Agree, the bathhouse is a sacred place for Russian people, which is treated with special reverence. However, collecting firewood can be a very troublesome and expensive pleasure. Therefore, many consider a gas boiler for a sauna to be the best option - an efficient unit that quickly heats up to the desired temperature.

We will tell you about the advantages of a gas boiler, as well as the features of arranging a gas boiler room in a bathhouse. We'll tell you what you should pay attention to when purchasing it. As a bonus, we will reveal the secret of obtaining a gasification permit.

Advantages and disadvantages of a gas boiler

Most people living in gasified areas choose a gas boiler to heat their baths or saunas. This decision is economically justified.

Advantages of using gas equipment:

- small heating fee;

- no need to stock up on fuel;

- there is no need for a place to store fuel;

- the need for cleaning from ash and coals disappears;

- there are no processed gases in the room;

- small dimensions and weight with maximum power;

- minimum kindling time;

- safety and ease of operation.

A modern gas boiler for arranging your favorite bath or sauna solves several problems simultaneously:

- allows you to get rid of carbon monoxide and the unpleasant odor of scale;

- smoothly heats the air and maintains the temperature;

- Doesn't take up much space.

If you entrust the installation of equipment to specialists and do not interfere with the operation of the control unit and burners, then the risk of fire and carbon monoxide poisoning is minimal. At the same time, the chimney will remain clean.

Gas heating appliances are lighter and more compact than others and have sufficient power to heat a large room

The disadvantage is the high cost. To correctly connect all pipes, electronics, power supply, check the operation of the sensors and ensure tightness, you should seek the help of an experienced technician. You will also have to pay for the services of a contractor knowledgeable in plumbing, electrical and gas supply.

However, all investments will pay off in a couple of years, since the gas model of the boiler is more profitable than other types of heating equipment.

Electric heating in the bathhouse

If there is a need to heat only the steam room, then the ideal solution is a solid fuel stove. Otherwise, when you need to heat the dressing room, shower room and other rooms in the bathhouse building, this option can be safely discarded.

To heat a large area, it is better to use an electric boiler. Its production and installation do not have any technical difficulties. All that is needed is to weld the water heating elements into a container of water and properly arrange the heat exchange system.

The advantages of sauna boilers running on electricity are obvious:

- there is no need to equip a chimney system;

- ease of installation, operation and maintenance;

- high efficiency.

Along with the advantages, there is a significant drawback: significant energy consumption.

Types of gas boilers for baths

All equipment operating on blue fuel is divided into:

- single-circuit - installed in small rooms;

- double-circuit - in addition to heating, they will provide hot sanitary water;

- three-circuit - additionally heat pools or heated floors.

In order to not only heat the bathhouse, but also ensure the supply of hot water, you should choose a double-circuit boiler with a power of 20-30 kW. This power is enough for an area of 200-250 square meters. Water heating rate is 10-14 l/s.

Heats the heating circuit and hot water supply

Boilers can operate both on main gas and bottled liquefied gas. Not all holiday villages are gasified, so the latter type of boiler is optimal for a private bathhouse. Some models are equipped with replaceable nozzles, which allows the equipment to operate on liquefied and main fuel.

Classification of gas boilers:

- by material - metal, stone, brick;

- depending on the fuel used;

- equipped with different tanks for heating water;

- have different types of burners.

Compared to metal stoves, brick and stone stoves take longer to heat up, but they can retain heat longer. A metal boiler is chosen due to its compact size, after which it is lined with brick.

The burners used are atmospheric and inflatable. The atmospheric burner does not require electricity to operate, so it is more economical and at the same time completely silent. It functions due to the air entering the ash pan. The main requirement for boilers with an atmospheric burner is proper ventilation.

The amount of oxygen supplied can be increased by increasing the size of the slot

An inflatable burner is different in that it requires a fan that is powered by electricity to operate. The operating principle is the same: gas is mixed with air to heat it. To make the operation of such a model safer, you need to take care of installing an emergency power source.

Long combustion heating boilers

The newest types of boilers for baths are solid fuel boilers with long combustion. Their distinctive feature is a significant period of burning solid fuel with just one load. In some models this period reaches even 5 days.

Wood and drinkers are excellent fuel for such boilers, although in some models mixtures of coal, firewood and peat can be used. After all, the operating principle of such a boiler is ingeniously simple: the mechanism that supplies air descends from top to bottom, depending on the stage of smoldering of the loaded fuel. Thus, during operation, the boiler constantly maintains the temperature set for it and independently changes the air supply, and, therefore, the intensity of fuel combustion - using a draft regulator.

Long-burning boilers do not produce excess heat, and therefore do not require a storage tank. The most popular boilers today are the Lithuanian company Stropuva.

The main thing in choosing a boiler is a guarantee for the duration of its operation.

How does a gas oven work?

The operating principle of the equipment is similar to a classic wood-burning stove. The only difference is the type of fuel. Instead of a firewood compartment, gas boilers have a burner. The gas mixes with oxygen and produces heat.

In some models, the burners are combined with a firebox for firewood. Design Feature:

- gas burner in the housing;

- fuel source;

- in the upper part there is a tray for stones;

- device for removing combustion products;

- thermostat and fuse;

- sealed chamber with processed fuel.

During operation of such a boiler, there is no need to add firewood and monitor the temperature. Thanks to the automatic control system, you can not be distracted from bath procedures.

Required Tools

For bathhouse needs, they usually purchase double-circuit gas boilers with a closed combustion chamber. They are easier to install, and in addition, do not require the use of a carbon monoxide indicator. Such sensors are required for boiler equipment with an open chamber or with air intake from the dressing room or boiler room.

The sensors are very capricious in operation, they are easily triggered by cigarette smoke and even fried potatoes, so it is still better to buy closed models for a bathhouse.

To install the boiler you will need:

- Hammer with ring drill and drill;

- A set of anchor bolts or hooks, this fastener is often included with boiler equipment;

- Template for marking the wall.

Simultaneously with the installation of the boiler, the heating system is being installed, so you will need a soldering iron for polypropylene pipes, registers, taps and shut-off valves.

How to choose the perfect model?

When choosing a gas boiler for your sauna, you should pay attention to:

- coolant volume;

- area of the heated room;

- requirements for installation and presence of a chimney.

Heating equipment for baths and saunas can be wall-mounted, floor-mounted, or parapet-mounted. Floor-standing models are large in size, have a simple design and operate automatically. Disadvantage: it requires a lot of space for installation.

Wall-mounted models are more compact in size. They are easy to install and equipped with forced smoke removal. Parapet boilers do not require a chimney.

The optimal distance between the wall and the gas boiler is 50 cm

When choosing a boiler, you should pay attention that the high temperature stability of a heating device is not an indicator of quality. You also need to monitor the gas pressure. This is the main criterion when purchasing equipment. A disruption in the supply of blue fuel may be unsafe.

When choosing a gas boiler, it is important to correctly calculate its power. This indicator depends on the area of the heated room. Standard requirements: 0.4 cubic meters requires 252 kilocalories. To calculate the power value, you need to substitute your values.

Useful tips for choosing a gas boiler for a bath and sauna:

- Often the steam room has a small area. In order not to “steal” space with installed equipment, it is better to opt for a medium-sized model.

- The best option is a boiler with an external fuel channel. Advantages: space saving and higher operational safety.

- The lower the gas consumption, the more efficient the equipment and the higher its efficiency. The data can be found in the unit passport.

- Some boiler models operate only on main blue fuel. This should be taken into account if you plan to use liquefied bottled gas.

- When planning to cover the boiler with bricks, you need to pay attention to how many stones the power of the unit is designed for.

It is preferable to purchase a boiler from well-known manufacturers. The best domestic manufacturers: Ermak, KUTKIN, Termofor.

What materials and tools are needed to make a boiler?

Boilers for steam rooms in Russian baths are made using the following tools:

- welding machine;

- grinders, with a cutting wheel designed for working with metal.

We’ll talk a little later about how homemade sauna boilers are made from a pipe or barrel. First, we should talk about the most common sheet metal option. In addition to this you will need:

- small pieces of reinforcement and channels - they are needed for the manufacture of internal partitions;

- a thick sheet of metal (minimum 0.5 centimeters) - it is necessary for the production of grate bars;

- pipe with a diameter of at least 10 centimeters;

- awnings for firebox and vent doors;

- faucet for tank.

When talking about how to weld boilers for a bath, we should mention the manufacture of a heat-distributing screen. It is best made from brick. All you need to do is to tightly surround the boiler with it.

Safety and Installation Requirements

Since gas is used for operation, you should be as careful as possible during operation.

Necessary:

- monitor the wear of all equipment parts;

- regularly check the readings of the gas analyzer and other devices;

- Only trust a specialist to replace parts.

Savings when purchasing, installing and operating gas equipment can lead to dire consequences.

Requirements for the room where gas equipment is planned to be installed: no high humidity, no accumulation of dust, limited access for children.

Before a gas boiler room is installed in a sauna or bathhouse, you need to study the rules for safe installation:

- the height of the room must be at least 2.2 m;

- All doors must be opened outwards;

- It is necessary to have a window and exhaust ventilation;

- absence of flammable structures near the equipment (minimum distance - 0.5 m);

- if the walls of the room are made of fire-hazardous material, when installing the equipment, an indentation of at least half a meter should be made (the use of a fire-resistant barrier or heat-resistant screen is allowed);

- a hole for a rectangular burner (height - 48-55 cm, width - 35-45 cm);

- to prevent gas leakage, it is recommended to install a special sensor that will operate when the burner goes out;

- the smoke exhaust pipe should not pass through living rooms;

- the stove must have a metal base that will protrude at least 10 cm;

- To prevent the occurrence of condensation, the chimney must be made of stainless steel.

If the site is not gasified, then forced removal of combustion products should be organized. To maintain high temperatures, high-quality thermal insulation of the room is necessary.

The optimal solution would be to use foil insulation. It should be noted that heat loss increases in the presence of windows and uninsulated doors.

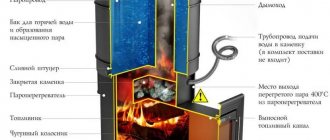

Main components of a sauna boiler

Any stove, including sauna boilers, consists of the following elements:

- A firebox in which the combustion process of wood, coal and other types of fuel occurs. It is made of thick metal. This is due to the fact that the firebox has the highest thermal load, metal of insufficient thickness will quickly burn out, and a homemade boiler for a bath will become unusable. A wood-burning boiler for a bath, namely a firebox, must be equipped with grates. Through them, ash from burnt fuel spills into the ash pan. The thickness of the metal from which they are made must be at least 0.5 centimeters.

- A chimney through which smoke is removed. When deciding how to make a boiler for baths, you need to thoroughly understand the principle of operation of the chimney system and carefully calculate its dimensions. The slightest mistake when installing a chimney can lead to insufficient efficiency of the stove (heat will go into the chimney) or an inability to cope with the removal of combustion products. The chimney must be equipped with a valve, with which the draft level is regulated. In winter, a tightly closed valve greatly contributes to the preservation of heat in the room. The chimney pipe may pass through the heater or be part of a heat exchange system.

- An ash pan designed to accumulate ash. This boiler element is located under the firebox. In addition to its main function, it is responsible for the supply of air, which is an integral component of the combustion process. When making a boiler for a bath with your own hands from pipes, you should carefully calculate the dimensions of the ash pan. It should be able to hold enough combustion products to be cleaned once a day.

- A heater that redistributes and removes thermal energy. It is a built-in or hanging container in which stones are placed. Its volume depends on the size of the boiler and steam room. A small heater will not be able to heat the room, and a large one will take too long to heat up. During this time, the water boilers have time to boil, which causes the room to fill with water vapor. At the same time, the steam room will become uncomfortable. The size of the heater and water tank should not be different. You can make a cauldron without a heater, but this is not entirely convenient. The room will be heated only from the walls of the boiler. In addition, it will not be possible to “give in to the park.”

- A water tank that is part of the heat exchange system. Cast iron sauna boilers with a water tank are the most common solution.

After the main components of the device that produces heat have been identified, we should move on to the main question: how to make boilers for a bath from scrap materials?

Features of gasification of a bath

Russian government decree No. 509 of 2008 states that gasification of a bathhouse is allowed. The only condition is that its use for commercial purposes is prohibited.

If the boiler is equipped with an atmospheric burner, the inspector will check the ventilation device and draft

The project should include:

- the presence of a separate entrance (heat-resistant materials are used to make the door);

- availability of fire extinguishing and alarm systems;

- the equipment must be industrially produced and have a quality certificate;

- It is mandatory to have a ventilation system and a carbon monoxide detector.

Practice shows that the chance of obtaining permission to gasify a bathhouse increases if all work is carried out by specialists competently and efficiently. After the building of a bathhouse or sauna is built, it should be registered with the BTI. The next stage is a trip to the city gas supply office, where an application for gasification is written.

When the application is reviewed, an inspector will visit the gasification site. As a result of the inspection, changes may be required (installation of additional ventilation, alteration of the chimney). When permission is received, all that remains is to connect the equipment and insulate the bathhouse building.

After selecting and installing a gas boiler in the bathhouse, you can enjoy the result of your labor. Money and time costs are compensated by maximum comfort and safety. After all, modern equipment allows you to create an optimal balance between temperature and humidity, does not dry out the air and is ideal for lovers of a traditional bath.

How to obtain permission to install equipment

Before starting the construction of a gas-heated bathhouse, it is necessary to check with the relevant services about the possibility of connecting the facility to the gas network. It is made on the basis of an application. Gas services, based on the power of the equipment planned for installation in the baths, calculate the maximum gas consumption m.cub./hour.

Based on this calculation and safety requirements, they develop technical conditions for connecting gas to the facility and issue its passport. After obtaining permission to connect gas, work is carried out by specialized organizations. At the same time, the bathhouse room to which gas is supplied must comply with the requirements of SNiP 2.04.08-87.

Conclusions on the topic

Gas boilers for saunas are more expensive than wood stoves. However, the cost is offset by many benefits. You no longer need to prepare firewood and monitor the temperature in the room. In addition, the gas boiler is easy to use and completely safe.

The disadvantages of the equipment are too insignificant in comparison with the advantages, so they can be neglected. It is important to observe safety precautions during operation and trust the installation of the boiler to professionals.

If you have experience using a gas boiler for a bath, please share your impressions. Which company's equipment do you consider more reliable? Write your recommendations in the comments and share photos of arranging your own bathhouse.

Pyrolysis

The operating principle of such boilers is the presence of fuel combustion chambers. The primary combustion process with the release of gas occurs in the first chamber, and in the second - afterburning, direct gas synthesis. To light such a boiler, it is enough to use an electric ignition system. The main advantage of gas pyrolysis boilers is that the fuel burns almost completely, and almost no soot and ash remain.

Design of a pyrolysis boiler.

Among the disadvantages of this type of boiler is the high price. In addition, most pyrolysis boilers for saunas operate only on well-dried wood, for example, boilers from the Czech company Atmos and the Polish Orlan.

Boiler installation methods

If the structure is equipped with an external tunnel, then the best option would be to install the boiler in the partition opening between the steam room and the dressing room. To control the operation of gas burners, use a remote control panel or control valves on the board. According to the standards for installing boilers and furnaces, the area in front of the tunnel must be illuminated either by an emergency lantern or through a window opening.

Methane heaters are installed mainly under the wall under the exhaust ventilation opening. For low-power models, you can choose a place next to the entrance door of the steam room.

Requirements

To talk about the pros and cons of a heating system, you must first determine what requirements it must satisfy.

And this:

- Safety.

- Economical.

- Ease of use.

- Warm-up speed.

Knowing the requirements listed above, you can see how gas sauna stoves meet these points.

Gas boiler-heaters in standard version

In appearance, standard models of gas boilers for baths, photo, are practically indistinguishable from wood-burning versions. The same high rectangular metal body, a filling heater in the upper part of the structure and a side tunnel for supplying air and fuel.

Modern models of domestically produced gas equipment copy well-known Finnish and Italian brands in shape and design.

A gas appliance is always easily recognizable by its automatic control unit. Where a wood-burning stove has a door or hatch for loading firewood, gas boilers for a bathhouse have a panel with nozzles, a fire front sensor and an ignition device.

The outer walls are made of thin sheet steel, which provides reliable protection from the hot combustion chamber. Its shape and dimensions are much smaller than a wood firebox, almost always made of heat-resistant alloy steel.

Inside the firebox there is a package of two or three nozzles. The dimensions and shape of the combustion chamber of a gas boiler are carefully selected and calculated during the production process. Therefore, you cannot simply take and install a gas burner into the combustion chamber of a wood stove. The firebox will burn out within a few months of use.

There are gas-wood models of heaters for baths. In this case, the dimensions of the combustion chamber are made such that they can burn wood with a very small combustion front and gas with a high flame height. But even in such designs, only the gas burner that comes with the boiler can be converted and installed; the use of a burner device of any model leads to burnout of the chamber walls and outlet channels.

In a classic gas boiler, tubular heat exchangers are always installed to heat water. To heat the bathhouse, the registers are connected to a storage tank and a pump that pumps hot coolant through radiators or underfloor heating pipes.

In low-power boiler systems, instead of a built-in heat exchanger, mounted water tanks are used, similar to tanks in wood-burning stoves. In powerful gas boilers, double-circuit coaxial heat exchangers can be installed to heat the bath. Essentially, these are two pipes, one inside the other. Water flows through the inner tube, which is heated to spray the heater; the coolant of the heating system usually flows in the space between the walls.

Advantages of using gas wood stoves

This category of universal units differs from the usual solid fuel, gas stoves and boilers by the ability to combine several types of energy sources. For this purpose, gas-burning stoves are equipped with auxiliary removable devices that allow the use of solid fuel or serve as an alternative in the form of gas-burning equipment.

The key operating components of this category of furnaces are gas burners, relief and shut-off valves, and filters. The fuel receiver is installed for processing firewood. This flexibility in the functionality of the stoves determines their high popularity among compatriots; their significant advantage is their affordable price range.