Metal door covered with vertical wooden paneling A high-quality metal door is an unaffordable luxury for many. We are now not talking about Chinese foil for 10,000 rubles, but about real steel doors, the price of which can exceed well over 50 thousand.

Can't afford such expenses? There is a way out, and in this article we will talk about metal doors with lining, and how you can make a decent finish yourself and save a fair amount of money on it.

What is the beauty of using lining

- Looks impressive. At the same time, wood processing is relevant at all times. This type of finishing does not go out of fashion and has been popular for a hundred years, if not more, and is not going to lose its position.

- Reasonable price. Moreover, this applies to any type of lining, including wood, plastic or metal. Covering with this material is a much more budget-friendly option compared to expensive natural materials.

- Heat retention and noise reduction, which is explained by the structural features of wood slats (their porosity and thermal insulation).

- Easy to install. The groove/tenon rule applies to all types of materials, and assembling panels into a single, impenetrable surface will be as easy as playing with a children's construction set or puzzles.

- Reliability, durability and wear resistance of raw materials. With proper care, the panels will remain in perfect condition for decades, but even in the event of force majeure, replacing a couple of damaged lamellas is a matter of five minutes.

Final stage

Well, we have come to the final stage, which includes gluing the sealing tape and installing all the components.

Advice! Apply the sealing tape gradually; there is no need to remove the entire protective layer at once, as there is a high probability that the tape will tangle and stick together. Tear off the protection in small sections, gradually gluing the tape to the door leaf, previously cleaned of dust and dirt.

Now all that remains is to install the locks and the peephole. There is nothing complicated here, especially if you remember how they were filmed.

Entrance doors with clapboard

That's all, we hang the door back on its hinges and check the work. If everything was done correctly, then no difficulties should arise, since we did not interfere with the design of the door itself, and therefore could not disrupt the functionality.

As you can see, finishing a door with your own hands is not a complicated process at all, which will require a minimum of time and effort, and if you have not yet decided on the material, we recommend that you watch the video in this article, which does not show finishing instructions, but does present metal doors with clapboard. It’s much easier to visually understand what your door will look like, and if you use a little imagination, you can create a real masterpiece yourself, as shown in one of the photos above.

Source

Required tools and accessories

In order to sheathe an iron door with clapboard correctly and beautifully, you need to select some equipment, including:

- a drill (ideally electric) and a screwdriver, you can try to get by with a screwdriver, but the process will become much more complicated;

- a hacksaw for metal or wood, depending on the original type of lining (here it is better to use hand-held equipment and not use a grinder);

- measuring instruments: ruler, square, tape measure;

- hammer.

In addition to the basic materials, the following will be useful: wooden blocks to create the frame of the sheathing; self-tapping screws; finishing nails with very small heads or no heads at all or clamps.

Why is this necessary?

Metal fabric does not have the necessary aesthetic qualities, especially for inexpensive models. Their decoration is primitive and unattractive. The first thing a person sees when coming to visit someone is the door, which is the face of the apartment.

You will need upholstery if you are tired of the appearance or if they are already worn out.

This type of finishing is needed for:

- Insulate the door, especially if this is not provided inside the door leaf, otherwise it will freeze.

- To create a decorative effect. This need arises after renovation.

- To update the appearance. A metal door performs its protective functions without having its original appearance.

Selection of materials

For cladding an iron door with clapboard, materials of “Extra” and “A” (the so-called “first”) classes are best suited. It is these categories that have the necessary qualities for interior and exterior work, because the surface is the smoothest and most even, and the number of knots and other defects, which, by the way, only worsen the appearance of the product over time, is minimal or not allowed at all.

Considering the fact that the metal door itself is quite heavy, voluminous and massive, then for cladding it is better to choose the thinnest, most elegant dies in the 12.5 mm category: “Calm”, “Standard”, “Softline”, “Eurolining” or “Landhais”, but textured “Blockhouse” or the same “American” will only add unnecessary extra volume, which is undesirable.

The type of wood for covering the door leaf does not play a special role; you can choose the most optimal option in terms of price and appearance from coniferous or deciduous varieties. The only thing is to immediately clarify whether these products have additional deep impregnation with special antiseptic agents or whether further finishing with varnish, stain or other means will be required.

If cladding with plastic lamellas is planned, then it is necessary to choose impact-resistant, heavy acrylic products intended for outdoor use. Such panels are simply attached with glue, but partial repair of single damaged dies will become much more complicated. In addition, the cost of such lining is very high, which is not always comfortable.

Metal lining for door trim is poorly suited because it does not have the necessary noise and heat insulation properties, and practically “does not withstand impact” in the event of mechanical damage.

Using leatherette

This material has been used for finishing doors made of different materials for a long time. It is mainly popular for insulating wooden entrance structures. But it can also be used for metal.

Leatherette has quite a lot of “advantages”:

- low cost;

- he is not afraid of temperature fluctuations;

- this is a fairly fire-resistant material: it smolders, but does not ignite;

- it is not afraid of moisture and can be washed with detergents;

- modern options practically do not fade in the light;

- With the help of leatherette you can easily make insulation using any thickness of the insulating layer.

The only significant drawback of covering iron entrance doors with leatherette is its poor resistance to mechanical damage: pets or vandals can easily ruin the beautiful coating. But it’s easy to replace such material on your own, use elements for fastening, creating an interesting pattern.

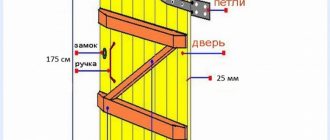

Work method (one-sided cladding)

It is worth considering that with this method of covering the door will become thicker by approximately 3 cm, or by the thickness of the panels themselves, if an option without insulation is provided. The treatment looks good on door modifications that are externally slightly pressed into the wall, then the increase in thickness is almost imperceptible due to the width of the slopes. This finishing method is also well suited for non-removable door leaf models, when it is not possible to remove the outer sheet and replace the inner lining.

The main stages of work with additional insulation:

- Fastening the sheathing to the outer door leaf horizontally (if the lining will be laid vertically) and along the perimeter of the opening if horizontal laying is planned. Fixation occurs with long self-tapping screws directly to the metal base of the door.

- Insulation of frame voids with foam plastic slabs, which are cut with a knife and simply sit on glue.

- Cutting off the tenon at the initial strip, sanding the part and fixing the panel to the sheathing from the lock side with finishing nails or clamps.

- Cladding with clapboard using the groove/tenon principle and reliable fixation.

If additional insulation is not planned, then the panels can be attached directly to the door leaf using metal screws. In the future, the caps can be carefully masked with a decorative strip, which is placed on regular glue, or left as is.

Fabric preparation

Preparing the door for finishing:

- All removable parts from the canvas must be removed , i.e. locks along with locking plates, peepholes, handles, etc.

- In steel doors, the inner panel is often removable ; it also needs to be dismantled.

- Then the canvas can be removed from the awnings and placed on trestles or something similar, but personally I find it more convenient to work without removing the doors.

It is easier to trim doors in a horizontal position

If your doors are already painted with some kind of paint, there is no point in stripping it off. At this stage, the main task is to protect the metal from corrosion.

- Bare metal must be cleaned with a metal cord brush and degreased with an alcohol-containing solution.

- Paint with any paint (except water-based) in one layer - the color does not matter.

Lining an iron door with clapboard from the inside

The technology is not much different from outdoor work. Here it is also necessary to provide a transverse strip if vertical orientation of the lining or only perimeter sheathing for horizontal laying is provided. The additional cross beam is attached to self-tapping screws using standard furniture corners, or screwed to the original stiffeners of the door leaf.

The easiest way to attach the lining to the sheathing is with the help of clamps (they provide reliable fixation and are practically invisible from the outside, which means they are not subject to corrosion, oxidation and deformation over time). In this case, the clamp is installed on the back side of the edge of the groove, screwed with self-tapping screws (staples, nails) and hidden with the tenon of the second strip, and so the assembly of the structure continues according to the principle of the designer. The first and outer strips are adjusted to size, cutting off the excess width along the entire length of the die.

Panels

You can easily decorate doors with MDF panels. Sequence of work:

- Degrease the canvas.

- Apply a primer that allows the adhesive to adhere to the surface and finish.

- Apply glue evenly around the perimeter and in the middle.

- Next, apply and press down the pad. To ensure even fastening while the glue hardens, you can “grab” the edges with masking tape - it will not leave marks on the surface, but at the same time it will fix the position of the panel.

- If both sides are covered, then after the glue has dried, the other panel is glued in the same way.

- After drying, the fittings are installed and the canvas is installed in place.

Door leaf made of metal, upholstered in MDF

Further processing

Having covered an iron door with clapboard, you need to take care of the finishing of the surface for an aesthetic appearance and improving the wear resistance of the product. There are several ways you can go here:

- Paint the surface (the most affordable and easiest way). Cheaper alkyd enamels or more expensive acrylic paints are suitable here. In any case, it is better to apply the paint in two layers.

- Varnish the panel with translucent, matte or glossy materials. You will need at least a three-layer coating, but the appearance of the product will be impeccable. At the same time, the natural texture and color of the wood is completely preserved.

- Coat with wax or oil (ideal environmentally friendly option for interior work), but will require frequent updating (every 1.5-2 years).

- Apply a layer of stain (color the surface) - this treatment will only be an intermediate step and will require further work with varnish/wax/oil, but it will allow you to give the desired shade to overly light wood and make the natural pattern more expressive. In addition, it will provide an additional antiseptic effect.

After all the finishing work has been completed and when all the layers have dried thoroughly, you can put the door hardware in place.

Treating an iron door with clapboard will give the product additional strength and significantly improve its appearance. Even a construction novice can cope with the work, and the advantages of the material are difficult to overestimate. It is thanks to this that lining has been one of the most popular finishing materials for many decades.

5/5 — (1 vote)

Finishing door slopes

MDF slopes

When the finishing of the front door is completed, the structure is installed in the doorway. However, in order to completely complete the work, you need to finish the door slopes. For these purposes, the following materials are most often used:

- Plaster. This is an affordable option for finishing slopes, which even a novice master can handle. The plaster lasts a very long time and reliably preserves the appearance of the slopes.

- Drywall. The material can be fixed on slopes using a building mixture or mounted on a lathing. After installation, the drywall must be treated with putty.

- MDF panels, lining, chipboard. When finishing using this method, the sheathing is first attached to the slopes. Then any selected materials are mounted on it.