Gutter systems made of polyvinyl chloride are much lighter and more practical than metal options. Plastic kits are much easier to work with. Despite the installation rules common to previous varieties, they do not require labor efforts commensurate in severity.

True, it is impossible to successfully install a roof drain with your own hands without taking into account the specific qualities of polymer products. Let's figure out what independent installers of PVC drainage systems should know and follow.

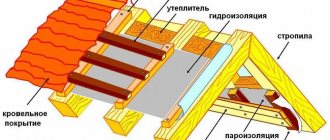

What does the drainage system consist of?

It includes two main elements:

- gutters, also known as trays, that are installed on the roof eaves, and their main task is to collect rain or melt water from the slopes;

- the pipes into which water flows from the trays are located vertically, and their task is to discharge water into the surface drainage system or onto the ground.

There are additional elements:

- funnels through which water flows from the trays into the pipes:

- elbows for installing pipes, for draining from the eaves to the wall of the building, for fastening pipes;

- brackets for fastening trays;

- clamps for attaching pipes to walls;

- plugs for closing the ends of the trays.

Elements of the drainage system Source donstroyservis.ru

We install gutters

The next point in the instructions for installing a metal drain is the installation of gutters. Start with the lowest level (the one with the funnel). Install them one after another with a slight overlap of 2-3 cm. Fix them with holders - for this they have a special petal that bends inside the gutter.

We fasten the gutters to each other, as well as to the corner elements, using a connector with a rubber seal. We hook the short flange of the connector to the inner edge of the gutter and press the part against it. Place the front hook on the outer edge of the gutter and close the lock.

The ends of the gutters, if they do not connect into a closed perimeter, close with plugs. This can be done using a regular mallet, without additional fasteners.

Important: For additional insulation, coat all connections with roofing sealant. Please note: not silicone, but roofing - on a rubber or bitumen basis.

Sequence of installation of the drainage system

The first step is to install the gutters. They are attached to brackets, which are attached either to the first two boards of the sheathing, or to the rafters, or to the front board. The best option is the first one. But it can only be carried out if the roofing material has not yet been installed on the rafter system. If the roof is already covered, then the brackets use short hooks with fastening to the front board.

Installing brackets on the frontal board Source krovelson.ru

Attaching brackets to sheathing

For this purpose, brackets with a long leg are used. It is simply bent back to the required length, applied to the sheathing and secured to it with self-tapping screws through the holes made.

Bracket with a long leg Source www.braersnab.ru

It is important to strictly adhere to two parameters during installation:

- distances between fasteners;

- distance from the middle of the hook to the edge of the roof overhang.

The last parameter should vary in the range of 30-40 mm. This is done so that the water coming off the roof gets into the middle of the gutter. To avoid overflowing over the edges of the trays and splashing water.

Important! When installing gutter fasteners, it is important to use anodized “yellow” rather than “black” screws (Pz 5*40 yellow zinc screw), because The “yellows” have more resistance to breakaway.

The calculation of these self-tapping screws is as follows:

- long hook – 3 pcs/mount

- short hook – 4 pcs/mount

Installation and fastening of brackets to the sheathing Source grandline.ru

Attaching to rafter legs

If the roofing material has already been laid, then one of the options for attaching the brackets is to the rafters. For this, the same fasteners with a long leg are used, only they have it rotated 90°. This way it is simply more convenient to carry out the fastening.

Bracket with leg rotated 90° Source profiroof.com

Fastening to the front board

One of the top photos already shows how to attach the gutter brackets to the front board. For this, short hooks are used, but with a platform in which mounting holes are made.

It should be noted that today manufacturers offer various models, which mainly differ from each other in the method of fastening. The photo below shows an option where the fastening element is a bar with a full-length groove. It is attached to the front board, and the brackets themselves are inserted into the grooves.

Mounting plate with brackets for gutters Source oookifa.com

Other options

If it is not possible to install the brackets according to the options described above, then you can attach them to the roof overhang. For this purpose, brackets with a long leg are used, which bends to the required angle and length. The photo below shows this installation option.

Attachment to roof eaves sheathing Source ms.decorexpro.com

See also: Catalog of companies that specialize in roof repair and design.

Fixing extension cords

If there is no frontal board, you can use metal brackets or extensions for plastic elements. The second option has a hole with risks. Thanks to this, it becomes possible to control the position of the bracket and select the angle of inclination.

Fastening can be done from above the rafters. However, often their pitch does not coincide with the distance of the brackets. Then the straight extension is fixed in OSB-3 in a pre-made cut.

Step by step steps:

- Make cuts on the roof.

- Bend the metal elements to the angle of the roof with a special tool.

- Fix the extension in the cut.

- Attach the bracket to it.

If the roof has not yet been installed, straight extensions are used.

If the roof is already done, then the sides. They are fixed to the side of the surface of the rafter leg. This extension is convenient when reconstructing a roof when there is no frontal board.

Rules and sequence for assembling gutters

The main task of the work manufacturer is to fasten the gutters of the drainage system at a slight slope equal to 2-3 mm per 1 linear meter of the gutter, since the drainage system is a gravity flow system. Therefore, on one side of the slope, the bracket is installed closer to the roof eaves, and on the opposite side of the slope lower, so that a slope is formed. Then a thread is pulled between the two fasteners, along which other brackets are installed in increments of 50-60 cm.

All that remains is to lay and secure the gutters to the fasteners. The main thing is that the installation is done end-to-end with a gap of about 3 mm. At the junction, a gutter connector with a sealing gasket made of porous rubber is snapped into place. To reduce the possibility of leaks, the joints are treated with a special sealant for roofing work.

If the house is located in the same area with trees with dense foliage, a “spider” for the funnel and a mesh for the gutter can save you from it.

An example of a mesh for a gutter and funnel Source grandline.ru

At the same time, it is worth remembering that the mesh does not need to be maintained, because the foliage stuck to it is simply blown away by the wind, but sometimes the spider will have to be cleaned.

Installation of gutters Source ko.decorexpro.com

Pipe installation

The second stage of drainage installation is the installation of vertical pipes. For a drain with a pipe with a diameter of 90 mm, there is a rule: 1 funnel per 10 linear meters of gutter. For example, if the length of the building’s cornice is 10, then one standing one is mounted on its surface. If the length is greater than this value, but less than 20 m, then two risers are installed.

Although it is possible to install one pipe for a gutter length of up to 10 meters, we do not recommend making a long drain in one direction, since, visually, this slope will be visible and not everyone will like this aesthetic feature. The optimal gutter length for one drain pipe is no more than XXX meters.

This is both beautiful and will protect the system from overfilling during heavy rainfalls

If the length of the eaves is up to 10 meters, but the roof slope is large (more than 70 m2), then installing a rectangular drainage system, for example Vortex, will help, since the throughput of this system is 60% greater.

Grand Line technical specialist

Semyon Grafov

Pipes are fastened to the walls of the house with clamps in increments of 1.5 m. If the height of the house exceeds 10 m, then the installation spacing is reduced to 1.5 m. The clamps themselves are fastened with self-tapping screws through plastic dowels. The main requirement is strict vertical installation. Therefore, at the installation site, first determine the vertical along the wall using a plumb line. Then, measuring the installation step, they make notes in which they drill holes for the dowels.

Installation of a drain pipe riser Source krovlyakryshi.ru

The assembly of pipes, the standard length of which is 3 m, is carried out using the socket connection method. This is when one side of the pipe has a larger diameter than the opposite. That is, the pipes are inserted into one another. In this case, pipes with a large diameter are installed upward. To completely seal the joint, they are treated with a special sealant for roofing work.

Special sealants for roofing works Source grandline.ru

Pipes and trays are connected to each other by funnels. A drain is mounted at the bottom of the pipe riser - this is a branch at an angle of 60°. Here it is necessary to take into account that the lower edge of the drain should be at a distance of 20 cm from the surface of the soil or blind area.

Important! For efficient drainage of water from the house, so that the foundation is protected from destruction, a drainage system should be installed under each drainage elbow of the drainage system.

Also, an important point is that the funnel is attached to the gutter in which a hole is made for draining. In order to make a branch from the funnel to the pipe, which is mounted on the wall at a distance of 30 -80 cm, two pipe bends and a connecting pipe are used. The pipe extends the outlet and has a length of 1 m. The inclination of the outlet is 60°.

Connection of a funnel and a pipe riser with two bends Source obustroeno.com

Installing the outlet funnel

After the installation of hooks for the Metal Profile drain is completed, you can install gutters on them. However, before you install all the trays in place, some of them will need to cut holes for the outlet funnel in advance. The width of this cutout, as a rule, is not less than 10 cm. At the same time, at least 15 cm must remain to the edge of the gutter.

Important: When cutting drainage elements, do not use a grinder! It will burn the polymer coating on the drain, and corrosion can quickly begin in damaged areas. Stock up on a hacksaw and metal scissors.

Now we attach the funnels themselves. We hook the front solid part under the outer bend of the gutter. Then we press the funnel against the tray and bend the teeth on the opposite side of the gutter.

To prevent small debris and leaves from falling into the drainpipe, spiders can be installed on the funnels - special retention nets. But do not forget to clean them periodically, at least once a season, otherwise the throughput of the drain will drop sharply.

How to choose the right drainage system

Just going to the store and buying a drainage system without deciding on its parameters is wasted money. There are certain standards regarding the size of the roof, or more precisely, the area of the slope from which water will be collected into the drainage system. And the larger the area, the larger the dimensions of the trays and pipes should be in terms of their diameter. Therefore, before proceeding with the installation of the drainage system, it is necessary to accurately select its dimensions in accordance with the area of the roof slope.

- If the area of the roof slope does not exceed 70 m², then gutters with a width of 125 mm and pipes with a diameter of 90 mm are installed in the drainage system.

- The slope area is more than 100 m², gutters 150-200 mm, pipes 100-150 mm. Also, with a slope size of 70-110 m², you can install rectangular drainage systems.

- For industrial and civil buildings with slopes of a larger area, systems with gutters with a width of 200 mm or more and pipes with a width of 150 mm or more are used.

Quality, guarantee and price

It is important to note that not all drainage systems are the same in quality.

As in any other case, saving on a gutter system may lead to the need to replace it. Which is almost always more expensive than buying a good quality gutter outright.

One of the important parameters when choosing is a written guarantee for the gutter.

If, for some reason, the manufacturer refuses to provide it to you, you should think about it.

For high-quality drainage systems, the written guarantee has an impressive period of 25-30 years.

The issue of price is now important. Of course, different systems have different prices.

To check current prices, you can use online stores, where prices are updated in real time. For example, in the Grand Line online store.

Heating cable in a drainage system

Ice and snow inside the drainage system create a blockage (plugs) that prevent melted water from draining. As a result, it overflows over the edges of the trays, forming icicles. Everyone knows how dangerous they are. In addition, a large amount of ice and snow inside the trays means there is a high probability of collapse of the entire structure or deformation of its elements. To prevent this from happening, a heating cable is installed in the drain. It is a conductor of electric current that releases thermal energy.

Heating cable inside the gutter of the drainage system Source rooms-styling.com

The heating cable is installed after installing the roof drain. It is simply laid inside the gutters (along) and lowered inside the pipe risers. It is secured in trays with special clamps made either of stainless steel, or galvanized, or plastic.

In addition to the cable itself, the kit includes a power supply and a thermostat. The first supplies the current of the required voltage and strength, the second regulates the temperature of the cable depending on weather conditions. For example, if the temperature outside is -5C, then the cable does not heat up much. If the temperature drops below, the current inside the conductor increases, which increases heat transfer. This is what the thermostat controls.

It should be added that the thermostat itself does not determine the temperature. To do this, sensors are added to the system: either temperature or humidity.

Most often, the heating cable is installed not only inside trays and pipes. They cover part of the roof, or rather the overhang area. Here the conductor is laid in a snake pattern and secured to the roofing material with special clamps. This is clearly visible in the photo below. It should be noted that the heating cable both inside the drain and on the overhang is a single system with one power supply and thermostat.

Heating cable on the roof overhang Source tiu.ru

Drain

A drain is necessary to drain water from the system into the ground. First, it is attached to the end of the pipe, and then fixed to the facade with clamps. Its distance from the ground should be 20 cm. When planning a blind area, you can retreat 15 cm.

If the drain is too close to the ground, ice will form inside the pipe. This will damage it.

Varieties of modern drainage systems by material of manufacture

Traditionally, gutter systems were made of galvanized steel. And today this material has not left the market. They simply began to coat the galvanized drain with paint, thereby matching it to the color of the roofing material, creating a unified design for the house. In addition, the paint layer has protective properties, which increases the service life of the system. Mostly. Durability is ensured by double-sided polyurethane coating applied to galvanized steel with a galvanizing class of 275 g/m².

Today, manufacturers offer galvanized gutters and polymer coating. For economy class systems, steel with one-sided coating and a galvanizing class of 140 g/m² can be used. This means better protection and a huge variety of colors, unlimited in any way.

Plastic drainage structure Source grandline.ru

Plastic gutters are the most popular today. They are made from polyvinyl chloride (PVC). But this material is not used in its pure form, because it itself becomes brittle at low temperatures. Additives are added to it, which increase the strength of the polymer, so PVC gutters are not afraid of temperature changes and sunlight. And the biggest plus is that plastic is the cheapest material.

The modern market today offers drainage systems made of copper or stainless steel.

Copper drain Source pinterest.com

Wall swivel sill

This element is intended to protect the facade at the junction of the roof. It is in this area that water most often damages the roof.

If the slope ends up adjacent to the wall, the ebb is inserted under the shingles and underlayment.

A valley carpet with flexible tiles is laid. It is he who will fix the element.

This completes the installation. When carrying out work, it is important to take into account that installation must be carried out in accordance with all rules, in stages. In addition, the system requires regular maintenance. This will ensure a long service life.