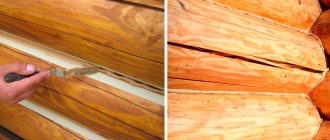

Over time, the wooden surface becomes covered with defects, cracks appear, which, as their number increases, spoil the decorative qualities of the material and also affect its durability. For this reason, it is necessary to additionally strengthen the material; wood putty is used. The rules for its selection, application features and properties will be discussed further.

Prevention of cracks

Wood is a material on which moisture has a destructive effect. The array is also breathable. When temperature changes with humidity, it becomes deformed.

The high density of the fibers does not allow the log to dry completely. The process occurs from the surface cover to the center, but the core remains moistened for a long time. As a result, the outer and inner layers have different resistance to mechanical stress: wet ones are more resistant, while dry ones become brittle. Therefore the tree bursts.

The likelihood of cracks appearing is affected by the period in which the cut was made. In summer, sap exchange occurs more intensely, which explains the high level of natural moisture in the material. Therefore, it is recommended to harvest timber in winter for the construction of houses.

Logging Source mainavi.ru

Preventive measures

Freshly cut timber cannot be used to build houses. The material must be dry so that when shrinking the walls do not become covered with cracks. In addition to reducing humidity, production lines carry out screening according to regulations, which are prescribed in state standard 2140-81. According to the rules, defects include the following:

- knots and cracks;

- curvature of the trunk shape and texture;

- damage by fungus, mold, bacteria and insects;

- foreign inclusions and chemical damage;

- deformation from mechanical stress.

Drying is carried out naturally. This ensures coolness, low relative humidity and shade. It takes at least two years to prepare wood for felling. Then the width of the cracks that will appear one way or another will be 1-2 mm. For comparison: on a one-year-old log, voids 6-10 mm wide will appear, and on a more recent log - 10-20 mm.

Also, before use, the material must undergo primary treatment with an antiseptic composition, a fire retardant and against bacteria and insects. After this, the tree is also dried.

Drying logs in production Source www.lestrade.ru

In order to avoid having to decide in the future how to repair cracks in the logs of a wooden house, the planners often make a compensatory longitudinal cut. It is otherwise called unloading. Its width is 8-10 mm, and its depth is ⅙ or ⅓ of the diameter of the log. The groove is formed by a chainsaw, machine, disk or router. It promotes uniform drying of the wood and speeds up this process. When assembling the log house, the cut is directed upward and covered with the next sheet.

However, not all experts agree with this preventive method. They explain this by the unpredictability of the behavior of the forest after 10 years of operation. Previously, wood was used after two years of aging without cuts or cuts.

Eliminating cracks using slats (wedges)

Here you will need thin slats, hewn at an angle in the shape of wedges. These wooden elements should completely cover the cracks and at the same time not push them apart too much.

The work is carried out in stages:

When this option is used to cover up cracks in the floor, the color of the batten being driven in will stand out strongly on the surface being repaired and therefore the wedge is covered with stain or painted with carefully selected paint.

If the floor is covered with a thick layer of paint, which has cracked and peeled off over time near the cracks, a hair dryer will help remove it. You can also use special drill attachments that have a soft iron brush, or use sandpaper attached to a sander.

Video description

A little about cuts and protective measures is described in the video:

See also: Catalog of projects of houses made of timber with two entrances for a family.

Why do you need to seal cracks?

Any split is a place for water to penetrate into the flesh of the log. The core cannot quickly release moisture, which increases the likelihood of rotting. This is where bacteria grow, fungus and mold appear. Bark beetles also like to live in cracks and destroy any tree. Among other things, heat escapes through these places. All this can be prevented only by sealing the damaged areas.

Consequences of the bark beetle's activity Source pbs.twimg.com

Epoxy resin

Using epoxy resin is the most reliable method for repairing cracks. Two-component products consisting of resin and hardener are easily modified into adhesive filler. With their help, you can obtain a composition of the desired viscosity and color, which will fill cracks, chips, potholes well and provide strong bonding.

After curing, epoxy resin gains strength that exceeds the strength of wood, and due to its fluidity and good adhesion, it penetrates into all cavities and thus restores the integral structure of the wooden product and prevents the further spread of cracks. This method is often used when working with solid wood, where, due to high internal stresses, the problem of cracks is especially acute.

After complete hardening, the epoxy resin turns into an inert and safe plastic of high strength. Epoxy can be used to repair defects in food contact items, such as repairing kitchen countertops or repairing cracks in a cutting board or dining table.

For minor repairs of cracks, it is more convenient to use two-component glue. According to the characteristics, it is 95% the same resin, but working with such material is much more convenient.

insulation of house facade from outside video

There is no need to measure out the components, mix them, dirty the containers and worry about where to put the rest of the composition. By pressing the double piston, you immediately receive the required amount of resin and hardener. After partial use, the glue is perfectly stored.

Epoxy resin allows you to not only fill a crack and hide a cosmetic defect, but also completely stabilize the wood. Often this is the only opportunity to restore life to a workpiece that seems hopelessly damaged by through cracks, as in the example shown below.

Methods for sealing cracks: pros and cons

Protecting wood involves preventing water from penetrating into the cavity of the wood. Therefore, the materials used must ensure tightness and adhere well to cracks. Options that will be resistant to operating conditions are also being considered.

Regardless of the material chosen, it is important to prepare the base. It should be dry, free of dust and nicks. Affected areas and damage must be repaired.

A mixture of sawdust and PVA

How to repair cracks in timber outside a house - the answer lies in materials that are resistant to environmental conditions. You can use moisture-resistant PVA glue and sawdust. The shavings are not suitable for the event, as they are large. A homogeneous mass is applied with a spatula. Since the product shrinks after drying, the seal is repeated. It is recommended to treat only minor damage.

Sawdust with PVA Source sbly-web-prod-shareably.netdna-ssl.com

In addition to PVA, it is permissible to use wood glue with a different composition. This will not affect the permissible width and depth of the split, but will have a positive effect on strength, moisture resistance and durability. High adhesion is also ensured. To minimize shrinkage, experts often use wood dust instead of sawdust. The composition is applied in excess; after drying, the excess is cut off and sanded with fine abrasive.

See also: Catalog of companies that specialize in the construction of garden houses and the manufacture of garden furniture.

Slivers

Before sealing the cracks in a wooden house with wood chips, you need to sharpen them with a wedge in cross section. The blanks are driven into a split of any width along the entire length. Additionally, to ensure strength and reliability, the cavity is treated with moisture-resistant PVA. If the damage is significant, then a mixture of sawdust and glue is used.

In order to prevent further expansion of the split, butterfly dowels can be installed. These are inserts shaped like an hourglass. This will ensure stabilization of the base. The parts usually have a thickness of 10-15 mm; they are inserted into the prepared groove along with glue.

Butterfly dowels Source www.peredelka.tv

Tyrsa

This material often means a mixture of sawdust and sand. In fact, this is fine-grained crumbly waste after cutting more than two types of limestone. The mass may contain up to 10% clay, which makes the material moisture resistant. The mass hardens quickly and has vapor permeability and high strength.

Wood putty

The requirements for how to repair cracks in timber inside a house are more specific than for the façade. Putty is often made on the basis of acrylic resins. The material can be applied in a layer of up to 3 mm, so it can only be used to treat minor cracks. Exceeding the norm contributes to cracking of the dry residue. Also, shrinkage of the solution can lead to its peeling off from the base.

According to its characteristics, the ready-to-use mass has plasticity. The material can be presented in two forms:

- One-component has one binder. It can be water, alkyd or acrylic resin. The product is ready for use after mixing the paste.

- Two-component ones must first be prepared. They are represented by filler and hardener. They are characterized by rapid hardening (several minutes), increased strength and elasticity, minimal shrinkage, and inertness to moisture and solvents.

Wood putty Source remont-samomy.ru

Preparation for repair

Regardless of what material is used to seal cracks, it will only hold if preparatory procedures are carried out, namely:

- Removing dirt from crevices - you need to take a stiff brush with long bristles and walk along the crevice several times. This will help remove the damaged layer of wood, dust, dirt and bacteria that are present there. A vacuum cleaner, which is convenient for handling even the smallest cracks, will help remove fine dust.

- Disinfection - it is important that bacteria do not grow in the crevice, which will subsequently cause rotting of the wood. For this purpose, the floor at the site where the material is applied is treated with any antiseptic. Chlorhexidine and copper sulfate have proven themselves well. After treatment, you need to allow several hours to dry completely.

- Expanding the gap - if, when removing dirt, the wood begins to crumble, it is necessary to remove the entire loose layer until strong and durable fibers appear. Otherwise, the material will not have the necessary adhesion to the wood, and cracks will appear again.

During work, it is recommended to ensure that the floor has a minimum load and maximum evenness of the surface being treated. All heavy furnishings should be removed from the room during the renovation.

Expert opinion

Levin Dmitry Konstantinovich

If the cracks are large and holes are formed during their processing, the option of replacing individual boards with new ones is considered. Worn wood not only fails to perform its basic functions, but is also difficult to repair.

Video description

The video shows how and what needs to be done to protect logs using putty and sawdust:

Acrylic sealant

Before sealing the cracks between the logs in a wooden house with sealant, you need to clean the base. A moisture-resistant elastic mass on an acrylic base can be applied in a layer of up to 5 mm. If the depth of the split is large, then a silicone cord or polymer cord is first immersed in it. They are not associated with the production environment, so the placeholder's behavior will not be changed.

Wood sealant Source massivcolor.ru

Experts have differing opinions regarding sealant. The cork practically does not breathe; the mass penetrates into the pores. This leads to a decrease in the ability of the log to release moisture in the damaged area. That is, the risk of rotting and subsequent biological damage increases.

There is a possibility of dust formation under the sealant film. This will cause the aggregate to fall out and cause the split to increase in width. Silicone or polymer cord can affect the creation of a greenhouse effect, which also results in mold, mildew, bacteria and rot.

The main reasons for the formation of cracks in the floor

If cracks appear after laying the wooden covering, it means that the work technology was violated, during which the material dried out and a gap formed.

The formation of cracks is also promoted by:

- Activity of rodents and insects that dig holes through the wood . This reason is the most common, since in order to save money, many people ignore the need to seal the underground space. The cracks in the concrete are open gates, which pests will definitely take advantage of and turn the wooden floor into dust.

- Increased humidity and improper care of the floor - if the ventilation system in the room is broken and high levels of humidity remain, the wood will certainly absorb it. Swelling of the fibers inevitably leads to the development of microscopic bacteria that will destroy the floor.

- Lack of protective coating - when the floor is not exposed to paint and varnish products, the wood wears out faster, and any temperature changes or mechanical damage can cause cracks and large holes to form.

The sooner the problem is identified and action taken, the greater the chance of maintaining the integrity of the wooden floor. Where there are cracks, there will always be insects, mice, rats and other parasites, the proximity of which is unacceptable for humans.

Traditional methods

How to seal the seams between the logs of a log house from the point of view of the grandfathers - the best solution is moss. Previously, gaps and splits were caulked. More often, a common plant was used as a material. If it was dry, then the moss was pre-soaked in water for 30 minutes and squeezed out before use. The mass must be rolled into rolls and pushed into the crack. In order to compact the aggregate, it is tapped using a caulking spatula and a hammer or mallet. It is important to achieve a spring-like result.

It takes about 72 hours for the moss to dry. During this time, the volume of material increases to 20-30%. As a result, the cracks are clogged, the filler breathes, and the excess is cut off using a petal circle.

DIY wood putty

It is possible to make the putty solution yourself, saving money. But quality ingredients are chosen. The chalk is crushed to a powdery state and mixed with PVA glue; it is necessary to create a homogeneous mass in the form of sour cream. You can add sawdust to the mixture. Drying lasts 24 hours.

Or the chalk is dissolved in varnish with an acrylic base, which is water-soluble. Achieve a consistency that is not too liquid; it should resemble toothpaste. Drying the layer takes 12 hours.

Cooking should be done in small portions, any smudges that form should be wiped off immediately.

Cooking should be done in small portions.

Puttying wood can improve the external qualities and strengthen the material. The process is not very difficult to carry out, for this reason you can do it yourself. But they choose the mixture carefully, taking into account the operating characteristics. To save money, it is possible to prepare a putty mixture with your own hands according to the recipes described earlier; you don’t need a large number of ingredients.

What happens if you don't seal the cracks in the logs?

The web of cracks that appear on the logs of the log house, as well as fairly deep crevices, have an extremely negative effect on the appearance of the structure, which actually spoils the mood of its owners. However, cracking of wood is not only a spoiled aesthetic component, but also a wide variety of repair problems. That is why, when cracks appear on the logs of a log house, you should not remain idle, but rather use proven methods to seal them. Note that cracks quite noticeably reduce the strength of the entire building structure, several times

We draw your attention to the fact that all the calculations that were made during construction and arrangement were based on the homogeneity, as well as the integrity of the material, that is, wood. A cracked log beam can ultimately simply cause the destruction of the entire supporting structure

Sealant

It is necessary to carry out work with sealant in dry weather so that the sun's rays do not fall on the composition. The optimal temperature for closing cracks will be +10 degrees.

At the first stage, the wooden product is cleaned of dust, rot and dried. Then masking tape is applied on both sides to reduce the consumption of sealant and prevent it from getting onto adjacent beams.

For convenience, they work with a spatula, and if the damage is larger, then a special gun is used. The maximum thickness of the extruded composition should not be more than 5-6 mm. The seam is spread with a spatula to create a more even surface.

Wax correctors

Special sticks made of hard waxes are a simple and convenient solution for cosmetic repairs of small cracks, chips, dents, deep scratches and other defects. Wax correctors have gained wide popularity mainly as a means for cosmetic repairs of furniture and other wooden products used indoors and not subject to heavy wear. Wax correctors are offered in colors that imitate various types of wood. The colors are easily mixed to achieve the desired shade.

Special restoration pencils are also used to repair small depressions on wooden surfaces. They are optimal for sealing chips, shallow cracks, and caulking joints. The basis of the filler, just like the correctors described above, is natural and synthetic waxes. But the performance characteristics of pencils (strength, moisture resistance, abrasion resistance) are significantly higher due to the presence of modifying additives in the composition.

Restoration markers are used to camouflage scratches. They do not have a filling effect, but only visually hide defects. But sometimes such repairs are quite enough. Markers also come in handy when you need to paint over a putty area, create an imitation of wood grain, or darken the edges of a restored fragment. Markers are available in a large number of colors to match the textures of popular tree species.

Modern sealing materials

In addition to the environmentally friendly materials that nature supplies us with, there are modern synthetic materials offered by domestic and foreign industry. Of course, one can argue about the environment, but reliability is guaranteed by the manufacturer.

Silicone sealant

There are many special sealants based on polyurethane. It is not susceptible to temperature changes and is resistant to ultraviolet rays. Putty based on it is quite suitable for sealing the seams of house crowns.

You cannot use polyurethane sealants sold in bottles to seal joints - they are not designed for direct exposure to sunlight!

Log putty

Putting joints with silicone One of these materials is silicone sealant. Since wood tends to absorb moisture and evaporate it, this sealing method is questionable, because evaporation under the sealant layer will not occur, which will sooner or later lead to the formation of rot.

Modern thermal insulation materials are resilient and elastic, so they are used quite widely when solving the question: how to seal seams in a bathhouse.

Their peculiarity is that it is easy to work with such sealants, they dry quickly, and it is possible to apply several layers if necessary. And this is convenient and profitable.

In addition, modern sealing materials have high adhesiveness, which significantly increases thermal insulation properties, and are not afraid of drops and changes in air temperature and humid environment

But, perhaps, the most important thing is that they do not interfere with the ventilation of the room and are safe for health. Sealants not only seal the seams of the bathhouse, but also any splits and cracks that form in the wood over time

Among the newest materials for preserving heat in a bathhouse, special sealing tapes should be noted. They need to be distributed in the space between the beams. They hardly caking, which means that there is no need to use other sealing materials, which creates additional savings. In addition, such a sealant can change its shape when the logs begin to move during the natural shrinkage of the bath.

Manufacturers of mixtures and types of materials - how to choose the best putty

Most hardware stores have at least several varieties of putty, and most often there is a whole range of choices. There are putties for wood for painting, for varnishing, for leveling, etc.

Manufacturers also differ, there are domestic options, most often they have a low price, as well as foreign ones.

Among foreign manufacturers, the most famous is Tikkurila wood putty, as it does an excellent job of creating a flat surface and preparing for further processing.

The company’s advantage is that the product range includes not only white wood putty. More often, various pigments are added to ensure maximum similarity between the color and type of wood, so that the mixture does not stand out and spoil the appearance.

At the same time, the climate zone does not play a role when using Tikkurila wood putty, whether in Moscow or Siberia.

Also quite popular manufacturers are:

Lakra

Excellent for parquet.

Lakra

VGT

For wood, it is best suited for preparing the surface for painting. In this case, there is vgt extra wood putty, which has the best adhesion and resistance to external influences.

vgt

Eurotex

Fairly cheap and high-quality wood putty Tex can be used in most applications.

Eurotex

Extra

Allows you to eliminate even minor cracks and surface unevenness.

Extra

Rainbow

The main advantages are that it dries quickly and has a high adhesion rate. Here we talk about how long it takes for the putty to dry.

Parade

Parade wood putty has an excellent level of plasticity, flexibility in processing, and resistance to water. It is also resistant to shrinkage and cracking.

Parade

Smes

The little-known Smes wood putty can surprise you with its high quality products.

Leroy Merlin wood putty is quite well known, but it is not a manufacturing company, but only an intermediary with many products in its assortment.