The appearance of cracks in a wooden house is a matter of time, and happens sooner or later with every building.

The process is considered natural if you prevent their spread immediately after detection and monitor the condition of the house on an ongoing basis.

There are several reasons that provoke the appearance of splits in wood; experts have developed a number of proven methods for elimination.

Causes of cracks

Timber is a material consisting entirely of natural wood. It is prone to cracks and there are several main reasons for this:

Poorly dried timber.

Cracks in such material appear already in the first stages of operation of the structure, after the elements dry out naturally. You can check the moisture content of the timber before starting construction with a special device; the indicator should not exceed 14%.If it turns out that the material has not dried completely, you need to lay it on a hill (30 cm from the ground) in the shade. Each element is laid separately. Then it dries to the desired humidity percentage.

During the construction process, part of the timber remains on the street, part inside the house. As a result, half dries out faster, the stress in the elements is distributed unevenly, the wood cannot withstand it and cracks.

- Frame overload .

The material is often used to create a frame structure. To reduce the number of walls and partitions inside the house, 15*15 or 20*20 cm timber is installed in the form of single columns. If installed incorrectly, cracks appear in the wall and on the frame, and the seams may come apart. To avoid this, installation must be carried out meticulously. Builders should not forget about expansion gaps. - Heating. A house made of timber must be allowed to shrink for at least 6 months before completing the installation of window openings and doors. According to the rules, the building cannot be heated for a year after the construction of the box.

One more point: intermittent heating has a detrimental effect on the integrity of the timber. For example, the owner comes to the dacha for the weekend in the fall and heats the house. After he leaves, he turns off the heating. A week or two later he comes again and heats the house again.During the cold period, the walls gain moisture, during the heating process they dry out sharply, after which the process is repeated and cracks appear. It is recommended to maintain a positive temperature, even during departure, if the house is regularly visited by the owners.

The appearance of cracks is influenced by untimely and inappropriate maintenance. The material must be treated with an antiseptic; hydro- and vapor barrier is required. It is also worth remembering the expiration dates of protective compounds.

Why do you need to fix the defect?

A crack is a suddenly formed free space, which carries with it several dangers :

- Reduced thermal insulation properties of the material. Splits make the timber thinner, additional cold bridges appear, and the temperature inside the building drops.

- The service life of the building is reduced. Cracks can appear unnoticed by the eye; insects can settle inside and increase the effect of destruction. As a result, the house becomes uninhabitable and even life-threatening.

- The appearance of microorganisms. Free space, warm, filled with oxygen, is an ideal environment for the development of mold and mildew. Part of the building begins to rot, and it becomes dangerous to stay in the house for a long time.

- Additional expenses. First of all, cracks increase heating costs. Then you have to spend money on eliminating splits and repairing thermal insulation.

- Loss of strength. The split disrupts the structure of the material, it becomes brittle.

- Not aesthetic appearance. A wooden house with cracks looks unkempt. A crack spoils the appearance of a building, despite the fact that it is a natural process.

As a rule, only one crack can be present in one element. The main task of home owners is to eliminate the defect in a timely manner so that the split does not increase and spread.

Methods for preventing timber cracking

The only way to completely prevent even small cracks is to dry with high frequency current. However, the price of such wood reaches $500/mᶾ, so more affordable preventive measures are used:

- When purchasing, choose tarred timber from northern wood species. Deep tears do not form on such material.

- Before starting construction, dry the timber in a place protected from the sun and precipitation. If you let it dry for a year, the maximum crack width will be 10 mm, and after two years - 20 mm.

- The ends are sealed with drying oil, varnish or oil paint to reduce the intensity of drying. Otherwise, breaks will form on them much earlier than on the rest of the surface.

- To relieve stress in the outer layers of wood, a compensation groove is made along the length of the beam at the top or bottom. It does not affect the appearance and strength, since it will be located between the crowns of the log house. The width of the groove is 7 - 10 mm, and the depth is 15 - 20% of the thickness of the beam. However, some woodworking experts do not recommend disturbing the wood structure with unnecessary cuts.

- To protect from the spring sun, a coating with ultraviolet filters is applied to the external walls to reduce moisture evaporation. Formulations based on linseed oil are recommended.

- To prevent large cracks from appearing on the internal walls, the stove should not be lit for 1-2 years after completion of construction.

Repair materials

Processing the timber after building the frame of the house implies complete waterproofing, vapor barrier, and sealing of joints.

To ensure that cracks do not pose a danger to building elements, they must be treated with a material that does not allow moisture to pass through . The composition must be firmly fixed to the timber and not be afraid of external influences.

Before application, the damaged element is prepared: the nicks are removed, leveled, and sanded.

Sawdust and PVA

A moisture-resistant mixture of these ingredients creates a coating that is resistant to external manifestations and is not afraid of humidity and cold.

You cannot use shavings to create mass; only small sawdust forms a viscous consistency. It is mixed with moisture-insensitive PVA glue and applied to the crack with a spatula. Afterwards, the excess is removed, wait until the mixture dries and sand.

How can I replace PVA and sawdust?:

- Wood glue with a different composition. This will not affect the properties of the mixture in terms of crack size, but it will become stronger. The material tolerates moisture better and lasts longer.

- Wood dust. The consistency of the composition becomes less loose and more homogeneous.

Since the composition contains wood materials, when mixed with glue they moisturize. When the crack is repaired, the PVA hardens, the sawdust dries out and decreases in size.

It is not recommended to use the mixture to eliminate large cracks.

Slivers

The material is suitable for repairing cracks of any size. Before starting work, the wood chips need to be sharpened into a wedge shape and used to fill the gap. The element is driven into the split until it stops, and fixed with PVA or carpentry glue. The essence of the method: the chip restores the pressure from which the timber was relieved after receiving a defect.

Instead of wood chips, you can use butterfly dowels 1-1.5 cm thick . These are specially cut pieces of veneer that will prevent the cracks from opening even further. Externally, they are shaped like an hourglass. To install the butterfly, a groove is milled in the split, and a key generously lubricated with glue is inserted into it. The excess is removed and waited for complete drying.

A gap can not only become a defect, but also decorate a building if it is located in a visible place and looks beautiful. Butterfly dowels allow you to maintain the shape of the split; it does not increase in size, retains its shape and is not dangerous.

Tyrsa

This word refers to the waste that is formed after processing limestone. The composition also contains no more than 10% clay, which creates additional density .

To seal a crack, the mixture must be moistened and the free space in the timber must be tightly filled with it. It will set, dry and become a strong, moisture-resistant bond for wood. After the work is completed, the surface is sanded.

Wood putty

The material is intended for repairing small cracks with a depth of no more than 3 mm. If you use putty for large splits, the composition will crack after drying and lose its properties. Another reason against thick layers is the shrinkage of the material, which entails detachment from the base. The putty is made on the basis of acrylic resins.

When finished, the mass is very plastic and easily falls on the timber.

There are two types of wood putty :

- With one leading component. It can be acrylic or alkyd resin, water. Before application, mix the mixture thoroughly.

- With two components. It consists of substances that need to be mixed: filler and hardener. They are characterized by a high solidification rate, high strength and ductility. The mixture practically does not shrink and is not afraid of moisture and solvents.

To apply the composition, use a rubber spatula, grind the surface after drying with a fine-grain abrasive. The putty is chosen by color; it must match the wood. After repair, the surface is covered with protective compounds or finishing materials.

When air temperature or humidity changes, the material changes shape relative to the wood and may peel off. Therefore, it is recommended to use wood putty for the inside of walls and structures located indoors.

Arbogypsum

The material consists of sawdust and a binder - alabaster, in a ratio of 3:1. To create alabaster, gypsum is diluted with water in a 2:1 ratio. The mass is prepared immediately before the start of repair work.

Instead of sawdust you can use:

- tyrsa;

- crushed bark;

- chopped straw.

The resulting composition can be diluted with an alkaline solution from soap or shampoo for plasticity. The material adheres well to wood and has a long service life.

When creating a mass, you need to eliminate all lumps and achieve maximum homogeneity of the composition. The mixture reliably holds the wood together, works for a long time, and does not shrink.

Epoxy resin

One of the best materials to combine with wood. Creates a strong, durable filling and prevents further splitting.

It has a viscous, viscous consistency, thanks to which the resin evenly fills the entire crack. If you mix resin with glue, it helps restore the integrity of the timber. Also used for repairing chips and potholes . After drying, shrinkage does not occur, the material performs a reinforcing function, and the defect will not increase.

Sealant

Suitable for medium-depth splits up to 5 mm. Before application, the crack must be processed, the jags removed, for better adhesion to the acrylic-based sealant. If the crack is deep, experts recommend placing a silicone or polymer cord inside to reduce its size.

The sealant blocks the function of moisture exchange in wood. The cord inside enhances this effect and can cause moisture accumulation, subsequent rotting and bacterial damage.

But there are also advantages from using this material.:

- the sealant is thick, elastic, fills the crack completely;

- not afraid of frost and moisture;

- can be used on extended cracks;

- dries quickly.

Wax corrector

Visually it looks like a stick made of hard wax. Used as a material for repairing small defects. The color of the corrector should be chosen according to the color of the wood ; you can mix shades if you don’t find a suitable one.

Work is carried out at a temperature not lower than +10 degrees; it can also be used for furniture repair. Before starting work, the split is cleaned of nicks and dust.

Wood putty

- One-component - putties made on the basis of an alkyd, water-based or other binder, and they are usually produced in finished form. Such materials are affordable and quite practical - you just need to knead the mixture to a paste consistency, and then you can start all the work. The relatively long life of the mixture allows you to slowly work with large volumes of space, namely, sealing cracks in a wooden floor or leveling other large-scale surfaces.

- Two-component - compositions that are offered for purchase in the form of two different components - a hardener and a putty. They should be mixed immediately before work begins, and all recommendations specified by the manufacturer should be strictly followed. This differs from the first version of the composition in that it is more durable, has greater elasticity, and there is practically no shrinkage, and it is also resistant to water and solvents.

For the most part, the disadvantages are relative - high cost and rapid hardening. The lifetime of a two-component putty is approximately 5 minutes, which creates some inconvenience when working with a large area, so such products are often used only for local repairs - to cover up a crack in a small area.

How to cover up a crack

Consumables and tools

To repair splits in timber use :

- fine sandpaper for cleaning the crack from nicks and debris, final sanding;

- dry rag to remove sawdust;

- masking tape to protect the surface from dirt;

- sealant gun;

- rubber spatula for putty;

- a clean small container if you need to mix filler ingredients;

- water (for compositions or cleaning after work);

- rubber hammer (if you need to hammer in a chip);

- a damp cloth to get rid of excess solutions;

- gloves.

Content:

- Where do the cracks come from?

- Why are deep cracks in timber dangerous?

- How to repair cracks

- How to Prevent Cracking

- Choosing a construction company

Repairing cracks in timber or logs is an almost obligatory part of maintaining wooden houses. Any wood cracks - this is a natural property of the material. Sometimes cracks look beautiful and decorate the surface. But when the quality and reliability of the walls suffers, you have to deal with the defect.

In the article we will talk about the reasons for the appearance of cracks in timber, working methods of combating, and methods for preventing the appearance of defects.

Step-by-step repair instructions

How the repair process is carried out:

- If a crack is detected, examine it, check the depth and decide on the material for repair.

- Using sandpaper, carefully clean the surface from nicks and debris.

- Remove the sawdust, check that there is no excess left inside the split and that it is clean.

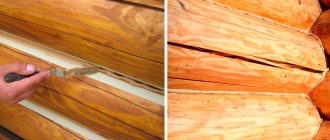

- Cover the edges of the crack with masking tape so as not to stain the surface.

- If the crack is deep and a sealant is used, a cord is placed inside using a long thin object (for example, a knitting needle or a toothpick). It should fill the inside so that 5 mm is left free from the edge. Afterwards, the sealant is filled carefully, leaving no empty spaces.

- The remaining materials are used according to the same principle - they fill the gap with them, trying to fill the maximum possible space. If you use a sliver, use a rubber mallet to hammer it into the split so that it holds tightly using a rubber mallet, using careful movements.

- Remove excess liquid material with a damp cloth.

- Wait for the filler to dry completely and remove the masking tape.

- Using sandpaper, level the surface, remove debris and nicks. If necessary, cover with protective and finishing materials.

Putty

This technique is used in cases where there is a small crack or chip on the tree. It is important to note that sealing cracks using putty gives a cosmetic rather than a practical effect. Moreover, even such sealing of cracks will allow you to perform any operations on the tree again, without fear of damaging it even more (for example, you can safely saw it).

Also, it is strongly recommended to putty before painting the material. To eliminate defects, you must first prepare a mixture purchased at the store. The resulting substance is applied to the damaged surface using a staple so as to fill all the cavities. You will definitely need to wait for the mixture to dry (this will take 15-20 minutes), after which you can begin secondary processing.

We suggest you read: Paper beacons are a myth, they don’t exist

Difficulties and errors

What you need to consider when repairing cracks in timber walls:

The material must be clean and dry before application. Jagged edges and debris are removed for better adhesion of the surface to the filler.- You cannot use repair mixtures on the inner surface of the wall outside the building. They will be of no practical use; the cracks will increase in size.

- Gaps need to be repaired in a timely manner, without waiting for the building to completely collapse. This also applies to small cracks, which must be repaired immediately after detection.

- Mixtures and solutions for sealing cracks are used immediately after combining the main substances (arbogypsum, putty and the like), otherwise they will harden before they hit the wall. Prepare solutions in small portions.

- Be sure to let the wet ingredients dry and leave the crack for the period required according to the instructions for the substance. Do not cover with finishing materials until the composition in the split is completely dry.

Neomid Thor Plus

Neomidator Plus has an aqueous composition, which includes synthetic copolymers and various auxiliary substances. It is intended to provide protection for the ends of logs, beams and other dimensional materials, both individually and in ready-made structures, such as bathhouses, houses, gazebos, etc. This composition prevents the occurrence of rotting and cracking of wood during drying of the material. After treatment with Neomid Tor Plus, a thin elastic coating is formed on the surface of the log structure, which will provide good water resistance and vapor permeability. Thus, the wood will not accumulate excess moisture. The structure of the wood will not change after processing.

List of expenses

The cost of repairing cracks in houses made of timber starts from 100 rubles/sq m. It may vary due to the complexity, volume, and material used to perform the work. Attracting highly qualified specialists increases the price several times.

Average cost of materials:

- carpentry PVA + sawdust – 150 RUR/piece + 120 RUR. per bag;

- wood putty - about 200 rubles. per kg, the manufacturer and volume of the can matter;

- epoxy resin 500-600 rubles, depends on the volume and manufacturer;

- sealant – 150 rub. per packaging;

- wax corrector 110-150 rub. per piece;

- tyrsa – 35 rubles. per bag.

Sealant

The sealant appeared on store shelves at the very beginning of the 90s. It came to us from the last century, but nevertheless, a better replacement has not yet been found for it. It is based on silicone. It is able to create a protective film on the surface that will be processed. It is valued for this unique property. It is clear that since the 90s the composition has been subject to changes, but not major ones. Now it has dyes and a couple of additional elements. The sealant is almost one hundred percent good, but it also has its pitfalls. The surface treated with it no longer allows air to pass through. Lack of oxygen, in turn, leads to gradual destruction of the material.

Folk methods of restoration

What can be used from improvised means for repairs?:

Moss. It is pushed tightly into the cracks so that there is no free space left. Before starting work, the moss is moistened in water and rolled into strands. Afterwards you need to wait for the plant to dry completely.- Beeswax. Before application, it must be melted, then spread over small cracks with a brush.

- Tow. Suitable for large cracks. Hammered inside using a spatula or small shovel.

If tow is used, you cannot apply much force, otherwise the crack may become even larger than it was before the work to eliminate it began.

How to fix defects

There are several known methods for sealing cracks. The following can be applied inside them:

- seam sealant (if the defects are deep);

- wood putty (suitable for frame buildings);

- a mixture of glue or drying oil with fine sawdust.

These recommendations are relevant for small cracks. Large defects are more difficult to deal with.

- The first method is to install a duplicate support or replace the rack in frame houses.

- The second is the use of U-shaped steel brackets, which prevent further propagation of cracks (at the beam).

Preventive measures

Prevention of cracking of timber begins at the stage of cutting down the tree and continues throughout the life of the material :

- It is recommended to cut down a tree in winter, when it does not absorb moisture from the soil. During this period, the trunk is as dry as possible, the process of industrial drying will proceed faster, and the likelihood of wet material entering the construction site is minimized.

- During the production process, special cuts are created inside the timber, similar to small cracks. Their task is to relieve stress from the material when it is under the pressure of the weight of the entire structure.

- The finished structure is painted and protected from moisture, frost and steam. Precipitation and climatic phenomena will in no way bring destruction.

What to do with already formed cracks?

Even if you apply all the above methods to protect wood from cracking, cracks will still occur. Sooner or later. Big or small. But they will be guaranteed. To prevent them from turning into cold bridges and homes for microorganisms and insects, they must be eliminated in a timely manner.

This is done in different ways. One of the simplest is to use colorless sealant . Cracks can also be caulked or sealed with putty. The ends of a log or beam require special attention. It is recommended to paint them or treat them with some modern compounds that are designed specifically for these purposes.

After sealing the cracks, repainting occurs. This will have to be done throughout almost the entire life of the wooden housing. This is the only way it will last as long as possible - it will be warm and comfortable, will not lose its presentability, will not rot and will not be eaten by wood-boring insects.