Before starting the construction of a bathhouse, it is good to estimate in advance how much it will cost, whether you will have to involve professionals or you can do it yourself. Laying the foundation is one of the most critical stages. After reading our article, you will get an idea of how to make a foundation for a bathhouse - with examples of calculations for each type.

We hope that this will be enough to estimate the estimate and scope of work at this stage, given that the foundation makes up from 20 to 50% of the total cost of building a bathhouse .

How to calculate the foundation for a bathhouse

Building a foundation for a bathhouse is not cheap. You can really imagine the cost of the foundation only after assessing the volume of materials that will be needed for the selected size of the bathhouse. We will show with examples how to calculate the foundation for a bathhouse.

But first you need to calculate the total load on the ground that the finished bathhouse will exert. You already have an idea of what size and what material you would like to build a bathhouse from and you can make a calculation. Calculate the area of the roof, walls and ceilings, and then multiply by the data from the table. Adding up the results, you get the weight of the finished structure:

| building element | Material | Density (kg/m²) |

| Walls (150 mm thickness) | Frame+mineral wool | 30-50 |

| Timber or log house | 70-100 | |

| Brick | 200-270 | |

| Roof | Sheet steel | 20-30 |

| Ruberoid | 30-50 | |

| Slate | 40-50 | |

| Ceramic tiles. | 60-80 |

Floors:

If the floor is reinforced concrete, then count as 500 kg/m².

| Along wooden beams | Tsokolnoe (kg/m²) | Attic (kg/m²) |

| Density up to 200 kg/m² | 100-150 | 70-100 |

| Density up to 500 kg/m² | 200-300 | 150-200 |

Calculation diagram for strip foundation

The previous calculations are needed in order to select the optimal belt width based on the total load and bearing capacity of the soil . You should learn the latter from geologists.

To begin, take the width of the foundation strip according to the rule:

Thickness of the future wall + 10 cm

After this, calculate the area of the entire foundation strip. You can divide it into rectangles, then add up their areas. As a result, we get the value of the reference area.

All that remains is to divide the total mass of the bathhouse by the supporting area to find out what the pressure on the ground will be. Compare with the bearing capacity of the soil - if it is less than the pressure of the bath, it is worth reconsidering either the design or the width of the tape. (In general, it is undesirable for the pressure of the structure to be more than 70% of the bearing capacity of the soil ).

IMPORTANT! By increasing the area of the foundation strip, we reduce the pressure on the ground.

We recalculate until the numbers become acceptable. Now that the area of the tape is known, it will not be difficult for us to calculate its volume. Multiply the area by the height. This will be the volume to be filled with concrete. Calculate the mass, based on the fact that 1 cube of reinforced concrete weighs 2400 kg.

Example of calculation of a columnar foundation (including bored piles)

In this case, let’s take one type of pillar, for example, bored piles. They have a variety that has a main diameter of 300mm and expands at the bottom into a shoe with a diameter of 500mm. Hence the area of the circle of the sole :

S = π x r² = 3.14 x 25 x 25 = 1962.5 cm²

You need to know two more quantities: the total weight of the bathhouse and the bearing capacity of the soil (soil resistance). The first is calculated from the tables above, the second is learned from geologists after research. Let's assume that the bathhouse is frame, and its weight is 23,000 kg, and the load-bearing capacity of the soil is 2 (we remember that it is worth taking only 70% of this value).

0.7 x 2 = 23000: (1962.5 x N),

where N is the number of pillars.

From here it is easy to calculate that rounded N = 9, but this is only a first approximation. Now we need to find out the weight of 9 pillars and add it to the weight of the bathhouse. We will count like this:

Pile length - 2 m Diameter - 0.3 m

All that remains is to multiply the area of the circle by the height of the cylinder to get the volume:

V = π x r² x h = 3.14 x 0.15 x 0.15 x 2 = 0.1413 m³

Accordingly, the volume of 9 piles is equal to 1.2717 m³, which, with a mass of 1 cube of reinforced concrete of 2400 kg, gives 3,052 kg, which we add to the 23,000 kg of mass of the bathhouse. Let's count again:

N = 26,052: (1.4 x 1962.5) = 9.48 rounded 10 piles

All that remains is to distribute them at the points of maximum load and evenly between them.

Calculation diagram for a pile foundation (here only a screw foundation)

Screw piles for foundations are 89 and 108 mm. The former are used only for light buildings, for example, frame ones. The second ones are for everyone else.

The simplest method of calculation is to arrange the piles according to the plan of the bathhouse in the corners and points of greatest load. (It is recommended to place at least 2 piles under the stove).

Another option is to use information about the mass of the bathhouse and divide it by the load-bearing capacity of one pile. The data can be gleaned from the table below (this is a calculation for a pile immersed 2 m in the ground).

By the way, many pile sellers have calculators that calculate the number of piles in relation to your case.

Slab foundation calculation diagram

And again, we must calculate the pressure of the bath on the ground to make sure that the structure is lighter than the soil can bear without subsidence.

In the case of a slab foundation, we have a very large area over which the total load is distributed, but it is worth taking into account that the slab weighs a lot.

Let's assume that a bathhouse of 4 x 4 meters is planned. And that we will place it on a slab 20 cm thick. Let the weight of the bath be estimated at 50 tons, and the soil resistance 2.5.

We already know that a cube of reinforced concrete weighs 2400 kg. Then the mass of the foundation is 7680 kg. The total load is 58 tons per 16 square meters or 3,625 kg per m². Soil can bear 2.5 kg per cm² or 25 tons per m². In a similar way, you can calculate the load for your data.

Basic calculation parameters

When creating a drawing of the foundation of a house, it is necessary to use the results of calculations made when designing the foundations. In particular, it is necessary to take into account:

- total weight of the house under construction;

- an increase in the load on the house during its operation, for example, the construction of a second floor;

- groundwater level;

- type of soil on the land plot.

These data take into account not only the geometric dimensions of the foundation, but the materials that will be used in its construction (grade of concrete, size of reinforcement, etc.). In addition, the designer will determine the type of hydraulic and thermal insulation. When building a foundation on land with high groundwater, it is necessary to design a drainage system that will drain excess water from the foundation structure, thereby extending its service life.

Ideally, the design of foundations for buildings and structures should be carried out by a company that has experience in such foundation design work. When designing building foundations yourself, it is advisable to use current guidelines and instructions for foundation design.

How to mark the foundation for a bathhouse

The initial stage of marking is no different for different types of foundations : you need to build a quadrangle with right angles.

General principles

Constructing a right angle - the problem can be solved “mechanically” or using calculations.

Laser level BOSCH PLL 1 P

The calculations are simple: the square of the hypotenuse is equal to the sum of the squares of the legs, and the legs are our walls. In a simplified way, you can use the case with integers: 3² + 4² = 5². To do this, take a 12 m string and its ends are connected very precisely. Marks are placed at 3 and 4 meters. It is enough to stretch the string into a triangle so that a clear right angle is formed between the smaller sides (3 and 4).

Mechanical methods are either to use a square made of slats, or a laser level (the video will tell you about the latter).

One way or another, it all starts from the very bottom corner of the future bathhouse , where the first peg is driven in and a right angle with the given sides is built from it.

Then the diagonal is checked and the next right angle is constructed. So - until all the corners are built. Corner points are marked with pegs .

The next stage is marking the inner or outer contour (depending on which one you have not yet made). Corner points are also marked with pegs.

Casting is the next stage of marking.

Racks of two posts with one or two crossbars are driven into the ground at a distance of 1.5-2 meters from the initial pegs (see below). These are cast-off racks .

They are driven into the ground in such a way that the edge of the crossbar is at a certain level:

- cutting strip or slab foundation;

- the edges of a pipe, pile or pillar of a pile or columnar foundation (for foundations with a grillage, two crossbars are made - the level of the pillar/pile and the level of the grillage).

Construction threads, stretched along the marks on the crossbars, form the internal and external contours of the foundation in the air.

The depth of the trench or hole is measured from the cast-off so that the perimeter is level regardless of the terrain.

Now let’s look at how to correctly mark the foundation for a bathhouse, depending on its type.

Nuances for different types of foundations

For the tape on the cast-off crossbar, the following risks are made:

- the axis of the wall is in the center;

- width of the foundation strip (axis at its center);

- width of the pillow under the base.

We highly recommend watching the video, which talks in detail about using a laser level when marking a strip foundation:

The casting of a columnar or pile foundation notes:

- foundation height (cut piles or pillars);

- grillage height;

- axis of pillars or piles.

The corner supports are marked immediately by the intersection of the threads. Intermediate supports are measured after. The axial points are lowered to the ground using a plumb line and marked with pegs.

Before drilling or digging holes, construction threads are removed.

Marking a slab is the easiest because you only need to mark the boundaries of the slab.

IMPORTANT! The pit is made 1-2 meters wider than the slab, so it is advisable to dig the cast-off material beyond the boundaries of the future pit.

Conditions and nuances of the process

In order for the marking for the strip foundation to be adequate, the following tools must be used to carry it out:

- 20-meter metal tape measure;

- reliable thick rope;

- strong wooden pegs and reliable clothespins, which are suitable for marking local points of the future structure.

Before starting work, be sure to determine the point that acts as the corner of the building. It is necessary to draw a special long line through this zone, which becomes the basis for the first wall (whether it is frontal or façade type does not really matter). The peg itself should be installed somewhere at a distance of 50 cm from the original corner, but we mark the last one with a clothespin.

Using a measuring tape, we set aside the required length from the wall itself, after which we drive in another peg at the same distance as the first, and also fix the location of the second corner with a clothespin.

It is not recommended to place the marker in the corner itself: it can either get damaged during the work, or simply interfere with the excavation procedure.

Through the mark-point, you should carefully draw a straight line of the second wall, just as it happened in the first case, to begin with, measure the required angle:

- we set aside four meters from the first wall and mark this point;

- on the second and third - and do the same;

- measure the resulting distance using a tape measure;

- if the result is 5m - great, you can also drive in the next peg of the next wall, measure the next angle;

- other geometric indicators are measured.

You should concentrate your attention - the cord, with which you can qualitatively mark the foundation yourself, must be located at the same height at all points. It is more than impractical to carry out measurements on the soil itself, since there is potentially a large error in the calculations due to the nuances of the relief

In itself, such work, in principle, is not particularly difficult. But sometimes its implementation requires the presence of an experienced and skillful assistant. You can complete the marking procedure by checking whether the diagonals of the resulting rectangle are the same. If a deviation within three centimeters is detected, then this indicator is quite acceptable.

The internal contour is marked in a similar way. Angles are controlled in the same way. If it is only intended to fill a trench using a foundation, the procedure can be performed immediately, always including formwork. In general, marking the area for the foundation is a fairly simple procedure; it is much more problematic to comply with all the geometric parameters of the installation of the formwork itself and the optimal installation of the mandatory upper level, adhering to the correct height. For this purpose, a procedure is carried out to thoroughly clear the construction site and level it even before marking is carried out.

The foundation project itself can be measured using technological reference measurements to the area being worked, which are indicated within its boundaries. Then, any of the potentially constructed corners of the structure are usually fixed, taking into account the selected distances from all control points. This will be the first corner of the structure.

All these facts are very important for the construction process. It is at this stage that we have the opportunity to make changes to the already approved construction plan that are necessary. It is worth taking into account only the fact that the parameters for residential development are maintained, for example, such as the minimum distance from the boundary limits of the site, as well as trunk-type pipelines.

Waterproofing the bathhouse foundation

The foundation should be protected not only from groundwater, but also from precipitation.

General principles

There is vertical and horizontal waterproofing of the bathhouse foundation. But vertical is needed only in special circumstances : high groundwater, a lot of precipitation, and horizontal is always required.

Waterproofing can be done either by gluing, painting or impregnating the foundation with appropriate materials. You can also combine both methods.

Vertical insulation is done from the sole to the upper boundary of the precipitation splash.

The cheapest way is to coat the foundation with bitumen, but this is an unreliable method, because its layer is easily damaged during backfilling or seasonal soil movement . This means that the coating must be protected. For this use:

- insulation;

- geotextiles;

- pressure brick wall.

Instead of bitumen, it is much better to use impregnation, although they are much more expensive.

You can also cover the foundation with roofing felt, iso- or technoelast.

Another option: plaster insulation in several layers with a special hot solution.

Horizontal insulation is designed to protect against water that rises through soil capillaries.

Most often, roofing felt is used, which is laid in several layers. Instead, you can coat it with mastic or impregnation. Or use modern membranes. The best would be a combined method of protection.

IMPORTANT! Particular care should be taken to isolate the horizontal and vertical joints - they must be sealed.

Horizontal waterproofing is also carried out along the edge of the foundation before laying the walls . To do this, you can put a hydrobelt, ruberite or aquaizol. In the old days, birch bark was used, as in the photo below (a log house on a base of stones is shown).

Nuances for specific types of foundation

Slab

The first layer of its waterproofing is laid directly on the sand and gravel bed. In this case, they use glass insulation or rubemast, because for roofing felt you first need to make a rough screed, but for these materials it is not necessary.

IMPORTANT! The overlap at the joints is 10 cm, and 20-25 cm is left at the edges of the foundation so that you can then “wrap” the slab from the sides.

The finished foundation slab is insulated again, only now coatings or impregnations can be used.

Tape

Its minimal waterproofing includes only two layers of roofing felt between the tape and the wall. However, this need not be done if high-quality concrete grades B15 and higher were used for pouring.

Pile or columnar

Since it is quite difficult to isolate a separate support , it is necessary to use special water-repellent impregnations. This applies to pillars and reinforced concrete piles. To protect against corrosion, screw piles are painted with high-adhesive paint.

Waterproofing of these types of foundations is also carried out along the grillage, in exactly the same way as before laying the walls on a strip foundation.

Under the stove

To pay attention! How to make a foundation for a stove in a bathhouse, see the link to a separate article.

Recommendations from experts

Thanks to the experience of professionals, the process of marking the site can be simplified and done using the following tips:

- the thread should be tightly stretched, without sagging or tearing out pegs; a damaged thread will not give the exact dimensions of the base;

- pegs can be made independently from remnants of reinforcement; they are perfectly installed in the soil and firmly fixed;

- always focus on the external boundaries of the land plot and the design of the house or extension;

- do not remove the threads until all work is completed;

- If possible, use professional equipment;

- If you are not confident in your abilities, seek help from professionals.

Insulation of the bathhouse foundation

When is it needed?

There are two real reasons that have nothing to do with the horror stories about condensation, mucus and mold that are often used to scare people on the Internet (because ventilation copes much better with condensation than insulation).

- This is a desire to reduce heat loss and time to warm up the bath.

- It also protects the waterproofing from damage to its integrity during the seasonal movement of freezing soil. Plus a reduction in the heaving of the soil itself if you insulate it too.

Typically, foundation insulation is typical for buildings with a basement. And bathhouses are rarely made with a basement. Therefore, there is no urgent need for insulation.

But if you still decide to insulate the foundation of the bathhouse, then do it from the outside.

There are people asking how to insulate the foundation of a bathhouse from the inside, but we do not recommend doing this. Internal insulation is not recommended.

As for the material, it is better to choose one whose life expectancy is comparable to the life expectancy of concrete. In this regard, polystyrene foam is much inferior to concrete in terms of “longevity” and the warm foundation will not last forever. Therefore, professionals recommend foam glass .

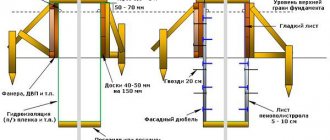

Insulation of the bathhouse foundation can be done at the laying stage. In this case, the width of the formwork is increased by the thickness of the heat-insulating material.

In the case when insulation is done for an already built bathhouse , you will have to: open the foundation;

- pour sand and gravel onto the bottom;

- the insulation can simply be glued to the walls of the foundation;

- Finally, the foundation is backfilled with soil, which must be thoroughly compacted.

If the foundation is columnar , you will have to work even more:

- a trench is dug along each wall (width 0.5 m and depth 1.5 m);

- Sand and gravel are poured into the bottom of the trench and compacted;

- a wall of bricks is laid on the cushion, which is raised almost to the start of the masonry;

- the gap between the brick and the wall is foamed with polyurethane foam;

- bricks are coated with bitumen mastic;

- the trench is backfilled and compacted.

Think about it ! Common sense dictates that such colossal expenses and efforts are useless for a bathhouse.

Brief description of the laser level

A laser level is one of the devices that belongs to a large group of measuring instruments.

The main purpose of the level is to determine the difference in heights of one place on the surface relative to another place and to construct planes: vertical, horizontal and any intermediate ones in the form of a line - a trace of a laser beam. In addition, such a device can construct point projections - give a point on the surface.

Most often, self-leveling cross levels are used, which build two perpendicular planes - horizontal and vertical. They can be rotated and installed in any direction. The horizontal plane is constantly adjusted by auto-leveling elements.

The main characteristics of laser leveling are:

- measurement accuracy, professional devices give an error of up to 3 mm at 10 m, and household devices up to 0.5 mm at a distance of 1 meter;

- measurement range: for households up to 10 m, professional – 30 m or more;

- number of projected planes - usually two or more, etc.

But a level is, first of all, a measuring instrument.

It will only help you well if you know how to use it correctly.

If you take it for temporary use, i.e., rent, do not expect it to work on its own.

If you do not know what adjustment is, do not rent the device.

When starting to work with it, check the accuracy of the measurements and whether the settings are messed up, i.e. check all the characteristics described in its passport. All verification operations are in the description of the device.

There is no work on laying out the foundation that cannot be carried out without a level. Therefore, an ordinary water level, used correctly, can easily replace it. Although a laser level speeds up and simplifies work on a construction site.

Installing a bathhouse on a foundation

When installing a bathhouse on a foundation, the difference between strip/slab and columnar/pile is leveled due to the grillage, so all the nuances are related only to the material of the walls.

Timber or log house

Let's look at how to place a log bathhouse on a foundation. To lay the first (tying) crown of a wooden bathhouse, you must first waterproof the foundation and soak the crowns with an antiseptic.

It is recommended to first lay a 50 mm thick board around the entire perimeter of the waterproofing, and only then place the first crown on it. The so-called spacer board will help seal the log frame to the waterproofing.

And what is important is that over time it is easier to replace a rotten layer of boards than to change the crown of a bathhouse. And the crowns at the bathhouses inevitably rot.

Before laying, the logs are disassembled according to the markings.

Locks are pre-cut in logs or beams. Usually the end is simply cut “half a tree” - half the thickness of the crown.

The lower crown is often not attached to the foundation at all , because it will not shift under the weight of the bathhouse.

Brick, foam block, cinder block

This is a group of block materials. They are laid on a strip or slab foundation immediately after it is waterproofed. If the foundation is piled or columnar, then the creation of a grillage becomes mandatory , and then everything is exactly the same as for a strip or slab foundation.

If you are just looking at building a block bathhouse, we also have an article for you about the foundation for a foam block bathhouse. And another article with an overview of foundation options for block baths.

Consequences of incorrect markup

Any error in the marking of the foundation can affect the entire construction process and the structure as a whole.

Any error in marking the foundation can affect the entire construction process and the structure as a whole. Among the adverse consequences it is worth noting:

- the difficulty of erecting the walls of the house and extension;

- formation of building distortion;

- destruction or deformation of the building;

- shortening the lifespan of a house or extension;

- problems in constructing the roof;

- inability to install rafters and wall trim;

You can do the correct transfer of the house plan to the site with your own hands, the main thing is to take into account the scale, dimensions and adhere to rectangularity.

List of tools

Marking the foundation of a bathhouse or house is quite simple if you prepare the following tools in advance:

- rope, fishing line or cord - the main element limiting the work space;

- measuring device - an ordinary tape measure;

- To place the corners on the ground, you will need wooden or metal pegs. Some builders recommend using the so-called. “benches” - 2 pegs knocked together with a board. The cord moves well over such cast-offs, which facilitates the adjustment process.

A simple set of devices is all that is required to ensure that the markings for the foundation of a private house or bathhouse are done correctly.

Marking by stages

What is breakdown

Before starting to build a house or even go for materials, it is necessary to determine the type of future construction and develop an action plan. It includes a detailed layout of the building on the site, foundation features and all dimensions. After this, you can begin to lay out the foundation of the house. It’s worth mentioning right away that this work is quite specific, and if you are not confident in your capabilities, the best solution would be to seek help from surveyors. This is especially true for uneven areas with strong differences in height and slopes located near ponds or ravines. Otherwise, problems may arise in the future involving significant shrinkage of the foundation of the house. The price of laying out the foundation axes depends on the complexity and volume of work.

The breakdown consists of transferring the overall axes of the future building, as well as marking the lines of its foundation directly on the ground. Such work precedes the digging of a trench or pit to fill the foundation. The dimensional axis is a conditional guide that marks the center or boundaries of the placement of structural floors and functional elements (formwork). The guides must correspond to the dimensions of all load-bearing elements and the foundation as a whole.

To lay out the foundation with your own hands, you will need the following materials:

- hammer;

- bright paint (red);

- bright colored rags (red);

- boards;

- wooden pegs or metal bars (you can use pieces of reinforcement) with a length of 100 cm or more;

- twine or wire;

- roulette;

- nails.

To properly lay out the foundation, it is necessary to constantly check all the corners of the casting - they must be perfectly level. Otherwise, the walls will stand at an angle, and there can be no question of any strength of the structure.

If you are making a floor with standard elements, it is important to accurately transfer all the dimensions of the axes to the base. Don’t be lazy to take all measurements and check the results 2-3 times

In this case, the saying that recommends measuring 7 times is very useful.

Average prices for work in the country

If you cannot carry out the leveling procedure yourself, you can use the services of contractor companies that offer to level the base part of the foundation with different materials.

For example, in Rostov craftsmen use extruded polystyrene foam, fiberglass mesh, and reinforcing mesh. For this they charge from 2550 rubles per 1 linear meter. In Moscow and the Moscow region, as well as in St. Petersburg, such a service will cost 3,500 rubles per linear meter. At the same time, the visit of the specialist to the point is often free.

The price consists of the individual characteristics of the base part, its size , as well as differences. The final cost is affected by the type of material used.

DIY block laying

Scheme of a columnar foundation made of blocks for a bathhouse.

The foundation in this case consists of expanded clay concrete blocks standing on concrete pillars. To begin with, we mark the directions for the blocks by driving 4 pegs along the outer perimeter of the future bathhouse. Pull and level the cord to the height of approximately the first block. If you made basement formwork when pouring concrete, the masonry is carried out according to its dimensions, placing the blocks on concrete pads.

Lay two blocks at a time, filling the seam with mortar. Lay the next row perpendicularly, the edge of the expanded clay block or foam block should touch the cord. Blocks are mainly used to raise the height of concrete foundations above the ground or when the site has a large slope. Lay the required height and leave it to dry. During laying, place studs between the blocks to secure the frame.

Useful tips

The following tips will help you mark out the foundation for your house with your own hands:

- before starting marking, check whether the setbacks from the red line and the boundaries of the site prescribed in the development permits are observed;

- To ensure that the lines of the cords run as accurately as possible, it is recommended to use pegs of small diameter - cuttings of reinforcing bars with a diameter of 10-12 mm are ideal, they easily enter the ground and hold firmly in it;

- the cord needs to be tightened so that it does not deviate due to tall grass getting in the way, etc.;

- you should not remove the cords until the trench has been dug, so as not to lose the accuracy of the markings;

- at the stage of installing the formwork and after pouring concrete, or when erecting supports for the grillage, check the diagonals so that the constructed house has right angles and stands firmly on the foundation.

A foundation made by yourself will evenly distribute the load on the ground, provided that the markings are correct and the installation technology is followed.

Background

The story happened 7 years ago. In those years, construction for me was more like a part-time job as an auxiliary worker.

And in general, the construction activity itself did not interest me in any way, but quite the contrary.

My uncle, of the most honest rules, built himself a garage on the site

.

It must be said that, as long as I can remember, he is constantly building something,

either at the dacha, then on the plot, or helping a neighbor build something, although he himself is not a builder by training and has never worked in the construction industry.

At the same time, in my opinion, he always builds wisely

, without possessing scientific knowledge.

And so, my dear uncle, having decided to test my intelligence, apparently sets me a task:

“I have put out the formwork for the foundation

.

Before pouring, I need to check all the sides and diagonals

again.

But here’s the problem, I just can’t check the diagonals, because I have pallets with bricks

, I don’t have a level, a theodolite and other expensive things. Think."

Until that moment, I had not encountered such problems, I repeat, because... I worked more on auxiliary jobs. 3 minutes of reflection helped me find the answer. Try to solve the problem yourself, and only then look at the answer.

Design Features

Diagonal 22 inches

The range of heating boilers is represented by different models. Some run on gas, others on electricity, and others on liquid fuel. Each type has its own operational advantages and disadvantages. The disadvantages of using certain installations haunt designers and technicians. So they decided to combine some models, and combined heating devices were born. They can operate, for example, on solid fuel and gas simultaneously.

This combination made it possible to minimize emergency risks and organize the operation of the same solid fuel boiler in autonomous mode. How do such installations work, and where is their use more than justified? As a rule, universal boilers are always equipped with an additional number of pipes. They can be used to connect underfloor heating, heating radiators, a greenhouse control system, heating water in a swimming pool or heating a bathhouse.

The gas burner in such a boiler is located below the combustion chamber, where firewood, briquettes, sawdust or coal are placed. Therefore, if necessary and switching, it allows you to completely burn the remaining solid fuel. If work is switched to solid fuel, the gas burner closes automatically. For ease of use, the steel heat exchanger responsible for heating the room passes through the entire body. All walls are thermally insulated with special mineral wool, so the efficiency of the unit is almost 92%. And this is a very high figure.

The heat exchanger for supplying hot water is made of copper and is located in the upper part of the installation. Copper is not afraid of corrosion, so the service life of the coil is equal to the service life of the entire device as a whole. Universal boilers have lever and air dampers that ensure the supply of the required portion of air.

How the installation works

The operating principle of a gas-wood boiler is extremely simple. The design uses two autonomous cameras. The furnace room is located above the gas room. This feature allows you to use two types of fuel simultaneously. Gas burners can operate at low pressure. Therefore, you can often see models that are connected not to central gas lines, but to liquefied gas cylinders.

Note! If there is a power outage, the gas-wood boiler will not be able to operate on gas. And all because the products of its combustion in this case will not be independently discharged through the chimney to the outside, and condensate instantly accumulates on its walls, clogging the chimney

If there is no light in the house, the boiler is heated exclusively with wood.

Advantages of installations

There are quite a lot of advantages of gas-wood boilers, so we will outline only the most basic ones:

- The main factor is the opportunity to save money and use cheap firewood instead of expensive blue fuel. If you run out of wood, you can switch to gas in automatic mode.

- The combined design allows the use of autonomous heating. Gas ensures operation of the installation at night without additional fuel loading. It’s also nice to come home after work to a well-heated house, knowing that the gas will maintain the desired temperature when there is no one to throw firewood into the stove.

- Universal combi boilers can have one or two circuits, so you can use the installation not only for heating, but also for supplying hot water for technical needs. Today, universal gas-wood boilers are equipped with storage boilers, and there are models that can heat water to the desired temperature using a flow-through method. The choice is great, and that makes me happy.

But before deciding to purchase such installations, experts recommend studying the features of their operation and disadvantages.