Convenience in the bathhouse is the most important factor for a good and productive holiday, so that all guests feel comfortable in their seats, you need to think carefully about how to make shelves in the bathhouse with your own hands. The correct location will allow a person to find an individual balance between temperature and comfort, and successful decoration will give a cozy atmosphere.

Brief overview of the article

- For every visitor

- More about materials

- Using wood

- Oak planks

- A little about ash

- Tempting alder

- Classic linden

- Design of a resting device

- Types of structures

- Pull-on model

- Auxiliary elements

- Advantages and disadvantages

- Photo of shelves in the bathhouse

For every visitor

People with experience in sauna activities often occupy the top tier, while the middle row is more suitable for amateurs. Beginners or people with weak hearts do not refuse the procedure, but occupy the lower step, where the steam temperatures are not so strong.

If the room is built in a private home or country house, most owners scrupulously approach the question of where to buy shelves for a bathhouse and what quality the material will be. To please every guest, people use unique solutions to decorate their relaxation room.

How to make shelves in a steam room. Installation Guide

Based not only on practicality, but also on considerations of universal installation of shelves, for the installation example we will use as few parts as possible of different sizes and types, i.e. so that their size is universal. Therefore, we will focus on a design in which the maximum number of meter-long bar blanks is possible. Universal size. The height of the top shelf (from the floor level) is 1 meter, the total width of all shelves including the top 60 cm and the bottom 40 cm is also 1 meter. The height of the first, low shelf is 50 cm, which is half a meter block. Almost all parts can be made from meter-long pieces. To construct the shelves we will use a 50mm*70mm block. With such dimensions, the distance to the ceiling from the top shelf is 125 cm, which is even very good for a steam room - there is room to wave a broom over your head.

In order to more clearly visualize the structure of the shelves in the figure, similar parts of the same type are depicted below in the same color: • green - length 60 cm; • blue – length 100 cm; • yellow – length 100 cm; • red - length 50 cm, 16 pieces of meter bars, 4 pieces of bars 50 cm long, 6 pieces of bars 60 cm long. In total, 22 meters of bars are needed for the frame.

The method of cutting the connections between the frame bars of the shelves is also of the same type and makes it possible to mass-produce these parts. For ease of perception of the picture, the parts that play the role of backs are not shown.

For installation, an ordinary planed spruce block is used. Before installation, it is recommended to lower the lower ends of the bars that will stand on the floor into a container with an antiseptic no deeper than 1 cm for 1 minute. This is the most vulnerable point of the shelf frame. This is especially important in the case of leaky wet floors.

The shelves themselves are usually made of low-density hardwood. The most affordable wood is linden. But in comparison with traditional building materials, the price of high-quality raw materials is much higher.

Those who like to have a good steam bath believe that the size of the shelf should be such that you can lie down with your arm extended forward and the width should be 80-90 cm. This size can be achieved in small steam rooms only if you do not use the bottom shelf for the seat, but only as a step. Or is it better then not to make a step at all, but to make the height of the top shelf such that it would be convenient for the one who carries out the procedures with a broom. This applies more to the professional use of steam rooms.

If you noticed, the frame is made in such a way that it is in no way attached to the frame. This is due to the fact that the log house shrinks and the structure may become deformed or prevent normal shrinkage. The greatest danger is the through fastening of the frame to the crowns through a layer of lining and foil wool for decorative cladding of the steam room. They are most easily destroyed when the log house moves.

More about materials

Most steam lovers do not trust factory products and resort to doing all the work themselves. To do this, you need to select the optimal material and purchase it.

The board chosen for the shelf in the bathhouse must correspond to the wet room and be of high quality; these features will give the owner confidence in his own bathhouse. Wood is quite common among those who like to construct such rooms with their own hands.

Among the more expensive components, natural stone and marble are noted; such materials are used for the construction of a hammam or an Irish bath. The technology of the room must be thought out to the smallest detail, otherwise you can get a severe burn from such shelves. The gentle mode will not be of interest to those people who are accustomed to higher temperatures.

Proper care of larch is important

Larch is very resistant to harmful bacteria, rot and mold. The planks can withstand high temperatures and humidity, so the log house will be safe and durable. But it happens that such wood begins to flow - that is, natural resin appears. This is because the material was not dried well. To do this, you need to sand the surface and treat it with stain or wax. And larch will last longer, delighting with its dignified appearance and excellent characteristics. There is still a lot of useful information on the site about the selection of wood for the construction of steam rooms of different sizes, please contact us!

Using wood

Wood is considered an affordable and appropriate material in most regions; a beautiful DIY bathhouse shelf, a photo that you can look at for hours, is proof of this.

Among the breeds it is worth noting:

- 1. Oak.

- 2. Ash.

- 3. Alder.

- 4. Linden.

Materials containing resin are rarely used to fill a room due to their specific properties. Although fir beds harmonize quite well with the design and you can choose excellent combinations of essential oils for them.

Oak planks

The noble and well-deserved tree was used at the dawn of the appearance of steam rooms; in the question of how to make shelves in a bathhouse with your own hands it will be an excellent option for decoration. The aroma of this material appears when the sun loungers are well steamed, which is why it is popular among true connoisseurs of baths.

Among the disadvantages, it is worth noting the high price of blanks and difficulty in processing. Another disadvantage can be safely called the tendency of sun loungers to become greasy in the pores; this consequence is combated by scraping, which not everyone can do.

The process of making a shelf with a pull-out bench-lounger

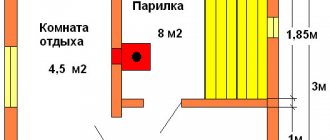

This option is suitable for those who have a small steam room. The height of the steam room is 220 cm, width 180 cm, length 210 cm. This compact system of shelves fits on an area of 110x210x220 cm. The rest of the space is for the stove and for the steamer.

This is what a finished shelf with a pull-out bench looks like

Costs For this shelf with a sunbed, 16 linden boards of 210 cm each, bars for the frame, screws, corners, Tikkurila wood impregnation were used - all together costing about 6,000 rubles. Everything is done by hand.

The top shelf is mounted at a height of 113 cm. Its width is 69 cm, length – 210 cm. The width of the pull-out lounger is 49 cm, and it also takes up space from wall to wall. The distance between the shelf and the lounger is 49 cm, making it convenient to use the lounger as a footrest while sitting on the shelf.

Since the upper stationary shelf is located significantly higher than required by the standards, for the convenience of the soaring, a bench of 3 boards, 36 cm wide, was additionally made. The distance between it and the shelf is 70 cm - this is a quite comfortable value.

The steam room shelf consists of two main elements: a supporting structure made of timber and flooring. The support is made of two load-bearing beams: they are installed along the width of the shelf and connected to each other by jumpers with a pitch of 50 cm:

Shelf frame made of two beams with lintels

One of the beams and the outer transverse beams are attached to the corresponding walls along the entire plane, the second beam is attached to the ends. To secure the lintels, grooves of the required size are made in the beams.

In this case, special racks resting on the wall are used to support the second beam. To ensure a tight connection, the ends of the racks are filed at the required angle. The structure is fastened with screws, two fasteners for each rack.

Thin, well-planed boards with rounded edges are placed on the manufactured frame. Slots 1-2 cm wide should be left between the boards to ensure rapid drainage of water and the necessary ventilation during drying.

The frame was covered with boards, leaving gaps for water to drain (there is also a bench in the photo)

It is important to use boards whose width does not exceed four times their thickness - such material dries well and is not susceptible to cracking during use.

In order to save space in the project under consideration, the width of the lounger is 69 cm, but it is recommended to make shelves at least 90 cm wide, which will require the use of 7 boards.

The principle of manufacturing a retractable lounger is the same as that of a shelf - the frame consists of two longitudinal bars with transverse struts. 5 boards were used for the flooring.

Retractable mechanism device

The design of the retractable “walking” mechanism requires special attention. How to make a folding shelf so that the bottom lounger slides under the top one? The bars are mounted to the end walls of the steam room. To them, and to the sides of the lounger on the inside, axles are attached, on which wooden planks are placed - levers. The corners of the slats should be filed (at least in the upper part) so that they do not interfere with the operation of the mechanism.

The thickness of the bars fixed to the wall must correspond to the thickness of the end elements of the lounger. To ensure that the slats sit tightly on the axle and move without play, wooden washers are installed.

“Walking” mechanism for extending the bench from under the shelf

Home pull-out sofas are made on a similar principle.

The mechanism allows you to effortlessly extend the lounger to a strictly defined distance, which in this case is 0.8 of the length of the lever. The lounger rests on its legs in the fully extended or fully retracted position.

This retractable design is most suitable for steam rooms, in which the length of the shelves and the lounger completely occupy the wall.

Protective wood treatment

Before using the steam room, it is necessary to treat the wood from which the shelves are made. Frequent contact with hot, humid air leads to rapid destruction of the material and deterioration of its appearance. Proper prevention will help avoid the appearance of mold and rot.

Attention! Under no circumstances should you use chemicals, including the usual drying oil and varnish, to treat the shelf. Otherwise, as the temperature in the room increases, substances that have an unpleasant, pungent odor and can cause an allergic reaction will be intensively released into the air.

It is recommended to use impregnation specially designed for bath shelves and benches. It is made on the basis of natural oils and allows you to create a protective film on the outer surface of wooden structures without compromising the natural properties of wood. This product is odorless and does not emit harmful fumes when heated.

A cheaper and more accessible option is edible flaxseed oil, which can be purchased at the grocery store. Hot oil is applied to the wood with a brush; it is recommended to rub it in well.

It is advisable to process the shelves by heating the stove well in the steam room - the oil polymerizes under the influence of high temperature. With another processing method, cold oil is rubbed in, and then the surface is heated with a hair dryer.

A little about ash

Noble wood has proven itself to be a high-quality and quite expensive material; when thinking about how to make shelves in a bathhouse, not every owner immediately chooses this option. The advantages and disadvantages of this type are identical to oak, the only difference will be the aroma, which is not so pronounced when steaming.

As for the pattern of the cut, it is quite textured and beautiful; over time it will become less visible due to salting, but this will not affect the elegance. The surface is treated with various protective agents based on beeswax and linseed oil.

Rules for processing lining

Lamels are perfect for cladding both inside and outside the building. Additional treatment of boards with antiseptics is not necessary, however, many owners still decide to play it safe and use these products and several other methods to increase the decorative properties of surfaces.

This:

- Polishing boards. This way they get rid of roughness and become smooth and with a soft shine. Calm and standard looks good on flat panels.

- Varnishing. For this, colorless varnish is most often used, since the wood itself has a rich, noble color.

- Aging. This technique is also called structuring - it makes the structure of the wood more expressive and adds a unique aesthetics.

Tempting alder

High-quality installation of a shelf in a bathhouse made of this material eliminates the possibility of getting burned, according to many experts. These positive properties make the breed in demand and attractive to true connoisseurs of the business. At the same time, the strength remains at a high level, and the color and aroma bring pleasure.

The price cannot be called budget in some regions, and the boards are quite demanding in terms of manipulations aimed at drying. If you do not adhere to certain rules, then the occurrence of defects cannot be avoided and the material will be damaged.

Necessary tool

Minimum set of tools for work

When all the necessary tools are at hand, you can install the frame and shelves quickly and efficiently. What to buy:

- Roulette and level. Basic measuring tools for both beginners and professional builders. After the construction of the sauna, the owner will come to the rescue more than once.

- Pencil and black marker. It’s even sold in hardware stores, but if you don’t have extra time, you can buy it at a stationery store.

- Wood saw. If you have extra money, it is better to purchase an electric jigsaw. Since during the construction of a steam room you have to work with small boards, a jigsaw will become an indispensable tool during the entire process.

- Electric screwdriver. You should not purchase models with batteries - such devices have low power.

- Hammer. Both ordinary and wooden or rubber (for precise fit).

- Electric drill. If the power of a screwdriver is not enough, and you want to build a bathhouse according to all the rules - using wooden planks.

Classic linden

This breed is the most common among experienced craftsmen; the width of the shelf in the bathhouse can be of any size, but quality will play a big role. The availability of the material causes considerable demand in the market; the boards are well processed without any extra effort.

The aroma is very pleasant, and the texture and pattern fit harmoniously into the interior of the room. At high temperatures, contact with the shelf is quite pleasant and does not cause inconvenience, which cannot be said about hard wood.

The correct dimensions of the bath shelf

Three-level shelves are the most common option in Russia.

Often, many bathhouse attendants make shelves in several tiers because “it’s beautiful” or they saw it in others.

But the two- or three-tier shelves with steps came from saunas, where people sit, not lie. Such options are not suitable in a Russian bath - they disturb the steamer. It is advisable to make shelves on one level. To make places comfortable for sitting and lying, you should focus on the following proportions:

Shelf height in a Russian bath

The height of the shelf should correspond to the height of the soaring person. To prevent the steamer from having to bend down or, on the contrary, work with his hands at an uncomfortable height, the shelf should be located at the level of the thumb bone of the lowered hand. On average, the height is 70-80 cm.

It is advisable to leave a distance of at least 110 cm between the shelf and the ceiling of the steam room; in this case, you can not only lie on the shelf, but also sit comfortably.

Lenght and width

The shelf should be comfortable for lying on, so the length is at least 220 cm, so as not to rest your head against the wall and prevent your legs from dangling. Width – about 90 cm.

Shelves and benches in the steam room are placed along walls without windows, spanning the entire width of the wall. The number of shelves depends on the size of the steam room. If space allows, the width of the main shelf can be made for two - these will already be chambers.

If space is limited, the “compartment” option is used - the bench and shelves are adjacent to one wall, the shelf folds back and is fixed for the convenience of sitting on the bench. If necessary, the shelves return to their original position. Another option: the lower bench is retractable, and the shelves are attached permanently.

Design of a resting device

The frame is designed to ensure reliability; it takes on the load that comes from the outside, steam, the weight of a person and other operational issues. The supporting frame structure is manufactured according to special standards with all the necessary calculations at the planning stage.

The flooring provides a flat surface for comfortable spending time in the bathhouse; wooden boards are placed on the frame, and sometimes are fastened with high quality from the inside.

Types of structures

Shelves are divided into two types, which affect the installation features of the entire product; there are free models and attached ones. In simple terms, free options imply the absence of points of contact with the partitions.

The basis for them is the floor, the structure moves around the room, but its implementation requires more effort and thoughtful actions.

Adviсe

Larch bathhouses should be built according to modern science; it is imperative to choose the right location and distance to other houses; for a black-style bathhouse, a distance of 12 meters from other houses should be taken into account. It is necessary to clearly make the layout of the washing room, steam room and dressing room, which should only be adjacent. The logs must be hewn to fit the bracket, and if the logs are thin, then additional processing of the walls must be done. If the bathhouse is made of larch, then it is better to use it as a foundation and for the manufacture of all floors, where this wood will be ideal.

Sources used:

- https://garantwood.ru/otdelka-bani-vagonkoj-iz-listvennicy-vyderzhit-li-derevo-parilku

- https://stroitelstvo.guru/listvennitsa-v-parilku/

- https://plusiminusi.ru/stroitelstvo-bani-iz-listvennicy-plyusy-i-minusy/

Pull-on model

This manufacturing option uses room partitions and auxiliary structural elements. Reliability is at a high level, and strength is many times better than the first option with free movement. One of the disadvantages is the acidification of fasteners due to constant contact with moisture.

Such rather unpleasant features will greatly upset the owners after a certain period of use. Before settling on one of the proposed options, you should think carefully about the issues that are currently in first place.

Auxiliary elements

Today, all sorts of innovations and practical ideas for decorating shelves in a bathhouse are quite common. Among them is the addition of railings, thanks to which it becomes possible to safely use the stove without a brick case.

Elderly people can easily go up and down to the upper tiers without fear for their health. Small railings are perfect for placing your feet on them during rest and procedures.

Advantages and disadvantages

There is no ideal design, so a person who is at the thinking or planning stage must think everything through carefully.

Every detail will be important and will play one role or another in convenience; you need to weigh the pros and cons, guided by the information received, and only then draw conclusions.

The most compromise option may be a pull-out or folding shelf. Removable and collapsible models are very practical and, in turn, reliable when manufactured correctly. Guided by personal preferences and life practice, you can achieve unique solutions.