To classify stoves, you can use different criteria: type of design, dimensions and shape, material of manufacture, types of fuel, power, etc. Each model has its own characteristic features designed to solve a specific problem. Which stove would be optimal for a sauna and why?

The health-improving function of the bath lies in the correct temperature and humidity conditions and light steam, for which the stove is responsible. Therefore, without exaggeration, it can be called the heart of the steam room. An incorrect selection can lead not only to disappointment, but also to harm to health.

Criterias of choice

The main indicators that must be taken into account when choosing a stove are the following:

- mechanism of action;

- manufacturing materials;

- fuel.

Baths can be heated using permanent or temporary (periodic) stoves. The first ones need to be kept burning the entire time the steam room is in use. For the second, preliminary high-quality heating is enough.

The range of materials from which a heater can be made now includes a large number of traditional and new technological elements.

The best stoves are made of steel and brick.

Brick structures

The leaders in demand are heaters made of periodic bricks. Continuous combustion heaters are also used to provide heating for saunas. but much less often.

Brick kilns of intermittent operation have both an advantage - they maintain a high temperature in the room for a long time, and a disadvantage - they need to be warmed up for at least 5 hours. In winter this takes even longer. Therefore, if bathing procedures are planned for the evening, then you need to start heating in the afternoon. After this, you can steam and not be distracted by other things, the heating will work without outside interference.

There is another disadvantage of such models - high cost. It is quite difficult to make such a heater yourself. To get a truly functional stove, you need an experienced stove maker. And his work is highly paid. The high cost of the heating structure can also be explained by the fact that it is necessary to lay a powerful foundation that will support a heavy brick heater.

Metal heat sources

Metal furnaces are characterized by the principle of constant operation. A stove with thin steel walls does not retain heat for long, which can be attributed to its disadvantages. And the advantage of a metal sauna stove is that it will take much less time to warm up the room.

In winter, this will take no more than 2 hours. It is better to organize heating using a steel heater in a small bathhouse. You can install the stove yourself.

Termofor - a good choice of sauna stoves and home heating

Termofor is considered the undisputed leader in the manufacture of heating stoves and sauna stoves. Siberian thermofor stoves were first developed in Novosibirsk by 2 men who really loved taking a steam bath. But the units turned out to be so magnificent that they were put into mass production.

Today, thermophores have won special love not only among residents of Russia, but also among foreigners. The company's products are successfully exported to the European Union and CIS countries; the domestic Ministry of Emergency Situations has also become a fan of Thermofor stoves.

Why do we choose Termofor?

A good choice for a real Russian bath is Termofor Stoves. They ask for solid fuel: wood or coal.

By the way, some variations are designed specifically for travel, which allows you to arrange a bathhouse in any place.

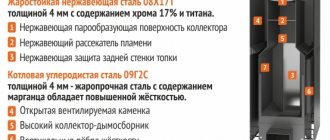

Thermofor sauna stoves have a sufficient service life due to the fact that chromium-alloyed steel is used for their manufacture. Chromium significantly increases the heat resistance of the alloy.

The thermofor sauna stove quickly heats up the stones and air. A cast iron grate supplies air to the fuel. In this case, as in the working principle of furnaces, a powerful flame of very high temperature is formed during the exhaust process. The heating surfaces of the stove heat up quite quickly, as they are made of fire-resistant steel.

This specificity of the material made it possible to reduce the thickness of the surfaces to 2 millimeters, without damaging the resource. Due to this, options made of cast iron equipment are used more often.

Equal heating of the entire bath

Only thermofor stoves are able to quickly warm up the air volume in a sauna. A hot and powerful convection flow, based on the principle of convection ovens, created by a convector casing, heats the steam room equally. Such a stove is not considered a source of hard heat radiation. The hard rays that come from the hot furnace are shielded by the same convector casing, so there is no danger to human health.

Equipment from Termofor tends not to burn excess oxygen from the air. This can be explained by the fact that its walls are chemically inert, which does not help oxidation under the influence of high temperatures. In addition, metal and cast iron bath stoves produce good steam. The deep heater of such stoves is not ventilated and is heated by fire from several sides. To burn the gases around the heater, secondary air is supplied through specialized channels. In this case, secondary combustion torches are obtained, which helps to better warm up the stones.

Termofor stoves – choose the best!

In a bathhouse with a thermofor stove there is no need to steam the broom in boiling water. Now you just need to hold the soaked broom on the steam that comes up from the hot stones. In addition, combustion can be controlled visually. This is due to the fact that most thermofor models are equipped with a transparent screen made of fire-resistant glass. With its help, you can not only adjust the fire, but also enjoy its view.

There is no need to clean the oven from soot. The production workers were worried about this. All places where there is a possibility of soot accumulation are burned with an open fire using specialized slots. And the appearance does not change for a long time. The outer surfaces of the units are painted with organosilicate enamel, which is resistant to high temperatures. Under any circumstances, if a production stove is not cheap for you, then you can always create a sauna stove with your own hands.

Sauna stoves and more...

The Termofor company creates stoves not only for baths, but also for heating premises. Thermofor heating stoves allow you to quickly warm up a room. Units for heating a home have similar positive qualities as stoves for baths. It is also necessary to say a few words about the price of the Thermofor stove, which is not as exorbitant as that of most other manufacturers.

But their purpose is somewhat different - they only heat the space, without the need to heat the stones.

Every person can use the Thermofor heating stove, as it is easy to use.

Excellent heating and bathing units are made in the north. And the Termofor company is proof of this. Its products are designed taking into account the peculiarities of the Russian climate. What makes thermofor stoves so special is that their prices are outrageous. Any person who likes to take a steam bath will first of all appreciate the quality and design of the stoves

Warm floor system

This option for heating a bathhouse is one of the modern methods, which has been used frequently in recent years. It is quite difficult to install special equipment without the appropriate experience.

It is much easier to install an electric floor system and you can do this work yourself:

- First of all, a waterproofing material is laid, on which a layer of mortar is placed.

- Next comes the installation of thermal insulation.

- An electrical cable is mounted on top of the thermal protection layer and the screed is refilled.

The technology for creating a floor with water heating is similar, but in this case they do not use a cable, but rather lay pipes to circulate the hot coolant.

Type of fuel

How is heat distributed? First, the furnace firebox heats up (if the furnace is electric, then the heating element), and heat is transferred from it to the stones. Then, as a result of air circulation, the entire room warms up.

Any type of solid fuel is suitable for heating houses. The same coal, for example, quickly gives off its first heat, and then smolderes for a long time, maintaining the desired air temperature. But in a sauna it will provoke the appearance of heavy steam, so a sauna stove can only be heated with wood. In this case, the appearance of heavy, harmful and unpleasant steam is excluded.

Rules for organizing heating in a bathhouse

Wood heating sauna

The simplest option is a sauna with heating from home. This scheme involves connecting the steam room, dressing room and other premises to the autonomous heat supply of the cottage. But this can only be realized if the bathhouse structure is closely adjacent to the house or is located at a distance of no more than 3-4 m from it.

The most common option for the location of a building on a site is remote from a residential building. How to make water heating in a bathhouse and at the same time optimize the costs of its organization? Options for using standard schemes are possible, but at the same time the specifics of using the bathhouse should be taken into account:

- The source of thermal energy (boiler) must ensure heating of the air in the steam room to a level of +90°C +100°C. For this purpose, special sauna stoves with a container for stones are used;

- For rooms larger than 60 m², it is recommended to install pipe heating. Together with it, you can make a hot water system to increase comfort. If there is a second floor, heating of the attic of the bathhouse must be provided;

- Ensuring the removal of carbon monoxide along with a well-thought-out ventilation system;

- Fire safety. Since wood is used in the vast majority of cases for finishing rooms, its contact with heating elements - pipes, radiators - should be prevented.

Gas heating baths

Another important point is the choice of energy carrier. Gas heating in a bathhouse is advisable only when installing a specialized boiler. Installing homemade structures can lead to emergency and dangerous situations.

In addition to gas, you can use other, no less effective sources of thermal energy:

- Firewood. A traditional type of fuel with which heating a bathhouse in winter turns into a kind of ritual. A significant drawback is the constant monitoring of the fuel level in the firebox, as well as the impossibility of quickly adjusting the water heating level;

- Diesel fuel or used oil. The most unacceptable energy source for a bathhouse. The problem is the unpleasant smell and the difficulty in organizing fuel storage.

How to make gas heating for a bathhouse yourself? To do this, you need to choose the right equipment and components for heat supply - pipes, radiators, as well as containers for indirect heating of hot water.

When heating a bathhouse from the heating system of the house, part of the pipeline located on the street must be insulated. To solve this problem, you can use special heat insulators or an electric heating wire.

Bath stove dimensions and drawings. Manufacturing process

To begin with, it is necessary to say that there are a number of similar products that differ in their design and operating principle. Therefore, the drawings of stoves for metal baths are different. However, they all have approximately the same operating principle (see also the article “Pipe sauna stove: manufacturing tips”).

Firebox

- First of all, you need to make a firebox. Everyone determines its dimensions himself, but professionals advise making it the same height for a width of 0.5 meters.

- Many drawings of a homemade metal sauna stove involve the use of some ready-made elements. These include grilles and doors. At the same time, craftsmen advise choosing these parts made specifically from metal, since cast iron products will have to be fixed in a special way.

Project for the manufacture of a metal structure with a detailed indication of the necessary elements and their dimensions

- A typical drawing of a stove for a metal bath assumes that the firebox will consist of two sections. In the first of them, fuel is burned, and the second is needed to collect ash. Taking this into account, they are separated by a grill and made into separate doors.

- It is worth noting that the window of the ash collection sections is often used to create draft, which is necessary for combustion.

- If the drawing of a metal sauna stove involves the placement of a heater, then the upper part of the firebox is also made of a grate

Advice! To make a stove, you should use thick metal. This way the structure will not behave when heated, and it will be able to generate more heat.

Heater and water tank

- Above the firebox it is necessary to make a separate chamber with a door, which will be separated by a grille.

- Special stones will be placed in it to maintain the temperature for a long time.

- At the same time, the drawings of a metal sauna stove recommend making a closing window that can be used to supply water and create steam.

- It should be noted that ordinary stones are not suitable for such furnaces. This especially applies to material containing silicon or other inclusions.

- The top of this compartment is made with a hole for the pipe. It will remove smoke and at the same time heat the water.

The operating principle of such furnaces

- The liquid container is installed on top. At the same time, drawings of metal sauna stoves recommend that the stove pipe pass through its middle. This way the water will heat up both from the chimney and from the top surface of the sauna heater.

- Professional craftsmen recommend installing a tap on the bottom of such a tank. In this case, you need to purchase special devices, the price of which can be high, but they will be able to work for a long time under conditions of constant temperature changes.

Two options for creating horizontal devices

Special attention is paid to the lid of the container. It can be made of wood, but then you need to protect the area of contact with the chimney. At the same time, the installation instructions advise making small slits in it to allow free steam escape.

Advice! Such a structure is usually made of thick-walled pipe. This helps solve the issue of cheap materials, since such products can be found at recycling centers at similar prices.

Project of a metal stove for a bath with proper installation and organization of the chimney

Chimney

When creating a drawing of a stove for a metal bath, special attention is paid to the chimney, namely to the places where it will pass through the roof. The fact is that the pipes during combustion have a fairly high temperature and in order to avoid fire they need to be additionally insulated. They must also be located at a certain height in order to create constant traction.

Proper organization of the chimney

When creating ovens with their own hands, many craftsmen advise purchasing ready-made products that are made specifically for these purposes to organize such passages. At the same time, they are quite often produced in the form of an integral complex with an outer pipe and a fungus.

You also need to think about a protective screen, the purpose of which is to prevent the impact of high temperatures on wooden walls. It is best to create them with a reflective surface to remove infrared radiation. These products are often sold ready-made and have a relatively low cost.

Heating system

In most cases, continuous burning stoves are installed in bathhouses. which do an excellent job as the main source of heat in the room. At the same time, it is worth immediately making a reservation that for arranging the stove it is advisable to use only cleaned stones, the diameter of which reaches 10 centimeters. To achieve the optimal temperature in the room, it takes at least two hours to heat such a stove, during which you will have to periodically add firewood.

The bathhouse is a wooden building with a high level of humidity in the premises. As you know, wood that is regularly exposed to water can become unusable in a very short time. Because of this, unpleasant odors may appear in the bathhouse, and the building itself will require repairs in the future.

To avoid this, issues related to its quality heating should be resolved in advance. At the same time, it is advisable not to limit yourself to just one stove, but to supplement it with various heating systems, which, moreover, will significantly reduce the time it takes to warm up the premises before taking water procedures.

For safety reasons, in a wet room such as a bathhouse, it is allowed to use one or two heating radiators, which must be connected to the heating system of a residential building. In addition, there are several other options for heating a bath, the choice of which depends only on your requirements and wishes.

Heating radiators in the bathhouse

Drying the bath

There are two components to quickly drying wet rooms: heating and ventilation. They should not be considered separately, because together they work most effectively. You just need to combine them in a specific case.

How to dry: ventilation methods

The ventilation system is laid at the stage of construction of the bathhouse (see here about the diagrams and design of the bathhouse ventilation). Therefore, if something is forgotten, it may be too late to redo everything.

For example, vents are usually made in the foundation - these are through holes lined with sewer (most often) pipes that lead to the underground space. They have plugs on the outside that allow you to open and close them at the right time.

For more details about the scheme, see

Such vents are opened only after procedures. And they serve for better ventilation and drying of the bath.

Also, another through hole is usually made in the wall of the steam room under the shelves, leading to the street. On the inside it has an adjustable plug. This hole is also used to speed up the drying of the steam room.

You can dry the bathhouse in winter with the help of ventilation by opening the windows and doors wide - after all, the air inside is much more saturated with water vapor. But you shouldn’t think that all the moisture will leave the bathhouse only thanks to open doors and windows.

In addition to ways to create a draft simply by opening holes, there is also a method where ventilation actively cooperates with heating and works when the stove is on - this is bastu, which you can read about.

Well, don’t forget that even if natural ventilation is not installed correctly or its power is not enough to ventilate the bathhouse, you can always install fans in the air ducts. Forced ventilation, although noisy, is still effective.

BY THE WAY! Heat guns can help here too.

For those who believe that heating alone is enough, and ventilation becomes optional, we recommend watching the video by Konstantin Bely:

After washing: methods of heating

Heating is just as necessary for drying as ventilation. You understand the mechanism: by heating water molecules, you make them more mobile, transform the water into a gaseous state (steam), and it is easily carried away by the breeze. What will the breeze do if the water is cold? Nothing. And if there is no breeze, the steam will cool over time and calmly settle as condensation.

So, the easiest way to dry a bathhouse after washing in winter is to put one or two logs in the firebox and let them burn out. All ventilation openings must be open.

This is for an iron stove. A brick stove is a heat-storage stove, so its heat is enough to dry the bathhouse after the procedures (together with open ventilation).

***

Well, as you can see, you have to invest some money and make an effort in order to use a large bathhouse in the winter. The smaller it is, the easier it is to warm it up even in cold weather. The power of the sauna stove is calculated for the steam room; it is difficult to fit other things into its responsibilities, because there is summer when all this is not needed. So it is better to use autonomous heaters.

Choice

What are the characteristics of gas stoves intended for baths?

Stones

The traditional stove for a Russian bath - a heater - is distinguished by a large number of round stones placed in a tray. The tray is located above the firebox and, after lighting the stove, heats up quite quickly; the stones heat up to temperatures of 200 degrees or more.

They perform a dual function:

- By accumulating heat, the stones maintain a high temperature in the steam room after the wood burns out.

- The very name “steam room” implies the presence of steam. The traditional mode for a Russian bath is 60 degrees with very high humidity. To add steam, just splash water from a ladle onto the stones.

Gas heater Ermak.

If you are a fan of the Russian bathhouse, a heater is your obvious choice. If you want to use a sauna with high temperatures and minimal humidity, you don't need stones. Heat accumulation in the case of gas, you understand, is of no value.

Water tank location

It may be located in the stove body or around the chimney. In the first case, the heat source for heating water is the burner flame, in the second - combustion products. In the author’s humble opinion, the second option is preferable: the tank additionally cools the combustion products, increasing the efficiency of the device.

Gas stoves

If you use bottled gas, a stove that combines two types of fuel would be an excellent solution for you. When the cylinder runs out, you can light the stove with wood.

Burner

Often it is purchased separately.

What should you pay attention to when purchasing?

- With a steam room volume of 18 m3, the reasonable maximum gas consumption by the burner is 1.5 m3 per hour. It is easy to recalculate the required productivity for your volume.

- The registration certificate and markings must be present. Automatic shutdown when the flame goes out is mandatory (in fact, now it is available almost everywhere).

- Any damage, even seemingly uncritical, puts an end to the device. Big and fat. We are talking about people's lives and health.

Domestic burner Teplofor.

Do-it-yourself steam gun for a bath - diagrams. Steam gun: principle of operation

Steam gun

A steam gun allows you to use not the upper part of the heater to prepare steam, but its bottom, which is also the arch of the firebox. This part of the furnace is characterized by the following:

- It is hotter than the upper stones (the temperature difference can reach 200–300 degrees).

- Due to direct contact with fire, it quickly restores temperature after steam generation.

- During heating, it heats up much faster than stones, therefore, to use the steam room you do not have to wait for the heater to fully warm up.

The gun is designed in such a way that it solves several problems:

- Provided water supply to the bottom of the heater (better if it was boiling water).

- It somewhat held back the resulting steam, giving it the opportunity to overheat and thus turn from damp (heavy) to dry (light). Superheated steam under pressure seems to shoot out, which is why this device was called a steam gun.

- I directed the generated steam into the heater so that, when it hit the stones or the bottom again, it would be crushed even more and thus reach an ideal condition. In this case, the thermal energy of the stones is not spent on steam formation, but only on reheating the steam, so they cool down just a little.

Factory-produced steam guns today have a wide variety of designs, sometimes quite complex. But there are also simple options that are quite accessible for self-production. We will now consider one of them. Using his example, it will be easier to understand the operating principle of such devices.

Electrical

And finally, let’s look at several ways to use electricity to heat a bathhouse. I’ll say right away: take care of the electrics in this case. Since the load on thermal electrical appliances is large, the quality of the electrical wiring should not be in doubt. Consider the total load, wire cross-section, wiring diagram and quality of electrical work.

Firstly, your room can be heated using an electric heater. True, in this case you will have to take care of heating the water in the shower in advance (for example, by installing a direct or indirect heating boiler). This type of heater does not require additional arrangement of the chimney and is considered environmentally friendly.

Secondly, the bathhouse (in particular the relaxation room) can be heated using electric convectors placed on the walls.

Well, thirdly, infrared film can come to your aid - the newest type of heater, which allows you to easily and quickly create warm floors both in the house and in the bathhouse. Detailed technology for installing heated floors is discussed in other articles.

Please note that the installation of heated floors is possible without the use of infrared film, but by laying electric heating cables. They are used both in underfloor heating systems and for heating water pipes. It is quite possible to use infrared heaters as an additional source of heat

Hung it on the ceiling and forgot

It is quite possible to use infrared heaters as an additional source of heat. I hung it on the ceiling and forgot about it.

Using electricity to heat a bath undoubtedly has its advantages. You can safely use all the structural elements (heater, heated floor, boiler) at any time all year round. At the same time, you don’t have to worry about fuel or worry about pipes freezing. The only serious drawback can be considered the high energy consumption.

In the case when you do not often use the bathhouse (especially in winter, rarely coming to the dacha), then the most optimal option would be a mixed heating device. For example, a stove is installed and electric heating is installed. If you decide to take a shower, rest or “stretch”, use electricity. If you decide to take a steam bath “like an adult”, turn on the stove thoroughly.

Remember. Whatever the heating in the bathhouse, if you do not use it constantly in winter, then be sure to drain the water from boilers, water heaters, pipes, toilet tank (if there is one), etc. This is guaranteed to protect them from damage, and you from unnecessary headaches.

Heated floor control unit

Brick or metal

The choice of furnace material matters only from the point of view of individual preferences and conditions:

- Price. Based on the cost of the final product, purchasing a metal furnace will be cheaper than purchasing material and paying workers to build a brick furnace. If you do the masonry yourself, the final cost will decrease due to the deduction of payments to hired workers, which will significantly affect the price.

- Bath area. Metal stoves take up less space, so if the area is small, the choice is definitely in favor of a metal product.

- Difficult to install. A brick stove requires a separate foundation, which lengthens the installation period; a metal stove is installed on a lighter base. The wood-burning sauna stove is quite popular and is practical.

- Sometimes the decisive factor is a photo of a factory-made metal stove - the range of modern manufacturers is distinguished by functionality and attractive design.