The tradition of building baths on a site separate from the main house was determined by two very important factors:

- fire prevention measures;

- not very favorable impact of the bath temperature and humidity conditions on the structures of the main residential building.

Despite the large number of modern protective materials, developed measures and technologies, baths continue to be built at some distance. Strictly speaking, the foundation for a bathhouse with your own hands is practically no different from any other similar separate structure, for example, a garage. The only difference is enhanced waterproofing and fire protection.

The same applies to the foundation. Its design diagram, calculation, structure depends on the loads acting on it from the weight of floors, walls, snow and wind influences.

Features of strip foundation

A strip foundation is a concrete strip that is installed under all load-bearing walls of the bathhouse. This type of base can be a completely monolithic, prefabricated or monolithic prefabricated structure.

A continuous monolithic strip is formed after curing of the solution poured into the formwork, which is created in a pre-dug trench. Creating this type of strip foundation requires the most effort and time. This is a complex but extremely reliable design. Therefore, it is often erected under baths.

To create a collapsible structure, separate ready-made reinforced concrete blocks are used. They are manufactured in a factory. Prefabricated strip foundations are erected on soil with good bearing capacity.

Prefabricated foundation from individual reinforced concrete blocks Source algoritm-stroi.ru

When constructing a prefabricated monolithic base, reinforced concrete blocks are used, and at the same time the solution is poured into the formwork. It turns out that the design is created using two technologies.

A strip foundation for a 6x6 bathhouse or a building of another size is also classified according to its depth. Create recessed and non-recessed foundations. The first option is erected during the construction of large baths with heavy walls. A ruined structure can even support a two-story building. Often its construction is carried out when the house is combined with a bathhouse. The deeper the foundation is located in the soil, the more funds are required for its construction.

A shallow strip foundation for a bathhouse is created when the walls of the building are light in weight. Its depth is usually 0.5 m. This is one of the best options for small structures.

Shallow monolithic structure for a bathhouse Source doma-kos.ru

Which foundation is better for a bathhouse, depending on the type of building

This table suggests that wall material is a factor that simply cannot be considered separately from the properties of the soil.

IMPORTANT! To the weight of the structure you also need to add the snow load characteristic of your region.

The heavier the structure, the more thoroughly the foundation has to be made, the more expensive it is, but lightweight structures put little pressure on the ground, so highly heaving soils can push out a structure made of light material.

You can combat frost heaving by either replacing the soil under the bathhouse with drainage soil, or by making a wide blind area (more than 1 meter) around it and discharging precipitation through gutters away from the bathhouse.

Advantages and disadvantages of a bath strip foundation

Among all types of foundations, it is the strip monolithic structure that is most often erected for a bathhouse. This is due to a number of its advantages:

- High load-bearing capacity with relatively low consumption of building materials. This allows you to save money and get reliable results.

- Possibility of production by not only pouring concrete into the formwork, but also laying bricks, ready-made reinforced concrete blocks and even stones.

- Creation of recessed and shallow structures depending on the size and weight of the bathhouse box. Thanks to several design options, it is possible to build a foundation above or below the freezing point of the soil, taking into account the type of soil on the site.

- A relatively simple and well-studied construction technology ensures that specialists will build a strong and durable foundation for a bathhouse.

The technology of constructing a strip foundation has been well studied by professionals, which guarantees the construction of a reliable structure. Source oteplicah.ru

Despite the fact that a strip foundation for a 3x3, 3x5, 3x4 bathhouse is inexpensive and quickly erected, it has certain disadvantages. One of them is the need to always take into account the type of soil when calculating the depth of the foundation. Only specialists can accurately calculate the value. Therefore, it is recommended to contact professionals who will provide a guarantee for the work performed.

Another disadvantage is the need for mandatory preparation before the main construction process. In particular, it is necessary to carry out excavation work, the volume of which depends on the size of the foundation.

The disadvantage is also the long curing time of the concrete solution. It dries completely under normal conditions in about one month. Although the curing time of concrete directly depends on the size of the base being created.

Curing of the concrete tape occurs within a month Source n-dom37.ru

See also: Catalog of companies that specialize in repairing foundations of any complexity

Conclusion

A strong foundation is very important for the strength of the entire structure. Therefore, it must be done efficiently. The work is easy to do yourself, which will save you a lot of money.

Also, for greater savings, in some cases you can use the installation of a pile foundation rather than a strip foundation.

Ready-made bathhouse on a columnar foundation

The dimensions depend on the quality and density of the soil, the choice of fill type, and the thickness of the proposed walls: the foundation for the bathhouse is calculated based on these parameters. It is important to remember here that a deeper and wider structure will be more reliable, but more expensive. You should try to find a balance using the recommendations proposed in the article.

It should be noted that the concrete base for the furnace has its own characteristics in laying and must be separate from the general structure. Its width and depth are determined by the material of manufacture: metal or brick.

Source

General scheme for the construction of a strip foundation

Bathhouses in Russia are traditionally built from wood. Thanks to the use of timber or logs, it is possible to build walls with high strength and good thermal insulation properties. Moreover, they weigh less than stone structures. Therefore, wooden walls do not create large loads even on a simple foundation for a bathhouse.

Due to the peculiarities of construction from logs or beams, the construction of a shallow foundation is often carried out. However, when constructing it, the hydrogeological situation in the area and the type of soil are always taken into account.

The concrete strip is created exactly under the load-bearing and internal walls. It bears most of the load. In this case, the concrete base for the furnace is created separately.

Important! Installation work on the construction of the foundation is always carried out in stages with strict adherence to construction rules. Even the slightest deviation from technology is not allowed. Failure to comply with building regulations reduces the load-bearing capacity of the foundation. This will lead to the destruction of the bathhouse in the future.

Failure to comply with technology leads to the destruction of the foundation and subsequently the entire bathhouse Source sdelai-lestnicu.ru

Excavation

The construction of a foundation for a bathhouse begins with the removal of the top layer of earth on the site allocated for construction. Often the work is carried out with a bulldozer. However, the use of special equipment is justified when it is necessary to remove a large volume of soil.

At the same stage, the construction site is planned. Then the foundation for the bathhouse is marked so that the boundaries of the trench, which is usually dug manually, are visually visible.

On a note! By agreement with the owner of the site, the craftsmen take the excavated soil outside the private territory or store it next to the construction site if it plans to be used in the future for any needs.

Creating a footing

At this stage, a bulk cushion is created under the foundation for a 3 by 4 bathhouse or another size. This is the so-called concrete footing. During its creation, sand and crushed stone are poured into the trench. Layers of these materials will perform a drainage function.

Typically, the thickness of the filled sand is from 200 to 300 mm. This layer is carefully compacted and spilled with water. The exact height of the sand layer will always be determined by specialists, taking into account the hydrogeological conditions of the site.

Sand cushion in the foundation trench Source nasha-besedka.ru

The crushed stone layer is created the same thickness as the sand cushion. It is also carefully compacted. Sand is again poured on top of the crushed stone layer. In this case, its thickness is already approximately 50 mm. This layer is also compacted and spilled with water.

Calculation of the depth and width of the foundation

Only specialists can correctly calculate the foundation. They will first conduct a soil test. Then they will calculate the weight of the building without and with a concrete base. In this case, various coefficients will be taken into account, of which quite a lot are used in the correct calculation.

To monitor the work of specialists, you can use an online calculator. Of course, this method of calculation will not provide accurate results. However, they will be enough to make sure that the work was actually ordered from specialists.

Alternative ways to build a plinth

Sometimes craftsmen use non-standard designs for the installation of a bathhouse plinth, for example, from sand-lime brick, ordinary ordinary brick, wall stones, slate, etc. It is worth noting that any wall materials as plinths are undesirable, since they are not designed for direct contact with the ground . Still, it is better to construct structures in a single mass with a base. If the foundation base is made in the form of piles, then it is preferable to make the above-ground part in the form of a monolithic reinforced concrete belt.

The first and last row of the red brick plinth must be placed in a poke, and all the inner ones in a spoon. This will ensure a good bond and give the necessary rigidity. If there are more than 10 bricks nearby, then on the 5th row it is also necessary to “plug” the base.

If the foundation ends at a level equal to the ground level, additional brickwork can be made as a plinth for the construction of wooden walls of the bathhouse. It is better to use silicate type bricks, as they interact well with a humid environment. It is necessary to raise the level by 500-600 mm from the ground surface (but not less than 250 mm). The thickness of such a wall will be 400 mm for a large bathhouse and 250 mm for a small one-room building.

Ventilation outlets must be made. To do this, vents are left approximately in the middle part of the masonry in height. It is advisable to make a reinforcing belt of reinforcement and concrete on top of the masonry. Waterproofing is laid under the brick and under the wall, since in this case we use three types of materials for the foundation, plinth and walls.

Plinth cladding

The external cladding will additionally protect the base and wall structures from moisture and temperature changes. The materials used for cladding are extremely durable - moisture-resistant and frost-resistant. These include decorative facing bricks, tiles, and hanging plastic systems. The base, decorated with natural stone - limestone, sandstone, as well as artificial stones, looks very beautiful.

The basement part of the foundation of a small bathhouse in a summer cottage can also be lined with various available materials, for example, fragments of ceramic tiles or glass, laying them out in the form of a mosaic.

Source

Video description

A specialist talks about the reinforcement and formwork of a shallow foundation in the video:

Pouring the foundation

Before pouring the foundation for a 3x4 or other size bathhouse, prepare the required volume of concrete. Professionals usually choose the M200 or M300 brand and order the solution from the factory, from where it is delivered in an automixer. This option allows you to fill the entire formwork in one go. Thanks to this method, you will get a monolithic base, which will have the same properties at each point.

Filling is carried out evenly throughout the formwork. Concrete is never poured in one place, hoping that it will spread throughout the pre-prepared wooden structure.

The surface of the concrete strip is leveled in accordance with the design level. After pouring, the formwork along with the mortar is covered with plastic film. In this form, the foundation dries for 10 days. In this case, for the first 3 days the concrete is wetted every 4 hours. During further drying, watering is carried out only 3 times within 24 hours.

Filled, hardened and freed from formwork strip foundation Source gkrus-stroy.ru

Important! Complete curing of concrete occurs only after 28 days.

Waterproofing works

Waterproofing is done in different ways. For work, ready-made bitumen mastic is often chosen. It does not need to be preheated.

Bitumen mastic is applied in two layers to the concrete base of the bathhouse. At the same time, roofing felt can be used. However, it is laid even before the foundation for the bathhouse is poured. Roofing felt is placed on the walls of the formwork. This method will require more time and effort, but will create more reliable waterproofing.

Necessary tool

When making a bathhouse foundation from a log frame with your own hands, it is advisable to prepare the following tools and equipment in advance:

- Bulgarian;

- perforator;

- welding machine;

- electric drill;

- construction mixer;

- vibrator;

- shovel;

- scrap;

- hammer;

- sledgehammer;

- hacksaw;

- hacksaw for metal;

- chisel;

- measuring bucket;

- container for preparing the solution;

- scales;

- putty knife;

- Master OK;

- pliers;

- paint brush;

- knife;

- scissors;

- roulette;

- construction cord;

- plumb line;

- construction level.

Final work

At the last stage of construction of the strip foundation, backfilling is performed. For this purpose, previously excavated soil is used. They fill the sinuses between the concrete base and the walls of the trench. The soil must be compacted.

At the end of all work, the blind area is installed. However, its creation is often postponed until the interior decoration begins. In many cases, this is the best option, because the integrity of the blind area can be damaged during the construction of the walls and roof of the bathhouse.

Log house

A log house is the walls of a house made of solid logs. In the corners of a wooden house, logs are connected into so-called crowns. At the bottom of the log, a piece of wood is cut out the width of the transverse diameter of the log. Wooden elements in the corners of the house form locking systems that do not require additional strengthening. This confirms the popular expression - to build a house without a single nail.

Such houses are most often built in areas where timber is available to consumers at a low price. Such places include Central, Eastern Siberia and the Far East. Although it is worth noting that the popularity of building private houses from solid wooden elements has increased widely in all regions of our country.

The low specific gravity, excellent thermal insulation qualities, durability and environmental friendliness of wood are an undeniable advantage over other building materials.

Briefly about the main thing

More often, a strip foundation is erected under a bathhouse. Moreover, it can have a completely monolithic, prefabricated or prefabricated-monolithic structure and differ in its depth.

Often a strip shallow foundation is created for a wooden bathhouse. Any type of such base is distinguished by good load-bearing capacity, quick installation, and low price. The type of strip base is selected for the specific soil.

The creation of a foundation is accompanied by excavation work, backfilling of crushed stone and sand, creation of formwork, installation of reinforcement, and pouring of concrete. Finally, waterproofing and backfilling are carried out.

Ratings 0

Base reinforcement

Installation of the reinforcing frame is a very important point. The reinforcement is made of longitudinal and transverse rods approximately 10-12 mm thick. The rods are laid out with an overlap of 25-30 cm and tied together with wire.

The number of longitudinal rods will depend on the width of the bathhouse base. The overall structure should be approximately 5 cm smaller than the formwork and the base surface. It must be further strengthened in the corners. The top of the reinforced frame can be reinforced with U-shaped brackets for greater strength.

To prevent the reinforcement from shifting during the concrete pouring process, plastic fasteners are inserted between the formwork and the reinforcement. The finished structure is installed on supports.

Another option for installing reinforcement is that rods are driven into the bottom of trenches at regular intervals, the diameter of the rod being about 10 mm. Using wire, horizontal pins are attached to the vertical pins.

The first bottom row is performed at a height of 60-75 mm from the bottom of the trench. The distance between the rods should be about 50 cm.

The top row of rods is hidden with concrete mortar 70 mm from the top point of the foundation.

The rods must be treated with an anti-corrosion coating, because... Concrete, even after pouring, always contains moisture. It is not recommended to weld rods together due to the fragility of such joints in concrete.

Thermal protection measures

Laying insulation on the side surface of heaving soil to reduce soil freezing.

Styrofoam, Teploizoplit, Primap1ex, Penoplex and others are used as insulation materials.

Perhaps the most promising, economical and reliable way to reduce soil heaving is a shallow reinforced concrete foundation, which is placed on an anti-heaving cushion. A low-rise building rests on soil close to the surface.

Shallow foundations should be placed to the required depth. The reliability of such a foundation ensures:

- Calculation of the supporting area taking into account soil resistance and loads from the house;

- Calculation of the required width of pits and trenches, the cavities of which are filled with non-heaving soil to create the required stability;

- Calculation of the thickness of the anti-heaving load based on permissible deformations.

In heaving soils, SNiP 2.02.01-83 regulates the laying of foundations. The implementation of these measures will allow you to create a strong and reliable foundation on heaving soil that will serve you for decades.

Adviсe

Unfortunately, many developers neglect the above calculations due to time and financial costs, and, as a result, make the wrong choice. Before installing the foundation, it would be a good idea to consult with people who have already gone through this process. But remember that installing a large building is a long-term matter, and many problems (which may arise precisely because of non-compliance with the rules) often become noticeable after more than a dozen years. In any case, it is worth protecting yourself and your property now, so as not to deal with unpleasant consequences in the future.

To see what mistakes can happen when laying a foundation, watch the following video.

Building size

A strip foundation is a support structure closed around the perimeter under a building. When planning the construction of a bathhouse on a personal plot, the dimensions of the bathhouse in plan and the type of foundation are initially determined.

A facility for hygienic water procedures should have an optimal set of premises - these are:

- steam room,

- shower room,

- toilet,

- vestibule,

- restroom,

- small terrace.

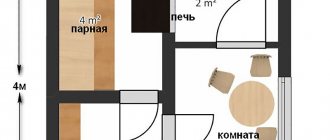

All this can be placed on a bathhouse plan measuring 6 x 6 m. The bottom picture shows the location of the rooms:

The configuration of the closed perimeter support strip depends on the size of the structure. The common dimensions of the building are a bathhouse with a plan of 6 x 6 m with axes of 5.4 x 5.4 m running in the middle of the width of the foundation.

The dimensions of the foundation are a fundamental factor influencing the total estimated cost of building a bathhouse. This determines the consumption of materials and the volume of overhead construction work.

Cost calculation

The cost of any foundation is calculated as the sum of the cost of concrete and reinforcement. When the volume of the foundation is calculated, it is laid out according to its components according to the principle - to produce one m3 of concrete it is required:

- cement - 0.22 m3 or about 0.35 tons (costs 5,600 rubles/t);

- sand - 0.31 m3 or about 0.45 tons (costs about 100 rubles/t);

- crushed stone - 0.70 m3 or one ton exactly (costs 600 rubles/t).

The cost of fittings at metal depots is usually calculated in rubles per ton. Knowing the length, the mass can be calculated by knowing how many meters of reinforcement are in one ton:

Reinforcement Ø 6 mm – 4,500 meters:

- 8 mm – 2,530 meters;

- 10 mm – 1,600 meters;

- 12 mm – 1,120 meters;

- 14 mm – 820 meters;

- 16 mm – 630 meters;

- 18 mm – 500 meters;

- 20 mm – 400 meters.

How to calculate how much to deepen?

The need for preliminary calculations of the foundation depth is explained by the following reasons:

- The lower the reinforced concrete pad is lowered, the higher the load-bearing capacity of the solid bottom underneath it.

- For areas with a high clay content, trenches are laid below the frost line or measures are taken to minimize the heaving factor.

- The soil at the construction site must be strong enough to support the weight of the building.

- The physical and chemical composition of the earth under the base of the house should not change much due to temperature changes in the environment.

To calculate the underground part of the tape you need to know:

- freezing depth (Dfn);

- a correction factor that takes into account the thermal conditions in the house (K).

As mentioned above, the degree of freezing is determined by the climatic conditions in the region. The value of this indicator can be taken from reference literature.

The freezing depth for some Russian regions is given in the table (the predominant soil types are taken into account):

| City | Freezing line, m | City | Freezing line, m |

| Arkhangelsk | 1,75 | Moscow | 1,30 |

| Vladivostok | 1,80 | Nizhny Novgorod | 1,55 |

| Ekaterinburg | 1,90 | Eagle | 1,30 |

| Kazan | 1,75 | Ryazan | 1,30 |

| Krasnoyarsk | 2,00 | Saint Petersburg | 1,20 |

| Kursk | 1,30 | Chelyabinsk | 2,15 |

Coefficient K is a reference value that reflects the average daily temperature in the room adjacent to the foundation. For clarity, below is a table from which you can take the coefficient for calculations:

| Temperature in the building, oC | Correction factor K | |||

| ground floor | floor on joists | insulated basement floor | basement | |

| 0,90 | 1,00 | 1,00 | 0,80 | |

| 5 | 0,80 | 0,90 | 1,00 | 0,70 |

| 10 | 0,70 | 0,80 | 0,90 | 0,60 |

| 15 | 0,60 | 0,70 | 0,80 | 0,50 |

| 20 and above | 0,50 | 0,60 | 0,70 | 0,4 |

So, how deep should you dig? Using the available data, you can calculate the depth of the sole (Df) using the formula: Df = (Dfn * K).

As a clear example, you can choose a house with an unheated basement in Yekaterinburg, where the temperature in the basement itself is kept at 10 ° C during the day. By substituting the tabular data into the formula, you can easily obtain the estimated foundation depth: Df = (1.9 * 0.6) = 1.14 m.

Let us assume that in the selected area the groundwater passes above the freezing line. Then you need to add 15 - 20 cm to the obtained value for the stability of the base. At what depth should the foundation be laid? The calculation shows that the reinforced concrete strip must be laid to a depth of at least 1.29 m.

Bathhouse on screw piles

Its design exactly replicates a pile foundation with a grillage. The only difference is that screw piles are screwed into the bottom of the dug trench instead of pouring concrete ones.

After the piles are screwed in, their ends are cut along the upper edge of the formwork. Horizontal reinforcement is installed in the trench, which is necessarily connected to the protruding ends of the piles through electric arc welding or other means.

There is an option to build some types of buildings on screw piles without a concrete grillage - on a rolled metal frame (usually a channel), welded directly at the ends of the piles. In this case, a screen made of various materials is attached to the frame along the perimeter of the building, which plays the role of a plinth instead of a foundation or grillage.