Home |Construction |How to raise a bathhouse yourself?

Date: August 28, 2017

Comments: 0

Wood is traditionally used to build bathhouses. Bath buildings built from logs, beams or panel elements are environmentally friendly buildings. They are characterized by increased strength characteristics and a long service life. However, the time factor gradually reduces the strength of the material. There is a need to restore or replace the lower crown of the building, which is its foundation, as well as to carry out major repairs of the load-bearing foundation.

Having an idea of how to raise a bathhouse onto a foundation, you can move a light building in a vertical direction with your own hands. To carry out repairs and ensure integrity, it is important to provide temporary fixation using metal or concrete supports.

It often happens that the frame of a bathhouse can last for many more years, but for some reason the foundation is seriously damaged

When deciding to lift the bathhouse yourself, you should prepare the necessary equipment and tools. It is important to correctly carry out a set of preparatory measures, competently select and install jacks, study the technological process, and also carry out work in compliance with safety regulations. Let's look at these questions in detail.

How can you raise a log house?

Raising the frame with a jack is the only way to provide access to the foundation without dismantling the building itself. With due care, it is possible to raise the building with minimal damage, replace rickety or destroyed pillars, and also remove the lower logs, after which the frame is lowered into place.

The same work is carried out if the building begins to sink into the ground after the destruction of the foundation. In rural areas you can still find old log houses placed on wooden decks: such a foundation has a minimum service life and will still have to be replaced.

To carefully lift the structure, it is better to use several jacks with a load capacity of at least 5 tons. They can be hydraulic or mechanical, and a log jack screw is often used.

It is important to ensure that everything necessary for the work is delivered to the construction site in advance: the sooner the work is completed, the better. It is impossible to keep the log house raised for a long time; this can lead to very serious consequences.

How to lift a log house with jacks? Before starting the ascent itself, several preparatory steps should be completed:

- The basement cladding (if any) is dismantled; access to the foundation needs to be cleared along the entire perimeter. A trench is being dug, which will allow you to see the entire foundation of the house and assess any existing damage.

- The condition of the lower crowns is checked: they should be inspected; tapping with a hammer will determine the presence of sore spots. If there are signs of rot or deep cracks, the lower crown must be replaced.

- It is advisable to prepare the house in advance to prevent possible damage: remove the window sashes so as not to damage the glass, temporarily remove the doors from their hinges, and sometimes dismantle the subfloor.

- Everything for work needs to be delivered to the site: jacks for raising log houses, material for the foundation, material for temporary supports, prepared logs for the new lower crown, etc.

It is also necessary to ensure that the jacks are installed on a durable base that can support the weight of the house and not sink into the ground. This can be a strong metal plate or at least a square wooden shield with a side of at least half a meter.

Log raising technology

Lifting a log house with a jack is not an easy, but completely doable task. It is important to take your time to avoid any serious damage.

If the building has a columnar foundation, it will not be difficult to place jacks under the lower crown, but if the building has a strip foundation, you will have to make recesses in the logs. In this case, you need to make a through hole in the log, into which you insert a lever and lift the wall with a jack.

The main stages of lifting a log house with your own hands:

- Work begins from the most damaged corner. Most often, the most serious damage is observed on the north side of the house. In a small structure, for example, in a small bathhouse, a log jack can only be installed at corners; in a permanent house, intermediate lifting and securing of the walls will be required, otherwise the logs will begin to sag.

- If you only have to use one jack to lift, the work will have to be done gradually. The wall is raised by a maximum of 2 cm, after which a support made of a concrete block, log or other durable material is placed under it, then the jack is moved to the next point, and the operation is repeated.

- Gradually the building rises along its entire perimeter. Usually, to carry out repair work, it is not necessary to lift it by more than 3-4 cm at a time. As a result, the building must be installed on strong temporary supports at the required height, after which you can proceed to restoring the foundation.

If a columnar base is used, the destroyed columns are broken and removed, after which they are replaced with new ones. If the house has a strip foundation, you will need to remove the remains of the destroyed foundation, deepen the trench and pour a layer of sand at the bottom.

Installation of a base of crushed stone and sand

The base installation technology may be slightly modified. Sand and crushed stone are often used for such purposes. This option is perfect for black soil areas. Sand and crushed stone are a stronger and more stable base for a building. To equip a base of sand and crushed stone, you need to act in accordance with the following recommendations:

- Dig a pit at least 80–100 centimeters deep. It should be understood that this is a labor-intensive process and can take a lot of time and effort.

- Remove drainage trenches. Their effective operation is ensured by a greater depth than the depth of the pit intended for installation of the base.

- Cover the bottom with sand, then lay a layer of crushed stone. For these purposes, building materials of the middle fraction are ideal.

- Fill the trenches with draining soil. You can arrange ditches like drainage wells, alternately laying layers of crushed stone and sand.

- The final stage of foundation installation is to carry out waterproofing work. For these purposes, any suitable waterproofing material can be used.

A bathhouse placed on such a base will last much longer. This is due to the fact that the base made of crushed stone can withstand heavy loads.

Lowering the frame after repairing the foundation

When the restoration work is completed, the building must be properly lowered into place. In order not to damage the frame, the jack is also moved gradually: the reverse work is performed. A jack is installed, a support is removed, after which part of the building is lowered a little, a temporary support is placed, and you can move to the next point.

It is important not to rush: it is very easy to damage the structure, but repairs will be extremely difficult. Work on raising a log house should not be carried out alone; it is better to first consult with experienced builders.

The procedure for installing a clay base

Preparatory work for arranging the base must begin with markings. Once the measurements have been taken and the boundaries of the base have been marked, you should begin arranging it. Such activities are carried out in the following order:

- The first step is to dig a pit. Its depth varies from 20 to 40 centimeters. The bottom of the pit must be level, so when carrying out work you need to use measuring instruments.

- Next you need to make the formwork. For these purposes, you can use boards with a thickness of 25 to 50 millimeters (used, but in good condition).

- The next stage of foundation installation is filling the pit with clay. She needs to stock up for future use, as a layer of at least 30 centimeters is needed. Filling the pit with clay should be done in stages - approximately 10 centimeters per day. It must be compacted thoroughly. For these purposes, you can use a special device or an ordinary hewn log.

- Immediately before installation of the above-ground part of the building, it is necessary to carry out waterproofing measures. Roofing felt and expanded clay are best suited for these purposes. You can use special waterproofing materials, but their cost is much higher.

The construction of a bathhouse without a foundation is beneficial (from an economic point of view) in places where clay is freely available. Otherwise, installation without a foundation can be much more expensive. In such a situation, it is better to initially place the building on a foundation.

How to raise a bathhouse

One of the most difficult problems of repairing the foundation and plinth of an old building always comes down to the same problem - how to raise the bathhouse without much damage to the frame of the building. The task is difficult, but quite feasible. The only generally accepted method involves lifting the bathhouse with jacks. In Europe and America, entire cottages and full-fledged brick buildings are lifted and moved, but before jacking up a bathhouse, serious preparatory work will be required. First of all, to ensure the safety of the lifting procedure.

Go straight to the project search

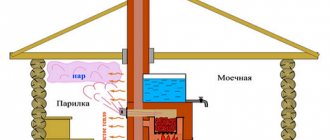

At our dacha, the bathhouse has already been used for more than a dozen years. The design of the bathhouse is quite traditional, a small log house. The roof is covered with slate, but for the time being, no one thought about the foundation.

Over time, the lower crowns, especially the very first one - the frame crown, began to rot. As far as I understand, this problem is typical for many baths; if you heat regularly, the bottom of the wall is constantly exposed to moisture.

At first they just wanted to change the two lower crowns, but during their examination it turned out that the bathhouse did not have a foundation as such. The corners of the log house rest on large stones dug into the ground, and that’s the entire foundation.

It was decided to cast a strip of shallow depth, and make a brick plinth on top of it. The equipment included two jacks, a chainsaw and hand tools, plus a concrete mixer and a welder borrowed from friends for the time of pouring.

The old brick stove was in need of repair for a long time, and it was decided to dismantle it and, after replacing the crowns, replace it with a new metal stove. Before starting to lift the log house, the stove and chimney were dismantled. The floors and joists were also not in the best condition and were sent for firewood.

The inside of the bathhouse is lined with boards; they decided not to remove it, but to avoid cracking, raise the bathhouse slowly and evenly. The roof, by and large, is also not in the best condition, but at the moment it is not leaking, and it was decided to leave it, so to speak, until better times.

Initially, they dug under two corners of one wall; they didn’t immediately cut out pieces of logs that needed to be replaced - who knows what will come of it. Jacks were placed into the resulting holes. To prevent the jacks from denting into the ground, shields made from scraps of 50 mm boards were placed under them. They lifted it very little - about two centimeters. Then they put up temporary supports made of boards and bricks and crossed to the other side. Two supports were placed on each wall - eight in total.

Since we moved it little by little, we had to do a fair amount of running around with the jacks, five approaches on each side, that is, we raised it by about 10 cm. Maybe we could have done all this faster - two approaches and it was done, but I didn’t want to risk the skin.

On the last climb, when the wall was still on the jack, the rotten logs were sawed down and the middle part was removed. After this, props were placed under a normal log, and the jack was lowered and the corner fragments of the rotten crowns were pulled out.

To prevent the log house from standing on temporary supports for a long time, it was decided to first make corner posts - the result was small posts with a base of approximately 40 by 40 cm, and the top narrowed to 30 by 30 cm. The depth of the post is 40 cm below ground level, plus 20 cm for a sand cushion . The total depth of the trench was 60 cm. Pieces of reinforcement were placed in the columns, to which the reinforcing frame of the tape was then attached.

The column rose just a little above the ground, only 10 cm, the rest was raised with bricks. By the way, this solution did not seem to me the best, and the tape under the walls was cast higher.

The pillars were allowed to stand for four days, after which a bathhouse was placed on them. I understand that the concrete has not gained strength, but the log house doesn’t weigh much at all, and the deadlines are running out, and vacations have an unpleasant tendency to end. They cast the tape and, after letting it sit for three days, raised the base.

Waterproofing was done with roofing felt in two layers. The first is between the foundation and the brick plinth, and the second is between the brick and the first crown of the frame.

The time was spent two weeks, and almost half of the time was waiting for the concrete to gain minimum strength.

Bathhouse foundation repair

Raising a small-sized box is not as difficult as it might seem at first glance. Sometimes this is the only real way to change the foundation under the bathhouse, and at the same time replace the lower crowns of the building.

Modern manual jacks are capable of developing a force of up to 10 tons, so, as a rule, there are no problems with the provision of equipment. Another thing is that not every building or log house can be raised. There are certain requirements for performing the lifting procedure, the fulfillment of which determines the safety and success of the event.

Brickwork as a method of repair

It will be possible to install red brick masonry under a wooden residential building in two ways: either by first raising the frame, or without lifting it.

It all depends on what foundation your house is built on, as well as on the age of the building and your financial capabilities. If the old building stands directly on the ground, without a foundation, it will be easier to replace the crown with brickwork; it is not necessary to raise the house. The same option is possible if a columnar foundation was used for construction.

The work is carried out as follows: the affected areas on the lower crown are cut out, a brick foundation is made, the surface of which is brought under the logs located on top and less damaged. First, the rotten corner joints are cut off and a reliable support is made. As for the height of the masonry, it can be different. You can replace the lower one with bricks or several rows of crowns.

Raising a house using jacks is a more expensive option. Using a screw jack or a hydraulic device, you can lift the house in order to carry out a thorough repair of the wooden elements of the frame and subsequent masonry. The house is raised at the corners, then leveled, and temporary supports are installed at the corners. Then the foundation of the building is cleaned, leveled and brickwork is built up.

In order to jack up a log house built on a strip foundation, the foundation will have to be partially destroyed. More precisely, it will be necessary to hollow out a niche about 0.4 meters wide in it, and the height of the niche will be such that a jack can fit. At the same time, they retreat a meter from the corner of the house. You can raise the whole house, or just one side. After the work is completed, the foundation is repaired. There is also a more modern way to raise a house - this is the use of special metal channels.

What can you really lift with your own hands?

Each building that has stood on the ground for 10-20 years acquires its own strictly individual characteristics and features, which can significantly affect how to raise a bathhouse onto the foundation with your own hands.

You cannot even attempt to raise the following categories of buildings:

All other bathhouse options, even if there is a strong tilt, the box is askew and one edge has grown into the ground, can be lifted. If the box has retained at least 40% of the initial rigidity, there will be no problems. All this can be raised, the bathhouse can be moved, or even moved to a more reliable foundation.

If the bathhouse used a brick stove on a separate foundation, then before raising the bathhouse onto a columnar foundation, you will need to disassemble the passage through the ceiling and roof.

If you plan to change the height of the lower crown of the building above the ground, for example, to raise it like a bathhouse on jacks, then in 9 out of 10 cases you have to disassemble and completely rearrange the stove box.

Basic requirements for structures without a foundation

Perhaps the main question of this article is “How to build a bathhouse without a foundation?” It should be understood that such structures do not imply a complete absence of foundation. They will have a foundation, but modified. Any structure without a foundation will sink unevenly into the ground.

It is important to understand that erecting a building without a foundation is not permissible in all places. Therefore, first you should make sure that there is solid soil on the site

The ideal solution would be rocky soil found in mountainous areas. If the soil is sandy, then the building will have to be placed on a foundation.

An important point is the requirements for structures without a foundation. To avoid questions from government regulatory authorities, you need to follow a number of rules during construction:

The weight of the structure should be no more than 4000 kilograms. The total area is no more than 30 square meters. The measurement must be taken along the outer perimeter. The bathhouse must have 1 floor

Installing a second floor will not only attract the attention of regulatory authorities, but will also significantly increase the load on the foundation. The building must be collapsible, at least conditionally. Of course, no one will try to dismantle your bathhouse, but you need to remember that according to the law, such an opportunity must be present.

https://youtube.com/watch?v=ilcK9v-jw-8

If you cannot meet all of the above requirements, the structure will have to be registered accordingly. In such a situation, the best option would be to place the bathhouse on the foundation.

Preparation for work

Before you raise the sauna with your own hands, you will need to do a little preparation:

- Calculate the weight of the building, taking into account internal partitions, floor material, roof and stove. This is necessary for the correct selection of jack power;

- Determine the installation points of lifting equipment under the lower crown of the building. The places through which it is planned to lift the bathhouse box should not be damaged, and the applied force should be evenly distributed along the perimeter of the building;

- Cross braces are placed into the window and doorway of the bathhouse, window glass and doors are removed, and all accessible furniture is removed from the room;

- If the building of the bathhouse is located directly on the ground, with a slope or flooding into the soil, then a bandage of one-inch boards nailed directly to the walls of the building is put on the box.

If the soil under a log house turns out to be clayey and oversaturated with water, then before lifting it with jacks, and even more so before moving the bathhouse to another place, drainage of top-water water must be arranged around the prepared foundation. If this is not done, the jacks will simply sink in the viscous soil.

Buying a ready-made bath

If you are not sure that you can build a bathhouse yourself, you can always purchase a ready-made option. Then the foundation must be done in the same way as described above. The technology won't change. You just have to focus on the dimensions of the finished bath; don’t forget to check them carefully and several times. In general, even if you want to buy a so-called “mobile” bathhouse on wheels, the base will not interfere with it.

It is always better for the structure, even a mobile one, to stand horizontally, without distortions. Especially if you are never going to transport the purchased bathhouse anywhere. The weight of the building will still cause it to sag. Distortions will cause inconvenience when using the bathhouse, so a solid base will be a good solution. The only thing is that when buying a mobile sauna, you can take a little less care of waterproofing. It will still rise above the ground.

So, if you are not afraid of difficulties, have ingenuity and some engineering imagination, it will not be difficult for you to build a bathhouse on your own at your summer cottage. The main thing to remember is that if something doesn’t work out for you, stop and ask for advice from more experienced friends and acquaintances. You can also often get qualified advice on some forum dedicated to construction. Of course, it is a very special pleasure to steam in a sauna built with your own hands, so overcoming all the difficulties on the way to this goal is really worth it.

Selection and preparation of equipment

On average, the weight of a standard-design log bathhouse with a metal heater and a gable roof does not exceed 4.2-4.7 tons. A modern car jack is capable of developing a force of up to 3 tons, and given the fact that the structure is supposed to be lifted by at least two devices, there are no problems with It shouldn't be a technique.

Experts recommend lifting any buildings - barns, summer kitchens, bathhouses, old houses made of brick and cinder block using two types of jacks:

- Screw lift, also called a sea stop, photo. The jack consists of two working tools and a pair of screws with thrust threads. Maximum force – up to 15 t;

- Hydraulic jacks with a lifting capacity of 10-12 tons, preferably of Soviet production.

It is better not to use rack or frame jacks for a bathhouse. Due to severe wear of the locking earring and stopper, the devices often fail before the bathhouse box can be completely raised to the desired height.

In addition to jacks, you need to get hold of lining material on which the lifting devices will rest. The best choice is a steel plate with a thickness of at least 10 mm, or a piece of not very old oak board - forty.

Replacement of damaged area without raising the house

If the foundation is not destroyed and most of the logs are intact, then you can replace a fragment of the crown without understanding the house and without making a complete replacement. The degree of damage in width and depth is determined. Using a chisel and a chisel, areas of wood damaged by rot are removed.

- Stepping back half a meter on both sides from the area to be restored, vertical ties are installed. The tie is a metal strip at least 2 mm thick and long, allowing three crowns to be pulled together. Through holes of 10x12 mm are drilled in the metal tie and in the center of the logs and tightened with pins.

- The damaged area is cut out with an electric circular saw or manually. At the ends of the lower crown in the repaired area, nests are made - notches for a tenon for connection with the insert. An insert is made according to the dimensions of the cutting, fits into place and secured with dowels.

- All cracks and gaps are caulked with resinous tow and treated with an antiseptic. Polyurethane foam will also work. The remaining foam is removed and the seams are decorated with putty matched to the color of the log.

How to raise a bathhouse onto a foundation

Before starting work, you will need to do a little preparation of the support site for installing the jacks. If the bathhouse is assembled on a strip foundation, a niche is cut out in the concrete using a hammer drill to create a nest. The body of the jack must completely fit under the lower crown of the frame, and between the tree and the supporting heel there must be space for an intermediate metal plate of 15x20 cm.

Under the log house of the bathhouse, you can simultaneously install either a pair of jacks, or, which is more convenient, install four lifting mechanisms at once. Before starting, hydraulic jacks are checked in operation, they try to lift a load of 500-900 kg, for example, jacking up a car wheel. The device is left under load for 10 minutes to make sure that the mechanism does not poison or spontaneously settle the working rod.

Screw jacks are checked only for the absence of scoring and metal jamming in the screw-nut pair.

They begin to work with the jack simultaneously in pairs, or by using all four mechanisms. The most difficult stage is the separation of the bathhouse box from the ground or concrete waterproofing. To go through it more or less smoothly, it is recommended to raise the bathhouse on jacks until the load suddenly increases, place supports and leave the box for 10 minutes. for the so-called "liberation". Most of the resin, soil, and insulation moves away from the lower crown of the bath, the resistance drops, and then you can raise it to the required height. After you have managed to raise the bathhouse with your own hands, you must definitely check the position of the crowns relative to the horizon.

Video description

This video shows how to prepare sites for installing jacks in an existing strip foundation:

But much more often, lifting mechanisms rest on the ground under the walls. To create a solid foundation, some preparatory work is performed.

- Drainage of groundwater using drainage ditches around the perimeter of the building - this is sometimes necessary in wetlands and clayey soils supersaturated with water.

- Marking reference points, in place of which holes are dug to remove the loose top layer of soil.

On a note! The minimum number of such points is 4 - two under each long wall with a distance from the corners of no more than half a meter. If the walls are long or made of joined logs, additional intermediate support platforms are installed.

- Compacting the bottom of the pits and constructing a platform on it from thick scraps of boards, flat stones, metal plates or other durable material.

- Sawing out areas of rotted crowns to ensure support for intact logs.

How to put an old bathhouse on a foundation

The next stage is installing the box on a new base. While the bathhouse building is on jacks, it is necessary to lay temporary supports made of available durable material next to the mechanisms. If the weight of the raised box is 4 tons, at least 8 supports made of red brick or 6 columns made of concrete blocks are laid out under the crown. In this case, the jacks are not removed or removed from under the bathhouse.

The freed up space allows you to repair the existing old foundation or lay a new foundation under the crowns. Usually, for an old bathhouse, the lower crown is changed; it is cut out in parts with a grinder. The corner sectors, pressed by the heels of the jacks, are spliced with repair logs or beams.

If the entire crown has rotted out, then under the base of the bathhouse you have to install additional supports under the middle points of the walls. For example, to replace a log or beam on one side of the bathhouse, you will need to install additional supports, two pillars along each of the adjacent walls. The result is a U-shaped line of pillars and jacks, the fourth wall is free for repairs to the crowns and foundation.

The strip foundation of the bathhouse is repaired and restored in the same way. On a line of supports free from jacks, a ditch is dug under the sand and gravel cushion, after which a new foundation strip is laid out of brick. The next step is to repair the adjacent wall of the bathhouse. After one L-shaped part of the brick base has been assembled, the jacks are moved to the center of the bathhouse and the remaining part of the tape is repaired.

Most often, the strip foundation is replaced with a columnar version. It is easier to manufacture, more convenient to work with jacks, and there is less need to rearrange mechanisms. The only thing that is required is that before raising the bathhouse onto a columnar foundation, the lower edge of the base and the plane of the supports must be leveled horizontally using a hydraulic level. On average, one jack is repositioned three times during the entire repair.

Carrying out repair work

Having completed the ascent, they immediately begin work on the reconstruction of the bathhouse. They are complicated by the fact that they have to be produced under an overhanging log house. To ensure your own safety, you need to make sure that the supports are reliable and strong, and if necessary, install additional ones to reduce the load on each point. Jacks must also be used until the work is completed.

Replacing the lower crowns

To change the crown, one wall is freed from supports, “hanging” it on a longitudinal beam laid on external support posts. The supports are left under the remaining walls, forming a U-shaped line from them and the jacks.

The rotten crown is dismantled, the one lying above is cleaned and treated with an antiseptic. After this, a new crown is installed through a felt pad or tow, pressed against the top one with jacks and secured with metal ties.

Moving the bathhouse to a new foundation

Often, in addition to lifting and repairing walls or replacing crowns, it is necessary to move the bathhouse box a certain distance or move it to a new foundation built next to the bathhouse. In this case, in addition to jacks, you will need:

- Cable winch;

- Four channels 150 mm high and a length equal to the width of the bathhouse wall;

- A dozen two-inch steel water pipes, equal in length to the width of the bathhouse box;

- Four beams 200x200 mm.

Initially, you need to jack up the bathhouse box to a height of at least 30 cm, after which the old foundation remains are dismantled, and the soil area under the bathhouse box is leveled and leveled to get rid of humps and slopes.

The next step is to lay timber beams on the ground; the jacks do not need to be removed or rearranged. A pair of channels are placed on top of the timber under each of the longitudinal walls of the bathhouse. Water pipes are laid between the steel beams and jacks are released. The building sits on an improvised platform, along which you can easily winch the bathhouse box to a prepared and compacted area.

At the new location, the building must be jacked up again and, without removing the upper channel beams, new supports must be assembled from brick.

Video description

How to replace the lower crowns, see the video:

Construction or repair of the foundation

The easiest way to pour the foundation under an overhanging bathhouse is by using the grappling method. To do this, first, formwork is built between the supports, and a reinforcement cage is installed in it so that the ends of the reinforcement extend outward from the formwork.

The lower crown is wrapped with roofing material before pouring concrete. After filling the formwork with concrete, the surface is carefully leveled.

After the concrete has hardened in the grips and gained strength, the supports are removed from under the walls, a frame is installed in the formwork erected in the gaps and connected to the rods protruding from the grips. Repeat the filling procedure.

You can lower the bathhouse onto a new foundation no earlier than after 2-3 weeks. This work is performed in the reverse order of lifting, and with the same precautions: not lowering the jack more than 3-5 cm in one cycle.

How to lay the foundation for a bathhouse

There are two ways to install a sauna frame on a new foundation.

If the bathhouse is relatively small, then the box is lifted with jacks, not supporting the lower rims, but through intermediate beams placed under the bottom of the frame at the stage of tearing it off from the old base.

For full-size bathhouse projects 5x6 m or 8x7 m, you need to raise the box to the maximum height, 60-70 cm. For this, special types of jacks are used, photo. In this case, the pillars are assembled from blocks under the building with each support individually adjusted in height and horizon level.

Video description

How to lift a box with rotten crowns is described in detail in this video:

Preparation of tools and materials

By removing the cladding and tearing off the foundation, you can accurately determine the scale of the problem, the nature and scope of the work to be done. This will allow you to prepare everything you need at this stage. In any case, you will need a laser or water level and a plumb line to control the verticality of the building, as well as materials for installing temporary supports. These can be thick boards, beams, concrete blocks, bricks from which support columns are built.

If it is necessary to pour a new foundation or move the frame, you will need long, strong wooden beams or steel channels, which are brought under the entire box from below, supported by posts placed outside its perimeter.

Logs or beams for replacing the lower crowns are also prepared in advance, cut to length and treated with antiseptic impregnation.

Preparing new crowns for installation Source dom-29.ru

All materials and tools that may be required to reconstruct the bathhouse should be at hand. The less time the log house spends in a “suspended” position, the less risk it will warp and deform. For example, sand, cement and reinforcement for building a foundation must be delivered to the site before the lifting begins.

How to raise a bathhouse

A bathhouse is a structure that is regularly exposed to moisture, and such conditions lead to rapid wear and tear. To extend the service life of a bathhouse, and often give it a second life, you need to strengthen the old foundation or build a new one. If necessary, you can raise the bathhouse yourself; the main thing is to follow the basic recommendations when lifting it.

Methods and recommendations on how to raise a bathhouse

In order to raise the bathhouse you will at least need:

Prepare everything you need to start lifting the bath. The jack must have a lifting capacity of 5 tons or more. Disassemble the corner of the bathhouse from below and install a jack stand. Thick metal, hardwood timber, or a small concrete slab are suitable. Place the jack on the base under the wall of the bathhouse, place a thick metal plate on top of it and begin to carefully lift the corner of the bathhouse with the jack. After the corner is raised to the desired height, place a beam under it on both sides, mounted on two supports at a distance of about a meter; this beam will serve as a support for the corner of the bathhouse. Once the beam is in place, lower the jack and remove it.

Dig a hole for the foundation at the corner of the bathhouse to the depth you need - in different cases it can be from 0.5 to 1 meter. Pour the concrete foundation and let it cure for two weeks. After the foundation becomes strong, build the base of the bathhouse from the material that is planned - it can be brick, rubble stone, logs, timber. Don’t forget to add a layer of waterproofing if you are laying the base out of brick, or an insulating layer if you are also laying wood underneath.

Place a jack on the side of the poured foundation column and raise the corner of the bathhouse enough to allow you to remove the beam supporting it. Remove the beam and smoothly lower the jack onto the new foundation.

After all 4 corners of the bathhouse are made, securely installed on new concrete pillars, you can lay out bricks or replace the logs in the old base in the spaces between the corners. Do not forget to provide a hole for water drainage, otherwise your bathhouse will begin to collapse again after repair.

Using a jack, you can simultaneously install two corners on the supports and pour the foundation under them, so the time required to lift the bathhouse will be significantly reduced.

[content-egg module=GdeSlon template=compare]

What is the technique of “drilled injection piles”?

One of the most modern methods of strengthening a flimsy foundation is the technology of drilled injection piles. It is quite expensive and cannot be accomplished using home remedies, but in the most difficult cases it is a real lifeline.

So, the essence of the method is this: inclined wells of about 25 cm in diameter are drilled on both sides of the foundation. How deep - until the drill hits solid soil. After this, workers pour cement mortar into the wells and immerse a special frame of reinforcement into it. When the concrete dries, the bathhouse will already rest on several reinforced concrete piles at once.

Typically, for such reinforcement, piles with a diameter of 108-219 mm are used - and sometimes even more. In total, it takes from two to five days to strengthen a typical old foundation - it all depends on the complexity and volume of work. They are mounted using a rather complex mechanized installation, thanks to which they are placed accurately and tightly to the foundation itself.

How to raise a bathhouse yourself?

Wood is traditionally used to build bathhouses. Bath buildings built from logs, beams or panel elements are environmentally friendly buildings. They are characterized by increased strength characteristics and a long service life. However, the time factor gradually reduces the strength of the material. There is a need to restore or replace the lower crown of the building, which is its foundation, as well as to carry out major repairs of the load-bearing foundation.

Having an idea of how to raise a bathhouse onto a foundation, you can move a light building in a vertical direction with your own hands. To carry out repairs and ensure integrity, it is important to provide temporary fixation using metal or concrete supports.

It often happens that the frame of a bathhouse can last for many more years, but for some reason the foundation is seriously damaged

When deciding to lift the bathhouse yourself, you should prepare the necessary equipment and tools. It is important to correctly carry out a set of preparatory measures, competently select and install jacks, study the technological process, and also carry out work in compliance with safety regulations. Let's look at these questions in detail.

About the need to raise the bath

The essence of the process of raising a wooden structure using jacks is to provide access to the foundation being repaired while maintaining the integrity of the building.

Using one or more powerful jacks, you can carefully lift the structure, the basis of which is:

- wooden beams of square section;

- prefabricated panel structure;

- cylindrical logs.

The basis for making a decision to raise the bath is the visual manifestation of the following signs:

- significant deviation of the building from its normal position with the frame skewed;

- formation of cracks on finishing materials outside and inside the premises;

- subsidence of the entire building along the perimeter of the bathhouse or its individual parts;

- immersion into the soil of parts of the foundation bearing the load from the mass of the structure;

- significant destruction of the foundation with cracking and spalling.

Often, the construction of a small bathhouse is carried out without a foundation, and its base is simply placed on compacted soil and a sand-crushed stone cushion

Raising the bathhouse with the help of modern technical means allows the following types of construction activities to be carried out:

- work to carry out major repairs of the destroyed foundation;

- partial restoration of fragments of the base;

- restoration and replacement of collapsing supporting elements along the contour of the building;

- eliminating distortions of the building frame while ensuring the verticality of the structure;

- antiseptic treatment, as well as protective impregnation of wooden structures;

- elimination of deviations and errors that the builders made during construction.

Before starting construction activities, it is necessary to deliver everything necessary to the construction site in advance, since it is problematic to keep the structure in a raised state for a long time.

Necessary equipment and tools for doing the work yourself

To carry out repair activities, you should prepare:

- jacks corresponding in lifting capacity to the weight of the building;

- panel elements made of metal or wood, reducing forces on the soil;

The most optimal option for carrying out such an event is the use of high-power jacks

- steel or wooden linings to compensate for the stroke of the rod;

- hand tools to provide access to the support beam when disconnecting it (crowbar, axe, shovels, sledgehammer, hammer);

- electrical equipment that speeds up repair work (circular saw, drill, grinder).

Having prepared the materials necessary to carry out the work, you can begin restoration activities.

Preparatory work

At the preparatory stage, before moving the building vertically, the necessary measures should be taken to prepare the structure in order to prevent emergency situations and possible destruction:

- turn off the electrical power supply;

- turn off the water supply lines;

- disconnect the sewer pipes;

- ensure a guaranteed gap between the stove chimney and the ceiling;

- disconnect the heating device installed on a separate basis from the pipes;

- dismantle the floor in the area adjacent to the stove or heating boiler;

- attach metal profiles to the corners of the building to secure the box;

- dismantle window sashes to preserve the integrity of the glass.

Before work begins, a lifting scheme is worked out, which is determined by the purpose of the operation and the type of damage to the structure.

It is also necessary to carry out the following work:

- Assess the level of damage and perform a visual inspection of the foundation. To do this, it is necessary to dismantle the basement cladding, provide access to the base along the contour of the building, and locally go deeper into the soil.

- Check the strength and condition of the support rim. The solid wood should be tapped with a hammer to identify problem areas prone to rotting and cracking.

- Ensure delivery of all necessary materials and equipment to the work site. Timely preparation of jacks, materials for repairs, and temporary supports will reduce the duration of repair activities.

It is important to correctly determine the method of lifting the structure and first analyze a number of points:

- Bath weight.

The weight of the box, ceiling elements, external and internal decoration, as well as equipment located in the room is taken into account. By multiplying the resulting value by a factor of 1.4 and dividing by the number of jacks, you can obtain the load capacity of each device. - Dimensions of a wooden box.

By installing additional supports in the areas where logs, beams or wooden frames join, you can significantly reduce the likelihood of box deformation in the area where the elements join. - Strength and presence of cladding on the inside and outside of the room.

The presence of decorative finishing complicates the work. Fixing diagonally spaced bars 5 cm thick will protect the bathhouse frame from deformation and avoid subsequent repairs.

The lifting operation must be carried out taking into account further work

- The nature of the soil.

The possibility of immersing lifting devices when moving a building in the vertical direction depends on the characteristics of the soil. Increasing the support area with the help of pads will ensure the immobility of the jacks. - Lifting height.

The design features of the lifting device limit the amount of free play of the rod. The required moving height is achieved by using supports made of durable wood. - Duration of repair work.

Depending on the level of complexity of the repair, the duration of restoration activities is determined. The use of temporary structures made of steel and durable wood reduces the load on the rod.

A responsible approach to repair work will allow you to avoid unforeseen situations, as well as promptly complete planned repairs.

Selection of jacks and their installation

The main criteria for choosing lifting devices are:

- Load capacity.

The technical characteristics of the equipment must exceed the effective load by 40%. - The amount of movement of the rod.

The maximum stroke of the working body must ensure movement of the bathhouse box to the required height.

To carry out the work, it is important to choose the right jacks for lifting the bathhouse body

To perform the assigned tasks, the following types of devices are used:

- screw.

They are used for small bath buildings with limited dimensions. Features: simple design, small dimensions, ease of operation; - hydraulic.

Used to move massive structures. They are characterized by an increased degree of reliability and increased load capacity. Requires qualified service.

Pay attention to the need to form a reliable support for the lifting device.

The following are used as a supporting structure capable of supporting the mass of the bathhouse and remaining at the zero level:

The use of square boards with a side of 50 cm will provide the necessary supporting surface area.

How to raise a bathhouse on a foundation - safety rules and technology

The bath is raised smoothly, with the following operations cyclically performed:

- Limited movement in one area.

- Alignment in height with the opposite zone.

- By placing support elements under the raised box.

Work begins from the most damaged corner

The impossibility of subsidence of the bathhouse box, the elimination of cracking and destruction of the structure is achieved:

- reliable fixation of construction areas with stationary supports;

- the size of the total vertical movement is not more than 0.5 m;

- ensuring the height of movement per cycle in the range of 6–8 cm;

- using thick beams to strengthen the box;

- fastening spacer elements into openings;

- correct installation, ensuring a fixed position of the jacks;

- the use of rigid thrust bearings under the rods of lifting devices.

To ensure the safe execution of repair work, it is important to ensure that the structure being lifted remains stationary.

The bathhouse lifting technology involves the use of a different number of lifting devices:

- Using one jack, you can alternately move different sections of the structure vertically, moving slightly in one cycle. After lifting, the sagging area is fixed with bars, and the lift is moved to the next point;

- the synchronous operation of two lifts allows the wall to be lifted evenly, maintaining the integrity of the corner areas. It is important to lift evenly, place the jacks correctly, moving the walls of the building to an equal height;

- the simultaneous operation of four jacks located in the corners of the bathhouse allows the wooden structure to be lifted with maximum efficiency. Safety of work is achieved by cyclically moving the rods by 2–3 cm.

When performing work, follow the technological sequence of operations:

- Select the movement pattern and areas for placing lifting devices.

- Thoroughly compact the soil in the area where the lifting devices are placed.

- Create a secure surface by placing support pads.

- Place jacks on the supporting plane and check the verticality.

- Place plates on the top end of the stem to improve the contact area.

- Raise each jack to a maximum height of 3-5 cm per cycle.

- Use shims to secure the position as needed.

- Monitor the stability of the structure when moving.

- Install stationary stops to secure the structure during lifting.

Remember that for the convenience of simultaneous movement of the bath, you can use a steel beam, which, passing under the box, rests on the rod supports.

Guided by technological recommendations and advice from professionals, you can independently jack up the bathhouse and restore the integrity of the foundation. Considering the degree of responsibility and the level of complexity of the work performed, it is advisable to consult with professional builders. Carrying out activities in compliance with technology requirements will ensure smooth movement and protect the building from possible damage.

[content-egg module=GdeSlon template=compare]

Complete replacement of the lower crowns

Replacement of the entire lower crown can be carried out according to the above scheme. This will require a lot of time and effort, since you will need to gradually cut off all the damaged areas, replacing them with new ones. But there is also a big advantage - you will no longer need to lift the frame with jacks.

It will be much stronger if the new lower crown is made not from pieces, but from whole logs. To do this, you need to move the entire structure of the sauna log house, lifting it with the help of jacks.

Replacement technology

1. Preparatory stage:

- To prevent windows and doors from cracking, they are removed during the raising of the frame;

- The log house must remain empty, and therefore all heavy objects must be removed from the bathhouse;

- The floor joists embedded in the lower crown need to be disassembled. The logs laid above the lower crown are not disassembled;

- To avoid damage to the ceilings and roofing by the heavy chimney pipe, it must be separated;

- The undamaged crowns of the log house must be fixed. This is done like this: on the inner and outer sides of each wall, at a distance of 0.5 meters from the corners of the log house, boards or bars (4 cm thick) are nailed vertically. Their lower edges should end exactly in the same place as the logs of the crown that cannot be replaced (second from the bottom), and the upper edges should be attached to the logs of the topmost crown. To fix undamaged areas, 16 boards are used, which must be secured at the bottom and top with through dowels. This is done so that when the log house is raised on jacks, its walls do not move.

As soon as all of the above work is completed, you can begin the procedure for repairing the lower crown of the log house.2. Main works

The process of replacing the lower crown of a log house depends on the type of foundation.

Strip foundation

A log frame consists of a top and bottom log that are joined and tied at the corner

It is very important to accurately determine which logs in the rotten crown are the top ones, since it is under them that the jacks will be installed; In the crown of the log house being replaced, at a distance of 0.7-1 m from the corner of the house, an opening 0.4 m wide is knocked out in the foundation. From the log of the lower crown, located opposite the resulting opening, a part is cut out so that the total height of the niche allows placing a jack there

According to this scheme, exactly the same niches are made on two opposite walls. The distance from the corners should be the same; Now you need to install jacks (2-4 pieces). A very important point is the choice of jacks. To do this, you need to select a mechanism with a load capacity of at least 10 tons. Depending on the size of the bathhouse, the lifting capacity of the jack can reach 25 tons. An error at this stage can lead to distortions and broken logs. The number of jacks depends on how the frame will be lifted: all at once or each wall separately. But if you raise the walls one by one, this can lead to distortions, so the best option would be to raise the entire frame together. To do this, you need to install 2 jacks under opposite walls so that they rest against the upper logs of the crown bandage; Using jacks, raise the frame by 7-10 cm and remove the lower logs of the dressing; Reliable temporary supports, such as bricks, concrete blocks, logs, boards, bars, are placed under the lower logs of the second crown. The main thing is that they can withstand the weight of the entire log house; The jacks, along with the upper logs of the crown being repaired, are lowered, and instead of them, new ones are immediately installed and pressed with jacks. All supports installed under the lower logs of the second crown are taken away. The upper logs of the dressing are placed on the lower ones, and the lower logs are laid on the foundation. The jack is lowered very slowly and synchronously; At the last stage, caulking is carried out - the cracks formed when connecting new logs with the second crown of the log house are sealed. To do this, fibrous materials (tow, moss and jute) are used, which are hammered into the resulting seams.

Columnar foundation

Replacing the crowns of a log house on this type of foundation is quite simple.

- It is necessary to install 4 jacks between the foundation columns, which are connected to the upper logs of the lower crown trim. Place 2 of them on each wall. It is necessary to install these jacks on a very solid base, such as a board made of boards measuring 50x50 cm. The head of the jack rod should rest against the log only through a metal plate;

- The jacks are raised synchronously. Further actions are exactly the same as when replacing the lower crown of a strip foundation frame.

The difference between replacing rotten crowns of a log house with a strip and column foundation is only in the process of installing jacks. The first option is more labor-intensive, since the foundation must be partially destroyed. There is no need to do this for a columnar foundation, since there is a lot of space in its structure for installing jacks.

Technology for lifting a log house with a jack

Buildings made of logs and timber are durable; they can last for tens and even hundreds of years. However, time has a destructive effect on even the strongest materials, so sooner or later the foundation will require repairs. Rotting often affects the lower crowns, after which the house will gradually begin to lean on its side.

How can you raise a log house?

Raising the frame with a jack is the only way to provide access to the foundation without dismantling the building itself. With due care, it is possible to raise the building with minimal damage, replace rickety or destroyed pillars, and also remove the lower logs, after which the frame is lowered into place.

The same work is carried out if the building begins to sink into the ground after the destruction of the foundation. In rural areas you can still find old log houses placed on wooden decks: such a foundation has a minimum service life and will still have to be replaced.

To carefully lift the structure, it is better to use several jacks with a load capacity of at least 5 tons. They can be hydraulic or mechanical, and a log jack screw is often used.

It is important to ensure that everything necessary for the work is delivered to the construction site in advance: the sooner the work is completed, the better. It is impossible to keep the log house raised for a long time; this can lead to very serious consequences.

How to lift a log house with jacks? Before starting the ascent itself, several preparatory steps should be completed:

- The basement cladding (if any) is dismantled; access to the foundation needs to be cleared along the entire perimeter. A trench is being dug, which will allow you to see the entire foundation of the house and assess any existing damage.

- The condition of the lower crowns is checked: they should be inspected; tapping with a hammer will determine the presence of sore spots. If there are signs of rot or deep cracks, the lower crown must be replaced.

- It is advisable to prepare the house in advance to prevent possible damage: remove the window sashes so as not to damage the glass, temporarily remove the doors from their hinges, and sometimes dismantle the subfloor.

- Everything for work needs to be delivered to the site: jacks for raising log houses, material for the foundation, material for temporary supports, prepared logs for the new lower crown, etc.

It is also necessary to ensure that the jacks are installed on a durable base that can support the weight of the house and not sink into the ground. This can be a strong metal plate or at least a square wooden shield with a side of at least half a meter.

Log raising technology

Lifting a log house with a jack is not an easy, but completely doable task. It is important to take your time to avoid any serious damage.

If the building has a columnar foundation, it will not be difficult to place jacks under the lower crown, but if the building has a strip foundation, you will have to make recesses in the logs. In this case, you need to make a through hole in the log, into which you insert a lever and lift the wall with a jack.

The main stages of lifting a log house with your own hands:

- Work begins from the most damaged corner. Most often, the most serious damage is observed on the north side of the house. In a small structure, for example, in a small bathhouse, a log jack can only be installed at corners; in a permanent house, intermediate lifting and securing of the walls will be required, otherwise the logs will begin to sag.

- If you only have to use one jack to lift, the work will have to be done gradually. The wall is raised by a maximum of 2 cm, after which a support made of a concrete block, log or other durable material is placed under it, then the jack is moved to the next point, and the operation is repeated.

- Gradually the building rises along its entire perimeter. Usually, to carry out repair work, it is not necessary to lift it by more than 3-4 cm at a time. As a result, the building must be installed on strong temporary supports at the required height, after which you can proceed to restoring the foundation.

If a columnar base is used, the destroyed columns are broken and removed, after which they are replaced with new ones. If the house has a strip foundation, you will need to remove the remains of the destroyed foundation, deepen the trench and pour a layer of sand at the bottom.

Lowering the frame after repairing the foundation

When the restoration work is completed, the building must be properly lowered into place. In order not to damage the frame, the jack is also moved gradually: the reverse work is performed. A jack is installed, a support is removed, after which part of the building is lowered a little, a temporary support is placed, and you can move to the next point.

It is important not to rush: it is very easy to damage the structure, but repairs will be extremely difficult. Work on raising a log house should not be carried out alone; it is better to first consult with experienced builders.

[content-egg module=GdeSlon template=compare]

Repairing the floor

When inspecting the floor, we pay attention to the condition of the beams, lower crown, joists and boards. If an unpleasant odor emanates from the underground, then the wood has begun to rot, although a visual inspection does not reveal any damage.

You can use an awl to check the integrity of the logs; they can be easily pierced if the tree has rotted at the core. Joists quickly begin to rot if waterproofing has not been installed.

Scheme for repairing damaged areas of the floor in the bathhouse

The process of rotting logs is especially dangerous for bathhouses made of logs and frame houses, since the damage can spread to the walls. If there is no need to completely change the coating, you can make partial repairs. Damaged areas are cut out, and new ones are installed in their place. The logs are fastened using aluminum plates and self-tapping screws. Then nail and mount new boards and the floor is completely dismantled and leveled with a plane.

If rot has damaged the beams, subfloor, joists and crowns, then you will have to replace it all:

- the floor is completely dismantled;

- logs and beams are removed;

- the two lower crowns are cut out in parts and replaced with a new beam;

- install new beams onto which to attach the logs;

- install flooring from new boards - subfloor;

- waterproofing and insulation are installed: 15 cm polystyrene foam for the dressing room, polystyrene foam for the washing compartment.

How is the preparation carried out?

The entire operation of raising the bath consists of several stages. First of all, preparatory activities are carried out. Work begins with the dismantling of the external cladding of the basement section of the building. After removing the outer covering, the condition of the logs in the lower crowns can be accurately assessed. The issue of the need to replace or repair them is decided, and the installation points for the jacks are outlined. Zones of active decay and the presence of cracks due to soil movement are especially highlighted.

The next necessary step is to dig a trench around the entire perimeter of the foundation. Inspection of the condition of the entire foundation finally forms the overhaul scheme. If the foundation has significantly collapsed, then in this area it will have to be completely removed and concrete poured again. To reduce the load on the mechanisms, all equipment, furniture, and shelves are removed from the bathhouse. Door panels and glazing from windows are temporarily removed. It is advisable to disassemble the floor covering (even better, the subfloor), but this event is carried out at the discretion of the work contractor.

Required Tools

When carrying out work with your own hands, you need to prepare the following tool in advance:

- a circular saw;

- Bulgarian;

- milling machine;

- hacksaw;

- electric drill;

- axe;

- chisel;

- sledgehammer;

- scrap;

- hammer;

- tools for laying and leveling concrete;

- plane;

- shovel;

- roulette;

- construction level;

- plumb line

Repairing rotten sections of the building crowns without raising the house itself

It often happens that the log of the lower crown of a wooden building, located closest to the ground, is not completely rotten - only a certain area can be affected by damage. This means that repairs can be made only in certain areas, without changing the crown completely. In this case, doing the work yourself will be much easier. This is especially true in cases where raising the house can cause serious problems. For example, a strip foundation under a log house that was raised to carry out repairs runs the risk of being destroyed. During “local” work, only the damaged section of the log is changed.

Repair of the lower crowns is carried out as follows:

- Step 1. Determine which area is damaged. We take a chisel and find out how much the wood has rotted. We clear the wood on both sides of the damaged area. Quite often, the use of a chisel makes it possible to understand that the area is much more damaged than is visible upon first inspection with the naked eye.

- Step 2. From the edges of the damaged area, make an indent of 40 centimeters in both directions. We place ties whose height coincides with the height of two or three crowns.

- Step 3. We take the “magpie” boards and nail them to the frame; such manipulations should be done from the inside and outside. We drill holes in the first crown, which is pulled together, and in the last one. We install special tie rods (they must pass through, and their diameter is 12 mm or more).

- Step 4. Take a chainsaw and carefully, but carefully, cut out the damaged part. In the crown, which required repair and replacement of rotten areas, we create notches, the width of which is 2 cm. Such notches are required in order to firmly connect the log with the new element, which will be inserted subsequently.

- Step 5. Make an insert using a log of the same diameter. The length of the insert is exactly the same as the length of the cut section. Don't forget to make counter cuts on the insert.

- Step 6. We insert a new element in place of the area that we previously cut out. Having placed the block, we carefully finish the insert into place using a sledgehammer.

- Step 7. In the places of notches, we make three holes all the way through from different sides, then we drive in dowels, which will then give us the opportunity to firmly connect the insert and the old log. All cracks must be caulked with tow; moss or jute are also often used for this purpose.

This way you can renovate multiple areas. Corner joints can also be repaired this way. However, such measures can be resorted to only in extreme cases, if the house cannot be raised, since the strength of the structure after repairs is somewhat reduced.

Preparation of thrust pads

It is possible to raise the building evenly only if there is a reliable and level foundation under the jacks. If the ground sags under load, then because of this it will not be possible to make the same movements. If the device is installed at an angle, the structure may move to the side.

The tool stem must rest against strong material. If the device rests on the ground, then several preparatory steps will need to be completed.

Groundwater should be drained using drainage channels.

You need to mark the reference points where you will dig. It is worth noting that there must be at least 4 such points. If necessary, more support platforms can be made.

It is very important to compact the bottom of the holes well. After this, you can make a platform using reliable and strong material.

All rotten crowns should be cut out so that there is support for strong logs that are not damaged.

Selection of jacks

To lift the bathhouse without causing any harm to it, you should use special, powerful jacks. In any case, it is important to prepare thoroughly, and only then proceed with the procedure.

It is worth understanding that not all jacks can be used for such work. It is worth refusing to use frame and rack jacks, because they cannot guarantee sufficient reliability. But screw and hydraulic jacks will be an excellent help in lifting the building. It is worth noting that a hydraulic tool can be used even if you need to lift a house with a large area.

When choosing equipment, you need to carefully check its load capacity and rod length. These characteristics can be found on the body. It is very important to choose a device with a margin of approximately 30-40% of the load you need. To find out the required lifting capacity of the jack, you need to calculate the weight of the building with the roof, trim and fixed equipment. You should multiply this result by 1.4, and then divide by the number of jacks that you are going to use during the work.

Typically, a standard bathhouse, having one floor and dimensions of 4x5 meters, will weigh no more than 5-6 tons.

The length of the rod allows you to determine the amount by which the frame can be raised.

Jacks should be load tested before using them to lift a structure. Use the devices to lift a load that weighs a lot and leave it in that state for a while. Check the working rod - it should not give any arbitrary upset.

As for the number of jacks that you will need to lift the building, this will depend on the complexity and scale of the work to be done. If the structure is light or only one part of it needs to be lifted, then only one jack with sufficient power will be sufficient. In other situations, you will need to use at least 2 devices for each wall.

If only one jack is used during work, then it should be gradually moved around the perimeter. After slightly lifting the wall and installing a stand under this location, the device should be moved. When the lower part reaches the required level, the procedure is considered complete;

If two jacks are used during work, this allows the wall to be lifted much more evenly, maintaining the integrity of the corner joints;

If four jacks are used during work, this minimizes the risk of deformation of the structure.

The greatest difficulty is lifting the building onto the base if the box is large, as well as the longitudinal joining of the beams. The fact is that the joint points are the weakest points. This is where deformation can occur. If the logs are long, they may sag and bend when you lift the bathhouse. In this case, the problem can be solved with the help of additional jacks.

Selection of jacks and preparatory work for their installation

To carry out the work, it is important to choose the right jacks for lifting the bathhouse body. The estimated parameters of the mechanisms are the load capacity and the stroke of maximum movement. In practical operations, 2 main types of devices can be used - screw and hydraulic jacks. The best hydraulic systems are those that have great power and are reliable in operation. For small wooden baths, you can use cheaper screw varieties.

Lifting the structure is only possible with reliable support from the jack. If it sinks into the ground under heavy load, the operation will be impossible to carry out.

That is why a solid foundation is built at the site where the equipment is installed.

What buildings should not be raised

If you have one of the above problems and you decide to raise buildings, then first you should find out whether it is safe to do so. Sometimes it happens that it is much easier to disassemble the building and then reassemble it than to raise the bathhouse.

There are also buildings that cannot be raised:

Structures made of aerated concrete and foam concrete;

Buildings made of monolithic block, brick or blocks, if there are serious cracks;

Frame baths, in which the supporting structure is built into concrete;

If the corner locks of the building are rotten.

In addition, you should not perform the procedure of lifting a bathhouse that has two or more floors. This should especially not be done if the second floor is made of a different material than the first.

Lifting rules

When lifting a building, you should know the weight and dimensions of the structure. Of course, you can use one jack, but the procedure will then take a very long time. But 2 or 4 jacks will seriously speed up the process. Do not forget that the walls must be securely fixed when the jacks are removed.

The lifting procedure is performed in several stages:

Devices should be placed at support points. Support areas should be prepared in advance.

Next, a rise of about 3-4 centimeters is performed. First you need to raise one wall, then put strong and reliable supports under the wall.

Supports made of boards, logs or other reliable, strong material should be installed between the devices at an angle.

Now we need to move the jacks. The load of the wall is transferred to pre-prepared supports. In the meantime, the devices need to be moved to the opposite wall. All previous steps are completed.

Once the supports are installed, the devices can be removed. Next, the walls are raised to the required height. You can raise two walls or all four in this way.

Walls

If heat is lost through the walls, you need to install thermal insulation. You need to do it like this:

- Remove the old coating from the walls, clean the logs from dust and cover with an antiseptic composition. Place vertical bars on the inner surface of the walls;

- secure the vapor barrier using a stapler;

- lay slab insulation in the gaps between the bars - it is better to use basalt wool;

- install a waterproofing film on top of the insulation;

- install facing material.

Installation of lathing under the lining in a bathhouse

If the insulation is external, then ventilated panels can be used as cladding. For internal use - lining, PVC or MDF panels. Sometimes it is enough to simply caulk the horizontal seams between the logs.