Wooden buildings are extremely attractive, both from the point of view of environmental friendliness and protection from the cold, and their appearance. Now there is a real trend towards building houses made of wood, and similar buildings, clearly not built in Soviet times, can be seen in various regions of the country. However, all the advantages of wooden houses appear only if there are no gaps between the logs in their walls. And in this material we will tell you exactly how to close these seams using traditional and modern methods.

How do cracks occur?

The appearance of cracks in a log or beam is a natural phenomenon, occurring due to uneven drying of the wood. It dries quickly on the outside when in contact with air, but remains damp inside for a long time. The dried layers stretch, the core remains wet and compressed, and strong tension arises and the wood cracks along the fibers.

If the walls are built from very fresh, recently cut down wood, then the lower crowns are subject to additional load from the weight of the overlying ones. In this case, the defects may be even more pronounced, and cracks in the timber outside the house will need to be repaired.

Cracks in a new log house Source slobodskoy-les.ru

For reference! An additional factor contributing to fiber rupture may be improper installation of crowns with distortions and uneven distribution of load on the log.

The working principle of a caulking machine

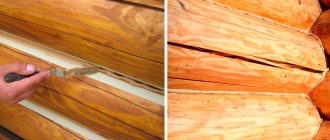

When professionally caulking the seams, the master, using a spatula and a road worker, arranges the seal into an even, barely protruding roller, which gives the log house a neat, finished look. The seam created in this way is more resistant to wind and rain. However, over time it is destroyed, and birds may also like it for building nests.

Therefore, when painting a log house, it is recommended to impregnate the protruding parts of the sealant with wood oil or other protective agent.

Note: Many experts do not recommend using tubular polyethylene foam materials instead of traditional fiber sealants - they trap moisture inside the seam, which is why the walls begin to rot faster.

The cost of the latter will increase significantly - some companies charge a separate fee for such a service (10-20 rubles per linear meter). But these costs will pay off in the future, since the service life of the interventional insulation will increase several times.

A jute rope with a diameter of 10-16 mm applied to the seam can protect the fibrous seal from wind and birds, and at the same time decorate the house. It is fixed to the logs with galvanized nails with a wide head or staplers.

Craftsmen estimate this method of decorating seams at 30 rubles per linear meter. Of course, it will not replace caulking, but it will allow you to hide the defects of sloppy caulking, which means saving money.

Share

- 68 shared

Is it possible to avoid cracks?

Repairing cracks in wood may not be necessary if you prevent them from occurring. Based on the nature of their occurrence, it is clear that for this it is necessary to ensure the most uniform drying of the logs and the absence of load on them.

The number of breaks and their size directly depend on the drying rate of the outer layer, so debarked logs must be dried for a long time, in natural conditions, protected from direct sunlight. Of course, loggers cannot afford to keep finished products for a year or two, providing normal conditions for drying. Quick profits are more important. This can only be done by the buyer, taking care to equip a dry area with a large canopy and stacking the logs in ventilated stacks.

Drying logs in stacks Source sib-zodchy.ru

The production of timber and rounded logs from damp wood aggravates the problem, since moisture evaporates faster through the exposed fibers. Therefore, first drying to 18-20%, and only then processing, cutting and other work. If you cut down a log house from damp wood, you will very soon have to think about how to repair cracks in the logs, since there will definitely be cracks, and rather large ones, 1.5-2 cm deep or more. Dry wood can also crack, but there will be few cracks, 1-2 mm deep, which is not at all critical for the integrity, strength and aesthetic appearance of the building.

In reality, not everyone and not always have the opportunity to buy dry wood or spend a couple of years drying it. In such cases, cracking can be reduced by sealing the ends through which the most intense evaporation of moisture occurs. To process them, you can use a polymer sealant for cracks in timber, oil paint, wax and any other material that forms a film impermeable to moisture. It will only have to evaporate through the outer surface of the log, which will slow down the process and smooth out the difference in stress in the outer and inner layers.

Sealing the ends of a log house Source chonemuzhik.ru

See also: Catalog of companies that specialize in finishing materials and related work

Experienced carpenters resort to another method - they make a longitudinal cut in each log of the log house, which compensates for the difference in stress in layers with different humidity. This is an artificial unloading crack, which is located in the upper part of the log and, when assembling the log house, is blocked by the overlying crown. But this method does not guarantee the absence of natural cracks; moreover, it can only be used by experienced craftsmen who are able to correctly calculate the sufficient cutting depth.

Compensation cut Source woodmaster-shop46.ru

Necessary equipment for work

Tools for caulking log houses.

Is it necessary to caulk a log house? Yes, this is necessary, because a correctly carried out process will eliminate cracks in the space between the timber and at the connection points of the crowns, heat will be retained in the room, drafts and icing will not appear there.

The material used for caulking must meet certain requirements. In terms of quality indicators, it should be similar to wood and have a clean, environmentally friendly base. Such raw materials are not characterized by changes in external data under the influence of high humidity and temperature indicators. Air should not pass through it; at the same time, the source must absorb moisture from the surrounding air and get rid of it in a timely manner. Such material should be free of rot or pests. An important indicator of such a source will be the preservation of valuable indicators for as long as possible.

Related article: 3D panels for the bathroom - a budget finishing option

Among the materials used for insulating the seams of houses, swamp moss-sphagnum, flax tow, and hemp have long been used. Modern achievements in the construction field have provided a new material, jute, for mass use. One of the best options is swamp moss, which reliably protects the walls of the building from putrefactive processes and fungal manifestations.

Types of caulk.

As a result, buildings last much longer. Moss is able to actively absorb moisture, and if the need arises, it saturates the wood with it. Its base is highly breathable and has antiseptic properties. Moss can be considered an ideal material for caulking. However, it is quite difficult to finish seams in a log house with it. And it’s not easy to collect such raw materials in the required volume.

Flax tow and hemp are also used for caulking at home, but their quality indicators are much lower than the considered option. These options are classified as industrial waste, have a similar structure, hemp has thicker and stronger fibers. The disadvantage of such materials is the residue in the form of fires; over time, it begins to crumble, and there is a need for repeated work.

Jute is an imported product; it has been used in construction not so long ago. Any house will be reliably caulked with this type of material, providing it with special strength, hygroscopicity, and excellent air conduction. Jute is not capable of rotting or molding; its strong base does not allow birds to pull fibers out of cracks, which is often observed when using tow and hemp.

Jute is sold in strips and fibers. The first form creates comfortable conditions for defining them in the space between the crowns in the log house. Pure jute fiber helps in constructing a uniform compaction. But such material will have a fairly high price. To reduce its cost, flax becomes a component of jute, which does not have the best effect on its quality indicators.

Related article: Ceiling cornice for bay window: design features

Why seal cracks?

It is believed that any defects on the surface of wood, and especially cracks, become a haven for wood-boring insects, fungal and mold spores. Which over time destroy the wood, causing it to rot and lose strength. But looking at the old wooden houses, some of which are more than a hundred years old, one can doubt this. Our ancestors did not know and did not use modern means for protecting wood and built houses without external decoration. Their walls have darkened with time, they are often covered with numerous cracks, but they are intact and unharmed. Only the lower crowns rot and collapse, and most often due to the lack of a high foundation and direct contact with wet soil and melting snow.

Therefore, before you seal cracks in the timber of a house outside or inside, think about whether this is necessary. In any case, small and shallow tears are safe for the structure. For fungus to multiply, a constantly moist environment is needed, and walls dry out very quickly when exposed to air.

Such cracks are not dangerous Source mwood-hause.ru

What is better for end protection?

Wood is considered a delicate material, so the best modern materials are used to process it, including specialized acrylic sealants for wooden houses. Today they are actively used in various types of construction - industrial and private.

Industry, domestic and foreign, offers special sealing compounds created for processing the end elements of wooden buildings. Such materials cope well with the negative effects of atmospheric phenomena and protect wooden structures from rapid destruction. After applying the substance, the ends are under a layer of elastic film with water-repellent properties.

“Acrylic sealant for wood ends” of domestic production is a protective material created on the basis of a water-dispersed acrylic composition of very high quality. This allows you to reliably protect structures made of wood from drying out, moisture and rotting for a long time. In addition, treatment with this substance gives the ends additional stability.

Acrylic sealant for end cuts

Acrylic sealants used in the construction of environmentally friendly buildings are themselves materials that are harmless to humans.

>Surface preparation

It should be noted that proper preparation of the surface of the ends for the subsequent application of protective material is the key to preserving a wooden house for many years.

Materials for sealing cracks

Very small cracks are eliminated by sanding, simultaneously becoming clogged with the resulting wood dust. Sandpaper is selected taking into account the size and type of wood: the softer it is, the finer the grain should be, otherwise noticeable marks will remain on the surface.

Sanding a log house Source ocilindrovannoe-brevno.ru

Before sealing, larger gaps are cleaned of debris, traces of mold and treated with antiseptic impregnation or insecticide.

Putties

In stores there are special acrylic wood putties that can be matched to your log house. When choosing what to cover up cracks in wood, carefully read the instructions, because most of them are intended to:

- for interior work;

- for cracks no more than 2-3 mm wide.

With significant temperature fluctuations, under the influence of sunlight, the putty freezes or dries out and begins to crumble.

Wood putty Source ozone.ru

Homemade putty, which is prepared from 4-5 parts of wood dust or small sawdust and 1 part of wood glue or PVA glue, has excellent properties. The mixture should be homogeneous and quite thick.

The putty is applied with a spatula, trying to press it deeply into the cracks. Excess is removed with a damp cloth or sponge. The procedure will probably need to be repeated after the mixture dries, as it shrinks and “falls” inward.

Another type of homemade putty that adheres well to wood is made from gypsum. For two parts of powder, take 5-6 parts of fine sawdust, 1 part of water and a couple of drops of liquid detergent for plasticity. Use it immediately, placing it into the cracks with a spatula. Cover the top with acrylic putty or sealant.

Which sealant to choose for a wooden house?

Interventional sealant for processing wooden log houses must be chosen wisely. We recommend purchasing special formulations. Only with them you will carry out effective sealing.

We recommend that you study forums on the Internet to find out which sealant is best to use for a wooden house. At them, craftsmen actively share their experience on the use of products for sealing wooden buildings.

Video description

How to seal large cracks in a log is shown in this video:

The use of sealant depends on the form of release. If it is a thick paste in plastic buckets, it is applied with a spatula. It is more convenient to work with the product packaged in tubes with a spout. They are inserted into a special syringe and squeezed into the cracks.

A sealant for exterior use must have very high elasticity and frost resistance in order to absorb the narrowing and expansion of cracks due to changes in humidity and air temperature.

Natural materials

When choosing how to repair cracks in wood, many experienced craftsmen prefer traditional natural materials - tow, moss, jute. The fact is that polymer-based gap fillers sooner or later begin to lag behind the walls of the recess, crack, and crumble. Since they do not allow moisture to pass through, they prevent it from evaporating from the wood when it gets wet from precipitation, creating ideal conditions for the growth of fungus in the depths of the cracks. That is, they begin to have the opposite effect.

It is much safer to caulk large and deep cracks, like seams between logs. Tow or moss are excellent natural heat insulators that are easily embedded in cracks and reliably fill them, expanding and contracting as the free space changes.

Caulk seams and cracks with tow Source winterhouse.ru

Before use, the moss is first soaked briefly in water, then wrung out and rolled out with a roller on a flat surface. Lay it down damp. As it dries, it expands, gains volume and tightly fills all voids.

The modern choice is sealing using the “Warm Seam” technology

All the materials we have looked at so far have had a long past, but it can hardly be said that they will have a great future. After all, they do not correspond to the characteristics that modern polymer materials are ready to provide for waterproofing buildings.

What properties does the modern composition have?

- Elasticity is an important indicator. Since the material stretches and contracts with the seam, it will not peel away from it.

- High resistance to weathering and ultraviolet light.

- High degree of resistance to the development of fungus and mold on the surface of the logs and the entire structure.

- Long service life is also one of the features inherent in modern materials.

- Ease of use is what distinguishes the new sealants most of all. No caulking: simple and quick application.

- High-tech and artificial do not mean harmful. The environmental safety of using this material confirms this statement.

- Aesthetic superiority will be best liked by owners of country houses who are struggling for comfortable and cozy content.

Briefly about the main thing

The obvious question that arises for a person who discovers cracks in the logs of a log house is: how to repair them. But first, think about whether you need to do this. Small cracks do not have a negative impact on the strength and integrity of the structure, but they do spoil the appearance of the walls. Serious breaks - long and deep - can weaken the frame, cause its uneven shrinkage, and freezing. Such defects must be eliminated by driving tow, jute or moss into the cracks, filling them with elastic bands and sealing them with sealant on top. Small internal cracks can be filled with putty.

Ratings 0

Pros and cons of sealing a log house

environmentally friendly The sealant does not contain harmful substances and has no pungent odor;

universal. It is used for insulating seams inside and outside the house, eliminating minor damage;

hypoallergenic. Does not have a harmful effect on the health of people, even those prone to allergies;

Wear-resistant: resists weather conditions. The warm seam is not afraid of rain, heat, wind or frost;

thanks to special additives, it does not harbor pests;

when sealing a log house, the seam is invisible, because the product is matched to the color of the walls;

dense filling with cord and sealant eliminates heat loss in a wooden house;

sealing is an economical method of insulation. Thanks to it, the costs of heating, repairs, and periodic sealing of cracks and gaps between logs are reduced;

optimizes air exchange, creating a healthy microclimate in the house.

the need to carry out work in dry weather;

warm seam technology is carried out only a year after the construction of the building;

the surface of the seam must be thoroughly cleaned and dried; only in this case is high-quality insulation of the log house possible;