Wood is a natural and traditional way of building houses, which is still actively used in construction, despite its shortcomings (by the way, they are trying to correct them in different ways). Now there are a lot of materials that consist of wood only to a certain percentage, which allows you to retain its positive properties and get rid of the negative ones. Despite the fact that such materials are not harmful to health, they are not used as actively as pure wood.

Thus, wooden log houses do not lose their popularity and are significantly increasing in price. Such a house has a lot of advantages, however, to make it truly comfortable to live in, it is important to correctly perform some additional work. One of them is caulking a log house, or, more simply, sealing the cracks that form between the logs and at the joints.

A characteristic disadvantage of houses built from logs or profiled timber is the presence of a large number of cracks in the walls. For log cabins, another problem is relevant - during the drying process, the logs can crack, as a result of which their thermal resistance is significantly reduced.

This process is important because it eliminates drafts and makes the home more energy efficient, eliminates the possibility of mold, mildew and condensation, and also helps keep the logs intact.

Caulking technology and methods

Two classic ways to fill inter-crown seams – caulk “set” and caulk “stretched”

Wide seams are caulked using the “set” method. The insulation is formed in the form of flat loops and the inter-crown cracks are filled with them tightly, completely, until the insulation enters.

With the “stretch” method, insulating materials are slightly stretched along the fiber in the form of a sheet, and a special tool called a caulk is pushed into the gaps between the crowns. The insulation sheet remaining outside the gap is rolled up with a roller and driven tightly into the gap.

The most difficult thing to caulk is the corners of the house, due to cramped conditions and inconvenience of work. But it is in the corners that you should caulk especially carefully, since the corners are the main cold bridge of a wooden house, and are blown even more than window openings.

The technology is simple, but the work is very long and painstaking. It’s not difficult to master caulking; the point is to fill the seams with insulation as evenly and densely as possible, and the skill, as usual, comes along the way. Caulking is carried out using heat. They start working from the lower crowns, from the very bottom. Fill the seam, passing it around the entire perimeter, first from the inside and then from the outside. After passing the perimeter of one crown twice, you can proceed to the next crown, and so on for the entire frame. Under no circumstances should you caulk walls and corners in sections, or one wall or partition at a time. This can distort the entire frame. The shrinkage of the frame is uniform, but caulking can create uneven rises of the crowns, ultimately leading to a general uneven deformation.

If tape insulation is used, then before caulking, carefully straighten it and lay it out along the entire length of the crown or wall. They start from the corner joint, hammering the end of the tape insulation into it, and then evenly pass along the entire perimeter of the crown, laying and hammering the tape into the gap, and thoroughly compacting it. Caulking requires great care and does not like to be rushed. The insulation strips should not be twisted, but should be wrapped in a tight, tight roller.

It is necessary to caulk a log house regardless of whether it will be finished inside or along the façade. Caulking will not only insulate the log house, but will also not prevent infection and rotting of the logs. It is unacceptable to caulk the log house only from the inside or only from the outside, for the reasons given above - this can cause distortion and deformation of the log house.

Time to caulk timber walls

If you start sealing the cracks between the crowns of the log house too early, then after a while all the work will have to be redone. This is due to how the gaps are formed. During the first stages of operation of a log house, the wood completely dries out, which is why it significantly decreases in size. Plus, the bathhouse shrinks - the crowns fall down, and unevenly. Stronger below, weaker above. If you caulk the gaps before the period of most intense shrinkage has passed, after a few months the wood will dry out a little more, the gaps will increase, and the caulk will become ineffective.

Much fewer problems arise in cases where the caulking process was delayed for one reason or another. Actually, on the contrary, this will have a positive effect on the quality of seam sealing. However, operating a bathhouse with unsealed cracks will lead to large heat losses and increased maintenance costs. From the outside, water will inevitably get between the crowns, which will freeze with the first frost and damage the timber. Also, microorganisms will settle in a humid environment, accelerating wood decay.

The optimal time for re-caulking a timber bathhouse largely depends on what building material was used during construction. If the timber is profiled and chamber dried, this issue can be addressed within six months after assembling the log house. Lumber with natural moisture requires much more time to fully dry and shrink - about a year and a half. Sometimes re-caulking in such cases begins two to three years after construction. But, at the same time, you should remember the danger that open cracks pose.

How to properly caulk a log house

Cold air will penetrate into small, at first glance, corner joints and cracks, significantly lowering the temperature in the house, and identifying such places is quite difficult. That is why such stringent requirements are imposed on the caulking of a log house made from rounded logs.

Even the smallest cracks and crevices must be filled with insulation as tightly and efficiently as possible, and caulking must be done not only outside, but also inside the log house. Although, in high-quality rounded logs there are almost no gaps left, neither outside nor inside.

Roller caulking is considered to be the most optimal for a log house made of rounded logs, since its quality and efficiency are much higher. To check how well it is carried out, it is enough to determine its rigidity.

It should be hard to the touch and cannot be pulled out with your hands, even if you try very hard. If the caulk passes this test, it means that the work was done with truly high quality, the house will retain heat well, and even with temperature changes, the insulation will not dry out and fall out.

The greatest advantage of rounded log houses is that after professional caulking, the house does not require any additional insulation.

Wood has long been known for its excellent insulating properties, but for the full warmth experience the village has to work hard.

It is necessary to carefully seal the cracks between the logs, thereby insulating the rooms from the freezing ice.

Execution of work

Caulking of log houses or beams is a labor-intensive task that is performed entirely by hand. There are no devices that mechanize such work. This process is long and quite difficult; the master performs it only with his own hands.

Caulkers are a special specialty in wood construction. The caulking team consists of several physically resilient and strong men who perform caulking exclusively.

Since these masters are not involved in other types of work, they reach the pinnacle of mastery in their specialization and have the highest qualifications. If possible, you should definitely use the services of such a team, since everything is done quickly and with the highest quality.

It is quite clear that a team of caulkers has at its disposal the entire necessary set of tools to carry out caulking of a log house of any complexity:

- in the presence of any material for sealing the seams of the log house;

- different sizes of seams;

- different types of wood for wooden buildings;

- the need to seal seams in complex elements.

Every stage of work is important. It is impossible to neglect caulking, on which the warmth and comfort of living in the house depends. It is impossible to do without it in wooden construction.

Caulking technology

All! The tool is ready. Next we do the following procedure. We have a bale of tow. We tear out a not very large beard from it and tuck it into a rope. This rope is usually about the thickness of your index finger, but can be thinner or thicker depending on your gaps. After this, we use caulk to drive the resulting rope into the gap between the logs. Here you will definitely notice that your hands are too tender and weak for such work and you will want to take a hammer to caulk more efficiently. Of course, you can do this, just don’t get carried away. You can easily stuff so much tow between the logs that it will tear the log from the log and lift the house. Don't let this happen.

Another subtlety. You can find places where logs, especially for timber, fit together with amazing precision, and you can’t not only insert tow between them, but even drive in our caulk even 5 mm. Do not delude yourself and do not strive to sharpen the tool to the level of a razor! Usually this means that, going around the wall on the other side, we will see between the same logs a gap into which a palm fits! This is a very typical case when the beam is twisted with a screw. Obviously, in this case, you should caulk from the side from which this can be done. And in general, compressing tow beyond any reasonable limits is a mistake for a novice caulker.

And finally, one last piece of advice. When it seems to you that the house is caulked, I advise you to fill the cracks between the logs with narrow slats, or even better, lay an additional strand of tow between the crack and the slats. In section, the wall will look like this:

or, if you have a house made of round logs, then this

Please note that in appearance, a caulked wall made of round timber looks warmer than a wall made of timber. It also seems to me that a log house made of round logs is better

The only advantage of timber is that a house can be built from it without being a specialist, and with only one assistant. I don’t see any other advantages of timber over logs. But this is already lyrics.

Let's talk about personal experience. Remember my neighbor who bought a house that was not only not caulked, but built without any tow at all? So, we tried the described method of caulking with slats on his house, and it worked! Then I did the same to myself and I don’t regret it.

Please note that I wrote all of my advice on the assumption that you are going to decorate your house with some kind of finishing material. If this is not the case, then a worthy completion of the caulking process would be to impregnate the tow, which is visible from the outside of the building, with oil paint. This is usually done in conjunction with painting the entire house. This way, you will protect your caulked house from being caulked by birds.

Finally, I apologize to experts and adherents of the Russian language for being too bold in using the word caulk and its cognates.

Article created 08/07/2007

Article edited 12/15/2011

Jute fiber

Jute is from the linden family. Its golden color is closest to the color of wood. Jute fiber is the undisputed favorite among inter-crown sealants. During the shrinkage of the walls, the jute is evenly compacted. It is little susceptible to rotting, absorbs and releases moisture depending on environmental conditions, just like wood does. Jute is not affected by moths and is not pulled apart by birds. Mixed products are also used as an interventional sealant: jute and flax-jute felt.

The use of a tape seal not only insulates a log house, protects it from blowing, but also speeds up the assembly of the log house

Choose carefully a non-uniform seal with a low density, a sign that the material is the result of recycled jute or linen sack packaging, i.e., of poor quality.

Tape seal (flax-jute) | Tape seal (flax-jute) |

Materials used for caulking a log house

In order to choose the right material for caulking, you need to know the properties that it should have (or at least most of them).

These are properties such as:

- high thermal insulation performance;

- moisture resistance and resistance to temperature changes (the material works under constant atmospheric influences);

- harmless to the human body;

- resistance to processes such as rotting and mold formation, as well as “uninteresting” for rodents and parasites;

- resistance to mechanical damage;

- no pungent odor;

- relative durability (at least 20 years) while maintaining performance characteristics.

All materials used to insulate a log house are divided into two groups: natural and synthetic.

Video: lesson on proper caulking

Note: hereinafter we adhere to the following. terminology: caulk – a special tool for caulking work and also the caulking process itself; caulk – materials for caulking.

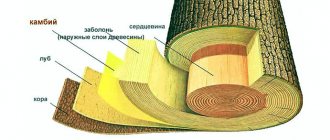

Most of today's carpenters build conscientiously. But if one of them has to dismantle an old log house made of wild logs, he will understand that it is not only inter-crown insulation that needs to be caulked. It is also a kind of “solder”, which over time “glues” the frame together into a kind of monolith, extremely resistant to operational loads, external conditions and pests. It is not always possible to “tear” an old log house for scrapping with hand tools; you have to use special equipment. And if the building is intended for a museum, it can be completely removed from the foundation, taking out the windows and removing the doors from their hinges, loading it onto a vehicle, reloading it 2-3 more times along the way, and it will arrive intact: the cambium of a wild tree with caulk form a very strong seam . Treated lumber does not “glue” as firmly, but it is sufficient for the structure to last for more than 120-150 years. This article is about how to caulk a log house for a service life exceeding the standard.

Materials for caulking

Historically, the very first material for insulating inter-crown seams was moss. Today it is used extremely rarely for these purposes, replacing it with more advanced tow, hemp, jute and flax.

Tow is a material made from waste from processing plant fibers. It is quite rough and inexpensive, but with fairly high insulating properties. It is absolutely natural and has the qualities of a natural antiseptic.

Hemp is close to tow, but less coarse. It uses exclusively hemp fibers. Hemp can be processed quite well, so it is woven into ropes and cords, and is also used in construction.

Jute (or flax-jute) has a grayish-yellow or golden color. This material is made from a mixture of flax and jute. Jute insulation is excellent for caulking wooden houses.

Linen batting is similar in characteristics to jute fabric, but is slightly cheaper. Linen has become one of the most used fabrics for filling seams due to its unique characteristics. Firstly, it is able to regulate moisture exchange, accumulating and then releasing vapor. This provides protection against fungus and insect pests. Secondly, the material is completely natural, it is made from flax and has a natural grayish color.

Insulation sheets are cut into strips of the required width and length with a small margin. It is laid in several layers depending on the density of the material and the width of the seam. The edges of the strip are carefully tucked in and also driven into the gap. A well-placed seal provides the house with not only high thermal insulation properties, but also good sound insulation.

Caulking tools

Tools for caulking walls are called caulking tools and are several types of metal or pointed wooden spatulas, as well as a wooden mallet. The wooden tool is used for straight seams; it is made from soft wood. Metal caulks are intricately curved and are used for corner joints. They hit the blade with a mallet, driving the required amount of compaction into the gap between the logs. The process continues until the elastic resistance of the material becomes noticeable.

Caulking technology

During the caulking process, the gaps between logs or beams are filled with sealing material. Work begins from the lower crown and moves around the perimeter of the house. At the same time, first the walls are caulked from the outside, and then from the inside. Particular care is taken to fill the gaps in the area of the corner connection of logs or beams. Caulking is often done in two stages: during the assembly of the log house and after its shrinkage. The first stage is called roughing and is performed to reduce the amount of work at the final stage. The second caulking is done more carefully, sometimes the crown joints are even disassembled in order to more carefully lay it with sealing material.

You can caulk the walls “in a stretch” or “in a set”. The first method is applicable to long and relatively narrow seams: fill the seam with insulation tapes, and at the end the entire layer is tacked with a tightly rolled roller. The caulking “set” is carried out in wide slots: the material is wound in a special way into a strand, from which loops are “set” for driving into the groove.

Despite the fact that the principle of caulking is extremely simple, the quality of the work performed directly depends on the experience and skill of the performer. A balance must be strictly maintained between the density of the material being driven into the seam and the effectiveness of the insulation achieved. In rare cases, too active clogging of the seal can even lead to the log slipping and the risk of destruction of the log house. If the technology is followed, then upon completion of the work the log house will “grow” by about 10-15 cm and will become much warmer.

Caulked seams retain heat well, but do not look very aesthetically pleasing. To make them attractive, they are decorated with jute rope or other materials. This additional finishing slightly increases the cost of caulking.

Cost of caulking

The price of caulking in the price lists of construction companies is most often indicated per linear meter. It is higher for houses made of logs and slightly lower for timber buildings. The final amount may differ slightly from the calculated amount depending on the characteristics of a particular object: the quality of its assembly, the type of corner joints, etc.

Video description

Caulking timber: how it happens is shown in the video:

To understand how to properly caulk a house made of timber, we will consider in detail the methods of caulking with various materials.

Caulking technology with fiber insulation:

- Moss or flax tow is applied to the gap with fibers across it, then, holding the material, it is pressed deep with force with a special spatula.

Caulking tow Source fasad-exp.ru

Tool for caulking at home

Before you get to work, you need to make a special tool - a caulk. It's easy to do with an axe, but I usually use a jigsaw whenever possible because I'm always afraid of chopping something off myself. Caulking is done, if you don’t rush, in exactly 10 minutes.

Here is the sequence of actions.

1. Take some scrap of board 25 mm thick and cut out the following blank:

The length of the workpiece is such that it is comfortable to hold in your hands.

2. We cut or trim it as follows:

3. Sharpen the caulk with an ax so that it forms a wedge and makes it convenient to push the tow between the logs.

How to caulk a log house

During the assembly of the log house, the sealing material is spread as evenly as possible, always with fibers across the groove, while it is necessary that the thickness of the insulation is about a centimeter, and its ends protrude on both sides by at least 50 mm. A layer of insulation up to 4.5 cm thick can be laid over doorways and window frames. After completing the installation of the log house, the material is rolled into a roller and driven into the gap using a special blade - caulk

Particular attention is paid to corner connections

It is recommended to make the blade for this procedure from the same type of wood as the log house, since when made from a harder material during operation, it will inevitably damage the logs, forming chips, scratches and dents.

There are two ways of caulking: “stretched” and “set”.

Extended caulk is used, as a rule, as the first caulk when assembling a log house.

Caulk “as a set” is used for additional processing of seams after the house has given the necessary shrinkage, or to eliminate wide cracks and grooves.

It must be remembered that caulking is a very complex technological operation that requires special professional skills and extensive work experience, therefore this procedure must be performed exclusively by highly qualified craftsmen - caulkers.

Despite the presence of a number of advantages, such as environmental friendliness, good thermal insulation and reliable wind protection of a wooden building, caulking a log house also has some disadvantages.

Features of a wooden instrument

This tool is something like a wooden spatula. It can be made on your own. It may seem that there cannot be any special difficulties. You just need to plan a wooden blade and start insulating it. Slowly tap the instrument with a wooden mallet, sealing the seam with tow.

Some craftsmen even try to use an axe. They just try to stick the tow inside the seam.

Insulation is not an easy process. In ancient times, self-made blades of different widths and sharpness were used to perform it. But this was not entrusted to everyone, but only to a recognized craftsman.

A caulk is a tool that must have the following necessary qualities. It must be made from hardwood. If the material was unsuitable, it lost its qualities after just a couple of meters of sealed seam. The blade could become covered with burrs and become completely unusable.

If the hammer for hammering is made of metal, then the caulk must also have a metal handle.

The purpose of the application is to fill the seam as tightly as possible with insulation. When using low-quality logs in the construction of a log house, it will be necessary to seal fairly wide seams. This circumstance will allow you to fill them out without any extra effort. When finishing a log house with thin logs, you will need to use a metal device.

Using a caulking chisel

A caulking chisel is a metal version of this tool. Today you can buy it in a store without any problems. Branded products are offered by the best manufacturers.

A good quality chisel can also be adapted under certain conditions. It should not be particularly thick and have a blade less than 5 mm thick. A regular chisel is too narrow. They will have to carry out insulation for an unreasonably long time. The process will be speeded up by a 100 mm spatula. It is this device that needs to do the job. This tool is called a caulking tool.

Chisels are used to perform specific operations. They have different lengths and blade thicknesses. It is necessary when sealing seams and grooves of different sizes.

Using caulk with a hammer drill

A caulk with a hammer drill will significantly speed up the progress of work. In this case, the quality will be worse, since there is a high risk of damage to the logs of the log house. The load becomes uncontrollable. This is due to its shock nature. Manual execution requires the master to make only 1 blow per width of the blade of the device.

The insulation is placed at a given depth. Using a hammer drill involves frequent impacts that the worker cannot accurately assess. The insulation is laid unevenly, the seams are insulated poorly.

Mallet for performing insulation

A wooden hammer or mallet is simply necessary when insulating a log house. A good master with experience and significant experience usually has his own large set of mallets of various modifications. It is preferable to use a mallet of the same type of wood as the log house that needs to be caulked. This is not always essential, but it is desirable. Mallet has other names. Some masters call it a mushel, a beater.

A curved caulk will be very useful in this work. In a log house there are a large number of rounded sections, the ends of the logs. This type of caulk has a narrower blade than a flat caulk, its size is 50 mm with the same thickness of the blades of both modifications of the tool.

A road worker is also used. This tool has a fork-shaped appearance. It is necessary for forming rollers in the most convenient way. A road builder is used when caulking a log house using the stretch method. It should have a width of 170 mm. The recess in the road construction must be selected in accordance with the dimensions of the grooves. An experienced master always has at least 3 tools of this type with him. They are used for seams of different sizes.

It is equally important to have a breaking caulk on hand when caulking a log house. It is necessary to widen an excessively narrow groove. The breaking caulk has a wedge-shaped blade, which makes it possible to expand the space. It will have to be filled with material using another device.

Materials for caulking

Experts call traditional sphagnum moss the best and unsurpassed in terms of durability, insulating qualities and healing effects on residents. Other natural materials are also good for caulking - tow, jute, linen and felt (wool) insulation.

Today there is a huge selection of various polymer sealants that have the undeniable properties of excellent adhesion, strength, elasticity and durability. But for caulking a natural log house, it would be more accurate to focus on the use of natural materials.

In addition, polymer synthetics as sealants are not so durable compared to natural materials. The moss in the inter-crown joints of very old, up to a hundred years old, log houses when they are dismantled is surprising, it is so whole, dense and clean. The ability of sphagnum to quickly absorb moisture, retain it without releasing it to the wood, and just as quickly release this moisture into the air when air humidity fluctuates is amazing. Moss lives and breathes together with the log house, preserving the warmth in the house, the health of the log house, and at the same time the health of the residents. It’s not for nothing that sphagnum has been used for caulking since ancient times, and in our time this material is by no means archaic; on the contrary, moss insulation between the crowns of a log house is a sign of an eco-house.

In addition to being ecologically impeccable, moss has antiseptic qualities and prevents the development of fungus and mold between the crowns of the log house.

Polymer synthetics are lagging behind here too. Excellent adhesion to wood does not prevent moisture from penetrating into the joints, but it does prevent the escape of this moisture. This may cause the wood to rot. And over time, the elastic and adhesive properties of sealants decrease, and the process of infection of logs can accelerate.

Of all the representatives of the extensive family of mosses, two are used for caulking - swamp white sphagnum moss and green moss called cuckoo flax. Moss must also be laid when cutting a log house, laying it between the crowns, while the moss is moistened and evenly distributed over the logs of the log house, and the moss stems are placed in the transverse direction and the ends of the stems are left outside the walls by 100-150 mm, for caulking. The thickness of the moss layer should be at least 100 mm. Moss can be bought or harvested. Collecting moss is easy, but cleaning it thoroughly takes time. Soil, leaves, twigs and twigs cannot be left in the future insulation. drying moss is not very difficult, due to the properties of moss it can dry in the sun, in the shade, and even in rainy weather under a canopy.

Jute or jute fiber is very popular and in demand for insulating log houses. This material does not grow here, and therefore is not cheap. It is characterized by excellent heat protection, biostability and excellent “breathes” between the crowns, comparable in quality to sphagnum. Birds do not value jute and do not use it for nests.

An excellent insulation material that has no less ancient history than moss - natural sheep's wool. Excellent energy-saving properties, the ability to densely fill even thin cracks, high elasticity and elastic properties of wool fibers make wool the champion of caulking. Another excellent property is that when caulking seams with sheep wool, as a rule, there is no need for repeated caulking, due to the elastic properties of wool. The downside is that this insulation is expensive.

The traditional tools for caulking are considered to be a caulk - this is what the device is called - and also a mallet, a wooden or rubber hammer with a wide striker part. Various spatulas that are easy to use, often steel, are also used. You can use any convenient tool if the main task is to fill the inter-crown seam evenly and as densely as possible. For speed, small-scale mechanization tools are also used - hammer drills or electric chisels. In the right hands, any tool can be used, but the impact force of a hammer drill must be contained. Torn and twisted insulation strips and damaged logs as a result of hammering with a hammer drill are a very poor caulking method and a guarantee of future problems with the log house.

You can use an electric chisel to fill the seam, but you will still have to roll the tape by hand. Manual caulking was and remains a long and painstaking process, but the result is worth it - a warm and healthy log house.

Types of caulking material suitable for timber

Scheme for insulating a house made of tow timber.

Wood has been used in the construction of houses for many thousands of years, so our ancestors accumulated considerable experience in caulking and the use of materials.

Moss remains the best material for caulking wooden log houses today. But not any moss is suitable for these purposes. For caulking, sphagnum moss is used, which grows in swamps and has a red, light or brown tint. Subsequently, when it rots, peat deposits are formed. Even modern materials are inferior in durability and environmental friendliness to moss. Proof of this are old abandoned wooden huts in villages, in which the log itself has already rotted, and the moss is in excellent condition.

As an interventional sealant, moss is an indispensable material due to its antibacterial, antiseptic and healing properties. Sandwiched between the timber, it prevents the development of putrefactive bacteria and mold fungi. Due to this, the tree retains its qualities longer and extends its service life. Freely passing air through itself, the moss imbues it with healing vapors, so the internal atmosphere of the house turns into a healing one. The hygroscopicity of moss allows you to level out changes in humidity. The properties of moss do not allow us to detect any shortcomings in this material. But the “minus” lies elsewhere - caulking from moss is not very easy, otherwise no other materials for these purposes would exist.

Tow made from flax fibers is used as a sealant and sealant everywhere, and as a caulking material - more often in those regions where it grows and where there are no swamps that allow moss to be extracted.

Tools for caulking walls.

There is no production of flax tow. It is obtained by tweezing and combing when cleaning flax fibers. It is also formed as waste from the manufacture of ropes, fabrics, ropes. Like moss, but to a slightly lesser extent, tow made from flax is endowed with bactericidal and antiseptic qualities. That is why tow is treated with resins to increase its resistance to moisture. If natural tree resins are used for processing, then tow is still considered an environmentally friendly material. But if it is impregnated with petroleum products, there is no longer any talk of naturalness and harmlessness. Tow consists of a large amount of fire, shaken out during the first years of operation of the house. That’s why they caulk with tow not just once, but several times.

Hemp hemp is very similar to flax tow, with one exception - its fibers are coarser, which is why this type of caulk is often confused with each other.

Hemp is not afraid of temperature changes and high humidity, so it is advisable to use it in regions with high humidity. These characteristics of hemp are due to the polymer lignin, which is found in any type of wood, holding cellulose fibers together. Hemp is able to retain its qualities even when wetted, so it is not in danger of rotting.

Insulation technology for log walls

From ancient times to this day, two main technologies have been used to insulate wooden walls.

Stretching - used mainly for caulking narrow cracks:

- a strand is formed from the selected insulation, placed in the slot and pushed through with a spatula, leaving an edge of the material about 5 cm long outside;

- then a thin roll is rolled out of the insulation, which is wrapped into the left free edge of the insulation and carefully, using a chisel, hammered into the groove.

Included in the set - used for caulking large grooves and cracks between logs:

- the sealant is twisted into long strands up to 15 mm thick and wound into balls;

- then it is carefully unwound, while simultaneously hammering the material into the cracks using a caulking chisel;

- if the gaps have different sizes, then for larger ones the required thickness of the insulation is gained by twisting it into loops.

Tools for work:

- caulks (they are different: type-setting, curved, broken);

- wooden mallet or rubber mallet with a wide head.

Caulking tools have a steel blade that must be soft and smooth, otherwise it may damage the seal.

Work order:

- The caulking process itself begins from the bottom, from the very bottom crown and continues upward. It must be taken into account that caulking the seams changes the height of the log house.

- One seam must be caulked along the entire perimeter of the log house, first from the outside, then from the inside. This will avoid distortions in the walls of the house.

- Then the next highest seam is processed. And so on until the very top.

It is forbidden to caulk individual walls; this may cause the wall to deviate from the vertical.

As you can see, the process of caulking a log house is not that complicated, but it requires great care and careful execution of all operations. Then your home will be protected from atmospheric influences for many years, and the facades of the house will take on a finished look.

(Visited 868 times, 1 visits today)

Video description

Caulking with rolled material: you will see how to do it correctly in the video:

The corners of the timber are caulked using the same technology:

- If the gaps are wide, a cord is formed from the insulation tape. Roll it into a ball.

- Unwind part of the cord and weave loops from it. Then each loop is pushed inside the seam.

- Hammer the loops with a spatula, first from above the joint, then from below.

- After sealing the seams, final caulking is carried out if necessary. It involves residual filling of joints and is carried out if necessary.

- The density of the caulk is checked with a kitchen knife. The knife blade should not extend into the joint more than 1.5 cm. If this condition is met, caulking is done correctly. If not, then additional caulking is required.

Checking the density of the caulk Source 24aul.ru

Caulking corners is done using the same technologies using roll insulation, for this they move along the seam from the bottom up. To ensure uniform laying of the material, it is constantly tensioned and straightened.

Tow

This material is waste generated after the primary processing of natural fibers.

The logs are caulked with jute, hemp and flax tow. The properties and quality of such material are determined by the raw materials, the length of the fibers and the level of their purification. During production, tow is pressed into blocks. To use it, you need to pull a strip of material from the block, twist it into a rope and place it in the seam.

Although, it is easier to use tow sold in rolls.

In general, tow is not very convenient to work with, since it is very difficult to get an even seam. When caulking a log house, due to the high rigidity of the material, it is difficult to obtain a tight seam from the first approach. We have to resort to a repeat process.

If you decide how to properly caulk a bathhouse by choosing between moss and jute tow, then you can confidently say that it is better to choose moss, since it does not harbor fungus and bacteria.

What to caulk with?

Of course, you cannot caulk cracks in a bathhouse with ordinary cotton wool - this will require more suitable, ideally natural, materials. An alternative to them may be industrial sealants.

Moss

Moss is considered to be the most commonly used material for these purposes. Despite the fact that today a sufficient amount of materials has appeared, this plant still remains in a leading position due to its outstanding characteristics. The environmentally friendly material has a significant antibacterial effect and provides high-quality thermal insulation. It is not prone to rotting and can be used for a long time. It is also worth mentioning that microorganisms do not multiply in moss.

However, the material has a number of disadvantages. Considerable time will have to be devoted to selecting and collecting moss. Samples that are too wet will contribute to the rotting of the structure, and samples that are too dry will break and crumble. We must not forget that buying moss costs a significant amount. Natural material is not particularly easy to lay out, so it is better to combine it with tow.

Before starting work, the moss must first be left to dry in the fresh air, turning regularly. Then the material is soaked for 30-60 minutes, wrung out and then laid out in a layer and leveled so that the ends of the fragment hang from both ends of the frame. When all the logs are laid, the excess fibers will have to be shortened, or wrapped and tucked back into the cracks. Subsequent stages of work will occur only after 6 months and 1.5 years, and the entire process will be a three-stage process.

Jute

Recently, jute fiber has been used quite often to caulk cracks in a building. This material promotes high-quality thermal insulation due to the presence of natural binding resins and does not get wet at all, even in conditions of high humidity. It is worth noting that fiber rarely deteriorates due to rotting. The environmentally friendly material fits well between the logs, simplifying the entire caulking task.

It is customary to distinguish three main varieties of jute.

- Jute tow is formed by combing the fiber and aligning it in the required direction. The material retains its properties, but its rigidity and low density complicate the caulking process. Since the fiber dries out, it has to be laid out several times. There is also a high probability that the tow may simply be stolen for birds’ nests.

- Jute felt is formed by combining 90% jute and 10% flax fibers. The flexible material is easier to work with than tow, but its short length can be a problem, causing it to fall out. To prevent this situation, it is better to select fibers that are at least 20 millimeters in length. It is for jute felt that moths appear.

- Flax-jute looks like a ribbon created by combining soft flax and hard jute fibers. It is easy to use, but is prone to rot and requires pest control. In its properties it resembles flax wool.

Tow

Tow is the waste remaining after the first stage of processing of jute fiber, hemp or flax. This material is very inconvenient to work with; in addition, it is very often subject to rotting and transformation into dust, which has to be cleaned out and caulked again. However, this fiber is an environmentally friendly material with thermal insulation and antibacterial characteristics. The higher the quality of the initially processed material, the better the quality of the tow. These fibers are cheap and available. Tow is sold in blocks and rolls. During caulking, the required amount of material is removed from the packaging, which is twisted into a rope and used to fill the seam.

Disadvantages of caulk

1. Caulk work is accompanied by quite a lot of noise, since in order to properly compact the insulation in the crack, it is necessary to hit the blade with a special wooden hammer, so this procedure will inevitably interfere with a quiet everyday life.

2. It is also necessary to take into account that the sealing material will be pulled out of the seams by birds, which use it to build nests. Often, to distract birds from the structure, small pieces of insulation are placed nearby as bait.

3. Insects and various microorganisms can grow in the thickness of the sealing material over time; in the process of life, they destroy the insulation, which leads to the loss of its physical properties and spillage from the gaps. To avoid this problem, wooden houses are treated with special protective impregnations and coatings.

The cost of caulking a log house is an expensive job, and since this procedure must be carried out many times to obtain an optimal result, it becomes clear that the costs of high-quality processing of the structure will be considerable. You also need to remember that if the building requires primary or repeated caulking of the log house, the prices for the materials used and the work of the caulkers will depend on the design features of the house and the corner connections of the logs.

Another feature of caulking is that caulked seams, as a rule, do not look very attractive, so they often require additional decorative finishing. Linen tow, woolen felt and moss were traditionally used as sealing materials, which are distinguished by their reliability, availability and good thermal insulation. However, recently more modern tape insulation materials based on natural flax and jute fibers have appeared. Their main advantage is that when using them there is no need for double caulking, which significantly reduces construction time. That is why today the most popular is jute insulation, characterized by high strength, low hygroscopicity and excellent spinning properties.

The caulking of a log house, carried out in compliance with all technological rules, allows you to reliably insulate the structure and ensure its moisture and wind protection for many years.

Sealing of inter-crown seams

Sealing seams is easier and faster than caulking using sealants. It is easier to work with them than with insulating inter-crown materials. Neomid's sealed formulations have proven themselves well: Word Professional and Word Professional plus. These products are very similar to each other, but only the second sealant is more elastic and can be applied to surfaces with a large angle of inclination. Otherwise they are no different.

Neomid sealants have good adhesion, excellent adhesion to wooden material and excellent elasticity. Sealed compounds are applied using a construction gun. The sealed seam is not afraid of weathering, moisture, does not turn yellow under the influence of sunlight, and mold does not form on it.

Caulking rules

Caulking of a log house is carried out in two stages - immediately after construction and after some time, when shrinkage occurs. Primary (or rough) caulking can be carried out in two ways: with laying insulation during the process of assembling the walls or performing one-time work upon completion of construction.

Each log house requires high-quality caulking, which is performed in two stages

1 way

Lay the bottom row of logs on the base.

Layed logs of the log house and inter-crown insulation between them

Then the insulation is spread on top so that the ends of the material hang evenly on both sides. Next, lay the second crown, and again a layer of insulation. This is repeated until the very top of the log house. After all work on the construction of the log house is completed and the roof is installed, the protruding ends of the seal are driven into the gaps between the beams using caulking.

The result of caulking a log house

Method 2

Caulking begins after installation of the roofing system on the log house. Insulation (preferably tape) is applied to the seam of the bottom row and, using a tool, is pushed into the gaps between the logs along the entire length, leaving hanging edges 5-7 cm wide. Then these edges are folded in, formed into a roller and hammered inside the seam. Repeat the procedure in the next row and so on until the top of the structure.

The second stage of caulking is carried out after shrinkage of the log house - after 1-2 years. The selected insulation is applied to the cracks between the crowns and driven tightly inside. You should always start work from the bottom row, and be sure to do it along the perimeter of the log house.

Insulation padding

You cannot caulk one wall first, then the second, and so on. In addition, each row is caulked both from the outside and from the inside to avoid distortions in the structure. The insulation raises the frame by 5-10 cm, and its uneven distribution contributes to the vertical deviation of the walls. In some cases, the log house is caulked for the third time - 5-6 years after construction. During this time, the wood completely shrinks and new gaps form.

Gaps between crowns

There are two ways of caulking - “set” and “stretched”. The first is used to eliminate wide gaps between logs, the second is usually used during primary caulking, when the gaps are still narrow.

To work, you need tools - a set of caulking tools, a road worker and a mallet. As a rule, metal caulks are used, although many craftsmen make them themselves from hardwood.

This is interesting: Why does the stove smoke in the bathhouse?

The final touch - sanding

Caulking has not yet completed the construction of the log house until it is ready for flooring, installation of the attic floor, roof, installation of windows, doors, partitions, for finishing and equipment - it is desirable to sand the log house, but it is necessary to sand the inside. Especially - chopped from wild logs, debarked by hand.

Sanding a frame with sandpaper is extremely time-consuming, tedious, and this damages the outer most resistant layers of the wood. The frame is sanded using a hand-held universal grinder with nylon brushes. Worse - grinder with them; drive is too powerful. But the main thing here is still brushes for sanding wood, see video review:

Video: review of nylon brushes for sanding logs

Sanding a log frame with a brush is actually a controversial issue: the brush removes the bead of caulk, see fig.:

Sanding a log frame with a nylon brush

It is definitely clear that it is better not to touch the outside of the log house with a brush. However, there is a way to polish the outside of a log house - this is abrasive blasting. The abrasive used is... baking soda, which does not harm either the wood or the caulk. Of course, during your work you must observe all the safety precautions necessary for abrasive blasting. But the process itself can be carried out with a homemade sandblasting machine (sandblasting), because soft abrasive powder is used, see video:

How to make a log house correctly

Unfortunately, without this additional procedure it is impossible to achieve a normal microclimate in a wooden house.

Our ancestors came up with an effective way to deal with uninvited “fickle” guests. To do this, write down the rope with your own hands: after the trailer structure in the house, the room is tightly packed with insulating material on a natural basis (for example, moss, hemp, yarn).

Then the wooden cottage was completely protected from the weather, and the thermally insulated seams adequately played the role of a protective “jacket”.

Until now, the ancient technology is still in process, only the tools and materials for the work have been improved.

Builders systematized this process by developing two algorithms for constructing poles.

Services of professional caulkers

Entrust the caulking of your home or bathhouse to qualified specialists who will quickly and efficiently complete all the work.

We employ caulkers with ten years of experience who are well aware of all the subtleties and nuances of caulking. We use high-quality and dried natural materials that meet all requirements. We work under a contract and provide quality guarantees. Our specialists will make caulking of any complexity and volume at an affordable cost. Contact us in any convenient way using the coordinates in the “Contacts” section. Calculate the cost of painting and insulating your home right now

Do you have accurate measurements of the house?

I measured it myself. I have a house design. Measurers came. I want to call a measurer.

By clicking on the button, you consent to the processing of personal data

Technology and rules for painting an old wooden house

How to properly varnish a wooden floor

Features of insulating a log house with penoplex

Insulation of a wooden house with Accent 125 sealant

Do-it-yourself log caulking technology

The technology for caulking a log house with your own hands is quite complex, although you can’t tell it from the outside. As we said earlier, when caulking a log house, the structure becomes 7-10 cm higher, so you need to caulk it evenly and correctly.

You should know that no finishing activities should be carried out before caulking the log house, because... during lifting of the structure they will be immediately damaged.

Proper caulking of a log house involves insulating the inter-crown space in tiers (from lower to upper). First, we caulk the very bottom joint (between the first and second crown). This must be done along the perimeter, starting from one corner and ending with it. As soon as the tier is insulated, you need to move to the overlying crown.

It should be noted that experienced builders can straighten a skewed frame using only caulking.

When caulking a log house, it is necessary to carefully hammer in the insulation at the corners, because These nodes need this the most (due to the presence of locks and complex grooves).

There are two ways to caulk a log house with your own hands: “stretch” and “set”. The first method is used if the gaps between the rims are small, respectively, the second is intended for wide gaps. Let's take a closer look at each of the methods.

Extended log caulk

To caulk a log house "expanded" you will need a strand of insulating material for the length of the entire crack. First, you need to tamp one side of the strand into the gap, then bend the other side (as shown in the picture) and carefully hammer it in with a breaking or type-setting caulk.

Extended log caulk

Log caulking “set”

Log caulking “set”

This method of caulking a log house with your own hands requires much more insulation material, but it insulates the bathhouse from the log house more efficiently. The caulking technology proceeds differently: a strand with a thickness of at least 15 mm is prepared. Next, you need to gather the strands into the loops and hammer each loop into the gap one by one (so that the strand goes across the gap, as shown in the picture). It is necessary to hammer the strand using a breaking caulk, tamping the material from above and then from below. After the strand is completely hammered into the cracks, it is recommended to make a final compaction using a road builder.

You can study the technology of caulking timber in more detail in this video tutorial:

Video lesson on how to caulk a log house with your own hands

As you can see, the technology for caulking timber with your own hands is quite difficult and requires certain work skills!

We also recommend that you read the article: waterproofing a bathhouse with your own hands!

Synthetics and sealants

Synthetic caulking is used in combination with rough jute tape, or, for “aesthetics,” with twisted white jute rope. The rough tape is placed in the grooves of the log house under caulking with sealants without wings, flush with the edges of the groove. If the logs have a Finnish groove, then the edges of the tape should lie exactly on the longitudinal cuts in the log under the edge protrusions of the groove of the upper log.

Sealants for wood are chemically neutral polyurethane: silicone is less compatible with wood in terms of mechanical and physico-chemical properties (in particular, in terms of the thermal expansion coefficient TCR), and is destroyed under the influence of even very weak acids. In turn, the silicone solvent - acetic acid - spoils the wood, so do not try to replace special sealants for wood with ordinary construction ones. Synthetics are used to caulk mainly log houses made of laminated logs and timber - their estimated service life is the same as that of glue joints of laminated lumber.

Caulking with sealants is done quickly and simply: the initial composition is squeezed out of the tube into the groove, pos. 1 in Fig.. When it has set, the seams are puttied on top with a finishing compound to match the wood, pos. 2.:

Caulking a log house and sealing cracks in logs with synthetic sealants

There is also an “ultra-modern” method of caulking log houses built without rough caulking at all: cuts are made along the seams, strands of self-expanding polyethylene foam are inserted into them and sealed with wood-like sealant, pos. 3. In essence, this is no longer caulking, because This method is suitable for buildings made of lumber without shaped grooves, assembled on dowels and impregnated with water repellents (water-repellent impregnations). In addition, it is only suitable for selected chamber-drying materials that are completely dried and settled. And then what will happen with warping from moisture during operation - we’ll wait and see: in practice, “caulk-free caulking” has so far been used for no more than 10-12 years.

Let's return to caulking, which is still caulking, albeit synthetic. Finishing compounds darken when dry, so they are selected to match the wood using test strokes on the container. But in the light, the finishing synthetic caulk fades and the walls of the log house take on the appearance shown in pos. 4. Some people, since such “decoration” cannot be avoided, order caulking seams to be glued or filled with white twisted cord. How much this adds “aesthetics and respect” to the building is a matter of taste of the owner. And there is no arguing about tastes. Moreover, about the tastes of people who believe that natural wood needs additional “refinement”.

It is much more practical to use synthetic caulk to seal gaping cracks in logs, pos. 5 in Fig. On top of the sealant, the cracks are filled with any wood putty for exterior use, and the entire structure is rejuvenated. The putty has to be renewed every 2-3 years - it also fades in the light - but this doesn’t last long, it’s not difficult and inexpensive.

Summarizing the above

The caulking of the bathhouse, according to all the rules, retains thermal energy in the bathhouse and significantly extends its service life.

Improperly carried out work on insulating a building will lead to its rapid cooling, rotting of the log house and the breeding of pests in it. Remodeling takes a lot of time, effort and material costs. Properly performed work will help increase the service life of the bathhouse. The erected structure will delight you for many years with its warmth, power and solidity.

Proper insulation of a bathhouse can be the key to its good quality and optimal heat retention. You can caulk the walls of such a building yourself, thereby significantly saving money

It is important to know well the basic rules of the process. Typically, such work extends significantly over a long period.

Note that the basic process of insulating a bathhouse has become a tradition; it is no different from the methods that were used by our distant ancestors during the reign of kings and monarchs. The process of caulking a bathhouse seems to be a complex and painstaking process that requires a lot of time and effort. Its implementation must be approached only with certain knowledge and practical work skills.

Recommendations and nuances for work

Extended caulk is used for cracks; stacked caulk is used to compact felt.

Caulking a building is usually done in two steps. The first stage is associated with the moment of initial construction of this building, the second is done after a year, when the natural process of shrinkage of the bathhouse frame occurs.

You can also insulate the room after 5 years, as soon as the bathhouse is fixed in its place. In this case, we can talk about the completion of the process of caulking the bath. The moment of thermal insulation of the building will be completed.

It is necessary to insulate a bathhouse (log house) both from the outside and from the inside of the building. Under this condition, good results can be achieved.

The log house needs to be caulked in a certain direction. You should start with the lower logs, gradually moving to the upper points.

Indeed, during the work process, the building can rise to a certain height. And this will lead to the curvature of the building. Work on insulating a building usually begins from the outside of the building, gradually moving to the interior.

An equally important point will be the insulation of the corners of the bathhouse. This is a very important point.

They usually start caulking a log house using the most common methods. This is “set” and “stretched”. In the first case, it is possible to insulate the interslot space in logs that have small defects, in the second - in the presence of large holes.

Insulation using the “stretch” method involves forming strands of the required size from the insulating material. Then it is installed in a transverse position relative to the fibers and inserted with a spatula into the gaps. The edges of such strands should be visible. The tow joints are driven inwards using a chisel.

The caulking of the external walls of the bathhouse begins with the lower logs, gradually moving to the upper beams.

Insulating a bath using the “set” method: tow is twisted into thin strips, and they are rolled into a skein. Using a chisel, the material is hammered first at the top, then at the bottom of the crack. High-quality caulking of a log bathhouse can be carried out in a short time, knowing the main points of the work.

Insulation of a building should begin with the selection of suitable material. These include tow, hemp, felt, and sphagnum moss. When choosing moss, you should focus on its dryness. But it shouldn't crumble.

Mixing moss with tow gives a good insulating effect. Felt is often soaked in resin, bitumen or formaldehyde, then dried. Such actions will help make it reliable, capable of protecting the bathhouse from harmful insects.

Each of the listed options is not durable, because they are capable of strongly absorbing moisture, and this is an indispensable path to rotting of the bathhouse frame. Jute and linen wool are good options for innovative options.

The second option is a tape made from low-quality flax or its waste. Jute is based on a natural material. It is durable and remains dry under any external conditions. These foundations are not capable of rotting, breaking or crumbling, and insects do not eat them.

The seams are filled evenly with jute, but it is particularly rigid, which means it can break easily. Glass wool can be used as an insulating material. It is rolled out into a small strip and fixed with a stapler. Jute is almost always mixed with flax fibers. The result is a dense insulating material that is resistant to high temperatures and unattractive to pests.