Bored piles are often used for a strong and functional foundation. This is a type of pile foundation, when concrete is poured into a hole made in the ground, in which a reinforcing frame is placed. On loose soils, special formwork or casing are used for strengthening. This technology is suitable for the construction of country houses and industrial facilities. It is used for work in urban areas, where vibration is contraindicated for surrounding buildings.

Classification and design of bored piles

Bored piles are reinforced concrete structures, the well for installation of which is formed by drilling. A typical bored support structure consists of two elements - a concrete body and a reinforcement cage. For reinforcement of piles, ready-made, factory-produced reinforcement cages are used. The frame type is longitudinal-transverse; it consists of vertical reinforcing bars that are connected by horizontal jumpers. To create a longitudinal contour, corrugated reinforcement is used, produced using the hot-rolled method (class A1-A3). The diameter of the rods is selected based on the size of the pile; it can vary between 12-20 mm.

Fig : Reinforced frame for bored piles

The fixing crossbars are made of smooth reinforcement (diameter 8-15 mm). The frame connection is made by electric arc welding. After joining, the frame is coated with a protective primer to prevent corrosion.

Important : the concrete body of the bored pile is created from a mixture of grade M200-M300, corresponding to strength class B25. The standard frost resistance of the concrete used is 200 cycles, water resistance class is 6.

According to the design features, there are two types of bored piles:

- Cylindrical;

- With widened support sole.

Cylindrical piles have the same cross-section along the entire length of the trunk, while in widened piles the lower part of the trunk has an increased diameter. Due to the increased support area, such supports receive increased stability in the ground and greater load-bearing capacity.

Fig : Installation diagram of bored piles with widening

The widening can be formed by two methods - through the use of special drill strings with folding cutters or the camouflage method, in which an explosive is placed at the bottom of the well and its subsequent detonation is carried out.

Technology of work execution

Marking the area where the foundation is supposed to be constructed is carried out using a cord and pegs (metal or wooden). The perimeter of the future foundation is marked, as well as the location of the piles (they will be located at the intersection points of the two ropes). The pitch of the supports is determined according to the project.

The preparation of wells in the ground is carried out in such a way that the supports are below the soil freezing level. The diameter of the pit is selected depending on the specific conditions (for individual low-rise buildings, this figure is usually twenty to thirty centimeters).

The formation of piles can be done in several ways:

Dry. Suitable for use on hard, non-flowing soils when additional strengthening of the well walls is not required. Do not use if aggressive or industrial waters are present. The formwork is concrete pipes. As the well is filled with solution, they are removed. To protect the top of the pile from exposure to negative temperatures, additional insulation is required. In order to prevent the negative impact of groundwater on the pile, it is recommended to waterproof the well - roofing felt is used for this.

Using casing pipes. They can be asbestos-cement (characterized by durability and resistance to corrosion), metal (have high strength, but require special treatment to prevent destruction under the influence of moisture). The technology is suitable for any hydrogeological conditions. Additional compaction of concrete is ensured by imparting a rotational-translational movement to the casing pipe (jacks are used for this purpose).

Using clay solution. Does not require arrangement of formwork. At the first stage of the work, a pipe is formed from bentonite clays (by injecting a mixture under pressure into the well), which is subsequently removed. The technology is applicable to unstable, water-logged soils and provides the required level of waterproofing.

Using Fundex technology. It assumes a gentle effect on the soil: the well is constructed by pressing the soil. In this case, the tip of the roller used for these purposes is not removed to the surface, but serves as the basis for the pile. It is used, as a rule, for the construction of buildings and structures in conditions of seismically unstable soils.

The frame for bored piles is steel reinforcement: the thickness of the rods installed vertically is 10 (at low loads) or 12-20 mm (at large loads), horizontally - 6-15 mm. For better adhesion of concrete mortar with a reinforcing lattice, it is desirable that the vertical rods have transverse annular projections. Horizontally located rods can also be smooth; they are attached in increments of 1 meter. Depending on the type of load, the frame can be installed to the entire depth of the well or to a certain length of the pile (including serving only as a connecting link between the support and the grillage - the upper part of the foundation). To prevent rusting of the frame rods, they are primed with anti-corrosion compounds.

In order to distribute the load evenly between the supports, a grillage is installed. It should be noted that when constructing low-rise individual housing (for example, frame houses), it is possible to use a bored foundation without this element. However, for the construction of massive structures, the use of pile-grillage technology is a necessary condition for the reliability and durability of the entire structure. Works include:

- cutting the piles so that their upper ends are in the same plane;

- arrangement of formwork;

- installation of fittings;

- pouring concrete mortar.

In addition, the grillage can be made using factory-made concrete blocks. In this case, it has slightly worse indicators of rigidity, strength and durability.

The grillage itself can be recessed or suspended. The second option is used when constructing houses from light materials (timber, OSB boards) on soils subject to severe swelling. A recessed grillage is installed during the construction of monolithic and brick buildings. The minimum height of this element in both cases is 30 centimeters, width – 40 cm.

Bored piles: how it's done

In areas with dense buildings or when there is a danger of soil shifting (during driving piles using the usual method), the bored method of constructing piles is often used. To do this, the following types of work are performed:

- design of a pile foundation based on engineering calculations of the planned load and soil studies on the site

- identification of drilling points on the ground according to the project

- drilling a well and installing casing

- installation of reinforcement cage

- pouring and compacting concrete mixture

- sequential removal of casing pipe.

Fig .: Reinforcement of a bored foundation

An example of calculating a bored pile foundation

Before starting work, you should determine the required number of support elements and their diameter.

When performing calculations, you should take into account the type and characteristics of the soil on the site, the level of groundwater and the depth of freezing. For a private house, these indicators can be determined independently by drilling a well.

The minimum diameter of bored piles with an element length of less than 3 m should be 30 cm.

Initial data for calculation:

- brick house, external wall thickness 640 mm;

- internal load-bearing wall 380 mm thick, 8 meters long;

- house size 7x8 meters;

- floor height 3 meters.

We calculate the loads on foundations taking into account the specific gravity of the materials and structures used in construction.

Table 2. Specific gravity of basic materials.

| Material | Weight kg/m3 |

| Brick | 1800 |

| Reinforced concrete | 2400 |

| Pine lumber | 500 |

| Metal tiles (kg/m2) | 70 |

Load collection

- Walls:

Wall mass = 7 m (length) × 2 + 8 m (width) × 2 × 3 (height) × 0.64 (wall thickness) + 8 × 3 × 0.38 (inner wall) × 1800 kg/m3 (brick density ) × 1.2 (K – correction factor) = 116,294.4 kg.

- Monolithic floors:

Floor mass = 7 m (length) × 8 m (width) × 0.12 (thickness) × 2400 (specific gravity of monolithic reinforced concrete) × 1.3 (K) = 20,966 kg.

- Gable roof made of wood:

Roof mass = 7.5 m3 lumber × 500 kg (specific weight of wood) = 3,750 kg.

- Roof:

Roof mass = 7 × 8 × 1.3 (slope slope) × 70 kg (weight of 1 m2 of metal tiles) = 5,096 kg.

- Reinforced concrete grillage:

For brick walls 64 cm thick, we accept a grillage made of monolithic reinforced concrete with a section of 60 cm × 50 cm. The length of the grillage is equal to the length of the load-bearing walls

Grillage mass = 7 × 2 + 8 × 2 +8 × 0.6 × 0.5 × 2400 (specific gravity of reinforced concrete) × 1.2 (K) = 32,832 kg.

Weight of the house with grillage = 116,294 + 20,966 + 3750 + 5096 + 32,832 = 178,938 kg.

Calculation of the bearing capacity of the pile

To construct the foundation of a private house, we make piles with a diameter of 30 cm and a length of 2 meters.

Sectional area of the pile S = πR² = 3.14 × 15² = 706 cm2.

To fill the piles we use B12.5 concrete, with a strength of 261.8 kgf/cm2.

Load-bearing capacity of one pile = 706 × 16.05 = 11,331 kg.

Required number of piles = 178,938 / 11,331 = 16 pieces.

Pile pitch = 38/16 = 2.37 m.

When calculating, you should be guided by the joint venture “Pile foundations”

For a more accurate calculation, the specific gravity of all building materials and structures should be taken into account.

Technologies for constructing bored piles

Depending on the construction technology, all bored piles are classified into three types:

- Supports formed without shell;

- Supports with removable and permanent shell

As a shell, casing pipes are used - cylindrical steel structures connected to each other by means of a threaded or anchor connection.

Drilling wells for piles without a shell is not accompanied by their use, which is only possible in stable conditions (not prone to landslides) with a minimum groundwater level. Important : if necessary, in the process of drilling without casing, a bentonite solution can be used, which is fed into the well being developed, washes out soil masses from it and settles on the walls of the cavity, forming a crust that prevents soil shedding.

Fig : Casing pipes for drilling under piles

The technology for creating bored piles with a removable shell is implemented when working in problematic, moisture-saturated soils. The casing pipe, in this case, prevents the collapse of the well walls and isolates the cavity from groundwater. Dismantling of the casing occurs after filling the well with concrete. The creation of piles with a permanent shell is practiced when working in clayey soils, sands and sandy loams with a high level of groundwater, which can destroy the body of the pile at the stage of hardening of the concrete solution.

Advantages of using cast-in-place piles

This type of construction of building foundations has not yet become widespread due to the specificity of the equipment used for its construction. However, the development of technology and the machines used can significantly increase the economic importance of foundations of this type. Their use has a number of advantages, including:

The possibility of concentrated absorption of significant loads by individual piles, reaching 1000 tons, which allows them to be placed under structures that transfer a large mass to the foundation. In most cases, these are buildings used in industry and production or multi-story buildings.

The possibility of the piles individually accepting enormous loads makes it possible to simplify the design of the grillage or abandon its use in principle. A connecting or transition link, in the form of a grillage, can be mounted without the use of additional parts and reference to depth.

Advantage of cast-in-place piles

One of the main positive qualities that characterize this type of piles is the insignificant absolute and relative values of their displacement in the soil during settlement.

The significant load carried by the design of a single load-bearing element avoids the use of multiple drive-in type parts.

If it is necessary to use small-sized cast-in-place piles, their load-bearing capacity can be increased by widening the lower surface of the structure. An increase in the supporting surface of the load-bearing elements from 7 to 12 times allows the perceived load to be increased several times.

This type of load-bearing elements can be used to strengthen the structure of existing foundation structures.

Technology for installing bored piles with casing

The process of installing bored piles begins with the relocation of special equipment to the site. Three types of installations are used for arranging supports:

- Drilling machine;

- Jib crane;

- Concrete mixer truck.

After marking the pile field (drilling points for piles), the drilling machine is placed at the well development site. The drilling rig is brought into working condition and the cavity is drilled to a depth identical to the length of the first casing section. Next, the auger is removed from the well, the installation fixes the pipe in the supporting unit and places it in the cavity. The second casing section is installed in a similar way, the sections are joined using a threaded connection, after which the well is deepened until the upper contour of the casing is equal to the ground level and the process is repeated again.

Fig: Drilling using casing

Important : during the drilling process, the auger string rotates inside the casing. The casing itself is deepened by excavating soil from under its walls, under the influence of its own weight and the applied effect of a vibration unit, which exerts reciprocating loads on the pipe.

After drilling the cavity to the required depth, the auger column is removed from the well and a reinforcement cage is loaded into the cavity using a jib crane. Upon completion of the installation of the frame, a concrete pipe is installed at the wellhead, through which the excavation is filled with concrete. During the process of pumping the mixture, the well casing is sequentially dismantled.

Fig: Installing the reinforcement cage in the well

To increase the strength characteristics of a bored pile, the mixture is compacted using deep electric vibrators, which remove air cavities formed in the concrete. The support is suitable for subsequent use (tied with a grillage) 25-30 days after pouring (this time is necessary for the concrete to gain its design strength).

Fig : Filling a hole for a bored pile with concrete

Disadvantages in arrangement

The use of drilling injection technology also has certain disadvantages. Thus, during the construction of these piles, unlike cast-in-place and bored supports, there is no artificial soil compaction. That is, their carrying capacity is at the level of the natural state.

The use of drill-injection supports is often impossible due to the threat of squeezing out the concrete composition from the soil by groundwater until it dries completely. This process can occur during the construction of foundations in sandy, water-logged soils with a high filtration coefficient, as well as active movement of groundwater.

The technology of their arrangement may also raise some doubts about the quality of already manufactured foundations. Difficulties often arise during the immersion of the reinforcement cage into concrete, which, at low pressure, sinks to a depth of no more than 75-85% of the length of the support. Subsequent immersion of the reinforcement, which occurs under increased pressure, leads to a violation of the integrity of the reinforcement and its protrusion from the support walls. That is, the lower section of the pile is almost without reinforcement.

Technology for installing bored piles with a grillage

The configuration of the grillage of bored supports is selected based on the arrangement of piles in the foundation:

- Tape grillage tying is used in a sequential arrangement scheme, which is used for arranging foundations for low-rise buildings (the supports are placed under the contour of the walls of the house);

- A slab grillage is used to tie the pile fields of the foundations of high-rise buildings, in which the piles are located along the entire perimeter of the structure.

Important : at the stage of forming bored piles, the supports are reinforced with a frame, the length of which is 30-50 cm longer than the length of the concrete body of the pile. The protrusions of the reinforcement are necessary for subsequent connection with the reinforcement frame of the harness.

Depending on the level of elevation above the ground, 3 types of grillages are classified:

- Low (lowered into the soil below its freezing level or so that the upper contour of the piping is flush with the ground);

- Elevated (laid on the ground surface);

- High (raised above the ground to a height of 20-30 cm).

Fig : Types of bored pile grillages

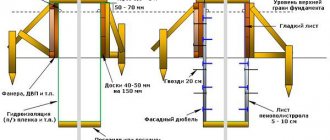

The sequence of installation of the grillage of bored piles is as follows:

- A layer of sand and crushed stone bedding 20-30 cm thick is laid around the perimeter of the piping; if necessary, the soil level is lowered by digging;

- A formwork is formed on top of the bedding, made from planed boards. The formwork is fixed by means of side struts;

- The internal walls of the formwork are covered with waterproofing material (oilcloth, roofing felt);

- A reinforcement frame is assembled from reinforcing bars, which is placed in the formwork and welded to the protrusions of the reinforcement of bored piles;

- The grillage is filled with concrete. Filling the formwork is carried out simultaneously, without pauses. After pouring, the mixture is compacted by vibration.

Fig : The process of arranging a grillage of bored piles

Important : upon completion of installation of the grillage, a 30-day pause is maintained for the concrete to gain strength, after which time the foundation of bored piles becomes suitable for further construction.

Step-by-step instructions on how to make a bored foundation with your own hands

The process of making a bored foundation with your own hands consists of several stages. When carrying out work, it is necessary to scrupulously follow the order of activities so as not to reduce the strength of the future building.

Calculation

The width of the base is determined taking into account the dimensions of the walls. The number of piles is determined by dividing the total load by the load-bearing characteristic of one support. Piles must certainly be present at the corners of the building, at the junction of the walls.

Then the depth of the piles is calculated. Their lower part must certainly be located below the maximum level, where soil freezing extends in winter. Having received these indicators, they draw up a project and determine the amount of materials needed.

Marking

Having received the diagram, they mark out the area for a self-built bored foundation. First, they take pegs, connect them with a rope and place them in the corners of the building. Align the corners of the markings. It helps to achieve the desired measurement of diagonals.

When making markings, errors are unacceptable, otherwise the base will turn out uneven. Drive pegs along the rope where the supports are supposed to be installed.

Drilling

Figure 3. Drilling wells for piles

Wells are made with a hand drill or special equipment is used.

Their diameter is 10 cm larger than that of piles, since it is still necessary to construct formwork. When using a hand drill, a level should be attached to it, making sure that the tool is positioned correctly. To get a solid foundation, it is better to use a drill with a plow at the end - then there will be a slight expansion at the base.

Formwork

This stage consists of installing the formwork to make the pile cap.

It is made using any available materials. The most common option is plank formwork. It is simple to do, but it takes up a lot of usable space, and after completion of the work, disassembling the structure is difficult.

It is recommended to carry out the construction using plastic pipes that give the piles the desired shape. The cheapest method is to use roofing felt. But it has a significant drawback, since such material is not able to hold even a slight collapse of the walls.

A good way is formwork made of concrete pipes. It not only holds its shape well, but also takes on some load.

Bored foundation - reinforcement

Figure 4. Reinforcement of a bored foundation

After constructing the formwork, reinforcement bars are inserted into it, reinforcing the strength of the finished structure. Metal reduces the risk of subsequent cracking of the pile in the presence of horizontal loads from soil movement. The procedure requires rods with a diameter of 1 cm, which are connected with wire. You can knit both rectangular and triangular frames. The mesh is placed at a distance of 5 cm from the formwork.

Fill

First, a cushion is made in the well. Use concrete or sand with crushed stone for it. The pillow needs to be compacted well. Concrete is poured continuously, which is why a supply must be prepared in advance. Concrete grade M200 or higher is suitable for pouring. The piles are poured in thirty-centimeter layers, each of which is certainly compacted. The presence of even minor voids is unacceptable, so it is recommended to use a construction drill for the work.

When a technology that involves expanding piles is used, after pouring the bottom layer, the formwork is raised so that the concrete completely fills the entire base. Periodic lifting of the reinforcement and returning it to its place helps remove voids. Once all the concrete has been poured, it is left to dry for a couple of weeks. After this, the tops of the pipes are cut off with a grinder, obtaining a smoothly planned surface for installing the grillage.

Grillage

Although this step is optional, with a grillage the foundation will become stronger. The piles are tied with a tape grillage made of timber, metal or reinforced concrete. To install the latter, formwork is made and its reinforcement is provided. Concrete is poured inside.

Bored pile driving technology

In construction practice, the injection method of constructing bored piles is often used. The essence of the method is to use hollow drill columns to develop wells for piles, while the concrete mixture is supplied immediately upon completion of their penetration through a channel inside the auger. This technology is called CFA drilling.

Fig : Column of hollow augers

The process of constructing piles using CFA technology is as follows:

- The well is developed to the designed depth (if necessary, under the protection of the casing);

- Concrete is pumped into the well through an auger, and the column is systematically removed as the cavity is filled;

- A reinforced frame is installed into a well filled with concrete using a vibrating hammer.

When implementing this method, the time spent on installing bored piles is significantly reduced.

Equipment, drilling machines

Drilling rig

Drilling rig Geax EK 90 Drilling rig

Drilling rig MDT CMV TH 18 Drilling rig

Drilling rig Delmag RH 30

Bored piles: pros and cons

If the construction site is located in an area where the use of technologies that cause the slightest vibration of the ground, as a rule, it is impossible to do without bored piles.

However, the technology for their manufacture, although proven, is quite labor-intensive and requires precise adherence. The level of professional training and experience of the employees performing this work must be appropriate, since this process, depending on the condition of the soil on the site, has a lot of nuances. Bored piles, photo :

In weak, sandy, dusty soils, on peat bogs and in some other cases, the surface of bored piles turns out to be uneven. Such a surface is more susceptible to the destructive effects of moisture and heaving forces when the soil freezes than the smooth surface of finished driven piles. See also:

- How to close a pile foundation

- Strengthening the pile foundation

Description and Application

Figure 1. Bored foundation

The strip version of the pile-bored foundation is used in the following situations:

- Construction of a building in a populated area where the installation of a buried strip or monolithic foundation is impossible.

- When the surface of the site is weak-bearing soil. In this case, piles are driven until solid soils are reached.

- A geological study of the territory has not been completed. Then it’s better to play it safe and organize a reliable foundation.

- A site with changes and difficult terrain. The base of the structure is leveled with different heights of piles and the installation of a suspended strip foundation.

- When the soil is too alkaline, it is not possible to build a pile-screw foundation with a monolithic slab or strip.

Bored-type strip foundations are convenient for constructing cottages. If heavy building materials are used, the number and diameter of supports are increased. When lightweight blocks are used, such a bored strip base is inexpensive.

An alternative to bored piles - leader drilling for piles

An excellent alternative to the production of bored piles is leader drilling of wells for piles. The cost of drilling one linear meter of a well starts from 200 rubles, and depends on the condition of the soil.

Our equipment allows us to immediately immerse piles into drilled holes without changing position. What is the advantage of this method?

- Such immersion does not create a high level of vibration impact on neighboring buildings.

- Allows you to build reliable pile foundations even in urban areas with dense buildings.

- Provides accurate calculated driving of piles in complex soils (permafrost soils, areas with high groundwater levels, soils with quicksand and lenses, etc.).

In addition, we carry out leader drilling for screw piles and their installation. Contact us, our specialists know and love their job!

Benefits of foundation design

Bored piles allow construction to be carried out close to existing buildings, since when constructing such foundations there are no shock and vibration effects.

The main advantages of a pile foundation with a grillage include:

- high load-bearing capacity;

- versatility and efficiency;

- simple technology;

- small amount of excavation work;

- affordable price;

- durability.

The absence of dynamic effects on soils makes it possible to install bored foundations in close proximity to existing buildings, utilities and main pipelines.

The costs of constructing pile foundations are significantly lower than those of installing slab and strip foundations, due to the smaller amount of reinforcement and concrete used.

Pile technology has both advantages and disadvantages:

- Complexity of calculations. To accurately calculate the parameters of the foundation, you should perform a geological survey of the site, study the regulatory requirements, and take into account all possible nuances for each structure.

- Impossibility of constructing a basement or ground floor. When excavating the soil, the adhesion of the soil to the piles is disrupted, which entails a decrease in the bearing capacity of the entire structure;

- Significant heat losses due to raising the structure above ground level. To reduce heat losses, floor insulation is required.

Errors in foundation calculations can lead to deformations due to uneven settlement of structures and excessive consumption of building materials.

House on screw stilts.

Additional recommendations

When constructing a pile field and determining the dimensions of pile columns, the recommended pile spacing should be taken into account, on which the frequency of wells and load distribution will depend. Watch the video on the correct installation of piles:

To uniformly distribute the pressure of the mass of the future building on the foundation slab, the following rules must be observed:

- the maximum distance between bored piles should not exceed two meters;

- the minimum pitch of pile columns should be within three to four pile diameters - in order to prevent the collapse of the walls of adjacent wells in loose soils, the minimum limit must be increased;

- the layout of the pile field should be made taking into account the location of the piles at the corner points of the foundation;

- according to the results of calculating the geometric characteristics, after layout, the total number of piles must correspond to the recommended step values - if the maximum step of the piles is exceeded, the number of wells should be increased and the diameter of the piles reduced to the maximum possible;

- the maximum and minimum dimensions of well diameters should not exceed those permissible for the selected type of installation.

By following these recommendations, you can design the most effective and efficient foundation without worrying about its reliability. If necessary, you should seek help from specialists, but all calculations can be done independently, without much difficulty.