The technology and process of arranging floors in a steam bath and washing department differ significantly from the principles of constructing floors in residential and commercial buildings.

To ensure an effective system of drainage, ventilation, water and thermal insulation, it is necessary to adhere to the basic rules of installation. A properly equipped bathhouse floor ensures rapid removal of wastewater and maintains the microclimate in the room.

Often the floor for a bathhouse is made of wood or concrete. It is difficult to determine which floor is better, since each type of base has its own operational features and characteristics that should be taken into account when arranging a private bathhouse.

Concrete floor

Many experts recommend installing a concrete floor in bath rooms, which is the most durable and practical option.

Concrete screed has the following characteristics:

- Long service life - from 30 to 50 years.

- Resistant to the negative effects of high temperatures and humidity.

- Resistant to rotting, deformation, destruction, development of pathogenic organisms and mold.

- Affordable cost of consumables for manufacturing.

- Possibility of decorative cladding.

- Simple and affordable care without the use of expensive chemicals.

Wooden floor

A wooden floor is simpler and more accessible to install, but less durable than its concrete counterpart. After only 10 years of active operation, individual elements of such a structure are subject to reconstruction or replacement.

Plank floors can be made from coniferous and deciduous wood, resistant to moisture and temperature changes. The wooden base comes in two types: leaking and non-leaking.

Leaky type floor

This is a budget design option, presented in the form of a wooden lattice, the individual elements of which are installed in compliance with the gaps for the free discharge of wastewater into the ground.

A leaky floor does not require the installation of a complex drainage system and additional insulation. For this reason, it is recommended to use a bathhouse with a similar floor in the summer or in regions with a warm climate.

Such a foundation is available for self-arrangement; in addition, repair work will not cause technical difficulties. In this design, the floorboards are not attached to the joists, so if necessary, they can be dismantled for drying or replacement.

Non-leakage floor

The non-leakage floor has a continuous structure installed on wooden logs, which are built into the ground or concrete base. For efficient drainage, it is performed at a slight slope towards the drain hole.

To install a solid floor, a tongue-and-groove board made of larch or pine, installed on supports, is used. High-quality floor boards should not have deformations or defects.

The top flooring is laid on the subfloor, which is pre-insulated with moisture-resistant material.

A bathhouse with this type of floor can be used throughout the year at any temperature.

Primer

After the beacons are fixed, the solution on the stains has hardened a little, the base can be primed. This will improve the adhesion of concrete to the base.

The primer is poured onto the base, then spread over the surface with a roller or wide brush.

If the solution will be laid on a waterproofing film, before installing the beacons, carefully seal all joints and check the entire surface for holes and openings. In this case, the use of dowels is impossible - the tightness is broken, and all work on installing beacons and laying the solution will need to be carried out carefully, without damaging the integrity of the film.

Selection of consumables and basic calculations

The construction of the floor in the bathhouse involves the use of construction and thermal insulation materials, waste pipes made of metal and plastic, and galvanized fasteners.

What is the best material to make the floor from in the steam room and sink? The quantity and type of consumables depend on the type of floor structure and how it is installed.

Calculations for a concrete floor

The following are calculations for a steam room in a sauna or bathhouse measuring 3 × 3 meters, in which the base is located at a height of 55 cm from the top soil level.

For installation work you need to prepare:

- Fine sand for filling a layer 12 cm thick. Volume of material (O) = (3 × 3) × 0.12 cm = 1.08 cubic meters. m.

- Expanded clay for backfilling before thermal insulation with a layer thickness of 30 cm. Volume of material (O) = (3 × 3) × 0.30 = 2.7 cubic meters. m.

- Expanded polystyrene sheets extruded for thermal insulation. The thickness of the insulating layer is 10 cm. The number of sheets for a room of 9 square meters. m – 2.5 packs.

- A mixture based on cement and sand (ready-made or homemade). The thickness of the screed is from 6 to 12 cm. The consumption of the dry mixture is on average 18 kg/sq.m. m. Concrete layer of 1 cm = (3 × 3) × 18 kg/sq. m = 162 kg. For a 6 cm layer: 162 × 7 = 1134 kg or 63 bags of ready-made mixture.

- Reinforcement mesh for fixing a concrete layer measuring 5 × 5 cm.

- Rolled roofing felt for waterproofing the sand cushion from the expanded clay layer.

- Metal profile for beacons under screed. For a steam room with an area of 9 sq. m. 18 meters of profile will be required.

- Plastic pipe for drainage up to 5 meters long, with a cross-section up to 3.2 cm, siphon and swivel elbow.

Calculations for wooden floors

As a working example, the calculation of materials for installing a wooden floor in a steam room with an area of 9 square meters is given. m.

To build a simple leaky floor, you will need:

- A block for the subfloor measuring 3 × 3 or 4 × 4 cm along the length of the beam. The distance between the beams is 0.5 meters, the total amount of material is 30 meters.

- Unplaned board for a base up to 25 cm wide and 2.5 cm thick. For one section you need: (300/25) × 0.5 = 6 meters. To design 5 floor sections: 5 × 6 = 30 meters.

- Guide bar for creating a drain slope with a cross-section of 2 × 3 or 3 × 3 cm.

- A block for fixing joists for a finished base with a section of 6 × 6 cm.

- Rolled or sheet roofing felt for waterproofing. For the steam room you need 16 meters of material, taking into account allowances.

- Rolled basalt wool 8 cm thick for thermal insulation.

- Galvanized steel sheets up to 0.6 mm thick – 11 sq. m. material.

- Polymer pipe, elbow and drain for installation in a drain hole. To organize proper drainage, the installation of the elbow with the connected pipe must be performed at a right angle.

Do-it-yourself insulation and finishing screed

An example of insulating a rough screed with foam sheets.

To create a thermal insulation barrier under a concrete floor base, it is better to use polymer moisture-resistant insulation. In our case, you can use sheet foam with a density of 35 kg/m3, but extruded polystyrene foam is better, which is stronger and absolutely impervious to moisture. In addition, the slabs of this material are equipped with joining protrusions, which makes its installation more convenient without the formation of gaps.

If the rough base is fairly level, the insulation boards can be laid directly on the surface. When existing unevenness does not allow for a high-quality installation of polystyrene foam, you can use polymer-cement glue, which will help smooth out the unevenness and “beautifully” lay the insulation sheets. The slabs should be placed offset to avoid the formation of long longitudinal joints. A gap of about a centimeter should be left between the polystyrene foam and the wall to allow for deformation expansion. It is advisable to fill all seams and gaps with polyurethane foam to prevent the formation of cold bridges.

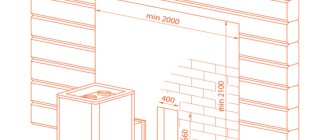

Using plaster profiles as beacons for finishing screed

If glue was used to lay the insulation, you should wait a day, after which you can install the beacons. A long building level is used for control. As guides, you can use plaster beacons with a T-shaped end, or guide profiles, which are used to assemble frames for sheathing. Beacons are installed on thick cement-sand or gypsum mortar laid out in slides. When adjusting their position, they are pressed into the applied mixture.

If you want to make a slope, the beacons should be placed at an angle. In order for water to drain from the tiles, and at the same time the inclined surface does not create discomfort while walking on it, the optimal height difference is within 1.5-2 cm/m.

Taking into account possible temperature changes, even with a small area of finishing pouring, a damper tape should be attached to the perimeter of the wall, which would protrude 2-3 cm above the surface level. The excess can then be cut off or covered with a plinth.

Laying reinforced cement screed

If the choice for finishing pouring is concrete, the proportions of the solution are as follows: 4:2:1, where, respectively, are the volume fractions of sand, fine crushed stone and M-400 cement. The cement-sand mixture is prepared in a ratio of 4:1. The prepared solution is poured between the beacons and leveled using the rule. When the solution has set, the surface should be rubbed using a plaster trowel. The beacons do not need to be removed during subsequent laying of tiles. If this is done, the seams should be filled with freshly prepared mortar and smoothed.

Concrete floor installation technology

The arrangement of the floor begins with preparing the soil inside the foundation - clearing it of debris and dirt.

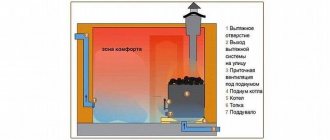

The layout of the monolithic base is as follows:

- The soil is carefully compacted and leveled. The inner walls of the foundation are treated with bitumen in several layers.

- At the preparatory stage, the sewer pipe is laid through the foundation. To do this, it is enough to make an inlet hole in the base and install a metal adapter for supplying a plastic pipe.

- The drain pipe is brought to the place where the drain hole is provided. The end of the pipe is plugged to prevent clogging.

- A sand cushion up to 12 cm high is poured onto the ground, moistened and compacted.

- Next, you need to put roofing felt on the internal walls of the base with an overlap of 15 cm. Additionally, the joints are treated with bitumen-based mastic.

- Expanded clay up to 35 cm thick is laid, leveled and compacted. There is 8 cm left to the edge of the base.

- Expanded clay is covered with a film 200 microns thick, and the joints are taped with construction tape. Thermal insulation is installed on top of the waterproofing.

- After the foundation is insulated, guides are installed for pouring concrete in increments of 55 to 95 cm. The beacons are laid on a mixture of cement and sand.

- When installing guides, it is important to maintain the required slope for proper water drainage. In this case, the beacons are set strictly according to level.

- At the bottom of the walls along the perimeter of the room, a damper tape up to 12 cm high is fixed. After pouring and drying the concrete screed, the remaining tape can be removed.

- The concrete is poured with the prepared mixture and left until completely dry.

Important! 5 days after pouring, the beacons are dismantled, and the existing voids are filled with the mixture. For the first 10 days, the floor is thoroughly moistened with water up to 3 times a day.

First stage

Having prepared the tool and purchased the necessary materials, we begin the preparatory work. First we dig a drainage hole. Its task is the reception and subsequent disposal of wastewater. On the outgoing sewer pipe we install a valve, the so-called drain ladder, which:

- hermetically connects the drain and waste systems;

- thanks to the installed grille, it ensures filtration of incoming water, which significantly reduces the possibility of blockages;

- prevents gases from entering the sewer pits into the room, as it is equipped with a water seal located inside the siphon.

Depending on the location of the drain hole, a drain is used with a straight line (when the pipe exits strictly vertically) or a side connection (if it is horizontal). When purchasing a drain ladder, pay attention to its height, which is fundamental when calculating the height of the coating being formed.

Having prepared the drainage pit, lay out the sewer pipes. If the drain is located in the corner of the room, the pipe is laid along the wall. When the drain is located in the center of the base, the pipes are laid diagonally, avoiding bends as much as possible, which lead to the formation of unwanted blockages. The plumbing elements are connected and brought to the cesspool. When organizing drainage from several rooms, they distribute communications throughout the room. The trenches are filled with sand and compacted tightly. To prevent pipes from becoming clogged with debris while the floor is being poured, they are covered with special plugs or thick fabric.

Installation of bath floors, usually done on the ground or logs

Laying technology for leaking wooden floors

A step-by-step guide to installing a leaking floor provides for step-by-step work: preparing the underground, installing joists and wooden flooring.

Preparation of the underground

In order for water entering the underground to be discharged into the ground, it is necessary to properly prepare the base - for this, the top layer of soil is cut off and a waterproofing cushion made of small crushed stone up to 26 cm thick is backfilled.

For soils with a low level of moisture absorption, soil removal is carried out at a slight angle, and wastewater is discharged into a 30-centimeter pit through a drain pipe. The soil is covered with clay and leveled.

Important! Before backfilling the pillows, supports are installed under wooden logs, and a foundation is erected for heating equipment.

Installation of support beams

How to install logs correctly? They are mounted on concrete supports equipped with a brick stand. The height of the lag is determined by the height of the pillars (column foundation) or strips (strip foundation).

The installation of the logs is carried out opposite the short wall of the building. To avoid deformation of the joists or their swelling, the supports are covered with a double layer of waterproofing made of roofing felt treated with hot bitumen.

To ensure natural ventilation when laying logs to the walls, a minimum technological gap of 4 cm should be observed.

Wood flooring

To lay the floor, use boards that are fixed perpendicular to the installed joists. In this case, it is necessary to maintain 5 mm gaps between individual floor elements and 2.5 cm between boards and walls. The wooden panel is fixed to the joists using metal nails.

Well with a filter at the bottom

The design of a drain pit with a filter bottom is used primarily to purify wastewater from dirt and chemical elements, as well as to retain bacteria. Subsequent filtration of water is carried out directly by the soil layer. But at the bottom of the well, crushed stone, crushed brick or sand are used as a filter.

To ensure the outflow of water from a bathhouse designed for 3-4 people, a well with a diameter of 1.5 m and a depth of 2 m is sufficient. It can be either rectangular or round in shape - the latter option is preferable due to the uniform distribution of pressure on all walls. The cylindrical design will need correction much less often.

Since it is necessary to drain the bathhouse at the dacha without damaging the building itself, it is advisable to retreat from it at a distance of about 3-5 meters. Such a gap will ensure, first of all, the safety of the bathhouse foundation from being washed away, and will also prevent the penetration of unpleasant odors from the well into the bathhouse. But if you locate the drainage hole further, you will inevitably have to purchase additional pipes for water drainage. In addition, it is difficult to ensure the correct angle of inclination over a long distance.

If the soil on your site is dense enough, then simply dig a hole for drainage and lay filter materials at the bottom - sand, crushed stone and broken brick. Additional strengthening of the walls is not required.

According to the drainage diagram in the bathhouse, a trench can be dug from it to the pit, through which water will randomly flow by gravity into the well. However, it is best to equip the drain with pipes made of asbestos, metal, plastic or ceramic, with a diameter of 50-100 mm. In this case, a trench is also necessary, but its depth will depend on the depth of soil freezing, but not less than 50 cm. The pipes are laid at a slope of 20 mm at every meter of distance.

At the design stage, the future design of the drain and the features of the floor organization are thought out in detail. An economical option for draining a bathhouse in a country house is to make the floor sloping towards the drain hole. With this design, wastewater enters the pipes and is discharged directly into the drainage pit.

An alternative to a drainage pit is to use a sealed septic tank, such as one made of plastic. Such a device will be especially relevant in cases where the bathhouse is equipped with a toilet, that is, the nature of the wastewater will require more thorough cleaning.

Technology for laying leak-proof wooden floors

The installation of a wooden floor in a bathhouse involves the installation of support beams similar to the previous option, with the formation of an inclined surface for effective drainage of wastewater.

Installation of the floor in the bathhouse is carried out in the following order:

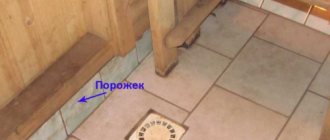

- Organization of water intake system. The first stage of installing a non-leaky floor is the organization of a water intake measuring 45 × 45 cm, located between the supports and thermally insulated with a solution of clay or cement. The depth of the water intake is 35 cm. At a height of 3 cm from the bottom of the receiver, at a slight slope, a pipe is installed to discharge wastewater into a drainage well or pit.

- Installation of subfloor. After installing the logs on the support posts, the subfloor is fixed - a sheet of cheap material, for example, a second-grade board. Hydro-, heat- and vapor barrier is laid on the boards in layers to protect against moisture.

- Fixation of the finishing coating. The installed logs are covered with a finishing coating made of tongue-and-groove boards with a low moisture absorption coefficient. Along the perimeter of the room, a gap of 2 cm is maintained from the walls for natural ventilation. The boards are fixed with nails at an angle of 50 degrees. Finally, decorative plinth is installed.

Important! Wall surfaces are covered over the installed baseboard to prevent condensation from collecting under the baseboard.