. It is better to determine its thickness when the door is ready in order to level out possible errors.

- From the width of the box, subtract the thickness of the timber that you plan to use (the most popular is 110x60 mm) and another 6 mm (the required gap on both sides). This will be the final width of the finished door.

- To determine the height of the door, subtract the thickness of the beam and another 18 mm from the height of the frame (3 mm gap at the top and 15 mm ventilation gap at the bottom).

If the result obtained differs from standard models by only 1–2 cm, you can make a standard door and simply use thicker bars to secure the frame in the opening.

Painting a clapboard door

The lining is coated with a layer of varnish to preserve the structure of the wood.

High-quality lining is usually not painted, but covered with a layer of varnish several times. Varnishing shows the texture of the design. If the wood is too light, use stain to reveal the wood.

Painting is carried out in the following cases:

- peeling of the old layer;

- tarnishing of lamellas;

- ingress of fat, oil, dye, the appearance of fungus and mold;

- interior renovation.

Painting is required if it is necessary to level the surface, repair chips, fallen knots, or large cracks. Use Senezh Neo or Frost to whiten darkened areas on the slats. Degrease the surface with acetone solvents. Roughness is smoothed out with sandpaper.

Use wood putty, press it into cracks, places where knots have fallen out, and after drying, sand it. The putty areas are then primed and painted.

Preparation

The lining itself is very thin (10-12 millimeters), which is why it will not be possible to make a durable door from it alone. You will need to build an additional strong frame from a good board or timber.

- It is advisable to buy them already planed, but if they are not on sale, you will have to arm yourself with sandpaper or a sanding machine to give the parts the proper smoothness and visual appeal.

- In order for the connection of the lining to the frame to look solid and look beautiful, you will need to cut grooves in the boards using a milling machine. If you don’t have the opportunity to get one, then you can take the blanks to the nearest child care center, where they will cut them for you as needed for a nominal fee.

- All elements must fit tightly to each other, which means the cuts must be exactly 90 or 45 degrees. To perform these, you cannot do without a miter box with a hacksaw or a miter saw.

- You may also need a jigsaw, a screwdriver and a drill.

- We will fasten the elements together with glue, wood glue or PVA. It is reliable and beautiful, as there are no traces of fasteners left in sight.

Schemes for the direction of the lining on the doors

- Then you need to choose the scheme according to which you will type the canvas. Among the options presented above, the most durable will be numbers 1 and 3, with transverse drawers. Model No. 5 will be the most difficult and time-consuming to execute, since the edges of the lining will have to be cut at an angle.

Insulation

If the entrance door to the bathhouse is made of boards or lining, then it must be insulated to reduce heat loss during heating. For insulation, felt, batting or polyethylene foam is used. The material must be measured according to the size of the door, cut and secured to the canvas with furniture staples or nails, leaving free edges at least 5 cm wide.

Leatherette is good for door trim. The material is cut in such a way that the edges can be folded under the insulation by 2-2.5 cm. To ensure that the upholstery lies flat, the material must be fastened from the middle. The fasteners are decorative upholstery nails with large heads. To form a convex pattern between the nails, you need to pull the line tight.

Along the perimeter of the door you need to attach leatherette rollers, inside of which there is insulation. The edges of the rollers are nailed to the door with decorative nails in small increments (5-10 cm). The seam can be made decorative: hammer nails tightly, in 2 rows, in a zigzag, etc.