Home / Ceiling design / Design solutions / The wall behind or near the fireplace or stove - how to decorate it?

When a fireplace or stove is lit, the wall near it becomes heated. This is unsafe if the walls and floor where the stove or fireplace is located are not properly finished. This part of the house structure must be insulated with fireproof materials that can completely prevent fire. In addition, you need to take into account the requirements for installing heating devices - the distance from the partitions.

When is it necessary to create fire walls?

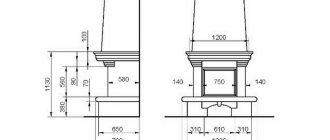

Fire safety requirements for the installation of stoves and fireplaces are set out in a number of GOSTs and SNiPs. They are summarized in the “Code of Rules” - SP 7.13130 “Heating, ventilation and air conditioning”, approved by Order No. 116 of 02/21/2013. by the Ministry of Emergency Situations of Russia. The requirements of the joint venture boil down to compliance with the temperatures allowed on the surfaces of the heating device and the establishment of distances between the heated surfaces of the furnaces and combustible structures. The following poster illustrates these requirements

If there is a forced reduction in the specified dimensions of fire-resistant offsets and cuts, it is necessary to use non-combustible materials for wall finishing. Considering the high decorative qualities of modern non-combustible finishing materials, their use is justified not only to prevent fires, but also in interior design projects in general.

Protective stainless steel sheets

This material is not cheap, but it is very reliable. Using it, you can protect not only the walls of the house, but also the basement when installing a solid fuel heating unit.

In order to protect yourself and create maximum protection, special fiberglass with thermal protective properties is placed under the stainless steel. Such a design will cope well with the function of protection against the slightest attempt at fire. The choice of substrate should be approached very carefully; you need to thoroughly inspect the product for the presence of phenolic resins, which release harmful substances when heated strongly.

Scope of use

The scope of use of fire-resistant materials is somewhat wider than non-combustible materials for finishing walls under a boiler, stove or fireplace. It also includes materials used for the construction and decoration of the heating devices themselves. Refractory bricks are used for laying the internal surfaces of stoves and fireplace inserts. Fire-resistant glass inserts are tripled in stove doors and fireplace protective screens. External finishing of heating devices is not only fire-resistant plaster for the stove, but also tiles and clinker used as facing material

Why insulate the stove?

In the furnace structure the following must be insulated:

- Chimney.

Thermal insulation for a chimney is important for several reasons:

- Insulation can prevent the chimney from cooling quickly, as a result of which the heat in your home will remain warm for a longer time.

- A layer of insulation prevents heating of household structures.

- Condensate accumulates in uninsulated pipelines, which is not just dampness, but a very aggressive substance. The fact is that during the combustion process, moisture and acids are released from the fuel, which mix and settle on the walls of the pipeline, leading to the slow destruction of not only the heating system, but also the structural elements of the building.

- Those walls of the stove that are located in close proximity to the wall of the house.

Thermal insulation of the wall from the stove is also a very important process, since the heat of the stove leads to cracking of brick walls with their subsequent destruction. In block or wooden houses, the stove must also be insulated from the walls by laying insulation.

Types of non-combustible wall products

Non-combustible wall products include heat-resistant plasters and mortars intended for laying heat-resistant ceramic tiles:

- terracotta;

- majolica;

- clinker tiles;

- fireclay tiles.

There are many recipes for plaster and mortar for laying ceramics.

Advice! For an amateur finishing his first stove, it is easier to purchase a ready-made mixture for plastering or laying tiles. It’s even easier, although more expensive, to entrust the matter to professionals!

An example of a fireplace with a firebox and a closed glass door. The presence of glazed doors, on the one hand, protects the interior from contamination by combustion products, and on the other, allows you to admire the fire.

Advice! Glass must be washed after each fire. Without this, they will become smoky and quickly lose transparency. This can be done with special detergent compositions for fireplace glass, or, in their absence, with powdered dishwashing detergent. The glass in the doors is tempered. Powdered detergent will not harm it.

SKL products

SCL - calcium silicate sheet - environmentally friendly material. Does not contain harmful substances and carcinogens. Retains mechanical properties - strength and hardness when heated. Contains:

- paper pulp - 10%;

- quartz powder 45%;

- cement – 40%;

- additives that increase the mechanical properties of the material – 5%.

A decorative layer with ultraviolet painting is applied to the front side of the SC sheet. The levels of fire and moisture resistance allow the use of SCL both in the external and internal decoration of buildings. This material is good for finishing rooms with high humidity - household rooms, baths, bathrooms. The ability to resist fire allows the use of SCL for finishing the walls and ceilings of rooms near the hot surfaces of the stove and fireplace.

SML products

SML - glass-magnesium sheet - is a relatively new material that has strength, flexibility, moisture and heat resistance. It includes:

- magnesium oxide – 40%;

- magnesium chloride – 35%;

- fine wood shavings – 15%;

- extruded perlite – 5%;

- additives – 4%

- fiberglass – 1%.

LSU does not have a harmful effect on the human body, therefore it is used in interior decoration. High fire resistance up to 1000°C allows it to be used as fireproof panels for interior wall decoration near heating sources and open fire.

GKLO products

GKLO is a fire-resistant plasterboard sheet. According to GOST 32614-2012, developed jointly with the Knauf company, and put into effect on the territory of the Russian Federation in 2015, this material is designated by the letter F - “fire-resistant boards”. Its fire resistance must be at least 20 minutes when exposed to open flame.

The heat resistance of gypsum plasterboard is achieved by introducing special additives into gypsum that increase the resistance of the material to high temperatures and prevent smoke from occurring in a fire. To facilitate recognition, the surface of the gypsum board is painted light pink, and the markings are done in red. Knauf Fireboard - the most fire-resistant product from Knauf - has an additional reinforcing layer of fiberglass. Used as fire-resistant cladding for walls and ceilings.

What parameters to pay attention to when choosing

When choosing thermal insulation, you need to pay attention to several points. Important criteria are the price of materials and work, as well as the installation method that will be carried out. At the same time, it is necessary to carefully analyze the characteristics of the selected option. These characteristics include:

Thermal conductivity. It is important that the piece of consumable you choose is not raw, otherwise it will not cope with the plans assigned to it.

Thermal conductivity depends on the degree of humidity, since water has the ability to transmit heat better than air. Non-flammable substances retain heat inside the product.

The porosity of the heat insulator. There are closed or open pores on the elements.

It is important to ensure that they are evenly distributed over the surface; these pores are involved in heat exchange and air circulation.

Rapid water absorption. This criterion shows how much water has accumulated and how much of it can be retained. To test water absorption, you need to place the item in a humid environment.

Density and vapor permeability. Density depends on its mass in combination with the volume of the source. The vapor permeability level shows how much steam can pass through non-combustible wall insulation in a certain period of time.

Resistant to biodegradation. If fire-resistant materials have high biological resistance, they will be able to resist insects and fungi in conditions of constant or simply high humidity.

Fire resistance and heat resistance. Emphasis on the flammability and combustibility of the material.

If the insulation can withstand flames, then the level is high.

Combustible substances are added, so during heating the level of heat reached is checked, as well as the stability of the properties during it. At high temperatures, characteristics may decrease, as well as strength, and as a result, quality.

Frost resistance. To check this parameter, insulating structures are placed in low temperatures and analyzed to see if their properties have been lost during freezing and thawing.

Fireproof ceilings

In the event of a fire, hot air and flames move upward to the ceiling of the room. Therefore, it is important to take the necessary measures in advance to ensure that a fire ceiling does not become a source of additional dangers for people caught in the fire zone. Non-combustible ceilings can be:

- Painted. Non-combustibility here depends on what material the interfloor ceiling is made of. Concrete is good! The painting was done with silicate or silicone paint - even better! Concrete does not burn. These paints also do not support combustion.

- Wallpapered. With a base on which the wallpaper is glued, as in step 1. The wallpaper itself can also be chosen as heat-resistant - based on fiberglass and metal threads.

- Tensioned. The ceiling, made of polyester impregnated with a fire-retardant compound that protects against fire, is relatively safe. Polyvinyl chloride is also considered heat-resistant, but when exposed to direct fire, it ignites and emits a large amount of gases harmful to humans. It should be used with caution.

- Plasterboard. To be considered non-flammable, such a ceiling must be made of gypsum plasterboard and painted with non-flammable paint.

- Hanging. Such ceilings are made on non-combustible metal frames made of SKL, SML or metal composite elements. The requirement of non-flammability is met.

Do you need protection in your bathhouse?

Protecting the walls of the bathhouse from the heat of the stove is not always required. For example, you can provide a distance between the wall and the stove, which will allow you to achieve fire safety without additional protection. The fact is that at some distance the IR rays emitted by the furnace begin to dissipate, which significantly reduces their impact on nearby surfaces.

The distance from the stove to the wall in the bathhouse varies depending on the type of stove:

- 0.32 m or more - the distance for a stone oven with quarter-brick masonry;

- 0.7 m or more is the required distance between the wall and the metal furnace lined with fireclay or brick from the inside;

- 1 m or more is a safe distance for an unlined metal furnace.

At first glance, it seems that creating such a distance is much easier than installing additional protection, but this is fundamentally wrong. Maintaining a safe distance is only advisable in large steam rooms, but in small private baths, the stove, including the indentations, will occupy most of the room, so it will be much easier to use insulation.

Manufacturers and prices

When purchasing heat-resistant materials for finishing walls near the stove, it is necessary to decide the issue of choosing manufacturers and prices. It is desirable that the manufacturer of the purchased material is known, and the price is close to the generally accepted price at the time of purchase. An example of such popularity among the construction community is the Knauf company. The quality and range of products, as well as a reasonable pricing policy, allowed it to occupy 70% of the plasterboard market in the Russian Federation. Since the market situation is fluid, it makes no sense to name specific prices for materials. They depend on the region and the state of affairs in the industry. One should, however, remember the popular wisdom: “You shouldn’t chase after cheapness, priest!..”

Advice! A developer who does not want to overpay when purchasing materials should not delegate this work to a foreman. In this case, inflated prices and costs are inevitable!

How to protect the walls of a bathhouse from the heat of a stove - technologies and materials

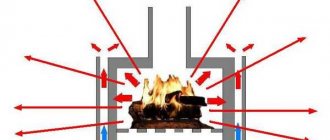

When planning the construction of a bathhouse, it is important to remember to create safety indoors. First of all, this concerns fire safety. By melting the bathhouse, the stove can be heated to 300-400°C, which significantly exceeds the combustion temperature of the wood from which the bathhouse is most often built.

All the heat from the stove is released into the room, but the main heat is absorbed by nearby walls, which leads to their charring and fire. It is extremely important to avoid such consequences, so in this article we will tell you in detail how to insulate a stove in a bathhouse from the wall.

Care Tips

In houses with stove heating, maintaining the stove and fences that protect the combustible structures of the house from overheating in good condition is the key to trouble-free living for its owners. Fire is no joke, and there are no trifles in observing fire safety rules! If they say that a sheet of metal measuring 500x700 mm is needed in front of the furnace loading door, it should be there!

Every year, before the start of the heating season, you should check the condition of the heating appliances at home. It is necessary to check whether the heat-resistant plaster of the stove is damaged, whether there are cracks in the chimney, or whether the facing tiles have fallen off. All identified defects must be corrected in a timely manner.

Fire-resistant panels are an excellent guarantee of the safety of your property.

What else to consider

To avoid any troubles during the operation of the furnace, you need to take into account the requirements of SNiP in all cases - even with installed protection, even without it. They are simple and compliance with these rules guarantees you the necessary level of protection:

- The distance from unprotected wooden walls to the heating device is 1000 mm.

- If the wall is protected by a material equivalent in thermal conductivity to brick - 130 mm.

- If the floor is not protected by anything, then the distance to the bottom side of the heater should be at least 140 mm.

The floor is best protected with ceramic tiles or porcelain stoneware. You can also use a mineralite slab or a regular sheet of metal. It is most important to protect the area directly in front of the firebox door, as embers can fall out and cause a fire. Directly under the heating device, the floor covering does not heat up particularly strongly and if a distance of 4 - 15 centimeters to the bottom of the oven is maintained, additional protection may not be needed there.

Conclusion

Thermal insulation materials for stoves are an important component of the stove itself, without which it will not be possible to properly arrange the work.

Also, it is worth adding that it is very important to choose the right material, install it firmly and not overpay a lot of money for it. Fortunately, there are now a huge number of materials and by studying them, you can understand for yourself which one will suit your stove or wall

Fireproof decorative panels for stoves can not only protect you, but also complement your interior. Experts say that choosing insulating material should be like choosing wallpaper. Sheets, panels or slabs must fit correctly into the overall picture of the room, especially if we are talking about a stove inside the house.

Heat-resistant insulation for furnaces is not a luxury, it is a necessity. You could even say that this is an important element of the stove, which you cannot do without. When equipping your stove, do not forget to immediately make a list of the necessary materials for thermal insulation of the surface around the stove.

We invite you to familiarize yourself with a DIY flower vase made of cardboard

Cladding with cladding

This option is practically no different from the previous one, however, if you don’t know how to decorate the wall behind the stove in the steam room in such a way as to preserve the beauty of the room while creating safe conditions, then this option is undoubtedly for you. Protect the walls using heat-resistant decorative materials laid on thermal insulation.

The finishing around the stove in the bathhouse can be done with the following materials:

- Clinker tiles are made from baked clay. It is characterized by high strength, heat resistance and durability. One of the advantages of this option is also the rich color palette, which includes not only black and white tones, but also blue or green colors;

- Terracotta tiles are also made from clay, but they are inferior to the previous option in terms of density and the number of possible colors;

- Soapstone is a good cladding option for a bathhouse, made from rocks of green and grayish shades. Has good heat resistance and strength;

- Tiles are ordinary ceramic tiles, characterized by good heat resistance and a pattern on their surface;

- Porcelain tiles are heat-resistant tiles that imitate natural stone or wood.

The tile will not dissipate heat, protecting the walls from fire, so it cannot be mounted directly on the wall. We recommend using the following design:

- Wall;

- Clearance for ventilation;

- Fireproof material;

- Tiles (the distance from the tile to the stove must be at least 15 cm).

Such a “pie” will create reliable protection for walls from heat, preserving the beauty of the room.

One of the following options can be used as a fireproof material:

- Fireproof drywall - made from the same materials as regular drywall, but using fiberglass;

- Minerite slabs for baths are absolutely not exposed to moisture and heat.

- Glass-magnesium sheet - plates made of fiberglass and magnesium binder. Excellent resistance to heat, moisture and noise.

This option will perfectly protect your bathhouse from the possibility of fire, and will also insulate the room, preserving its aesthetic component.

Leave feedback:

Step-by-step instruction

Thermal insulation work is carried out taking into account certain rules and safety standards. It is first recommended to decide on the method of insulating the stove. The following elements are thermally insulated in the furnace structure:

The first structure is insulated in the following cases:

- reduction of heat consumption - thermal insulation work is carried out when the fireplace or stove is not designed correctly, when all the heat comes out through the chimney (due to excessive draft or the use of materials with high heat transfer);

- insulation retains heat;

- elimination of condensate: if the pipe is not insulated, condensate collects in it, it destroys the pipe masonry or welded coating joints.

Experts recommend insulating the surface of the stove located close to the walls of the house. Otherwise, cracking of the brick will occur due to temperature fluctuations. Thermal insulation between the wall and the stove is carried out using the following materials:

- asbestos slabs;

- thermofoil (as a heat reflector).

The method under consideration is used if the space between the stove and the wall exceeds 5 mm. If the distance is small, then asbestos cannot be used (due to the composition of the material).

It is possible to carry out thermal insulation work using the following technology:

- strengthening the wall using metal sheet hangers;

- installation of slabs of ceramic or asbestos insulating material;

- filling gaps and seams with mineral wool;

- winding the pipe with an external reflector (foil).

Since mineral wool does not tolerate condensation, a special material should be used to insulate this seal. A similar technology is used for furnace thermal insulation. At the same time, the wall does not heat up or heat up.