Flooring is necessary when building a private new home, but also when you need to replace old rickety parquet, covering or floorboards that constantly creak.

Installing a wooden floor on joists is an excellent solution. They will not only get rid of squeaks, but will also improve the thermal insulation of your home, level the surface and help hide various communications and wires from prying eyes. You will learn below how to make a wooden floor in this way in your home with your own hands.

What are ceilings and floors?

The fact that a house is made of wood presupposes that all parts of the construction are made of this material. Thus, logs are wooden floors that serve to enhance the stability of the log structure and as a base for the floor and ceiling. Logs in a log house are important elements in the construction of a residential building.

They come in several types: Let's take a closer look at the advantages and disadvantages of all. What do you need to know about each of them before starting construction? Pros:

Now about the cons:

- Weight. This is due to the fact that shrinkage of the house can deform the entire structure. And then the weight of the log will be a threatening factor for the ceilings. This is especially true for multi-storey construction.

- Price. If, when buying a turnkey house, the cost of lumber is not specified separately in the contract, then you need to ask a company representative about this. It may turn out that they will charge for them separately, but a solid log, whether it be the floor joists of a log house or the ceiling ones, is not cheap.

- It will not be easy to install such structures. After all, you will need more than one thing.

What interior style are ceiling beams suitable for?

The ceiling, decorated with logs, gives the room an unusual look, transforming it. Ceiling beams not only improve the appearance of the ceiling, but also influence the microclimate in the best possible way. Modern designers believe that this type of decor will decorate any room, no matter what style it is decorated in. The main thing is to choose the most suitable material, shape and color of the ceiling decor.

There are interior styles in which ceilings with beams look most advantageous. For example, wooden types are especially good in interiors decorated in a classical style, as well as Victorian and Scandinavian. This type of decoration additionally emphasizes the atmosphere in a rustic interior and gives an original touch to the interior in country and Provence style. In houses decorated in high-tech style, ceilings are also good, only made of metal. They emphasize the functionality and restraint of this style.

The ceilings can be left untouched, preserving the natural structure of the wood, or they can be painted in different colors, giving the interior originality. For example, for the Provence style, light colors are usually used, creating a certain lightness and airiness in the room. For the chalet style, the use of natural wood, often roughly processed or even with bark, is more suitable.

Timber logs

Unfortunately, this option has more disadvantages:

- High cracking potential. It is best to use timber for the floor. Or take a section for the ceiling no smaller than the one from which the crowns were erected.

- The beam is springy. Having danced on housewarming day, the owner risks first jumping on the trampoline and then falling into the basement due to a broken ceiling. It’s scary to think what awaits such lags on the ceiling.

- When the house shrinks, there is a possibility that they may be pulled out of the grooves. And even inserting a log into a frame and then securing it is little hope for stability. Of course, nothing bad will happen before the construction of the rafter system.

But shrinkage is a phenomenon that happens all the time. Therefore, when the lags “play” is an open question.

Room correction options

Logs are a universal tool that allows you to adjust and improve any home. They can be placed over the entire surface or partially, choose clear shapes or unusual designs. There are many styling options, you can always find your ideal option. European design is very popular these days, in which the joists are moved to the wall.

Floors are subjected to the following types of treatment:

Brushing. In this case, a realistic imitation of wood texture is created. They even make marks from the bark beetle. This method is used when you need to create a spirit of antiquity in a room.

Textured processing is another method of artificially aging wood. This effect is achieved by treating the wood with special brushes and a special planing technique.

Vintage style - the ceilings are treated with paints and varnishes, also giving them an antique look.

Traditional style combines simplicity and lightness. A room decorated in this style is especially cozy and comfortable. For this effect, a varnish or oil-wax coating of the floors is done.

Self-installation

Next, it’s worth describing the process in detail - how to install logs in a log house. This is important information for beginners. So, let's start with the floors; the actual installation of the ceilings is no different from this:

- Having chosen the option, you need to start inserting from the second crown of the log house, already laid and secured with dowels.

- The insertion of lags is carried out using the dovetail method. That is, the gash represents a carved void in the crown, and the log is a figure. By inserting one into the other, fastening is performed. The crown should not be cut down before it comes out. It is enough if the “tail” is equal to half of the log or timber.

- The elements need to be secured using reliable material - one notch will not be enough. The longitudinal logs are always placed first, then the transverse ones. The pitch of one from the other is calculated from the material - the log can be laid at a distance of 1300 mm, and the boards will require no more than 700 mm.

- After installation, the question of how to embed logs into a log house is no longer of interest; you need to give the house time to shrink and look at the behavior of the newborn elements. It is quite possible that after some time there will be a need to correct them.

Causes and possible solutions to lag-related problems:

- Falling out of cutting or cutting areas due to inappropriate size. This may indicate a low qualification of the hewer.

- Deflection indicates poor drying of the material. This is especially noticeable when installing log joists. Protruding - the same thing.

- Also, ceilings may generally fall out of the grooves if the deformation of the log house is severe. Therefore, to avoid this, there is no need to mount the ceiling elements immediately and make them exactly to length. It's better to cut it off later.

- When it comes to fasteners, it is important to remember that they must fit snugly into the wood and even be recessed into it.

- If, after a period of time, damage is noticed on the material, then ignoring it risks the whole house. It is better to replace such a lag or try to fix it by chipping. But if there is no effect, you need to buy a new one.

That's all. The process that requires attention is outlined. However, if you still have questions, don’t hesitate to ask them to experienced ones.

Selecting the material for load-bearing structures, which are logs, requires great care. The stability of the structure as a whole depends on this. One should not neglect the method of cutting and chopping - they were not invented in vain, and have been tested for centuries.

Until the house has been shrinked and dried, you should not do any work in the log house, and even more so there can be no talk about the rafter system. It is better to devote this forced downtime to supplying communications and choosing interior decoration. After all, with the finishing touches coming soon, these benefits of civilization will be needed more than ever. Good luck!

Methods and rules for installing floor and ceiling joists in a log house

A strong construction of crowns in a wooden frame alone will not be enough without strengthening them with logs. In addition, without them it will be impossible to lay either the floor or the ceiling. What they are, how they are installed, and construction features will be described below.

How to install beams on the ceiling with your own hands?

Many who want to decorate their interior with such an element are wondering how to make beams on the ceiling themselves? Let’s say right away that this matter is quite accessible to non-professionals; it is enough to carefully study the material on this topic. It’s also good to consult with a familiar master, if you have one. We will briefly describe the installation algorithm in this article.

First, metal profiles are installed on the ceiling, and wooden logs are attached to them using self-tapping screws. Since the heads of the screws do not look aesthetically pleasing, they are slightly recessed into the wood and masked with a decorative plug matched to the tone of the ceiling.

Metal beams on the ceiling can only be installed by professionals. After all, they have a lot of weight, plus they require special tools and equipment. So in this case it is better to use the services of professionals.

What are ceilings and floors?

The fact that the house is made of wood implies that all parts of the construction are made of this material. Thus, logs are wooden floors that serve to enhance the stability of the log structure and as a base for the floor and ceiling. Logs in a log house are important elements in the construction of a residential building.

They come in several types:

- Solid log.

- Prefabricated.

- Timber.

Let's take a closer look at the advantages and disadvantages of all. What do you need to know about each of them before starting construction?

Solid log

- If the owner understands the importance of solid logs in house construction, then it is no secret that he will choose just such floors for his own home. They are supplied along with the material according to the contract. What are they good for? Firstly, there is no doubt about their stability - the array has always been famous for this quality. Secondly, when turning a log into ceiling joists in a log house or flooring, material suppliers know exactly how much sapwood needs to be removed without damaging the log.

- Further, it is an important fact that the internal appearance of a wooden house must match the external one. That is, if the log house is a log, the logs should be the same - it’s very beautiful.

- Weight. This is due to the fact that shrinkage of the house can deform the entire structure. And then the weight of the log will be a threatening factor for the ceilings. This is especially true for multi-storey construction.

- Price. If, when buying a turnkey house, the cost of lumber is not specified separately in the contract, then you need to ask a company representative about this. It may turn out that they will charge for them separately, but a solid log, whether it be the floor joists of a log house or the ceiling ones, is not cheap.

- It will not be easy to install such structures. After all, you will need more than one thing.

Now about the cons:

Timber logs

Unfortunately, this option has more disadvantages:

- High cracking potential. It is best to use timber for the floor. Or take a section for the ceiling no smaller than the one from which the crowns were erected.

- The beam is springy. Having danced on housewarming day, the owner risks first jumping on the trampoline and then falling into the basement due to a broken ceiling. It’s scary to think what awaits such lags on the ceiling.

But shrinkage is a phenomenon that happens all the time. Therefore, when the lags “play” is an open question.

Prefabricated structures

They consist of three boards with a cross-section of 50*150 mm, fastened together with pieces of the same lumber and anchor bolts, and laid on edge. Today this design is considered the most reliable.

Well, the disadvantages of such logs are the same as for wood in general. That is, susceptibility to rotting, shrinkage, etc.

Self-installation

- Having chosen the option, you need to start inserting from the second crown of the log house, already laid and secured with dowels.

- The insertion of lags is carried out using the dovetail method. That is, the gash represents a carved void in the crown, and the log is a figure. By inserting one into the other, fastening is performed. The crown should not be cut down before it comes out. It is enough if the “tail” is equal to half of the log or timber.

- The elements need to be secured using reliable material - one notch will not be enough. The longitudinal logs are always placed first, then the transverse ones. The pitch of one from the other is calculated from the material - the log can be laid at a distance of 1300 mm, and the boards will require no more than 700 mm.

- After installation, the question of how to embed logs into a log house is no longer of interest; you need to give the house time to shrink and look at the behavior of the newborn elements. It is quite possible that after some time there will be a need to correct them.

Causes and possible solutions to lag-related problems:

- Falling out of cutting or cutting areas due to inappropriate size. This may indicate a low qualification of the hewer.

- Deflection indicates poor drying of the material. This is especially noticeable when installing log joists. Protruding - the same thing.

- Also, ceilings may generally fall out of the grooves if the deformation of the log house is severe. Therefore, to avoid this, there is no need to mount the ceiling elements immediately and make them exactly to length. It's better to cut it off later.

- When it comes to fasteners, it is important to remember that they must fit snugly into the wood and even be recessed into it.

- If, after a period of time, damage is noticed on the material, then ignoring it risks the whole house. It is better to replace such a lag or try to fix it by chipping. But if there is no effect, you need to buy a new one.

That's all. The process that requires attention is outlined. However, if you still have questions, don’t hesitate to ask them to experienced ones.

Selecting the material for load-bearing structures, which are logs, requires great care. The stability of the structure as a whole depends on this. One should not neglect the method of cutting and chopping - they were not invented in vain, and have been tested for centuries.

Based on materials from the site: https://1drevo.ru

Are you the happy owner of a log house, but don’t know what flooring to use? Then this article is for you - here we will look at implementation options and installation steps.

Let's start, perhaps, with the classics for this type of construction.

Prefabricated structures

They consist of three boards with a cross-section of 50*150 mm, fastened together with pieces of the same lumber and anchor bolts, and laid on edge. Today this design is considered the most reliable.

- When inserted, they are held firmly in place.

- They are processed before installation, which is easier than climbing the ceiling to get to a log or timber.

- They will not spoil the appearance, because in this case it is customary to sew up the ceiling.

Well, the disadvantages of such logs are the same as for wood in general. That is, susceptibility to rotting, shrinkage, etc.

Wood floors - general provisions

It is also very convenient to make the floor in a wooden frame from wood, so as not to disturb the natural harmony. A floor covering made of material identical to the entire building will only increase the warmth, comfort and softness of shades provided by the log house.

And although humanity has used wood as indoor flooring throughout its history, new, constantly improving installation technologies can sometimes surprise even experienced craftsmen.

In order to be less surprised and be able to carry out the installation yourself, let’s look at all the nuances of this important matter.

Single layer coating

The peculiarity of this coating is that it can be laid either with or without joists. This is affected only by the thickness of the boards being laid. In this case, the distance between products should be no more than sixty centimeters.

Double layer coating

The peculiarity of this floor is that it also has a rough layer on which the insulation material is laid. Both sheet versions and a mound of expanded clay can be used as an insulating material.

Advice: between the finishing and insulating layers you should leave a void of about two centimeters to ensure ventilation. This will prevent the boards from breaking.

When you make a subfloor in a log house with your own hands, you need to consider the following points:

- The rough layer should act as a rigidity frame for the entire structure and be the most durable.

- mineral wool;

- polyurethane;

- expanded polystyrene;

- glass wool;

- mineral mats;

- polystyrene foam, etc.

Also very important is the creation of ventilation. Regular ventilation flows dry the base and prevent the appearance and spread of rot and mold.

For this:

- We drill holes in the corners of the room or under the walls in a convenient place with a diameter of about half a centimeter.

- We close the cluster of holes with decorative special grilles.

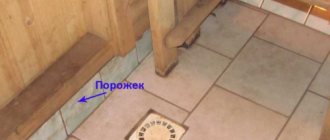

- Alternatively, ventilation can also be done in the floor fillet.

Mounting methods

Depending on the location of the logs, there are several methods for attaching them. Previously, when installing this floor on a concrete screed or reinforced concrete beams, the logs were attached using simple long nails, but this method was not distinguished by its durability.

Currently, more reliable devices are used for fastening - U-shaped fasteners or galvanized metal corners. The corners, on the one hand, are fixed with self-tapping screws to a wooden beam , and on the second - to the base with dowels. The depth of insertion of the fastening into the beam is 3-5 cm. If you arrange the floor on the ground for brick pillars, then the algorithm of actions is similar.

Sometimes the logs are not long enough, so many are interested in how to build up the timber so that it is as strong as solid material. The logs can be joined end-to-end or by notching , and in both cases the length of the extended element is at least one meter. And if you need to increase several of them at once, you need to shift the joining points by 50 cm or more so that the load is uniform.

The logs are fixed to the wooden floor beams using screws . The length of the fasteners must be 2.5 times greater than the width of the joist, and the diameter must be at least 6 mm. To protect the wood from splitting, before installing the fasteners, the joists and beams should be drilled in the required location. And the diameter of the hole should be 2.5 mm less than the mounting diameter.

Installation of wooden floors

We have become familiar with the general provisions of this type of coating. Now we will consider in detail the construction of the floor in a log house, made in different ways.

On support pillars

- We remove soil from the underground to a depth of half a meter.

- Pour gravel or river sand into the freed space. We wet each layer of the embankment and thoroughly compact it with a vibrating plate.

- At the end of the process, the level of the pillow should be twenty centimeters higher than the chernozem.

- We install support pillars around the perimeter of the building, and then on the inside. We use red bricks or ready-made concrete products as pillars. The installation step is 70-90 cm. We maintain a distance of about a meter between the rows.

You should know: in buildings with a small area you can do without internal supports. Since they can be completely replaced by floor beams.

- We lay waterproofing in the form of plastic film or roofing felt on top of the supporting products.

- We install timber logs on the water-repellent material.

- Using a spirit level, we level the level of the joists by placing wood wedges.

- We place them at a distance of about seventy centimeters from each other, securing them with nails.

- We lay the boards on top along the light falling from the window.

- We install the first one, retreating 10-15 mm from the wall. This will ensure air movement under the decking. When finishing the interior, we will cover it with a baguette.

- For better fixation, hammer the nails at an angle. We choose their length so that they are at least twice the thickness of the wood product.

- We putty the joints and nail heads and paint. After drying, the coating is ready for further work.

This method of implementing flooring is convenient in buildings that are heated during the cold season. Because frost causes the gravel or sand cushion to expand and can damage or displace the support pillars.

Single from boards

In this case, two execution paths are possible.

- If the distance between supports does not exceed one meter:

- We lay beams on the ends of the supporting columns.

- We fix the boards on them with nails.

- If the distance between supports is more than one meter:

- On top of the beams we install logs in the form of beams with a cross-section of 5 cm and a pitch of 50-60 cm.

- We check the evenness of the surface with a spirit level. If necessary, level it using pads.

- After leveling the sheathing, we fix it with steel nails.

- Only after the work has been done can the rough or finishing coating be applied.

In both cases, when installing the rough layer, an unedged board is used, and when installing the finishing layer, an unedged board is used.

Double plank

Subsequently, linoleum or laminate can be laid on the rough surface. The finishing one is covered with several layers of varnish.

The price of such work is relatively low, which makes this method the most accessible. A significant disadvantage is poor thermal insulation.

Double plank

Double coating, as we noted earlier, means the presence of both rough and finishing layers.

The following instructions will help with its installation:

- We install cranial bars on the surface of the beams.

- We tightly install unedged boards about thirty millimeters thick across the bars. Even the use of low-grade lumber treated with anesthetics is allowed.

- We create a thermal insulation layer on top. Suitable materials for this are listed above. It is also worth mentioning the possibility of implementation. What will be the most effective, but also expensive solution.

tongue and groove floorboard.

Subsequently, linoleum or laminate can be laid on the rough surface. The finishing one is covered with several layers of varnish.

The price of such work is relatively low, which makes this method the most accessible. A significant disadvantage is poor thermal insulation.

Double plank

Double coating, as we noted earlier, means the presence of both rough and finishing layers.

The following instructions will help with its installation:

- We install cranial bars on the surface of the beams.

- We tightly install unedged boards about thirty millimeters thick across the bars. Even the use of low-grade lumber treated with anesthetics is allowed.

- We create a thermal insulation layer on top. Suitable materials for this are listed above. It is also worth mentioning the possibility of implementation. What will be the most effective, but also expensive solution.

A tongue-and-groove floor board is a lightweight solution to the problem.” href=”https://shkolapola.ru/derevyannie/394-shpuntovannaya-doska-dlya-pola”>tongue-and-groove floor board.

Subsequently, linoleum or laminate can be laid on the rough surface. The finishing one is covered with several layers of varnish.

The price of such work is relatively low, which makes this method the most accessible. A significant disadvantage is poor thermal insulation.

Double plank

Double coating, as we noted earlier, means the presence of both rough and finishing layers.

The following instructions will help with its installation:

- We install cranial bars on the surface of the beams.

- We tightly install unedged boards about thirty millimeters thick across the bars. Even the use of low-grade lumber treated with anesthetics is allowed.

- We create a thermal insulation layer on top. Suitable materials for this are listed above. It is also worth mentioning the possibility of implementation. What will be the most effective, but also expensive solution.

I-11=»»>Concrete flooring

It is necessary to pay attention to this method of resolving the issue.

Although this is not the most harmonious solution to the issue, it can also be used.

- We determine the level of the screed by marking it along the perimeter of the walls.

- Cover the base with plastic film for waterproofing.

- Pour in the cement mortar and also cover the top with film to speed up hardening.

- We moisten the surface for a month to prevent it from cracking.

- Next, for convenience, you can use a self-leveling mixture and pour it onto the concrete screed surface.

.

Linoleum tiles: selection and technology for installing vinyl covering” href=”https://shkolapola.ru/elast/linoleym/raznovidnosti/288-linoleumnaya-plitka”>tiles, laminate, linoleum

.

I-12=»»>Conclusion

The wooden house is cozy, warm, bright and lively. Floors in such a structure should be made of a similar material to enhance the positive effects.

A cement base is also suitable, but it will always give off an alien feel in the abode of nature. In addition, an appropriate foundation should be laid under it.

Wood flooring has several ways of implementation. Choose the one that best suits your preferences, needs and budget. And be sure to take care of high-quality insulation.

The video in this article will provide more material on this topic. In general, installing floors in a log house is not very difficult. Good luck with your construction work!

» width=”640″ height=”360″ frameborder=”0″ allowfullscreen=”allowfullscreen”>

To install the floor of a wooden room, logs are used. They are round logs made of pine or other types of wood. An important condition for their installation is low humidity of the building material. Alignment of log logs is carried out if during assembly the condition of compliance with the level was not met, the lumber has defects, or it is not dried well enough. Therefore, all work related to the installation of the floor is carried out several months after the completion of construction, after the log house has given its final shrinkage.

| Name of works | Unit | Price |

| Floor construction | ||

| Installation of logs | PC. | 1000 |

| Alignment of logs | m2 | 200 |

| Subfloor in a log house | m2 | 220 |

| Vapor and waterproofing | m2 | 70 |

| Insulation of the floor in the log house (50mm) | m2 | 60 |

| Laying plywood | m2 | 220 |

| Finish floors in a log house | m2 | 400 |

| Skirting | m.p. | 100 |

Get an individual price

Leveling floor joists in a wooden house: basic methods, advantages, disadvantages

There are 3 main methods of leveling log logs, tested by masters:

- ● Chopping the surface with an axe, plane, saw, chisels. To do this, a rope level is placed along each log, along which further alignment occurs. Next, using an electric saw, chainsaw, or ax, a layer of wood is removed, not reaching the marked line of 5 cm. The remaining layer is removed with chisels (plane). The disadvantage of this method is that it is labor intensive and reduces the strength of the structure, as the thickness of the material becomes smaller.

- ● Fastening of edged boards. The sides of the log are subject to cutting off part of the wood. An edged board with its wide side, set straight, is attached to the resulting planes. Fastening is done with hardware with a maximum length of 150 mm, staples, fastening step - 0.5-1 m. The recommended board size is 40 mm thick, 100/150 mm wide.

- ● Horizontal installation of edged boards. Their leveling occurs by laying wedges between the lag and the board. But the ceiling height decreases.

All methods have been tested by the company’s specialists, they give a good result - a flat floor.

Correct level marking when leveling log logs

Alignment of log logs is carried out according to the level. To do this, a basic “zero” floor level is marked, placed 5 centimeters above the main one. Using a laser device or a long tube filled with water, nails are driven at the same height in each corner. Along the perimeter of the room, twine (construction fishing line) is attached to them. More nails are placed above each lag, on which a thread running along the log is also secured. Then equal distances are measured from the obtained level and corresponding marks are made on the tree. This creates the layer that needs to be removed for leveling.

We trust the leveling of floor joists in a wooden house to professionals

In order not to be disappointed in the results obtained, engage professional craftsmen and carpenters to perform work related to the arrangement of a wooden house. They must know all the features of the work being performed, the material, and the technology. Don't try to save money by doing everything yourself. When arranging floors, your mistakes will become fatal. It is recommended to contact official companies that are ready to enter into a written cooperation agreement. This way you will protect yourself from unscrupulous performers.

4 reasons to contact us for lag leveling

To ensure the floor is perfectly level, contact.

We will provide our clients with:

- ● Drawing up an estimate based on measurements made by our specialists. Their departure is free for you.

- ● Services of all types of log finishing (carried out by craftsmen from Russia and Belarus).

- ● Independent delivery of your own scaffolding (for working with logs on the attic, second floor).

- ● Possibility of payment only for work actually completed.

Call us, we will make the logs smooth, right on time!

Which floor arrangement should I choose?

With decorative ceilings you can achieve different effects in a room, for example, making it visually wider or longer. By installing massive beams on the ceiling, you will achieve a visual expansion of the space.

You can make a room longer if you distribute the crossbars evenly over the entire surface. You can achieve more space in the room by placing the logs crosswise.

A kitchen with a bar counter can be decorated in an interesting way by placing just one crossbar at the level of the counter.

The frequency of the location of the floors also matters. In rooms with high ceilings they can be placed quite close to each other. When the ceiling is of medium height, it is better to space the logs sparsely. When using metal floors, they are often used for electrical wiring, lowering lamps from them directly above the desired area.

No matter how you arrange the logs, and no matter what materials you use, a room with such decor looks unusual and exclusive.