Internal insulation of an attic is one of the most difficult construction tasks. And all because the result is important here: how the roofing pie will behave in winter, whether there will be any leaks, whether there will be a smell of dampness, and whether it will all have to be dismantled later. Why such difficulties? The fact is that no matter how carefully the budget for building a house is planned, as a rule, it is still not enough for everything. To the point that even the owners of the future family home decide to buy laminate flooring cheaper - just to finish the repairs and just start living. And the most popular expense item, which is immediately cut as soon as the lack of funds becomes clear, is attic insulation. “Later, in the future,” the owners promise themselves, especially since insulating the attic from the inside is not a problem at all, and you can start it at any time, even in winter.

In fact, there are a lot of subtleties and nuances here, and therefore, if you have already taken up this matter, carefully study this article. And everything will work out!

General points

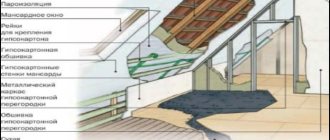

Let's start with the fact that the attic is a bit of a special room. Its overall structure requires a careful, meticulous approach. And the insulation of the attic roof is even more so:

- Mostly vertical or inclined surfaces . Therefore, it is better to immediately exclude all soft “pliable” materials, namely mineral wool rolls.

- It is advisable to focus on materials with low dead weight . Since the rafter system is already experiencing significant loads from wind and snow. In addition, the load on load-bearing walls will not increase much.

- Often insulation is required for gables . They are not always made by analogy with a main wall. May be made of facing material. Or the frame is simply built for insulation.

- It happens that the area of the attic significantly exceeds the size of the house itself , while part of it rests on columns. In this case, you will also have to insulate the ceiling in contact with the street.

If the attic floor protrudes beyond the house, additional insulation of the floor is required. Source metasold.com

It should be understood that the thickness of the insulation must correspond to the weather conditions of a particular climate zone, while having a small margin. To gain the required thickness, the insulation is installed in several layers, and the relatively small dimensions require joining.

Important: splicing any insulation requires a careful approach. The joints of different layers should not be concentrated in one place. To prevent freezing, they should be spaced as far apart as possible. It is important to constantly remember this so as not to spoil the material, especially when insulating a sloping roof.

Materials

The main material of the multilayer system is insulation. The fact that inclined surfaces have to be insulated dictates its own conditions for this material. Preference is given to semi-rigid and rigid thermal insulation materials in the form of slabs. Most often used:

- Polyfoam has good thermal insulation properties, low weight, ease of cutting and installation. Its price is low, which makes it popular. There are disadvantages that need to be taken into account. It is highly flammable and, when burned, releases toxic substances, is not protected from rodents, does not allow air to pass through well and contributes to the formation of condensation.

- Mineral wool. Another type of inexpensive insulation. Installation of mineral wool slabs is quite simple. It is not subject to rotting, does not form condensation, and is resistant to fire. The slabs are laid in several layers, creating a protective layer of 20-25 cm. Such layers require additional measures against sagging.

- Foamed polyurethane foam. This material is gaining popularity due to its ability to create a thermal insulation layer on any surface. It is produced in liquid form and is saturated with gas using special equipment. This mixture is applied to the surface and hardens, creating a uniform coating with a high thermal insulation coefficient. The disadvantage of the material is its high cost, the need for special equipment and installation by qualified specialists.

- It is worth considering very carefully a modern version of a thermal insulation material that can replace a bulky multilayer structure. We are talking about Teplofom thermal insulation panels. Designed to create the most effective combination of layers at a small thickness, the panels have a thermal insulation layer of extruded polystyrene, covered with a durable layer of polymer cement and reinforced with fiberglass mesh. This design gives them advantages in many ways, such as:

- high thermal insulation characteristics, a layer of material 10 cm thick is capable of retaining heat on a par with one and a half meter walls made of hollow brick, 60 cm of aerated concrete or 40 cm of pine boards;

- vapor tightness;

- moisture resistance;

- strength combined with flexibility, which allows it to be used to create curved surfaces;

- durability, panels made using this technology have withstood a service life of more than 30 years;

- versatility in use, the material can withstand a wide temperature range (from -50 to 75 degrees Celsius) and is suitable for interior and exterior decoration, walls, floors, ceilings;

- ease of installation, not requiring professional skills;

- Full readiness for finishing without additional measures

Preparation

All wooden surfaces must be treated with antiseptic and fireproof impregnations.

All wooden components must be treated with protective materials Source remontik.org

It is necessary to immediately identify “unreliable places” on structural elements. For example, the connection of the outer rafter to a pediment made of facing bricks. Or an overlapping connection between a rafter and a screed, made without insulation. It is necessary to eliminate the shortcomings - if possible, foam them or line them with a sealant. Otherwise, they will not be able to withstand through blowing and freezing.

It is necessary to minimize the use of metal fasteners. This is especially true for metal linings secured with bolts. Of course, the bolted connections will remain, but the plates should be made from thick, durable plywood and replaced. The remaining metal parts are painted with primer-enamel and covered with a layer of polyurethane foam. Metal directly in the insulation is a source of condensation and dampness.

Insulation of the rafter system

It’s great when the insulation of the attic from the inside was planned in advance, or “just in case” the constructive points for this were observed by the builders:

- A roofing membrane is mounted on the rafters.

- A counter-lattice is provided.

- The pitch of the rafters is maintained corresponding to the common length or width of the insulation.

It is convenient to carry out insulation if it was planned at the construction stage Source bamban.ru

It is worth noting that these are ideal initial data that allow you not to look for a “way out of the situation” and to insulate the maximum volume of the attic efficiently without extra costs. Such conditions make it possible to use vapor-permeable insulation. And these are comfortable living conditions.

See also: Catalog of projects of houses with an attic presented at the exhibition “Low-Rise Country”.

Common mistakes

Insulating an attic is a costly and difficult task. To ensure that the result does not disappoint and that money is not wasted, scrupulous adherence to the technology of work is required if they are carried out independently and control over them in the case of work by third-party specialists.

The most common errors include the following:

- Absence or incorrectly installed layers of hydro- and vapor barrier. This leads to moisture getting inside the insulation, thereby reducing its thermal insulation properties and creating favorable conditions for the development of fungus.

- Failure to comply with ventilation clearance standards. Condensed moisture cannot be evaporated and the system becomes a breeding ground for fungus.

- Loose fit of insulation slabs to the rafters and non-compliance with the rules for laying slabs with overlapping seams, as well as poor-quality sealing of all kinds of technological holes. These shortcomings lead to the formation of cold bridges and reduce the effectiveness of the insulation system.

- Compaction of soft insulation when laid in cells between rafters. Such actions reduce the heat-shielding properties of the material, which affects the final result. If the height of the rafters is less than the layer of insulation being laid, then the best solution would be to install slats on the rafters to increase the depth of the cells.

- Mistakes include using roll insulation instead of slabs. This material is intended for horizontal surfaces, but on inclined surfaces it can sag and slide, creating gaps that are not protected from the cold.

- Even at the construction stage, all wooden roof elements must be treated with antiseptic agents. If the elements are metal, then use anti-corrosion agents. This will protect the roofs from destruction even if moisture gets into the insulation system.

Insulation of an unprepared roof

When the decision to insulate is forced, the roof is usually not prepared. There is nothing terrible about this, it is even possible to choose the following options:

- Insulate with materials that do not require waterproofing.

- Build a special frame for living space.

In case of insulation of a roof that is not prepared for this, special compounds can help Source paspraypros.com

Foamed polyurethane foam can play a special role here. Although equipment is required to apply it, insulation occurs in a continuous layer and does not depend on the design features of the roof.

Foamed polyurethane foam is one of them Source da.decorexpro.com

This also includes ecowool. Although its installation requires a roofing membrane, it is quite possible to make a continuous layer of insulation.

Answers to popular questions

What is the best insulation for an attic under metal tiles?

Metal tiles do not place any special requirements on insulation. All types of mineral wool and foam plastics are suitable. The main condition is a sufficient layer of insulation, reliable waterproofing and vapor barrier.

Soundproofing insulation should be installed under a metal roof. Basalt wool and polystyrene foam have these qualities. In addition, roll and block insulation materials with a soundproofing substrate are produced.

How to insulate an attic if the roof is without waterproofing

If there is no waterproofing, it should be installed. With a cold roof, the absence of a water barrier is not critical - if there is no difference in the external and internal temperatures, there will be no condensation, as well as ice dams.

If you install a roofing pie for a warm attic without waterproofing, the insulation will get wet and lose all its performance properties.

The waterproofing film can be laid from the inside, securely connecting the joints. In this case, the need for ventilation under the roofing should be taken into account. Therefore, there must be an additional sheathing above the waterproofing film to create a ventilation gap. If there is no gap, the roofing material is laid on the rafters, then it must be removed.

Waterproofing is laid on top, connected without gaps, sheathing is made and the roofing is installed.

Effective insulation

Next, we will consider the most effective materials that do not require serious equipment in order to efficiently insulate the attic.

Stone wool

Due to their elasticity, the mats adhere well between the rafters and allow installation without additional fastening. And the relatively dense structure of stone wool prevents its shrinkage over time. Therefore, it has proven itself well on vertical surfaces.

Stone wool mats come in different thicknesses, and you can choose the one you need based on climatic conditions and other materials used Source pallazzo.su

To further reduce the risks, every 3 meters of height it is necessary to arrange supports for the insulation - add a horizontal frame element.

Teplofom panels for waterproofing

From the above it can be understood that protection from moisture is a very difficult and labor-intensive process. At the same time, there is a way to reduce the cost of time, materials and labor to a minimum. This is possible when using Teplofom panels. Why does this happen:

- All work on hydro- and vapor barrier will be reduced only to the installation of panels.

- This material is not afraid of moisture (moisture absorption is 0.1%), which means that no additional membranes are required to protect it. Accordingly, you will not have to lay insulation and film several times.

- The resulting surface is not subject to the risk of mechanical damage and is ready for finishing.

Proper completion of work

The insulation has been installed, but the process must also be completed correctly. It must be protected from damp vapors from the room. For this, a vapor barrier film is installed. Moreover, the overall result greatly depends on the thoroughness of execution. Although each package is supplied with instructions, let us briefly repeat:

- The subsequent canvas overlaps the previous one by at least 15 cm.

- The joints are taped with special tape.

However, attic vapor barrier has a dual purpose. Oddly enough, it also protects the residents themselves. The fact is that vapor-permeable insulation is not strong enough and can be slightly weathered. From the outside this is not so important, plus it is protected by the roofing membrane. And inside it is necessary to exclude even the minimal possibility of the insulation components being released into the air - to reliably cover it.

The final stage is covering the insulation with canvases, on which the finishing is subsequently applied. Source obustroeno.com

Of course, this does not apply to Penoplex. But it is also recommended to protect against it; an effective material is penofol.

As for insulation of any type. In addition to the vapor barrier device, a technique that at first glance is unnecessary, but effective, is often used. Before finishing, intermediate, seemingly unnecessary material is installed. It can be OSB, GVL or GKL - it depends on the design. Moreover, the technology is fully observed - all joints are carefully sealed. This is an additional barrier against the unwanted effects of materials.

Consumer Reviews

Information from consumers who have already used this or that material will help you choose insulation.

It is very undesirable to insulate the attic with polystyrene foam (expanded polystyrene), not even because it will not breathe, but because the flammability class of this material is maximum suitable for insulating the foundation or floors for pouring.

It is definitely better to insulate with basalt insulation (Rockwool or Parok), but if you already want to save money, you can insulate with fiberglass such as Ursa, Knauf, Izover. NikopolSPb

https://www.forumhouse.ru/threads/152214/

Foam plastic, oddly enough, has vapor permeability just like wood.

That is, it breathes like a tree. Combustible current. There are imported dampening foams, but they are expensive. If you use mineral wool, then only dense, hard slabs. Density 50–70 kg/cu.m. The thickness of the insulation is at least 20 cm. The attic is residential. On the warm side there is a vapor barrier, a layer of mineral wool, then a vapor-permeable windproof membrane. Rolled mineral wool (Isover, Ursa, etc.) cannot be used for insulating walls and attics; they settle. And their thermal resistance is generally worthless. These insulation materials are used only for insulating hot pipes. So, vapor barrier films burn cleaner than polystyrene foam and the air from them is no less bad. Films are evil, but without them mineral wool is a dummy. And the thermal resistance of many mineral wool with a density of up to 50 kg per cubic meter is, to put it mildly, exaggerated. In general, the Moscow government issued an order banning the use of water and windproof films in ventilation facades. Sarma38ru

https://www.forumhouse.ru/threads/152214/

I would advise using penofol (10 mm) + polystyrene foam 20 mm (this is the same as what you call penoplex).

This pillow will hold enough. But when insulating the attic, the question arises with the removal of condensate - if the roof is cold. Gainov Ramil Fagimovich

https://www.remontnik.ru/forum/post/8218/

Before recommending insulation of the attic, you need to study the load-bearing structure of the roof, how the rafters, braces, screed slopes, etc. are located, whether there is step-by-step lathing and counter lathing.

It is necessary to arrange channels for external ventilation of the roof and removal of condensate. Otherwise, the lumber will begin to rot. Depending on the roofing materials and the cross-sectional height of the rafters, it is necessary to choose a method of insulation. If the roof structure and the height of the rafters allow it, it is better to lay mineral wool of at least H-200 mm (for some specialists, I will decipher MINERAL BASALT WOOL, abbreviated as mineral wool), with the required membranes under one or another roofing material. When laying mineral wool, you should take into account and install the transverse thermal insulation of the rafters themselves (like a cold bridge). If the height of the rafters in section, only materials such as EPS (based on its thermal characteristics) are allowed. You should approach this issue very carefully; you need to make additional waterproofing of the rafter structure, carefully think through and arrange for the removal of condensates. Otherwise, in three to five years you will be left without an attic. But it’s better, of course, to invite a competent roofing specialist so as not to waste your nerves and extra money! I hope I helped with advice. Good luck! Barinov Dmitry Ivanovich

https://www.remontnik.ru/forum/post/8218/

ECO-WOOL!

do a search and study. I insulated my dacha house with it. And the attic too. I don’t know the disadvantages... There are a lot of advantages. Let's start with the fact that you won't have to disassemble anything... AND - THE MOST EFFECTIVE material for thermal insulation. А1ех

https://forums.drom.ru/house/t1151797950.html