Articles

All photos from the article

Nowadays, beautiful doors are quite expensive, however, you can make them yourself from plywood, and thereby save money. The only thing is that you should first familiarize yourself with all the nuances of this work. Therefore, next we will look in detail at how to make a door out of plywood with your own hands.

Plywood door

DIY plywood doors

If you have the necessary skills in working with plywood, you can make interior doors with your own hands. Firstly, it is cheaper than buying a ready-made structure or ordering a door from a manufacturer. Secondly, you can make a door that exactly matches the required dimensions, choose your design and decoration. Thirdly, you will be 100% confident in the quality and reliability of the design.

Results

You can make wooden or plywood doors with your own hands. It is important to choose a suitable design, have some patience and time, as well as a certain amount of materials.

Source

| Single layer | They consist of one sheet of plywood, which is reinforced along the contour on both sides with strips. This design resembles paneled doors, however, it has low noise and thermal insulation rates. Therefore, it is usually used as interior furniture. |

In what cases is it better to install

Sliding doors and sliding doors are installed between rooms. They are especially relevant in the following rooms:

- Kitchen where there is never enough space

- Interior space when two rooms are separated from each other

- Toilet and bathroom

- Dressing room, mirrored doors are often installed here

Doors can be made not only from plywood, but also from solid wood. However, plywood is preferable if you need to make a door leaf of a curved shape. Such designs are in demand mainly for dressing rooms. Plywood bends well, so giving it the desired shape will not be a problem. Radius doors are attached to the same curved profiles.

In addition, plywood is lightweight, it is resistant to high humidity and temperature changes, and is not afraid of direct sunlight. Plywood is easy to care for, as the material tolerates synthetic detergents well.

Types of products

You can make any door from sheets of plywood, you just need to decide on the type of future structure. Depending on the installation location, a single-layer or frame plywood structure can be made.

Single-layer options are very easy to manufacture. They consist of one thick sheet of plywood at least 1 cm thick, upholstered with planks along the contour on both sides.

Such products are called paneled and, as a rule, are installed on doorways in the apartment.

They transmit sound, do not retain heat and are not resistant to mechanical damage.

Frame structures using plywood are stronger and more durable, have a relatively high level of sound insulation, and if necessary, the product can be manufactured with a high-quality insulation layer to preserve heat in the room.

The manufacturing process for frame options differs from single-layer ones. First, a frame is assembled from slats, which is sheathed with plywood on both sides. Due to the additional stiffening ribs, the frames are more durable, which allows them to be installed at the entrance to an apartment or to a building in a private house.

Based on the type of structure, you need to measure the doorway and prepare a drawing. It should be taken into account that the size should be slightly smaller than the door frame.

The finished door leaf requires finishing - painting or varnishing. If desired, you can purchase laminated plywood, which is covered with a special protective film.

Sliding

The sliding door opening mechanism has the following advantages over standard swing structures:

- Doesn't take up extra space

- Do not accidentally open when there is a draft

- They do not slam shut on their own, which is important in families with small children

Plywood sheets are also lightweight, so the load on the walls is minimal.

Coupe doors

A sliding door is one of the options for sliding doors. Before you begin its manufacture and installation, you need to study the main features. The structure consists of the following elements:

- Door leaf

- Rollers for moving the web along the guides

- Profile

- Stoppers limiting door movement

Sliding doors have all the advantages of sliding structures. The difference is that the sashes remain outside and move along the walls, rather than being “recessed” inside. The main advantage compared to swing models is the saving of space in the room by using the usable area that is usually left for opening the door.

Compared to sliding structures, sliding doors are easier to install. For those who plan to install doors on their own, this is an important advantage. For such doors, only guides and rollers are needed. Complex work on installing the box, which is usually planned at the repair design stage, is absent here.

Paneled

The peculiarity of such doors is that they are assembled from separate boards or bars, and the middle is filled with thinner versions, glass or plywood. The manufacturing technology of a paneled door involves performing the following operations:

- First of all, you need to cut blanks for the frame from boards or timber. This design consists of a rectangular canvas, inside of which there are only partitions, and everything else is filled with other components.

- When the workpieces are ready, they are also carefully polished and leveled. Such operations should only be performed with dry wood in a dry and warm room. In another case, the tree may gain moisture and then change shape.

Next, grooves are cut out on each board. Please note that some elements have a tenon, while others have depressions. This allows you to form a tongue-and-groove connection. In a similar way, a rectangular frame is formed from boards

It is important here to carefully adjust all the elements. At this stage it is also important to cut out the slots for the lock. After the frame is made, its interior is filled with thinner boards or glass

To do this, grooves for these elements are formed on the support boards using a milling cutter and they are also carefully adjusted. If glass is used, then you need to cut it to the size of the internal opening. It is fixed using wooden glazing beads made from the same wood. The procedure is completed by assembling the entire canvas and gluing it together. Special glue is also used for this. The boards are also tightened together in a special vice. When the mixture has dried, the canvas is sanded and glass is installed (if necessary), and then the entire surface is varnished.

Required materials and tools

Installation of sliding plywood doors begins with preparatory work. You need to stock up on the necessary materials and tools so that nothing later distracts you from your work. To create a simple door you will need the following materials:

- Beams in the amount of 5 pieces, length 3 m and cross section 45 x 20 mm.

- Waterproof plywood, coniferous varieties are suitable. The dimensions of the sheet depend on the size of the door leaf.

- Insulation or filler. For a regular interior door, you can choose an inexpensive option that does not have noise and heat insulation properties. But even in interior structures, inexpensive mineral wool or expanded polystyrene can be used as insulation.

- PVA construction adhesive

- Rail

- Profile to be used as guides

- Rollers

- Wood putty

- Acrylic sealant for wood

The tools you need to prepare are:

- Circular saw, hand or electric

- Jigsaw

- Sandpaper

- Spatulas of different sizes

- Screwdriver

- Electric drill

- Fraser

- Ruler

- Pencil

- Masking tape

- Tassels

If you are planning decorative surface treatment, then a milling machine and a miter box will be useful to you.

How to make a door frame yourself?

The door frame is the basis of the door structure, it is the key to its quality and strength, long service life, as well as an attractive appearance. It is with the preparation of the doorway that all work on the manufacture of the door begins - this is the load-bearing fabric of the entire product, as well as the place for installing the lock plate. Making a door frame is quite simple, but only if you take a responsible attitude to this stage of manufacturing, you can ultimately get a good result and a door that will fulfill its direct responsibilities. The manufacturing scheme does not contain anything complicated.

You can use any type of wood for the box, but it is important to consider its properties

Let's look at an example. Pine is most often used for door frames. This is a material with an affordable price, which corresponds to the quality, but pine is categorically unacceptable for entrance doors, since it has such properties as softness and elasticity: such a product will not be able to have a high level of strength, and therefore not perform its direct functions. Oak is better suited for entrance doors, while pine is an excellent solution for interior structures.

Metal is a durable and high-quality alloy, which at the same time does not look very aesthetically pleasing.

Thus, MDF boards are the destiny of interior doors, and metal is the destiny of entrance doors. But while wood fiber is easy to work with, metal structures require remarkable welding skills.

The manufacture of a door frame traditionally begins with careful measuring manipulations, which should be done after dismantling the old structure. It is necessary to measure the sides of the doorway, as well as the threshold and the top of the opening, and then calculate the required amount of material. The width of the door frame is directly proportional to the width of the walls.

The next stage is cutting the material and connecting the structure

Here it is extremely important to decide on the type of connection. Experts prefer the groove method; it is considered the most reliable, but it is quite difficult to cut all the grooves yourself

The upper edges of the vertical and horizontal elements are cut at an angle of 45 degrees, thereby forming diagonal joints of the structure.

If all measurements are made correctly, then you can begin assembling the structure and processing it, and then installation. This process is quite simple, but some nuances may arise in the final stages.

When installing a door frame you must:

- make sure that the frame matches the parameters of the door;

- mark all areas where hinges or other fasteners will be located;

- mount the frame into the doorway, adjusting all dimensions using a plumb line and level;

- fix the position of the door using pegs or strips;

- secure the structure with bolts;

- Fill the cracks with foam.

In most cases, at this stage the installation of the door frame ends, but this is a practical part, and we must not forget about aesthetics. It is also necessary to hide the junction of the doorway and frame, as well as take care of closing empty spaces that may well arise if the owner wanted to change the geometry of the doorway and reduce it.

DIY plywood doors. Step-by-step instruction

If you follow the detailed instructions for installing a sliding door, then installing it yourself will not be a problem. It is quite possible to do without the help of specialists to make a plywood door yourself. This does not require extensive experience; basic repair skills and the ability to handle tools are sufficient.

Making a single-layer plywood door

- A sheet of plywood with a thickness of at least 1 cm must be cut according to predetermined parameters

- Slats or wooden planks are attached along the perimeter of the sheet. This is necessary to give rigidity to the door leaf. You can fasten the planks with screws, small nails or using wood glue.

- To increase the strength of the structure, horizontal jumpers are needed, for which the same rail is used. First they are installed on one side of the sheet, then on the other.

- To give the door a more aesthetic appearance, you can smooth out the transition from the slats to the main panel using glazing beads.

- Next, the door needs to be sanded, putty and painted in the desired color. You can simply coat the plywood with varnish.

- Fittings are installed on the finished door

Making a frame door

This product will require two plywood sheets, which will be attached to a frame made of bars and planks. The frame is made according to the dimensions of the doorway. Wooden parts are fastened into one structure with self-tapping screws or metal plates.

The first sheet of plywood is fixed on one side of the frame using self-tapping screws. Then a layer of thermal insulation material or simply filler is laid so that the door is not hollow. Next, a second plywood plate is attached to the other side of the structure. All that remains is to treat the canvas with putty and paint it in the desired color, fasten the fittings - and the sliding door is ready for installation.

Installation of the structure

- Attaching the rollers to the door leaf depends on the system used. Manufacturers' recommendations must be followed. Most of them recommend retreating a certain distance from the edge and attaching the plates under the rollers there. They are fastened with self-tapping screws, the length of which should not be less than 70 mm. They need to be screwed strictly perpendicularly. Supports for the rollers are installed in the plates, and the platforms themselves with wheels are already attached to them.

- The guides are installed from above the doorway. The best option is to first hang the profile on a dry beam using self-tapping screws, and then secure this structure above the doorway.

- Hanging doors on guides. It is important to leave a distance between the floor and the door leaf so that the door does not shuffle across the floor when opening and closing.

- Installation of stoppers. They are mounted from above directly into the profile, starting from the sides. At the bottom, the stopper is needed at the same level as at the top.

Related article: How to open a door handle in an interior door

The final work is finishing. The top beam can be covered with a strip that matches the color of the door.

How to insulate?

If the owner was able to make repairs in the apartment with his own hands and assemble the door structure, then insulating it would be a matter of a couple of minutes.

Basically, only the entrance doors or those products that open onto the balcony need to be insulated. Although insulation is a simple process, it contains several stages:

- installation of insulation materials around the perimeter of the door frame;

- sealing the gaps between the frame and the door leaf itself;

- if necessary, sealing fittings, locks and other elements;

- insulation of the door structure, including the leaf.

For insulation you will need:

- material for insulation (foam rubber, synthetic winterizer, etc.);

- sealing/sealing material;

- upholstery material for the door leaf (eco-leather or polycarbonate, wood panels);

- screwdriver;

- polyurethane foam;

- measuring instruments and scissors;

- construction stapler.

Before you start work, you need to decide on the materials for insulation and sealing and their quantity, therefore the door structure must first be examined in detail for the presence of gaps, and the door leaf for the upholstery material must be measured. Only after this can you begin installing the seal. It is attached either to adhesive tape or to staples, and the second option is much more reliable. The next step is upholstering the door leaf; this can be done both on the front side of the door and on the back. The owner determines the color and type of fastening independently.

If we are talking about insulating a metal door, then the progress of work will be slightly different. Such doors can be easily insulated from the inside using polystyrene foam and other synthetic materials. The canvas is attached in any way between the partitions of the main frame, then the metal base is welded back and you get a warm entrance door with additional noise and heat insulation.

Advice from professionals

- If the doorway is smooth, then the canvas can be measured strictly according to size. When opening with a curvature, take the canvas with a margin so that it covers all deviations.

- Sliding doors are hung after renovation, that is, the walls must be covered with wallpaper, and the opening itself must be plastered or painted.

- When installing the decorative beam, place it so that it covers the rollers. The design will look more beautiful and neat.

Thus, even a non-professional builder can make and install a sliding door with his own hands. The main thing is the ability to work with the tool, strict adherence to instructions and the desire to make a truly high-quality product.

An example of sliding door installation can be seen in the video.

General principles

When making doors yourself, the first thing you do is measure the doorway: you need to make a door frame. In most cases, it has the shape of the letter “P”: two vertical posts are installed and one horizontal one is installed at the top - the lintel or crossbar.

The strip, which is attached below, is rarely used today, but there are special-purpose rooms in which a threshold is required. For example, in the steam room of a Russian bath. A threshold is needed here to prevent steam from escaping.

Having previously assembled the door frame on the floor, you can decide on the dimensions of the future door: they should be a couple of centimeters smaller than the frame you made. After you make the door leaf, cut in the hinges. Doors made of wood are heavy, and it is very difficult to carry them and try on the hinges. Therefore, it is more convenient to do everything on the floor. Mark the fastenings for the hinges, make a recess to the required depth, install them on the jamb and on the door leaf.

Schematically, the door installation technology looks exactly like this

Then you install the box in the opening, secure it, and only then hang the doors. Here's a general outline of how the process works. Now let’s learn more about how to make doors with your own hands.

Instructions with photos and videos on how to make plywood doors with your own hands

Making plywood doors with your own hands is not as difficult as many people think. And this activity is very inexpensive and will save the family budget on purchasing ready-made doors. Both entrance and interior doors, including sliding ones, can be made from plywood. How to do this will be described and shown in this article.

Plywood door

Preparing tools

Anyone can make a door out of plywood with their own hands, but to do this you need to acquire not only sheet material, but also special tools and equipment. To create a simple panel version of doors you will need the following materials:

- Bar 3000x45x20 mm (5 pcs.).

- Rail 50x30 mm.

- Waterproof plywood grade FSF 3/3 (can be coniferous). Sheet parameters 1220x2440x9 mm.

- Insulation (for the entrance structure) or simply filler (expanded polystyrene).

- Self-tapping screws 30x3 mm (about 200 pcs.).

- PVA construction glue.

- Putty for wood products or acrylic-based sealant for wood.

- Dye.

You will also need various tools:

- Sandpaper;

- Spatulas;

- Brushes;

- Masking tape;

- Hand or electric circular saw;

- Jigsaw;

- For decoration you may need a miter box and a milling machine;

- Screwdrivers, screwdriver.

- Ruler, pencil.

Creating an entrance door from plywood

First of all, you need to create a drawing, then make a door casing, for this you will need a block. The easiest way is to make a U-shaped structure for the doorway, the diagram of which is presented below. After this, you can proceed to creating a frame for future doors from the slats. It is also possible to make connecting jumpers for plywood sheets.

Slat door frame

You can connect all the sections of the rail using screws - this is the easiest way and does not require much time. Then, using centering, we make a countersunk hole and screw the prepared plywood to the frame with screws. Each fastener is located at a distance of 20 cm from each other.

Tools for screwing in self-tapping screws

Note!

The hole under the putty is made in such a way as to hide the head of the self-tapping screw to a depth of 1 mm, but if a wooden plug is intended, then 3 mm.

We cut the plywood for the frame with a saw (manual or electric).

Now we need to insulate our door. To do this, you need to put mineral wool or other insulation inside. This will also eliminate extraneous sounds from outside and keep you warm.

Insulating a plywood door

We screw a second sheet of plywood on top, thereby covering the insulation. The door as such is ready. Decoration can be done using a hand router.

Decorating a plywood door

Now you can sand the surface with a machine and then with sandpaper (120 grit). The drawing is sanded entirely by hand.

All possible defects and holes must be filled with putty.

Puttying cracks and other holes

All that remains are decorative measures, cutting in locks and handles, priming the structure and painting it.

Embedding a lock with a handle and the finished door

How to make such doors from plywood with your own hands is demonstrated in more detail in the video.

Creating a sliding interior door from plywood

As an internal partition in the house, you can make a sliding door from plywood with your own hands. To do this, you will need guides, which can be purchased at a hardware store. Choose the length you need for your room and doorway. Mostly they already come with the mechanism, but if not, then you need to purchase the mechanism as well.

Sliding door kit

Note!

Rollers in a steel mechanism are more durable than rubber ones.

A plywood partition will be lightweight and to create it you will need, in addition to sheet material, wooden slats and glazing beads. From the slats we make a frame for the future partition, which is connected using glue and spikes. In the finished frame, you need to fix the plywood sheets using glazing beads and that’s it, the structure is ready.

All that remains is the decorative side of the process. Here, whatever you want, you can glue a special decorative film over the plywood, cover it with fabric, or simply varnish it, and paint it. You can create a more complex design with inserts from other materials: plastic, glass, etc.

Important! When calculating the materials for creating sliding doors, you must remember that it is recommended to make the canvas wider than the opening by 5-7 cm, and also 10-15 cm higher in height, unless of course the opening is the entire height of the room. This is necessary to avoid the appearance of large gaps around the perimeter.

Manufacturing a single-layer interior door

This design is suitable for residential premises and utility rooms where sound and heat insulation is not needed. It is a timber frame structure with slats nailed across a plywood sheet. For a single-layer door, any brand of grade 1-2 plywood is suitable so that there are fewer defects and chips on its surface.

Related article: How to properly cover a door with self-adhesive

You can also choose the thickness of the plywood at your discretion from 3 to 21 mm. If the room has high humidity, then you can purchase moisture-resistant sheets. Laminated material will not require subsequent decorative finishing. The main thing when choosing is not to take plywood that is made using phenol-formaldehyde adhesive mixtures.

The creation of the structure itself is similar to a combination of the two previous procedures, that is, the frame and the door itself are made like a sliding one, only a lock and handle are also embedded into it, and hinges are hung, as is the case with the entrance structure.

There is also an option for a multi-layer plywood door, an example would be the entrance structure presented above, where thermal insulation material is also laid between the layers of plywood. This door can also be installed in a steam room. But in this case, it is necessary to use moisture-resistant material.

Paneled

The peculiarity of such doors is that they are assembled from separate boards or bars, and the middle is filled with thinner versions, glass or plywood. The manufacturing technology of a paneled door involves performing the following operations:

- First of all, you need to cut blanks for the frame from boards or timber. This design consists of a rectangular canvas, inside of which there are only partitions, and everything else is filled with other components.

- When the workpieces are ready, they are also carefully polished and leveled. Such operations should only be performed with dry wood in a dry and warm room. In another case, the tree may gain moisture and then change shape.

Next, grooves are cut out on each board. Please note that some elements have a tenon, while others have depressions. This allows you to form a tongue-and-groove connection. In a similar way, a rectangular frame is formed from boards

It is important here to carefully adjust all the elements. At this stage it is also important to cut out the slots for the lock. After the frame is made, its interior is filled with thinner boards or glass

To do this, grooves for these elements are formed on the support boards using a milling cutter and they are also carefully adjusted. If glass is used, then you need to cut it to the size of the internal opening. It is fixed using wooden glazing beads made from the same wood. The procedure is completed by assembling the entire canvas and gluing it together. Special glue is also used for this. The boards are also tightened together in a special vice. When the mixture has dried, the canvas is sanded and glass is installed (if necessary), and then the entire surface is varnished.

Paneled doors are complex structures that require a lot of manual work. It is not always possible to make such a product the first time, since this requires skill and experience in working with various types of wood. These types of door leaves are often used as interior interior elements.

Another option for wooden doors is panel products. These are the cheapest and simplest designs. To obtain such a product, a wooden frame is knocked down from timber. After this, its inside is filled with paper or thin slats of wood. Externally, all this is sheathed with MDF or chipboard sheets.

Plywood doors: design, tools and materials, production of frame and single-layer products

Nowadays, beautiful doors are quite expensive, however, you can make them yourself from plywood, and thereby save money. The only thing is that you should first familiarize yourself with all the nuances of this work. Therefore, next we will look in detail at how to make a door out of plywood with your own hands.

Article on the topic: What material are interior doors made of?

Making a door

Project

The process of making a door is not as complicated as it might seem at first glance. The most important thing is to prepare the project correctly. It will serve as a kind of instruction for further work and will prevent errors during work. The only thing is that you first need to decide on the type of construction.

Most often, plywood doors are made of two types:

| Construction type | Peculiarities |

| Panel | They are a frame structure, which is sheathed on both sides with plywood. As a rule, insulation or stiffeners are located between two sheets. This type of door can be used in cases where good noise and heat insulation is required. |

| Single layer | They consist of one sheet of plywood, which is reinforced along the contour on both sides with strips. This design resembles paneled doors, however, it has low noise and thermal insulation rates. Therefore, it is usually used as interior furniture. |

Frame door design

Having decided on the type of construction, you should measure the door frame and indicate the size of the future product. After this, you need to draw its main details on paper and indicate their dimensions.

Note! The size of the doors should be slightly smaller than the size of the frame, otherwise they will not close well.

Tools and materials

When choosing plywood, first of all, you should pay attention to its brand. If you plan to manufacture an external door, you need to purchase material with increased moisture resistance, for example, FSF brand. True, its price is quite high, so for the manufacture of interior doors you can use cheaper FK plywood.

If you plan to open the product with transparent varnish, you should also pay attention to the type of sheets. It is desirable that they correspond to the first or, in extreme cases, second grade.

Plywood sheets FSF

In addition to plywood, you need to prepare wooden planks 100-150 mm wide. The thickness of all materials is selected taking into account the fact that the total thickness of the product should be 35-40 mm. To make a frame structure, you will also need insulation, which can be mineral wool or expanded polystyrene.

Advice! You can increase the moisture resistance of plywood yourself by impregnating the sheets with PVA glue, drying oil or other protective compound.

As for the tools, you will need the following set for work:

- jigsaw or regular hacksaw;

- electric drill;

- screwdriver or screwdriver;

- tape measure and pencil;

- sandpaper;

- wood glue;

- varnish or paint.

In addition, it is advisable to have a router that will allow you to make tenons and grooves for connecting frame parts, as well as a socket for the lock.

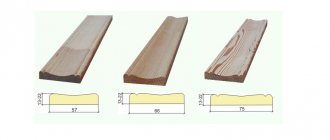

Option for connecting bars to a wooden floor using tongue and groove

Making a frame door

After preparing the project, you can proceed directly to the manufacture of the product. First of all, let's look at how a frame door is made.

So, the instructions for its manufacture are as follows:

- First of all, the frame is made, which is a frame with several jumpers. There are several ways to connect the frame strips. The most reliable is through tenons and grooves using wood glue. You can also use metal corners and screws;

- the locations of the locks should be reinforced with additional bars;

Door frame with insulation

- Next, you need to cut a sheet of plywood to the size of the door leaf and secure it with self-tapping screws to the frame. In this case, the caps must be recessed below the level of the sheet;

- then you need to lay heat-insulating material into the space in the frame and cover the second side of the door with plywood;

- The next step is to mortise the lock. To do this, you need to mill out a socket for it and drill holes for the handles;

- At the end of the work finishing is done. The product must be sanded, the screw heads and other defects must be filled, and then the surface must be varnished.

This completes the process of manufacturing the frame structure. It must be said that the product can be decorated at your discretion in different ways, for example, by gluing false panels or a wooden figure cut out with a jigsaw. You can also apply a design with a router or come up with your own version of decoration.

Single layer plywood door

Making a single-layer door

A do-it-yourself single-layer interior door from plywood is made in the following sequence:

- work should begin by preparing a sheet of plywood according to the size of the door. It is advisable to use a fairly thick sheet, at least 1 cm;

- Then, along the perimeter of the sheet, strips are attached, which can also be made from plywood. To fix them, use self-tapping screws and wood glue. It is also necessary to secure the lintels like a paneled door. To connect the planks to each other, you can use a tongue/groove or furniture tongues;

- Next, you need to attach the strips on the back side of the door in exactly the same way;

The photo shows the finished door leaf

- then you should mill out the space for the lock and the holes for the handles;

- to give the structure a complete and attractive appearance, the transition from the planks to the plywood should be decorated with profiled glazing beads;

- Now the product needs to be sanded and puttied. If you plan to open the door with varnish, then putty should be used to match the color of the wood;

- To complete the work, you need to open the product with varnish or paint.

Advice! To give the structure a certain color, but at the same time preserve the texture of the wood, it should be treated with stain before opening the varnish.

Here, in fact, are all the most optimal ways to make a plywood door yourself.

Covering the door leaf, attaching hinges and installing fittings

Before final finishing (coating with decorative film), it is necessary to prepare samples for hinges and latch. Accurate measurements are taken and the location of the loops is determined. Hinges are placed on the side edge of the door leaf at the required distance from the end and their contours are traced. The boundaries are cut with a chisel, after which a sample is made: a layer of material is removed to a depth equal to the thickness of the loop map.

Next, mark the places for the handles and drill holes. A latch is inserted into the previously prepared slot and the contours of the fastening strip are marked with a pencil. They cut a recess under it.

Having completed the preparatory work, they begin to cover the door leaf. To create a perfectly smooth surface, the plywood is sanded with fine-grained sandpaper, wiped and coated with a layer of varnish. It is more convenient to paste with an assistant who will hold the free part of the film and separate the paper backing.

If you don’t have experience working with self-adhesive film, you can watch the video and learn the nuances. To avoid the appearance of wrinkles and small bubbles, the film should be glued evenly across its entire width, carefully smoothing it out, but not allowing it to stretch. The film is folded over the side edges of the door leaf and overlapped. After completing this important process, screw the hinges with screws and install the latch with handles. They hang the door.

One of the methods for manufacturing a panel door is presented. You can choose a “lightweight” version of the canvas and not fill the voids with polystyrene foam, but use MDF instead of plywood.

/p{amp}gt;

Installing a latch on an interior door

Before deciding which door you need, you need to decide what room it is intended for.

Door leaves can also be divided according to the type of construction, of which there are several:

- massive,

- paneled,

- panel (solid and hollow),

- frame.

Massive

Main! Do not forget to subject the structures to mandatory treatment with water-repellent and

antiseptic

drugs.

Paneled

It must be said that a well-made paneled

door

outwardly it is almost impossible to distinguish it from solid wood.

Panel

- solid,

- small-hollow,

- hollow.

Conclusion

Making plywood wooden doors is beneficial from an economic point of view, and in addition, doing something yourself is always interesting. However, for this you need to stock up on time and patience, since the work must be done carefully and slowly. Only in this case the product will turn out beautiful and durable.

The video in this article contains some additional information on the topic discussed. If after reading the material you have any questions, you can ask them in the comments, and we will be happy to answer them.