One of the most important stages of arranging a bathhouse is the organization of timely disposal of wastewater into a treatment facility. The most affordable option for a sewer system is a drainage pit for a bathhouse.

To ensure the safe use of the drainage system, before starting work, it is recommended to carefully study its design features and perform the necessary calculations, and at the construction stage, follow the basic recommendations of specialists.

Homemade septic tanks - design options

The simplest solution to the problem of draining wastewater from a bathhouse is to purchase a ready-made industrial septic tank.

However, in some cases, it is more rational and practical to make a homemade septic tank for a bathhouse, which will cope with the task of cleaning wastewater no less efficiently and effectively. Let's consider several options for such structures, starting with the simplest and least expensive:

Filter cesspool

Device Features:

— A pit is dug, at the bottom of which a backfill consisting of a mixture of gravel, sand and pebbles is poured in a layer of 40-50 cm.

— The walls are strengthened with brick or rubble stone.

Pros:

- Easy to manufacture.

— Minimum construction costs and fairly high efficiency in cleaning wastewater from the bathhouse when used periodically.

Minuses:

— Not suitable for baths equipped with a toilet.

— Requires frequent cleaning and periodic replacement of the drainage layer.

Septic tank made from car tires

Pit for a septic tank

Device Features:

— Tires undergo preliminary preparation - their sides are cut off.

— Pits for the septic tank are dug at a distance of 2-3 m from the bathhouse. Their diameter should correspond to the diameter of the tires used with an overlap of 15 cm. Depth - depending on the expected water flow (recommended depth is about 2-3 meters).

Related article: Non-woven wallpaper for children's rooms

— The bottom of the first pit is sealed with clay or concrete, and the bottom of the second pit is filled with a mixture of sand and gravel for filtration.

— Tires are placed in the pit, secured at the joints using wire staples or plastic clamps.

— Holes are cut in the tires for supplying a pipeline with waste and for organizing an overflow between the two chambers of the septic tank.

— A sewer pipe with a diameter of 110 mm is connected to the first tank, which is laid below the freezing level of the soil.

Pipes are fed into the holes prepared in the tires

— An overflow pipe leads from the first tank to the second.

— The pit is filled with soil and clay.

— A sheet of iron or a thick board is placed on top, covered with soil.

Pros:

— A septic tank for a bathhouse made from tires requires minimal costs for installation and delivery of components.

— Possibility of manufacturing a septic tank of optimal volume, through the use of tires of a suitable diameter.

— Ease of use.

Minuses:

— Insufficient tightness of the structure.

— Not very high quality of wastewater treatment.

Septic tank from eurocubes

Device Features:

— Eurocubes (square-shaped plastic containers with a volume of about a thousand liters) are prepared for further use. To do this, tees are installed in their necks, and holes are made for connecting and outlet pipes.

Prepared Eurocubes with tees and ventilation

— The tanks are installed in a pre-dug pit, the width of which on all sides should be 15 cm wider than the width of the tanks used. Read more about constructing a septic tank from Eurocubes with your own hands without pumping.

— Before filling the septic tank, the tanks must be filled with water, and the gap between them with concrete mortar to give the structure additional strength. To insulate the septic tank, it must be covered with foam on top and then covered with earth. The ventilation pipes must remain on the surface.

Related article: How to decorate walls? Wall finishing methods

— Drainage is being installed from perforated pipes with a diameter of 50 mm. They are laid in trenches filled with a mixture of sand and gravel.

Pros:

— Cleaning efficiency.

— Durability and reliability.

Minuses:

— The relative labor intensity of manufacturing associated with concreting the pit.

Septic tank made of concrete rings

In its design, this design resembles a shallow well.

Installation of a septic tank made of reinforced concrete rings

Device Features:

— Excavation pits are being prepared for two septic tanks.

— A calculation is made of the required number of rings, taking into account the groundwater level and the volume of wastewater.

— The chamber from the first ring is equipped with a bottom, in the second ring, instead of a bottom, a layer of crushed stone 200-300 mm thick is filled.

— Installation of pipelines and a cover with a hatch is in progress.

Such a septic tank for a bathhouse made of concrete rings can be single-chamber without a bottom. A septic tank made from plastic barrels will function in a similar way.

Review of popular schemes

Despite the material of manufacture, sewerage structures can have different designs. The difference concerns, to a greater extent, the number of cameras - from one to three. Let's consider the schemes that are most suitable for providing private houses with autonomous sewerage.

Separate storage tank

Scavenging from one sealed chamber is the simplest option. It does not pollute the environment, therefore, it is safe and environmentally friendly. Such a pit takes up minimal space, and since it is underground, it does not interfere with growing flowers or setting up beds nearby.

Restrictions apply to planting trees, which with their roots can depressurize the sewer structure.

Diagram of the simplest single-chamber cesspool. It is necessary to ensure that wastewater does not rise above the level of the sewer pipe insertion, and call the sewer service in time

A single-chamber storage tank is relevant for those who rarely use the sewer system, that is, rarely visit their dacha. There is another option - if a single person lives in the house, and the sewer system consists of a minimum of active points of use (toilet, shower, sink).

When constructing a tank, it is necessary to remember that it is not filled to the very top, but to the level of the pipe inlet, therefore it is only used to 2/3 of the volume. A simple storage tank requires regular pumping, and for this you should prepare a convenient access road for sewer trucks and it is better to conclude a contract for constant maintenance.

Drain pit without bottom

A variant of a single storage tank is a pit with a filter bottom. The main purpose of the filter is to pass part of the wastewater directly into the ground in order to reduce the load on the structure and reduce the number of calls to specialists for pumping out waste.

The design of the bottom of the tank differs from the solid bottom of a sealed chamber. This could be a structure made of concrete blanks, a brick well or a plastic container.

Scheme of a cesspool with perforated walls and a filter bottom. A thick sand and gravel bed acts as a filter, which needs to be updated over time.

In soils with low permeability, for example, in plastic sandy loams, it is advisable to arrange additional perforation of the walls. To do this, small holes are formed approximately 10–15 cm apart.

They are placed along the entire height of the soil filter in a checkerboard pattern. These methods increase the filtration area and, as a result, speed up the recycling process.

Two important conditions for a filtration device:

- sandy or sandy loam soil - loose, with a high degree of water permeability;

- low level of water horizons.

Dense clay soils, hard sandy loams, loams of any consistency simply will not absorb water, so the perforation device is useless.

This scheme is more suitable for the construction of filter wells, which are the second or third compartment and are installed after the storage tank. The quality of post-treatment of partially clarified water in the ground is much higher than that of unsettled sewage from the first storage pit.

Pumping out waste from a pit without a bottom is carried out a little less frequently than from a regular pit. If the filter becomes clogged, the pumping mode is the same.

Two-chamber septic tank made of concrete rings

A more complicated version of the drainage pit is a double tank.

It can have different designs:

- concrete container divided into 2 parts by a partition;

- 2 wells connected by an overflow pipe.

Despite some differences in design, the goals of constructing two-chamber models are the same - to separate waste according to the degree of contamination. In the first section, which is a full-fledged storage facility, waste processing by anaerobes begins, resulting in the formation of solid sediment and turbid liquid.

In the second, the wastewater is even more clarified, and there is much less sediment.

Option for installing a two-chamber septic tank. The second tank is a filter well that receives wastewater from the first chamber and sends it to the ground for further treatment (+)

If the second container is equipped with a compressor, then the cleaning will be more effective, since the processing will also be carried out by aerobic microorganisms. Two-chamber models, in fact, are no longer just storage tanks, but septic tanks capable of partially purifying sewage.

The following photo selection briefly presents the process of building a two-chamber septic tank from concrete rings:

How to make a drainage hole for a bathhouse

Drain pit made of concrete rings

The simplest option for a drain pit, provided there is strong soil, is a pit with a drainage pad at the bottom. If the soil is unstable, the walls of the pit are strengthened with various materials: brick, slate, concrete rings, metal or plastic tanks. A small pit can be made from tires. Metal or plastic pipes are used to lay communications.

Construction stages:

- Laying the drain pipe.

The drain pipe should be installed at the stage of laying the foundation of the bathhouse. It is located in the lower part of the foundation with a certain slope towards the drainage pit. The correct slope is 2-3 cm per meter of pipe length. If it is followed, its insulation may not be necessary.

- Pit construction

At the same time as the trench under the pipe, a pit is dug for a drainage pit for the bathhouse. A cylindrical pit for a bathhouse with your own hands better distributes the load on the ground, so this shape of the pit is preferable to a cubic one. At the same stage of work, an overflow pipe is laid through the trench from the bathhouse.

- Strengthening the walls

To strengthen the walls of a sand pit, you can use ordinary slate. If you decide to use brick, it is better to choose ceramic as it is more resistant to water. The masonry is done in half a brick, and gaps are left between the ends for a drainage effect. The laying should be carried out until 40 cm remains to the ground.

After the pit is ready, a drainage layer needs to be poured onto the bottom. For this, a mixture of crushed stone with sand or gravel is used. The thickness of the drainage layer must be at least 20 cm. The pit is covered with a concrete slab or a sheet of thick metal.

Often barrels - metal or plastic - are placed inside the pits. The second option is preferable, since plastic is not subject to corrosion, and this directly affects the service life of the structure. In addition, a plastic barrel is easier to find, and it can have any volume.

Drainage in the washing room

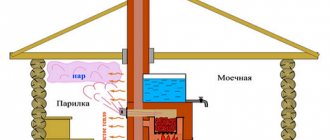

The layout of a standard Russian bathhouse has 2 rooms:

- dressing room;

- steam room connected to the washing room.

In standard modern designs, the washing room and steam room are two separate rooms. The dressing room serves as a rest room or locker room and does not need a drainage system.

The main factor that influences how to drain a bathhouse is the type of floor in the rooms where water is used.

Floors in the washing room and steam room are made according to the following principles:

- Torrential . The design is based on the installation of logs. Suitable for southern regions where the soil is loose and sandy. The floor is covered with boards, between which there are gaps. Through the flooring, water flows directly into the ground, where it is immediately absorbed. It is not practical to use such technology in the central zone and in the north.

Pouring floor in a washing bath Source stroypomochnik.ru

- Leaking. Suitable for paired rooms with a base on pillars or stilts. The wood floor is installed on joists. They are attached to the foundation supports or along the perimeter of the lower crown of the bathhouse frame. Through the distance between the floorboards, water flows into the lower compartment. From here it enters the drainage system.

- Solid. In this case, the floor is installed without gaps. Typically, this is poured concrete covered with ceramic tiles. You can make a slope of the floor in the bathhouse for drainage either towards the center or into one of the corners of the room where the drainage gutter is installed. At the first stages of construction, the drainage ladder is filled with a concrete screed. This floor can be made in steam rooms with a strip foundation.

Laying the floor in a washing room Source vladimiruzhegov.ru

In the first two options, the drainage design consists of 2 parts: a reservoir for collecting waste liquid and a drainage pipe. From the outside, the system looks different, depending on the size of the bathhouse, the type of soil and how it is affected by atmospheric temperature.

How to drain a bathhouse under the floor must be decided at the very first stages of its construction. The type of floor, pouring of concrete depends on this, it is necessary to lay communications in advance, if water will flow into the site, etc. For small rooms that are planned to be used rarely, a simple drainage system is suitable. A large drainage hole is not required here; it can be located directly under the floor or not far from the steam room.

If the family is large, and the bathhouse will be used on an ongoing basis at least 2 times a week, a full-fledged sewer system is installed, equipped with a drainage well.

Option for draining a shower for a bath Source handbuilder.ru

Options for installing a drain pit for a bathhouse

Drain pit made from a metal barrel

The design of such a drainage pit is similar to the structure of a drainage well. A metal barrel with a capacity of 200 liters can be used as a draining vessel. The process of creating a design is quite simple:

- Drainage holes are cut on the side surface of the container using a grinder. The holes are placed in a checkerboard pattern using a pitch of 15-20 cm.

Installation of drainage holes

- A pipe is installed in the bottom of the barrel, connected by a coupling to the sewer pipe. The joint is thoroughly sealed with silicone sealant. Sealing must be both external and internal.

- The entire surface of the barrel is wrapped in geotextile - a non-woven material consisting of polyester fibers and having protective properties. It will drain the wastewater without allowing large elements to enter the drain barrel.

- The geotextile is firmly secured to the barrel using twine or adhesive tape. They wrap it around the sides and bottom of the container so that there is an opening for the pipe. The top of the barrel is covered with a separate piece of geotextile, which is tightly fixed.

Next we proceed directly to its installation:

- The drain hole is dug in close proximity to the places where the water will drain (shower, washbasin, bidet, etc.). Its depth and width should be slightly larger than the dimensions of the barrel.

- The bottom of the pit is covered with a layer of crushed stone or gravel 20-30 cm thick. A barrel is installed on the resulting cushion so that the pipe is at the top.

Installing a barrel in a pit

- The voids in the pit are filled with gravel.

- A sewer pipe is connected to the pipe.

The barrel cesspool is ready!

Two-chamber septic tank made of polyethylene barrels

Polyethylene barrels can also be used as septic tanks. The design of a two-chamber septic tank is a system of two barrels:

- the first reception room, which serves to settle solid particles from wastewater;

- the second will additionally filter the water that has settled in the first barrel.

Water flows from the first barrel to the second through a specially equipped gap between the soil and the barrels, filled with a mixture of gravel and sand. This gap is a biological filter, passing through which purified water enters the ground. The upper part of the septic tank is closed with a lid, three times impregnated with a bioprotective composition.

Height difference between two tanks

A two-chamber septic tank involves laying sewer pipes from a steam room and a shower room in the foundation of a bathhouse, connected by a tee to a collector, which, in turn, is supplied to the septic tank. A hatch is installed in the dressing room for access to the pipes for the purpose of repair and inspection. If all of the above conditions are met, the sewage system will work flawlessly and properly.

Pro tip:

The advantage of using polymer barrels in the construction of a two-chamber septic tank is their resistance to rotting, destruction by corrosion and fungus. Therefore, by using them, you ensure a long service life of the treatment plant without replacement or repair.

Underground filtration fields

Underground filtration fields can be used to drain wastewater from the bathhouse. With their help, wastewater is purified and distributed into the soil through a system of irrigation pipelines throughout the entire area of the summer cottage. The design consists of a septic tank equipped with a dosing device, a drainage pipe and a distribution well.

The water flows through the pipe into a network of irrigation canals - into drainage pipes buried in the ground. The depth of laying pipes is from 0.8 to 1.5 meters, but they should not be located at a distance of less than 1 meter from the groundwater level. The disadvantages of underground filtration fields include complexity and labor-intensive installation, as well as high cost.

Underground filtration field

Now, having familiarized yourself with three options for organizing sewerage drainage from a bathhouse, you can opt for the most suitable one in your specific situation, based on material capabilities, as well as the frequency of use of the premises.

Video description

Installation of a drainage well:

Ground filtration

This is an optimal drainage system that can be used as a general sewer system for the entire site. Wastewater is transported through inclined pipes into a septic tank, where it is purified and distributed through several pipelines. They take it to the garden to organize irrigation, or accumulate it in a prepared tank. In some designs, the filtered liquid is simply poured into the ground and absorbed.

Advantages of the soil system:

- autonomy, no special maintenance required;

- water can enter the filtration part from different sources, that is, not only from the bathhouse (you can connect your house here);

- The septic tank has a high degree of purification, so it is used not only for gray wastewater, but also for black wastewater.

Flaws:

- To install a septic tank, you will need a large plot of land; it is recommended to start planning the distribution of pipes around the site in advance, in the first stages of building a steam room;

- creating a deep pit requires special equipment with which it is dug.

Ground wastewater filtration system Source orchardo.ru

How to install the system step by step:

- The septic tank is installed first. Sufficient depth is 1.2 - 2.5 meters.

- A sewer pipe is being installed. It is placed in a groove at a distance where the soil will not freeze.

- Drainage pipes are being installed. They have perforations along the entire length. Closer to the end of the pipe, the holes become smaller.

- The trenches are being prepared. To do this, pour 10 cm of sand or a mixture of sand and gravel onto the bottom.

- Pipes are laid in trenches with a mandatory slope.

- In some cases, due to soil conditions, pipes are wrapped in geotextiles.

- They are covered with an additional layer of gravel on top and then covered with soil.

- To allow air access, ventilation tubes are installed closer to the end of the pipes and covered to prevent foreign objects from entering.

The gravel layer will need to be changed periodically (every 10-12 years)

Design is carried out not only from the side of the site, but also inside the bathhouse.

Ground filtration installation Source aquaf.ru

Main types of drain pits

- 1 Main types of drainage pits

- 2 Materials for arranging a drainage pit for a bathhouse 2.1 Drainage pit from barrels

- 2.2 Brick drain pit

- 2.3 Drainage pit made of concrete rings

- 2.4 Pit made from old car tires

- 3.1 Inspection of the soil at the site of the planned drainage pit

Construction of any drainage pit is a rather labor-intensive process, since the pit will most likely have to be dug manually. At the same time, such a hydraulic structure is not very complex in design, so any owner of the site can build and equip it independently, without even involving assistants, of course, if there is enough strength for excavation work.

Drainage pits can be divided into three main types - a sealed container, a pit with drainage capacity, and a septic tank consisting of several chambers.

First, let’s figure out what each of the varieties is, in principle.

A sealed drainage pit is most often installed on construction sites with shallow groundwater aquifers. It is more often called a cesspool, that is, requiring periodic emptying of accumulated volumes of dirty water.

To build it, a pit is dug into which a container with a sufficiently large volume is installed. This is where wastewater will be collected. As the container is filled to a certain critical level, the waste is pumped out by a sewage disposal machine.

If you have a cesspool completely isolated from the external environment, you will have to very often use the services of sewerage equipment

This option is environmentally friendly, since no contaminants or chemical cleaning solutions get into the soil and groundwater, which can negatively affect the condition of the fertile soil on the site, as well as have a negative impact on high-lying ground aquifers. However, this option is not convenient and economical, since you will have to constantly monitor the filling level of the container and often call specialized vehicles, and such services are not cheap.

There is no hermetically sealed bottom created in the drainage drainage pit. It is used as a bulk layer of filtering building material - most often crushed stone or gravel is chosen for this purpose.

The bottom of the drainage pit is covered with a layer of filter material - crushed stone or gravel

In addition, holes are often made in the walls of the drainage pit at a certain height through which water will be absorbed into the soil. This option is perfect for a bathhouse and is perhaps the easiest to build, however, if the soil characteristics on the site allow it.

A septic tank is a whole system consisting of two or more chambers that have different purposes.

In any of the options, the first chamber is most often hermetically sealed and serves for collecting, primary filtration and purification of waste - solid components settle to the bottom, and liquid components are clarified and undergo a biological treatment cycle due to the action of aerobic microorganisms. This container is connected to the second chamber with a special overflow pipe - the clarified liquid waste flows into the next compartment, which is already organized according to the principle of a drainage well. The water passes through the drainage, is further purified and absorbed into the soil.

Approximate diagram of a simple septic tank

If a septic tank of three containers is planned, then the third chamber is made into a drainage chamber. The second serves for the final sedimentation of suspensions, deeper purification of water due to the action of anaerobic microorganisms. And from here the purified liquid is poured into the drainage well.

A septic tank is most often installed when it is expected to collect the entire considerable volume of liquid waste from both a residential building and a bathhouse.

What is important to know about the design and rules of septic tank equipment?

A septic tank is already a rather complex engineering structure, the creation of which must obey certain rules. Often home owners prefer to install a ready-made factory-produced system

What are the rules for setting up such a treatment plant, and what to pay special attention to when choosing a septic tank - read in a special publication on our portal

What are the differences? What types are there and in what case should they be used?

A large number of septic tanks for bathhouses have been developed. They have significant differences, representing containers made of plastic, metal, reinforced concrete of different volumes.

In addition to the material, these devices differ in their operating principle. The most recognized and effective method is biological treatment. Microorganisms that feed on waste in wastewater independently process human waste products.

Another simple method is partial purification and additional purification in the soil. So, passing through a layer of crushed stone, the wastewater ends up in the soil. This contributes to their more thorough cleansing.

Almost all designs work according to the same scheme. The first stage is to separate the dirty water from the feces by allowing them to settle at the bottom of the container.

Second stage: the water moves into the second compartment. Here it is further cleaned.

The third stage - the wastewater is clarified even more. At the last stage, the water is completely purified. Special filters can be used for this. The result is water that is not suitable for drinking; it is used only for technical needs.

Septic tanks can also be divided by type of installation. There are solid structures (made of reinforced concrete), as well as prefabricated ones.

Important! A septic tank can be made from different materials, but the price of the structure will ultimately be approximately the same. Therefore, when choosing them, it is better to focus on the properties of the structure and its functionality.

Prefabricated reinforced concrete septic tanks are considered the most popular.

Pit made from old tires

Tire drainage pit, top view

As a rule, the drains do not contain solid waste, which means that the arrangement options can be very simple. Special materials may not be required at all. Improvised means will also do. Used car tires are perfect for this. The larger the tire diameter, the better. The sidewalls of old tires need to be cut off using a grinder or jigsaw. So, the prepared tires are placed on top of each other in the pit. The lower part of the pit is also filled with crushed stone. In the tire lying on top you need to make a hole for the drain pipe and adapt it. After this, you need to put a metal sheet on the cylinders and fill it with earth according to the level.

Scheme for creating a drain pit from tires

Construction instructions

Materials for work

If the soil is dense and capable of absorbing moisture, the question of what materials to use almost never arises. In any case, the walls of the pit will not need additional reinforcement. It is enough just to fill the bottom with crushed stone and river sand. However, such a favorable combination of soil characteristics is not common.

Typically, the walls of such a septic tank need additional strengthening so that they do not crumble. For this, brickwork, boards, slate, etc. are suitable. You can also use a plastic or metal container, having previously cut out the bottom in them and made perforations in the walls closer to the bottom, to filter wastewater into the surrounding soil.

The most popular solution is a drainage pit made of concrete rings

Plumber's advice: A cylindrical section of the septic tank is preferable, since it ensures uniform distribution of the load on the ground, reducing the likelihood of destruction of the structure. The cubic shape of the pit is worse in this regard.

Preparing the trench and lining the pit

The trench from the bathhouse to the drainage pit, as well as the pit itself, can be made either manually or using earth-moving equipment. The main thing in this work is to maintain a slope of the bottom of the trench towards the drain of at least 2-3 cm per meter of pipe length.

If the slope when running the drain pipe from the bathhouse towards the cesspool is maintained correctly, insulation of the pipe may not be required.

It is important to maintain the correct level of slope of the drain pipe

It is best to line the edges of the pit around the perimeter with ceramic bricks, since they are durable and not afraid of contact with water. Bricks can be laid on edge, and gaps of 2-3 cm can be left between them for liquid drainage.

After laying, you need to form the bottom by adding crushed stone, sand or even construction waste. The thickness of the bedding layer is desirable to be at least 20 cm. The upper part of the masonry must be raised above ground level

If the hole has no bottom, you need to add sand for filtration.

or 300-400 mm. A concrete or metal panel is laid on top of the cesspool.

Plumber's advice: If the septic tank being equipped is located where cars will drive, then the reinforced concrete floor slab must have a thickness of at least 250 mm

When the drainage properties of the soil are weak, the top slab should have a hole to pump out water from time to time. Only it needs to be securely closed so that no one accidentally gets into it. After strengthening the walls of the pit, the outer side is filled with previously dug soil.

Use of available materials

Typically, bath drains do not contain solid waste, so methods for strengthening the drain pit may be simple. It is possible that you won’t even have to buy special materials: they can be replaced with improvised means.

For these purposes, it is quite possible to get by with old tires, for example, from a KamAZ car or any other larger diameter. It is better to cut off the sidewalls of old tires using a grinder or electric saw, and drill a series of holes in a circle in their lower part to drain water from them.

Drain pit made from tires - a budget solution to the problem

Then, the rubber prepared in this way is laid one after another in the ground. The bottom of the hole must also be filled with gravel. A hole is made in the second tire from the top, into which the pipe coming from the bathhouse is inserted and secured. A cover (made of metal, reinforced concrete or wood) is placed on top of the cylinders, covering them with a margin on all sides, which is covered with earth to the level of the surrounding soil.

Plumber's tip: You can also use wave asbestos cement slate to fill the volume of the drainage hole. These sheets are laid in it with the subsequent sheet turned 90 degrees until the hole is completely filled with slate

Layout of incoming pipes

The drain pipe is led to the upper part of the slate filling. Additionally, it can be strengthened with broken pieces of sheets, and the remaining voids can then be filled with excess earth. This method is most often used in sandy soils.

The last two methods cannot be used when vehicles can drive over the pit.

We recommend watching:

- Biological products for cesspools: how to choose the right one

- Popular bioactivators for cesspools

- Brick cesspool: how to lay it out correctly

- DIY cesspool made of concrete rings

- Tire cesspool: installation technique

General rules for sewerage installation

Depending on the level of sauna water supply and sewage system, wastewater with different levels of toxicity flows out of it. From showers in bathhouses and washing machines, water comes out saturated with washing powder and soap suds with minor inclusions of organic matter. In order to neutralize their influence, a simple settling tank equipped with a sand filter is sufficient. A septic tank for a bathhouse with a toilet should be more thoroughly equipped.

To do this, you will need to build a septic tank consisting of several interconnected settling tanks. In this case, you should take into account the volume of wastewater leaving the bathhouse and the type of soil on the site. The type of soil refers to its ability to absorb filtered liquid. If the soil composition is dominated by clay, then the issue of draining wastewater into a specially constructed closed reservoir should be considered.

As a rule, to keep the area clean, septic tanks are made, consisting of 2-3 tanks of various capacities. Their volume is selected based on preliminary calculations of the maximum amount of wastewater with a margin of 25-30%.

The first tank is used as a coarse filter. All large fragments of wastewater are retained in it. To delay them, crushed stone of medium and fine fractions is used. Content changes as needed. Depending on the intensity of use of the bathhouse, the septic tank for a bathhouse without pumping is cleaned once every 1-3 years.

In the second tank, the contaminated liquid is settled. All suspended substances precipitate. Within a few days the water becomes almost clear. It flows into the third tank.

A thick layer of fine crushed stone and sand is poured into the drainage container. The water passes through this filter and becomes almost pure. Absorbing into the soil, it moisturizes it, but does not poison it.

Such a system can operate successfully for years without requiring complex maintenance or cleaning. Given the insignificant volume of wastewater from the bathhouse, there is no need to bury large tanks in the ground. Moreover, installing an industrial septic tank will be economically unjustified, especially for equipping bathhouses that are used only in the warm season or periodically.

Type of sewer system

The installation of a well-designed waste water disposal system is prompted not only by aesthetic standards, but by current requirements aimed at maintaining environmental safety.

According to standards 30-02-97, the collection and disposal of wastewater from baths and showers must be carried out using treatment and filtering facilities that provide sand and gravel backfill

There can be many design solutions for autonomous sewers built during the construction of a bathhouse.

Based on the type of action, independent systems are divided into two types:

- Gravity system - involves the movement of wastewater through it by gravity. This effect is achieved due to the correctly maintained angle of inclination of the pipeline.

- Pressure system - provides for forced transportation of wastewater using pumping equipment.

A sewer system for a bathhouse building is constructed regardless of whether or not a water supply is connected to it. In any case, the very nature of the site implies a copious use of water, which must be disposed of.

When installing a gravity system, the angle of inclination of the main line is determined by the diameter of the pipes.

According to clause 18.2 of SNiPa 2.04.01-85, the sewerage slope, depending on the diameter of the pipes used, should be about 15 millimeters per linear meter

The gravity-flow system is energy-independent, but it is quite problematic to design it correctly in difficult terrain.

The pressure system is energy dependent and is more expensive than the non-pressure system. But she easily solves problems that gravity cannot handle. In order to be able to transport wastewater over long distances, when installing a pressure system, it is important to take care of the insulation of technical elements during the cold season.

Scheme for arranging a pressure independent sewerage system with the connection of pumping equipment in the basement of a building, when the septic tank is located above the pipe leaving the building

The service life of a pressure sewer system is more than ten years, and the costs of its installation are more than recouped. The main thing is to use pumping equipment equipped with a grinder, which grinds solid particles entering the drain.

Connecting a pipeline to a centralized sewerage system is a less labor-intensive, but at the same time more troublesome method. Since only a few bathhouse owners can apply it in practice, we will not study its features in detail.

Regardless of the type of sewerage scheme chosen for a bathhouse, it is extremely important to maintain the straightness of the pipeline. If turning points are provided when laying a pipeline, then inspection wells will need to be built at the locations where they are installed.

Options for arranging a water seal

The spread of a foul odor where there is a sewer is not a rare occurrence. Installing a water seal helps get rid of it. The design is an improvised water plug, which is always located in the cavity of the pipe, even during periods when the bathhouse is temporarily not in use.

The main purpose of the device is to separate two adjacent gas environments, cutting off unpleasant odors coming from the septic tank.

The simplest option for a water seal is to connect a U-shaped siphon to the pipeline, which is constructed from three shaped elements in the form of bends

The simple design has one drawback - if the system is rarely used, the liquid evaporates over time.

For such rarely used systems, it is better to install a “dry” water seal.

A “dry” water seal is a complex structure equipped with an elastic membrane and a spring mechanism that blocks the outlet from the pipe

This design is convenient in that when liquid enters the system under the influence of the created pressure, the valve lowers, opening the path for the flow, and after it passes, it returns to its original position.

In the absence of the opportunity to purchase a finished product, you can build a similar structure on your own.

The basis for the manufacture of a homemade “dry” water seal was a plastic pipe D50 mm, which was equipped with a 50/110 mm adapter

To make a water seal, the wide edge of the adapter is cut at an angle of 30°. A circle D 110 mm is cut out of dense rubber and fixed to the cut site. The finished structure is placed at the outlet of the pipe from the septic tank.

Design features

A drainage pit for a summer shower or bath consists of a drain pipe and a reservoir into which water flows. The water drainage pipe must be laid before the foundation is built. It is a wide outlet, for which the diameter and shape are extremely important.

An example of a drainage pit for a bathhouse

Bath design diagram

Mesh filter

The pipe is discharged into a drain tank. This pit is located at a certain distance from the bathhouse. Unlike a cesspool, this drain is almost always open. This approach is explained by the fact that bath water does not pose an environmental hazard.

The junction of the pipe and the drain tank is additionally sealed and strengthened with a flexible coupling.

Metal drain container for a bath

Design from the outside

The calculations use the size of the steam room, frequency of use in the future, and type of soil. Each of the water intake designs has its own installation nuances. A drainage well is used most often because of its basic design for personal use in summer cottages. The tank for wastewater treatment is enough for a group of up to 6 people to visit the bathhouse.

A professional design team will help determine the optimal size of the well in the conditions of a particular site. You won’t have to overpay for extra material and square meters of work by the installers.

Constructions that use a septic tank are sold ready-made. The volume of the tank varies depending on the number of possible visitors to the bathhouse. For a large family of 6-7 people, the average capacity of the tank should be at least 1.5 m3 per day.

How to lay pipes for drainage in a bathhouse:

Installation of inspection wells

The purpose of such wells is to provide access to the pipe in places where it may become clogged (turn, branch).

An example of placing an inspection type well

For a sewer system for a bathhouse, there is no point in making inspection wells of large diameter. As practice shows, one meter is enough. There are no restrictions on materials; the only requirement for them is to ensure waterproofing.

You can buy ready-made plastic structures; their price is relatively low, and a wide range of such products allows you to choose a design for almost any configuration of the sewer system.

The well must be provided with reliable thermal insulation so that the pipe does not freeze in winter. Installation of inspection wells is carried out according to the same principle as drainage wells and septic tanks.

In the article we looked at the main points that you should pay attention to when installing a sewage system in a bathhouse; as you can see, the design of this system is not difficult. For those who have some construction skills and have free time, it will not be difficult to both install a sewer system and provide water supply to the bathhouse

If you doubt your abilities, then it is better to delegate such work to specialists, but the cost of the project in this case will increase significantly.

How to choose the right material

Modern pipes for organizing a drainage system are made of high-strength plastic. Its service life is 50 years. Pipes are used from:

- polypropylene;

- low density polyethylene;

- polyvinyl chloride;

- chlorinated polyvinyl chloride.

They are not afraid of water, do not rust or rot. They are easily assembled into a system, attached to each other simply and without much effort. They come in different sizes, among which there is sure to be one that is necessary for specific conditions.

And although cast iron pipes are stronger and more reliable, they are practically not used to create bathhouse drains. They are difficult to transport and install; installation requires special equipment, additional tools and specialists. The result is a costly event that can be avoided.

Asbestos-cement pipes are not recommended for use. They have an uneven surface inside that catches debris. This is especially dangerous if the drainage system is more than 10 meters.

The diameter of the pipes for a steam room with an average degree of use is 11 cm, for small baths 7 cm is enough.

Washing room in the bathhouseSource 2gis.com

Briefly about the main thing

The wastewater drainage system for the bathhouse is organized before the start of the main construction.

There are 3 ways to make floors in a bathhouse with a drain: pouring, leaking and continuous. The last 2 coatings are most often used.

They choose a drainage system for a specific area, guided by the wishes for the operation of the steam room.

There are 4 main ways to organize a water drainage system in a bathhouse: pit, drainage and drainage wells, ground filtration. All methods are suitable for different requirements for the operation of the bath.

Criterias of choice

Select the type of well according to the following criteria:

- Dimensions. For many owners, the weight, length and cross-section of the shaft are important.

- Technical characteristics of the material: durability, resistance to corrosion and aggressive environments, fracture strength and tensile strength.

- Price. For many craftsmen, this parameter is important, since installing an extended drainage system can cost a pretty penny.

Often, in order to save money, owners of summer cottages decide to install a drainage well from tires or polymer containers with their own hands. But the tightness of such a tank remains in question, since it is difficult to achieve absolute integrity of the mine. Over time, it will still begin to allow underground water to pass through, and the tires will be deformed under the influence of heaving soil.

What do experts recommend?

Speaking about how to properly drain a bathhouse, experts offer several tips:

The well should be deepened to the level of soil freezing. A layer of drainage expanded clay is poured inside the finished pit, slightly above the freezing point. The rest of the space is covered with earth and compacted;

Digging a drain well

If water is absorbed by the soil with difficulty, it is advisable to dig a pit ─ an additional small hole from which the accumulated water is discharged outside the site through a drain outlet. The pipe is dug above the bottom of the pit.

Using a pit

Video description

Installation of a drainage system for a bath:

Indoor design

A floor with a drain in a bathhouse is designed internally according to the same principle by which a sewer system is created in a house. The requirements for both drainage systems are no different. The presence of a ventilation riser or shut-off valve depends on the specific room. A riser is necessary if drainage is organized from several rooms at once.

The concrete floor drainage system consists of:

- internal wall cladding;

- vapor barrier of walls;

- foundation waterproofing;

- load-bearing base;

- crushed stone cushion;

- concrete layer with thermal insulation;

- screeds for covering;

- finishing coating;

- sewer drain pipes;

- wooden gratings;

- drain hole or grate;

- water seal partitions;

- drain pipe or gutter.

Installation of a drain floor on a concrete base in a bathhouse Source slipguard.ru