Technologies in construction are developing by leaps and bounds. New materials are emerging that make it possible to build faster, without losing quality. And although aerated concrete is not an innovation - it is already three or four decades old - bathhouses have not been built from it before: this material has a fairly high hygroscopicity. But new impregnations have appeared that can significantly reduce the amount of moisture that the material absorbs. But even without impregnation, using modern vapor and waterproofing, you can achieve good results. The average lifespan of a bathhouse made of foam blocks is about 20-30 years. If you're happy with this, start looking for a project.

A gas silicate bathhouse can be built “with one hand”, and the process goes quickly: the blocks are large but light

You just have to remember that aerated concrete is produced using two technologies. In the production of some, hardening occurs in an autoclave - these are gas-concrete and gas silicate. When producing others (foam concrete), a foaming agent is simply added, then the foamed solution is poured into molds and hardens in air.

Autoclaved cellular concrete is considered to be of higher quality. An autoclave is not a cheap piece of equipment, so you can’t make the material using a homemade method. This is reflected in the cost - gas silicate is more expensive than foam concrete - but the geometry of the material and its quality are usually much better. Since it is desirable to make the seams between the blocks as thin as possible, the geometry is very important. Therefore, when purchasing, look for gas silicate blocks with the least deviations. Even if they are more expensive, you will save as a result: the glue costs a lot, if you can make a 1-2 mm seam, its consumption will be small. In addition, with such a seam there will be less heat loss, which means that it will be possible to make a smaller layer of insulation (if they are insulated) and less fuel will be consumed to heat the bath.

It is easy to distinguish gas silicate: due to the fact that lime is the binding element in it, it has a white color. The rest of the porous concrete is gray.

The gas silicate block is easy to distinguish: by color

Phased construction: walls and roof

The first row is fastened with cement mortar; it must be laid out evenly, so it is worth using a softened rubber hammer (since an iron hammer can destroy fragile blocks) and a building level to measure deviations.

Might be interesting Rolled lawn: what is it, types, how to choose, lay and care Do-it-yourself verandas and terraces in the country: types, design, arrangement with photos Assembling a garden shredder with your own hands

Foam blocks are laid not like ordinary bricks, but on edges. The second row is fixed using a thin layer of specialized construction adhesive. Every three to four rows you need to lay a rigid reinforcing mesh, which will contribute to the strength of the walls.

A standard roof with two slopes and a central ridge is suitable for a steam room.

Before deciding on the length of the rafter legs, you need to pay special attention to:

- width of the building;

- at what angle should the slopes be?

- climate features.

To connect the rafters together, staples are used. The bars are installed at a distance of about 1 m.

The material for the rafters must be of high quality, without any defects. After installing the rafters, it is necessary to create a sheathing. It is made from smooth boards. Lathing happens:

- solid;

- discharged.

The final option is chosen taking into account the characteristics of the roof covering, for:

- roofing felt – double;

- slate – single;

- tiles - from beams.

The roof, like everything else, is insulated and protected from moisture, steam, and insulated. The final stage is laying the roofing. It is chosen based on personal tastes and available budget.

Floor installation

After the floor has been insulated, preparation of the base should begin. A reinforcing mesh is placed on the insulation. This is the time to remember to leave drain holes where they are provided.

Install the drains, seal the holes on them with tape so that the solution does not get inside. After installing the beacons, concrete is poured.

The concrete layer should be about 10 centimeters. As soon as it hardens, we make a screed up to five centimeters thick. This is necessary for the final leveling of the floor.

The last stage is decorative coating. Here everyone chooses according to their taste. You can put porcelain tiles, wooden floors, linoleum, quartz vinyl tiles.

Types of material for block baths

You can build a bathhouse from blocks with your own hands using various types of building materials:

gas-filled concrete. It is the basis for the manufacture of blocks obtained as a result of a chemical reaction with the release of gas. It features a uniform distribution of air cells. Due to the varying degrees of pore concentration, it differs in density, ranging from 500 to 1000 kg/cm3. The thickness of the building material allows the construction of walls 20 cm thick, which is enough to maintain a comfortable temperature in the room; Types of building block material

ceramic blocks. In appearance they resemble traditional brick. They have increased moisture-resistant characteristics and provide a high level of thermal insulation. They are distinguished by the presence of air channels parallel to the height of the product. Mainly used for exterior decoration, rarely used for the construction of bathhouse walls due to the increased price. Inferior to brick in most characteristics; gas silicate products. The building material is produced by autoclave processing and contains lime. Gas silicate is externally easy to distinguish from other types of concrete products by its snow-white hue and regular geometric shape. The material intensively absorbs moisture, which negatively affects its integrity and strength characteristics. Its properties are inferior to aerated concrete and requires reliable waterproofing; foam concrete. It is a type of aerated concrete product. The manufacturing process involves the introduction of a foaming agent, which provides a porous structure. Available technology allows private production

When purchasing foam blocks made at home, pay attention to quality. For construction, it is convenient to use a foam block with dimensions of 60x20x30 cm; cinder blocks

Building materials, along with concrete, contain various types of slag, which are industrial waste. Cinder blocks are inexpensive compared to other varieties. They have an uneven surface, as well as significant dimensional deviations. You should not immediately use them for a block bath due to the release of harmful substances when heated. Before construction begins, the material must sit for a year; expanded clay concrete. Expanded clay granules made from baked clay are used as filler. Expanded clay concrete is characterized by reduced hygroscopicity and low weight. In terms of performance characteristics, it surpasses foamed concrete, as well as aerated blocks. Expanded clay concrete products have reduced dimensions compared to foam blocks and cinder blocks. Dimensions are 40x20x20 cm.

Types of building blocks blocks

Ready-made examples

Today, anyone can come across many different design options for baths made of foam blocks. Since foam concrete itself is not a beautiful finishing coating, it is better to cover it with decorative elements. Many designers suggest decorating the external surface with stone.

In construction stores, any buyer will be able to see a large selection of various decorative stones.

Many people choose similar elements of small size with a rough surface for their baths. The color scheme of such material can be very different. Her choice depends on the personal preferences of the owners. Often such elements are used to decorate the entire structure.

The roof for the bathhouse can be made from ordinary corrugated sheets. It is also possible to have a terrace. It can also be finished with decorative stone. According to most people, this type of design is beautiful and interesting.

- You can often see projects in which foam concrete baths are finished with siding on the outside. At the same time, the color palette of the material is varied. It is more profitable and practical to decorate the roof and all openings in dark shades.

- If the project includes a veranda, it can be made of siding in the same color scheme as the room itself. Often with this type of design a small staircase is made. It can be covered with a decorative wood coating.

You can learn more about how to build a bathhouse from foam blocks with your own hands.

Many are convinced that a bathhouse can only be made of wood. This opinion has every right to exist, but one should not deny the fact that traditional materials for the construction of such structures have an alternative in the form of artificial analogues.

Projects and drawings of foam block baths

At the bathhouse planning stage, it is worth including in its design such premises as a steam room, sink, rest room and vestibule. In order to save fuel, the building should not exceed the parameters of 5x5.5 m. If desired, the owners can place a bathroom in the bathhouse. Its dimensions will accordingly increase to 6x6 m. A terrace, veranda, or gazebo can be attached to the main room. Let's look at some bathhouse projects in more detail.

5x5.5

The construction of a bathhouse with dimensions of 5x5 m on a suburban site allows you to save space while maintaining the number of functional rooms. Unlike projects with large footage, such a building heats up quickly and evenly and retains heat longer.

Tambour (dressing room) - an entrance hall in which there is a locker room, a woodshed, and sometimes storage shelves.

The rest room is a room with sun loungers, benches and a table.

Shower room, steam room - washing compartments. In the steam room, a stove with a heater is laid out, shelves are installed, and the drain is dug. The shower room is also drained and a shower stall is installed.

Finishing of a block bath

Building blocks, no matter how high quality they are, still remain vulnerable to moisture, so proper waterproofing is indispensable. Moisture protection must be comprehensive. Thus, the blocks should be impregnated with special water-repellent compounds and additionally covered on the outside with special films (plain polyethylene will also do).

Construction of a bathhouse from blocks

Finishing a bathhouse requires the installation of a vapor barrier layer. The vapor barrier is attached to the internal surfaces of the bathhouse. It is best to use high-quality membranes. They will provide the necessary level of air exchange and will not allow moisture to damage the material.

Insulation

Vapor barrier

Insulation of walls outside

For external cladding, it is best to use modern hinged ventilated panels. Siding works well. Any cladding must be fixed in such a way that it is at a distance of at least 4-5 cm from the wall surface. An ordinary sheathing will allow you to fulfill this requirement.

For interior decoration, lining is traditionally used. It is best to cover the floors with ceramic tiles.

Sheathing

Covering the bathhouse with clapboard

For the rest, be guided by your preferences. The main thing is that the materials you use can withstand high temperatures and excessive air humidity, while remaining safe for bathhouse visitors and without losing their original aesthetic qualities.

Thus, even without an impressive budget and without the skills of a builder, you can personally build a full-fledged, reliable, safe, comfortable and durable bathhouse from blocks with your own hands. At the same time, the finished building will not be inferior to more expensive structures made of wood, brick and other popular materials. All you need is desire, attentiveness and following the instructions received.

Features of building a bathhouse from blocks

Any construction begins with choosing the type of foundation. If you decide to build a bathhouse from blocks, you should choose a strip or pile foundation - most blocks are light in weight, and bathhouses are usually a one-story structure and there is no need to spend extra time, money and effort on making a more complex foundation.

The laying of blocks is carried out by analogy with brickwork, with the only difference being that it is advisable to lay a metal mesh every 2-3 rows. It will add additional rigidity and strength to the entire structure.

To make the work easier, it is very important to lay out the first row of blocks evenly. They need to level and compensate for all existing unevenness in the foundation.

At the very top you can strengthen a crown of timber, to which it will be convenient to attach the rafter system and the base of the roof.

For insulation, it is advisable to use a layer of basalt wool, on top of which a foil film or vapor barrier membrane is laid. It is advisable to provide a gap between the foil (membrane) and the finishing materials by filling the slats with a thickness of 2.5 cm and then attaching the lining to them.

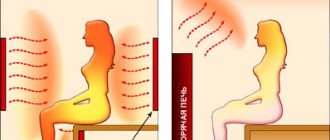

Insulation and moisture protection of a bath using foil films

Most units require exterior wall finishing. Here everyone chooses to their own taste: you can plaster and paint, cover it with finishing stone or brick, etc. You can decorate the walls with siding, but for better ventilation there should be a distance from the wall to the siding (for foam concrete at least 5 cm). The roof for a bathhouse made of blocks can be any - to your taste without any special restrictions.

Insulation from the inside

The insulation of the bathhouse must be carried out correctly. The first step is to insulate the foundation and underground. You can insulate it with mineral wool, using expanded clay, and also use polystyrene foam.

Walls can also be insulated with foam plastic; it can be easily mounted on the surface. It is inexpensive and holds heat well and does not absorb water.

Expanded clay is also used to insulate walls. The ceiling also needs to be insulated; for this, a frame is made of slats and a metal profile that will support the insulation.

A waterproofing film is attached on one side, which should not touch the insulation itself, and aluminum foil on the other.

Advantages and disadvantages

It would take a long time to list the advantages and disadvantages of blocks in bath walls. Everyone will find their own qualitative differences in this material, both good and bad.

It’s still more pleasant to start with the positives:

- foam blocks do not shrink at all;

- the bathhouse is ready for use immediately after construction, external and internal decoration and installation of the stove;

- minimum construction period;

- the cost of the finished structure is two times lower than a wooden frame or brickwork;

- absence of harmful chemicals in the production of concrete blocks and, as a result, absence of unpleasant odors;

- low weight of the material, allowing for easy masonry and the use of the simplest foundation;

- has high heat-repellent qualities;

- are not subject to the growth of mold, mildew or other microorganisms;

- The thickness of the walls is good because you can use just one block at a time, this will be enough to create a warm, comfortable room.

But there is often a fly in the ointment. Therefore, we note the disadvantages:

- If the blocks are not treated with a special hydrophobic solution, they can easily absorb moisture. In winter, even with double insulation, it can freeze and ruin the walls of the bathhouse. The structure may simply crumble.

- When using concrete blocks in such a building with high thermal parameters, the problem of condensation on the walls arises.

Bathhouse project 3x4

During the development of the project, a bathhouse made of a gas silicate block measuring 3x4 does not provide any special options for interior layout and exterior decoration. And at the same time, you should place a compartment for the steam room, a washing room and a resting place:

- For a steam room, approximately 2x1.8 m is allocated.

- In this case, one of the sides is selected for the steam room, where a lounger will be installed the length of a person’s height, approximately 190 cm for free lying.

- The distance between bench levels is considered optimal 30 cm to 60 cm.

- For the stove it is necessary to leave at least 1 m.

- The remaining area can be divided into two parts: a steam room and a washing room.

Projects

Currently, the bathhouse is a multifunctional space that is used not only for washing, but also for complete relaxation. Based on these goals, modern projects of block baths are being developed. In addition to the main premises (steam room, wash room), this building may contain a cozy relaxation room, a small terrace, an attic or a swimming pool. The size of the latter largely depends on the dimensions of the structure itself.

The most common are attractive bathhouse designs that include a relaxation room.

Most often, the relaxation zone is larger in area than the rest of the premises. This is because in the rest room it is necessary to place a table, armchairs or chairs and other necessary pieces of furniture that need enough free space.

The most common types of projects include the following options.

When building a block bathhouse with a rest room, be sure to take into account that the building must have a vestibule or a small dressing room separating the internal and external parts of the structure. Thanks to such additions, cold and frosty air will not penetrate into the room during the winter season.

Most often, this decision is made if there are no other residential spaces on the land plot. Also, similar structures are often used when designing a plot in a dacha. The attic is a great place to spend the night after being in the recreation area.

When developing a bathhouse project with dimensions of 3 by 5 m, it is necessary to organize several isolated rooms. Without them, the resulting design will be incomplete.

The first room a person enters may be a dressing room. It should be such that you can leave clothes in it. In the interior of such a bath it is necessary to place a small closet in which there is free space for storing all things. Many owners install an additional box in such baths, in which they separately store fuel (wood or coal).

Even in projects of very small baths it is necessary to provide this room. In a 3x5 m building, you can put a small table and a few chairs in the relaxation room.

Immediately behind the rest room you should organize a sink or shower. These spaces are necessary so that sauna users can cool down after steaming their bodies. These rooms should have a simple and uncomplicated interior design. They can accommodate several small benches, a shower and a clean container filled with water. Currently, many owners choose one shower stall to furnish such spaces, abandoning the classic sink.

The main room of the bathhouse is the steam room. Here you need to place a stove, as well as comfortable wooden benches. All listed rooms must be located in any bathhouse. In addition, the building with dimensions of 3x5 m also allows for the installation of a small terrace or attic.

Immediately after the dressing room, you can organize a small relaxation room and place a compact table in it, as well as a couple of chairs. You can get by with a not too large sofa and place a coffee table in front of it. This area should be separated from the rest of the space by a partition, and behind it a spacious steam room should be arranged. It can be divided by another partition and equipped with a washing space in the resulting small corner. In such conditions, a narrow shower stall will look best.

A partition should be placed behind it to close the three remaining zones - shower, steam room and toilet (if you want to install it in a bathhouse).

All bathhouse projects are similar to each other. Any building should have a washing room, steam room and rest room. Additionally, the building can be equipped with a spacious attic or a neat terrace. Some owners even combine such structures with a garage. In this case, it is recommended to contact specialists who can competently draw up correct drawings of such buildings.

DIY pool

The habit of combining a bathhouse and a swimming pool came to us from the Finns, since it is in the Finnish bathhouse that both cool water and a steam room are combined under one roof. In a traditional Russian bathhouse, instead of a pool in winter, snow or an ice hole were used; at other times of the year, simple dousing from a tub or basin was practiced.

But since time does not stand still, today more and more people dream of equipping their home steam room with at least a small pool. How to do it?

First, it’s worth finding out which kind of pool will “fit” into the building. For a small bathhouse, it is better to choose a corner model; it will take up minimal space, but will cope with its functional responsibilities perfectly.

And in a larger room you can already install a full-fledged swimming pool, in which it is not only pleasant to cool off after a steam room, but also comfortable to organize mini-competitions.

Most modern bathhouse projects with a large swimming pool involve the installation of a stationary artificial pond.

To create it, concrete is used, which is poured into a hole of the required size, and tiles as a finishing material.

In turn, PVC pools are another type of stationary swimming pool.

However, it is better to use them as a temporary option, since if used incorrectly, they crack very quickly.

SPA pools are a ready-made structure with which you can carry out a variety of relaxing procedures. At the same time, each owner determines the feasibility of installing such a design in a bathhouse independently.

So, the type of pool has been determined. What's next? And then the most interesting part begins: creating a project for a bathhouse or sauna with a swimming pool. And for this you need:

- Draw a floor plan;

- Determine the location for installing an artificial water source;

- Calculate the load on sewerage and other systems;

- Calculate the amount of materials used.

Attention! Before starting construction of a bathhouse with a swimming pool, it is necessary to find out the location of groundwater. And if the structure is erected at a distance of less than 1 m from them, then very soon the foundation of the bathhouse will be destroyed.. So, any construction begins with earthworks and ends with the finishing of the already erected structure

But there are also intermediate stages, without which it is impossible to build a bathhouse with a swimming pool

So, any construction begins with earthworks and ends with the finishing of an already erected structure. But there are also intermediate stages, without which it is impossible to build a bathhouse with a swimming pool.

Step-by-step instructions for building a bathhouse with your own hands:

- We are digging a pit for the future pool. The width and length of the pit must exceed the dimensions of the future pool by 0.5 m, and the bottom of the pit should be made inclined;

- We install the pipe, connect it with a plastic pipe to the sewer system;

- Fill the bottom of the pit with sand, about 6-8 cm;

- We strengthen the walls of the pit with boards;

- Compact the sand;

- We fill it with a layer of crushed stone;

- We compact the crushed stone;

- We hammer the reinforcement along the walls of the pit, retreating 5-7 cm from its upper edge;

- We make the strapping in a horizontal plane;

- Fill the pit with concrete (layer thickness - 10 cm);

- We install the reinforcing mesh and fill it with concrete again;

- Let it dry for 24 - 48 hours;

- We spread the roofing material;

- We knock down the formwork, which we install at a distance of 25 cm from the walls;

- We pour concrete with waterproofing additives into the formwork;

- We compact and, if necessary, repeat the procedure.

The concrete layer should rise to a height of 20 cm.

- Let the concrete dry for 48 - 72 hours, remove the formwork;

- We leave the pit alone for about 25-30 days until it dries completely.

During the first week, be sure to lubricate the walls with water several times a day, this will prevent the solution from cracking.

When the foundation pit is ready, we begin finishing.

- We install a durable plastic frame;

- We lay geotextiles;

- We lay a waterproofing film over the materials, which we fix with an adhesive solution containing latex;

- We plaster the walls and bottom of the pool;

- After drying, level the plaster;

- We check the waterproofing properties of the pool;

- We finish the pool with tiles or mosaics.

We pour water into it, make a mark on the walls and leave the pool alone for up to 14 days. If at the end of the period too much water has left, it means that the waterproofing was done incorrectly. A small outflow of water is attributed to natural evaporation.

Foam block construction project

The choice of cellular concrete blocks as the main building material is not accidental. This economical modern building material is characterized by a number of advantages in comparison with other wall materials, such as brick, stone or wooden beams.

Ease of machining

Among the advantages we note the following:

- The price of foam blocks is low, which has a positive effect on the cost of the entire facility;

- A house built using these blocks is characterized by low weight and, as a result, low load on the foundation;

- Walls made of foam blocks have a low degree of thermal conductivity, thanks to which it will be possible to save on heating;

- Foam concrete and building materials based on it “breathe” due to their porous structure. Thanks to this, optimal parameters of moisture content in the air are maintained at home.

- Cellular concrete blocks are easy to process. They are easy to drill and saw, as a result of which the construction process is significantly simplified and cheaper.

Clean masonry of foam blocks without extra effort

Example Project 1

As an example, let's look at the most popular designs of houses made of foam blocks with a bathhouse. In Figure No. 1 we can see a typical solution suitable for building a small country house with a steam room and shower.

The advantage of such planning is that in a limited area you can place not only a small bathhouse, but also a full-fledged relaxation room and even a terrace for comfortable spending time in the warm season (see also the article “Bathhouse with a veranda: features of projects”).

Considering that the house is planned to be built from foam concrete, a monolithic strip shallow foundation with sides of 6 and 8 meters can be used as a foundation.

Of course, such a small house cannot be considered as a full-fledged home, but as a building for spending weekends and holidays outside the city, such a house looks very attractive.

Sample Project 2

A similar structure is shown in Figure 2. This project is slightly larger in size than the first sample, but also includes only those rooms that are necessary for short-term temporary residence and for the operation of the washing department and steam room.

The advantage of the project is that all rooms have similar sizes, therefore, you can use the steam room and shower in comfortable, uncrowded conditions.

Due to the relatively small dimensions and light weight of building materials, this project can also be built with your own hands on a shallow strip foundation for a bathhouse.

Sample Project 3

However, all these projects of houses and bathhouses made of foam blocks are small and suitable exclusively for short-term living. Let's consider the plan of a full-fledged house with a steam room and shower.

This project provides for a full-fledged living room and a relaxation room, in addition there is a kitchen and a spacious hall. But, most importantly, the project includes a sauna, a washing room and a separate bathroom, which makes a temporary or all-season stay in the house most comfortable.

Where to order a project

Where can I order a project, and is it needed at all?

As already mentioned, having a project guarantees a number of advantages, including:

- Having a general idea of how to build the planned structure;

- Convenience of planning estimates of building materials and, as a result, the ability to prevent their overexpenditure;

- The ability to adjust the timing of the construction process, which results in an increase in labor productivity;

- No difficulties in registering real estate and registering it with the cadastral authorities.

Project documentation is, in fact, instructions according to which a house is built. Therefore, this plan, along with the location of rooms and individual utility rooms, should contain information about the thickness of the walls, the method of arranging the floor, roofing system, etc.

Thus, from all of the above, we can conclude that the development, preparation, and subsequently approval of project documentation should be carried out exclusively by professionals with specialized qualifications.

You can order projects of residential buildings made of foam blocks with a bathhouse directly on the Internet. To do this, just leave a request on the website of specialized design bureaus.

As a rule, the development of drawings is carried out taking into account all regulatory requirements and based on the personal wishes of the customer. The development of a project for your new home will be free if a construction organization acts as a contractor.

Subtleties of design

When developing a drawing of a future bathhouse, you must take into account its size. Only knowing the exact scale of the structure can you correctly draw up a project for such a room

This scale is small, so you need to be careful when designing these rooms. The design must simultaneously accommodate a steam room, a washing room, and often a shower room with a changing room. As a rule, in these cases, most of the space is set aside for the steam room. Often such baths have a window.

There may even be two openings (in the washing room and steam room). They act as necessary ventilation. Often, projects of such small rooms are combined with other residential buildings (garages, guest houses) to make the structures look more beautiful and solid.

In this case, many experts strongly recommend creating such areas outside the room. Today, a considerable number of projects for the design of larger baths have also been proposed. Their size is 6x6 m, some designs may be larger (+ 2-3 sq. m). Premises of this size can easily accommodate all the necessary rooms (shower, locker room, washing room, vestibule, steam room). In addition, such buildings often contain small recreation areas for the owners.

In these types of baths it is worth installing window openings. Their size must correspond to the dimensions of the room itself, since large structures require good ventilation. It is better to place windows in several rooms at once. Often such large-scale baths are made two-story. Moreover, the second tier is also made of a rather large size. Most often it is reserved for a swimming pool or a large recreation room.

The second floor of such premises does not necessarily need to be additionally insulated. Warm steam from the first tier will penetrate the room, warming it up. Due to the uniform distribution of heat, the temperature of the upper zone will not be too high, it will remain optimal. When building two-story bathhouses, experts and designers do not recommend combining them outside with other buildings. After all, they can completely ruin the beautiful appearance of the bathhouse and make the structure too overloaded. Therefore, it is better to place all other additional structures separately.

With swimming pool

Often, when building baths from foam blocks, swimming pools are placed in them. But it should be remembered that they should only be installed in structures with a large area. Otherwise, the design will be cumbersome and will cause significant inconvenience. If you are building a two-story building, it is better to place such an element on the second tier.

Today, on the building materials market, anyone can see various options for swimming pools for baths. They can be of various shapes (round, rectangular, square, semicircular). The choice of the appropriate option depends on the internal layout of the building. At the same time, we must not forget that the design of such premises with a swimming pool will cost the owners a lot.

With terrace

You can often find projects of bathhouses with a veranda. It can be included in projects of small buildings. According to some experts and designers, the terrace can fit perfectly into any type of design, regardless of size. If you are building your bathhouse from foam blocks, the veranda can be made from this material. But options are possible in which terraces are made from a different base (wood, metal, plastic, decorative stone).

Some designers advise placing small pieces of furniture (tables, sofas, chairs) on terraces. It is worth remembering that the veranda cannot be overloaded. Otherwise it will look ridiculous. If you are arranging a two-story bathhouse, then such structures should be placed on the upper tier.

Small buildings

Today, experts can offer designs for bathhouses made of foam blocks with dimensions smaller than standard ones. Such premises often include only a washing room and a steam room. Other zones in similar structures may be too small or cannot be accommodated there at all. Often, in order to increase the area of a small bathhouse, owners build a second floor of the same scale.

On the upper tier you can place a shower room, a relaxation room, and a small swimming pool. If you do not want to build another floor, remember that it is better not to load such structures with verandas and other additional elements. Even in small bath rooms it is necessary to place window openings. For these structures, two small windows are enough. In small-scale baths this will be enough for ventilation.

Preparation for construction work

- Washing bath. It is constructed for utilitarian purposes for washing. It consists of two compartments: a small dressing room for clothes with a stove firebox, a steam room and a shower room combined. The dimensions are small - 2 x 3 m on average. If you really want to, you can take a steam bath. A widespread type of bathhouse throughout the country.

- Bathhouse with steam room. Built by connoisseurs to take a steam bath with a broom. Sizes start from 16 square meters (4 x 4 m). A full-fledged bathhouse with several rooms: a dressing room, a shower and a steam room.

- Bath complex on one or two floors. Building with own heating. Year-round communications - hot and cold water. In addition to the steam room and shower, a relaxation room, a bathroom, a swimming pool and a sauna with dry and hot air are being built. A separate vestibule with a furnace firebox and a veranda are arranged.

Any type of bathhouse can be easily erected from foam blocks. The project depends on the budget and availability of space for construction. The best option for placing a bathhouse is an extension to the main residence. In this case, heating, hot and cold water are supplied.

Exemplary bathhouse - with a separate steam room. Then you won't have to wash in the scalding air. A dressing room with a place to relax will improve your emotional mood. A separate vestibule is built for the stove, where firewood and brooms are stored. The rooms will always remain clean - wood chips and smoke will not bother anyone. The built summer veranda and barbecue will replace a separate gazebo.

Steam room.

Next, we plan the upcoming work step by step:

- we determine the location of construction;

- We prepare a detailed construction project;

- We calculate the required amount of building materials;

- carefully select foam blocks and cement;

- prepare tools and equipment;

- pour the foundation;

- we install a drain;

- We waterproof the basement and interior spaces;

- we build walls;

- we build a roof;

- We complete the interior and exterior decoration.

After we’ve made the drawings, counted the blocks and found a suitable location, we get to work. It will take 2-3 weeks to pour the foundation, taking into account the complete hardening of the cement. Construction will take the same amount of time. In total, it will take a month and a half to erect the building with your own hands.

Finishing a block bath

The work on finishing the bath room includes:

- high-quality internal lining;

- exterior finishing.

Finishing activities indoors require fastening the sheathing, installing thermal insulation material, as well as protection with a vapor barrier membrane.

Finishing a bathhouse made of expanded clay concrete blocks

Various options for interior finishing are possible, which are attached to an insulated and vapor-insulated frame:

- wooden lining. It will saturate the room with a unique aroma during bath procedures;

- salt blocks. This is an original finishing option that has a beneficial effect on the respiratory system.

Exterior finishing activities include:

- Installation of external waterproofing.

- Fastening of thermal insulating ventilated panels.

- Installation of finishing.

Roof

The roof has one peculiarity: the roofing material must be light. It could be:

- soft roofing - made of rolled materials or soft bitumen tiles;

- corrugated sheeting;

- metal tiles;

- wooden roof.

The entire system is attached to the Mauerlat, and it is attached to the upper armored belt with long pins. When attaching the rafter system, everything is attached only to the beam. It is not worth attaching to the walls - there is no sense in it: gas silicate cannot withstand long-term point loads, it crumbles and cracks. That’s why an armored belt is needed.

Design

Many people believe that a bathhouse is a room in which it is impossible to show maximum imagination when creating an attractive design. Actually this is not true.

In the bathhouse it is quite possible to build a kind of living room with a large table and several chairs, as well as a cozy sofa, opposite which a wall-mounted TV will find its place. This layout can be used even in a small building if you use small-sized furniture or transformable folding models.

The interior of the room can be covered with siding or panels that imitate timber. Such coatings will look very attractive and appropriate in a bathhouse. Against their background, you can place furniture made of wood, as well as wall and ceiling lamps made of antique-style metal.

Some owners complete such a bathhouse interior with real fireplaces or fireplace stoves made of brick, stone or their imitations.

As a rule, a large number of wooden parts are present in steam rooms and washing rooms. Here you can also dilute the finishing with stone. Lighting fixtures in such spaces most often have a laconic appearance that does not attract too much attention.

Types of fonts

There are three types of pools in and next to the baths:

- stationary - reinforced concrete waterproofed or acrylic bowls;

- mobile – frame, inflatable or prefabricated structures made of polymer materials or wood;

- hydromassage - wooden or plastic tanks equipped with heaters, seats and a system of nozzles for water procedures.

When designing, they determine the place where the pool will be located, its shape, and the material used. Corner fonts are installed in the corner of the room. In the center - square, round or rectangular.

Depending on their location relative to the floor, tanks can be recessed, above-ground or semi-recessed.

A person experiences unusual sensations in a cascade pool - a shallow hydraulic structure consisting of several bowls, in each of which the water is heated to a different temperature.