You can build a bathhouse from wood concrete: this environmentally friendly material is loved for its high heat-saving qualities, which is necessary for a sauna.

It is recommended to follow the instructions and figure out why wood concrete blocks are good for a bathhouse on the site.

Is it possible to build a steam room from wood concrete?

Most experts answer this question in the affirmative. Arbolite stone perfectly retains heat indoors , and the walls can be additionally insulated. If the stone is not plastered, it allows air to pass through well. It is more expedient to line the bathhouse with wood from the inside, creating a ventilation gap and a vapor barrier.

It is better to use basalt wool as insulation, and in the outer part of the wood concrete it is better to make a windproof film, another ventilation gap and external cladding.

This material is excellent for building a bathhouse due to its properties . According to regulatory documents, the humidity of wood concrete blocks reaches 10%, and according to SNiP such indicators are unacceptable for a bathhouse. The sauna is always humid and the room will become covered with condensation, which can cause fungus to appear. This problem can be solved: it is enough to properly install a vapor barrier and protect the blocks from moisture.

Important ! It is not advisable to build a bathhouse made of wood concrete in regions with high climate humidity. In this case, it is worth paying great attention to the vapor barrier from the outside, otherwise all the building material will absorb moisture and mold will spread along the walls.

Pros and cons of the solution

Before starting construction, it is recommended that you familiarize yourself with all the pros and cons of building a bathhouse from this material. The undeniable advantages include :

good thermal insulation;- high fire safety;

- biostability;

- efficiency;

- availability;

- light weight;

- easy production and installation.

Thanks to good thermal insulation, the bathhouse will quickly heat up inside. This is due to the presence of voids between the wood chips in the block structure. Wood concrete does not support combustion, which is extremely important when building a bathhouse. The material is considered bioresistant - it is not susceptible to insect damage.

The cost of wood concrete is much cheaper than brick , and this is an important point, since it will not take a lot of money to build a bathhouse. Due to the fact that the material is light, an inexpensive foundation can be used, which will also reduce the cost of construction.

This block material also has disadvantages when constructing a bathhouse: high vapor permeability. The raw material will not be destroyed by moisture, but is capable of absorbing water in large quantities: this is due to the presence of wood in the block. Before leaving the steam room, the owner will have to add firewood to dry the walls properly.

Features of building a foundation for a furnace

Regardless of the type of foundation for the bathhouse, the load-bearing structure under the stove must be built autonomously. This is due to the fact that the heating device has significant weight and can shrink during service.

The foundations for the stove and the bathhouse itself must be separated by a sand cushion with a width of at least 0.5 m . In this case, each side of the base should be 5–10 cm larger than the dimensions of the heating device.

The foundation under the furnace is laid below the freezing depth. This can be a monolithic structure with a high sand cushion and a reinforcing frame or piles. In the first case, a pit is dug to the design depth, a compacted cushion is installed, formwork is installed, a reinforcement frame is laid, and the space is concreted.

Construction rules

If you follow certain rules, then building a bathhouse from wood concrete blocks will be quick and easy. Here's what experienced craftsmen recommend when working :

- make masonry in half a block, with the dimensions of one block being 500x300x200 mm according to GOST;

- use cement-sand mortar or perlite mixture for masonry;

- it is better to use a shallow strip foundation;

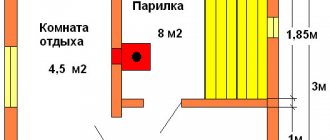

- the room should have a shower, steam room and rest room;

- the foundation blind area must be insulated;

- window and door openings require mandatory strengthening;

- It is better to carry out construction work in the spring.

Note ! If you plan to use the bathhouse regularly, then it makes no sense to build a separate room. To do this, it is better to build a full-fledged country house with rooms, a bathroom and a kitchen.

Project selection

If you decide to use wood concrete, it’s time to determine the size of the building. Often a bathhouse is created with a second floor, in this case it is necessary to find the correct design of the structure. The uniform size of the building is selected depending on how many people will use it at the same time.

For continuous, regular use of the bathhouse, an almost complete house should be built. It is preferable to select projects that, in addition to the steam room, allow you to locate a relaxation room, a gym and other office premises.

Tools and materials

To build a bathhouse from arbolite blocks, you need to prepare the stone itself.

It is sold by the cubic meter and delivered directly to the site. You can make wood concrete blocks yourself - but it will take a lot of time and effort. In addition to the stone, you will need a masonry mixture : it is prepared from cement, sand and water, as well as perlite. To arrange the foundation you will need concrete and metal rods for reinforcement.

Also, to continue construction after masonry, window blocks, doors, communication materials, and finishing materials from the inside and outside are needed.

To arrange the roof, you need raw materials for the roof. You will also need heat and vapor barrier.

Tools for laying walls need to be prepared:

- buckets for solution;

- trowel;

- putty knife;

- rubber mallet for correcting blocks;

- drill with mixer attachment;

- perforator;

- plumb line and cords for evenness of masonry;

- building level.

To completely build a bathhouse from scratch from wood concrete, a jigsaw, grinder, chainsaw, various screwdrivers, and a screwdriver will also be useful.

How to do it yourself?

To build a power structure, you can always invite highly specialized specialists to work . If the owner plans to do the foundation work with his own hands, he first needs to understand the construction technology and develop a project in accordance with current standards.

Terrain marking

After designing and preparing building materials, equipment and tools, the developer can begin the first stage of construction - marking the site. To do this, you need to prepare the site: remove construction debris and objects that interfere with work.

Markings are applied strictly according to plan. As a rule, the area of the pit is 1–2 meters larger than the dimensions of the bathhouse itself.

They mark the contour of the working field using reinforcing bars driven into the ground at the corners of the structure, as well as cords stretched between them. At the end, proportionality is checked by comparing the diagonals.

Excavation

Under the slab foundation, the builder needs to develop a pit to the designed depth.

Shovel work will take a lot of time and effort, and you will also have to cut off the roots of trees and shrubs. The depth of the pit can vary from 0.5 to 1 m depending on the type of soil on the site and design construction conditions.

The bottom of the excavated recess must be level in one horizontal plane and thoroughly compacted.

Manufacturing of formwork

The role of formwork is to provide a clear shape and design dimensions in the space of the finished monolithic structure. At the developer’s choice, the formwork can be removable (wooden, metal, plastic) or permanent (made of polystyrene foam) and at the same time serve as insulation.

In most cases, in private construction they choose the most budget-friendly method - installation of wooden panel formwork , knocked down with your own hands from boards or plywood.

The formwork is built along the perimeter of the pit, fixing the position of the panels from the outside with supports in increments of 0.5–1 m. The contour of the formwork can also be knocked down from the outside with wooden planks so that the structure does not move apart under the pressure of the solution.

For permanent formwork, insulation is installed on the inside in the form of slabs of polystyrene foam or other material with a low degree of thermal conductivity.

Filling the bottom of the pit

To reduce the effect of soil movements on the base of the bathhouse, a cushion of non-metallic materials - crushed stone and sand - is placed at the bottom of the pit. Before this, the surface of the earth is covered with geosynthetic material, which at the same time does not allow the soil and fill to mix with each other, and also acts as a barrier against the seepage of groundwater into the structure of the foundation base.

The geotextile layer is covered with an even layer of sand. The work uses purified bulk material - quarry or river sand.

The thickness of the compacted sand cushion must be at least 0.3 m . Tamping can be done manually, but the work will be more efficient if you rent a vibrating plate.

The sand is covered with medium-fraction crushed stone with a layer thickness of 0.2–0.3 m. The bulk material is also carefully compacted to obtain the most compacted and stable bottom.

Pouring a concrete pad

Pouring a concrete pad allows the developer to get a level base for the future bathhouse.

This is a low concrete screed, which should be distinguished from a foundation slab. Since at this stage of construction there is no need for a large consumption of material, they do not skimp on the quality of concrete, giving preference to high-quality solutions .

To completely harden, the concrete layer requires no more than 10 days.

A concrete pad is placed on top of the layers of hydro- and thermal insulation of the foundation. Polyethylene film or roofing felt is used as a waterproofing material, and extruded polystyrene foam is used as a heat insulator.

Reinforcement

Reinforcing frame - a spatial structure made of reinforcing steel bars . As a rule, these are two meshes that are placed in a horizontal plane and connected to each other by vertical rods.

The purpose of the reinforcement is to ensure the resistance of the slab foundation to tensile loads, as well as additional strength and rigidity to the base for the bathhouse.

The process of manufacturing a reinforced frame for a foundation is controlled by current standards (SNiP 52–01–2003 in the latest edition). The developer can order a ready-made power structure or assemble a frame from reinforcement with his own hands.

Steel rods must be recessed into the body of the monolithic slab by at least 5 cm on all sides. To maintain the design distance, builders use fixings, for example, pieces of crushed brick.

Installation of water drainage and power supply systems

For ease of operation of the bathhouse, drainage elements can be placed directly in the foundation slab. To ensure that sewer drain parts remain in working condition for a long time, they are placed in special sleeves. The absence of overhead water lines allows the developer not to carry out thermal protection of the water supply system from freezing.

It is also possible to install an electrical supply system into the slab foundation . The technology makes it possible to install a spiral pipeline in the foundation slab through which hot water will move in order to obtain a “warm floor” type structure.

Pouring the slab

Concrete is poured into the finished formwork with a reinforced frame installed inside.

The complexity of the technological stage lies in the fact that the screed requires a large volume of mortar, and the concreting process itself must be carried out in one stage .

Otherwise, the surface of the lower concrete layer will have time to set and the result will be a monolith with a heterogeneous structure, the strength of which will be significantly lower than the design value.

For a small slab, you can rent a concrete mixer or prepare the solution yourself using a shovel. If the area of the bathhouse is more than 6 by 6 meters, then it is more advisable to order factory-made concrete, which in the required volume will be delivered to the site immediately before the start of pouring, as required by the technology.

After pouring, air bubbles remain in the body of liquid concrete, which must be removed in order to obtain a dense and uniform structure of a durable monolith. This can be done by bayoneting the surface of the solution with reinforcement, but it will be faster, easier and more effective if you use a special vibration installation for this purpose.

Concrete maintenance and formwork removal

According to the technology for constructing reinforced concrete structures, concrete must harden at a certain temperature in order to become a strong and durable monolith. If the slab dries too quickly or changes in ambient temperature, cracks may appear in the slab.

To prevent this from happening, the concrete surface is covered with woven fabric (hay, film) and periodically irrigated with water . If construction is carried out in winter, then special heating ingredients are added to the solution.

When a gap appears between the formwork panels and the slab, you can begin dismantling the molding structure.

Step-by-step instructions describing the technology

Construction begins with the selection of a project and preparation of documentation . If you plan to live on a suburban area, then the bathhouse should be built together with the house. If it is free-standing, then it is made small in size. Step-by-step technology:

Foundation .

A strip foundation is poured, since it is the one that is best suited for building a bathhouse made of wood concrete. You can use an insulated slab 3 cm thick. Be sure to insulate the blind area: the base of the bathhouse should not come into contact with snow.- Wall masonry .

They are erected in the spring. When the foundation has already matured, a layer of roofing felt is laid and masonry work begins. To avoid the occurrence of cold bridges, use a mounting mixture or masonry mortar. To prepare it, mix 1 part M400 cement, 3 parts sand and 0.5 parts lime. During laying, reinforcement is carried out on every 3rd row. - Installation of doors and windows . The thickness of the openings should not exceed 22 cm. If this happens, they are trimmed. All fasteners are screwed into the wood concrete manually. In blocks where chips have opened, a protective mixture based on natural oil is used.

The walls of the steam room and washing room are plastered on the outside, dry rooms - a relaxation room, a hallway: can be lined with clapboard. When arranging the ceiling, a vapor barrier and hydraulic protection are also used.

Possible errors and difficulties

During the construction process, especially if beginners are building a bathhouse, difficulties and errors may arise. A few of them:

- Incorrect block selection . The blocks must be dense, otherwise in the future the bathhouse will shrink and vertical curvature of the walls will appear.

- Lack of reinforcement . Walls may become curved in the future due to the fact that the pressure on them is distributed unevenly. Reinforcement is done when laying stone.

- Poor stone geometry . If the wood concrete was purchased of not very good quality, then most likely its geometry will be damaged. This will lead to excess consumption of the masonry mixture.

- Base made of cellular concrete . This type of material will not protect wood concrete from moisture - it is better to give preference to a strip foundation.

To avoid these difficulties and prevent mistakes, it is recommended to contact professionals. There are a large number of reviews where people spoke negatively about the operation of the bathhouse only because the masonry and construction in general were done poorly without knowledge of the characteristics of wood concrete blocks.

Roof

The final stage is the installation of the roof. There are no special features or subtleties in this work. Everything is done as during the simple construction of any building:

- It is necessary to install Mauerlat bars on the walls.

- When finished, secure the rafter legs to them.

- After this, sheathe the pediment.

- Place a water-repellent film over the rafters.

- Secure the sheathing.

- Lay roofing material.

Now your design is completely ready. Only small finishing works of the building remain.

Owner reviews

Yuri, Saratov

When the house was already standing on the site, they made it from foam concrete, and decided to build a separate bathhouse. When building with block stone, I understood all the advantages, but I wanted to save a little money. I chose wood concrete and cast it ourselves.

The output is 40% less cost than if you take ready-made material from the base. The bathhouse turned out to be warm and comfortable.

Inga, Temryuk

I'm used to the Russian traditional wooden bathhouse. When I arrived at my friend’s site, they boasted of a new bathhouse made of wood concrete blocks. I didn't really enjoy spending time inside the steam room. In the hallway, not much mold was already visible on the walls, and the construction was only 2 years old.

Alexander, Nizhny Novgorod

Many people say that wood concrete is not relevant for baths, but I say the opposite. If you properly carry out vapor barrier and waterproofing, such a bathhouse will last for many years. We are engaged in the construction of premises from block material and wood concrete is now one of the most in demand.

Philip, Tambov

We built a bathhouse from wood-concrete blocks: I would never have thought that it would be so fast. Initially they wanted to insulate it, but then they realized that there was no point in it. They simply covered the outside with clapboard, creating a gap for ventilation. The bathhouse has been standing for 5 years - everything is fine, no fungus.

More reviews about the sauna made of arbolite blocks can be found here.