The construction of a traditional Russian bath requires a special approach and the use of special heat sources that can relatively quickly warm up the steam room space to a high temperature. For this purpose, boilers for wood-burning saunas are used, which have a special design that allows them to transfer maximum heat into the room.

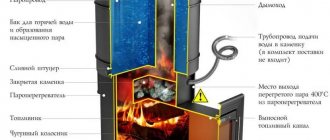

Sectional view of a boiler for a bath

Types of boilers for baths

Boilers for baths are primarily divided into several types according to the type of fuel. In this regard, the main groups can be distinguished:

- Gas;

- Electrical;

- Liquid fuel;

- Solid fuel;

- Pyrolysis.

Sometimes a combination boiler is installed in a bathhouse, which implies the ability to use different fuel options depending on the wishes of the owner. However, such models have an increased price, so they are not very popular on the market.

Each sauna boiler, its advantages and disadvantages should be considered in detail. Such an analysis will make it easy to make the right choice, taking into account the individual needs of each owner.

Gas

This option can easily be called one of the most economical. Modern sauna boilers of this type are easy to set up, they are able to maintain and control the temperature, which ensures ease of use. However, there is also a significant drawback, in particular the risk of explosion. If you plan to make a boiler for a bathhouse with your own hands, then you definitely need to follow many safety rules.

Electric

In this case, a boiler for a sauna or bath will be the easiest and safest to install. It can do without a chimney and requires a relatively small installation space. Heating is carried out using a heating element. Disadvantages include the high cost of electricity, as well as the need to install separate wiring to provide protection against short circuits.

Heating using liquid fuel

Such models are considered quite dangerous. It should be noted that boilers for baths of this type most often run on diesel fuel. This becomes a fire hazard if basic safety criteria are not met. Additionally, you need to pay attention to the fact that this option may have an unpleasant odor.

Pyrolysis

This is a boiler for a wood-burning sauna, which is designed in a special way. In it, the combustion process is divided into two stages, each taking place in its own compartment. In one of them there is smoldering, and in the other there is combustion. Thanks to the separation of such processes, it is quite easy to maintain the required temperature, which in the future contributes to significant fuel savings.

Solid fuel

These are boilers for wood-fired saunas. Also, almost any type of fuel can be burned in the firebox, it can be coal or other options. Everyone chooses the one that suits their main criteria. It is worth noting that due to their versatility, simple design and fairly economical consumption, these models are the most popular among all options.

Electrical

An electric heating boiler does not require a ventilation system.

Today, electric bath boilers are the cleanest in environmental terms . They do not require a ventilation system, which is important for the hot and humid atmosphere of any bathhouse. They are perfect for those steam rooms that do not have gas supply.

Electric boilers are easy to set to the optimal temperature and there is no need to worry about fuel reserves and its periodic supply. However, the electricity costs for this type of heating leave much to be desired - it can turn out to be very expensive.

Recommendations for choosing a boiler for a bath

There are several basic criteria to consider in order to choose the right boiler. These include the following factors:

- Ability to maintain temperature stably;

- The area of the room to be heated;

- Easy installation and the ability to install it yourself;

- Safety, in particular the type of fuel must be taken into account.

It is imperative to focus on these basic features so that construction and installation, as well as operation, do not cause additional problems.

What materials and tools are needed to make a boiler?

In villages there are usually problems with electricity. For this reason, in such conditions, another parameter that the Lemax gas boiler has is very important: it depends on electricity. Most of the thermal generators produced by foreign companies cannot operate at all without “feeding” with electricity, which is not at all surprising - residents do not face such problems. But, in any case, it seems possible to make the boiler independent of the electrical network. (See also: DIY boiler for oven)

The first method is that you can completely eliminate all automation (this is typical for all domestic models). The boiler will be able to maintain not only the specified temperature of the coolant, but it will also be guided by the air temperature in the room. The second and more progressive method is the use of generators, which independently, using heat, generate electricity, which is required for the operation of the automation. Such boilers can be used with remote room thermostats.

How to make a boiler for a bathhouse

Almost everyone is able to figure out how to make a boiler for a bath with their own hands using a simple algorithm. To do this, you first need to decide on the type of device, carefully prepare all the tools and materials, and then immediately proceed to step-by-step actions.

Construction of homemade boilers

Depending on the materials and your own skills, you can choose the simplest design, in particular, assemble a boiler for a bath with your own hands from a pipe, or find a more complex option that requires a long-term responsible approach. Based on its design, the device can be divided into several types.

View this publication on Instagram

Publication from work of any complexity (@alexsandrmontag)

Cylindrical boiler

This is the simplest option. This is due to the fact that there is a minimum number of joints. You can also use almost any materials. In this situation, a boiler for a bath from a pipe or barrel is made by simply cutting it according to size. In this case, it is necessary to take into account that the metal itself must be at least 6 mm thick, and the cylinder diameter must be from 50 cm. The difficult stage of making a pipe from a pipe with your own hands is just cutting through the firebox and ash pan.

Rectangular boiler

The dimensions of a rectangular boiler in a bath should be similar to a cylindrical one. However, it is made from individual metal sheets. They will first need to be cut, measured, and also formed into a firebox and ash pan. Before you figure out how to weld a boiler for a bath, you definitely need to draw up a diagram, take all the measurements in detail and cut the material into the necessary parts.

Do-it-yourself boiler for the bathhouse drawings

It is worth considering that they are almost universal, but for the gas version it will be necessary to organize the connection in the dressing room. You can see the drawings attached below.

Tools and materials

Coping with such a task as independently manufacturing such a unit, as well as its installation and assembly, becomes possible thanks to a simple list of tools. This includes welding, a grinder, a hammer, a chisel and pliers. Regarding materials, in most cases metal is chosen. In the future, the base can be finished at the user’s request, for example with stone.

Boiler installation rules

Even at the stage of building the bathhouse itself, it is necessary to think about a place for the boiler. The metal structure is quite bulky and heavy, which is why it is best to place it on an additional foundation, and you also need to take into account exactly how the chimney will be organized. It is best to install the boiler directly under it, so the draft will be much better.

Heating boilers using liquid diesel fuel

A diesel heating boiler requires a separate room, because

When burning, it produces an unpleasant odor. Bath boilers that run on liquid diesel fuel are considered second in convenience after gas boilers. After all, there is no problem with storing fuel here either - it is enough to find capacious metal or plastic containers, preferably with dense double walls, because diesel fuel can deteriorate its physical properties when stored for more than 1 year.

For a diesel fuel boiler, a separate room in the bathhouse must be allocated - otherwise all other rooms will become saturated with an unpleasant odor. However, some craftsmen purchase several tons of fuel at once and bury it in tanks in the ground, refilling them only once a year. But this can only be done under the guidance of an experienced person.

Today there are also homemade boilers for baths that run on liquid fuel . But before installing such a boiler, it must be shown to a specialist.

How to cook a sauna cauldron with your own hands

It must be taken into account that in most cases the solid fuel option is used; it does not require additional permits and is simple and universal.

For convenience, the welding process should be divided into several parts. First of all, it’s worth preparing drawings; they can be standard or homemade. Then come the next steps, none of which should be skipped.

Preparing consumables

It must be taken into account that in this case the main material will be metal, be it a sheet version, a pipe or a barrel. In addition to the consumables, it is worth including grinder circles; they will dull the thick walls quite often; they should be changed promptly. When using electric welding, electrodes with a diameter of about 4 mm should be prepared. If we are talking about gas welding, then there must be an oxygen cylinder and carbide, as well as a metal wire. During work, it is necessary to take care of personal protective equipment; a homemade boiler must be made in safe conditions.

Welding of structural supports

The first answer to the question of how to make a boiler for a bathhouse is welding the supports. For this purpose, reinforcement is used in the pipe, which significantly increases its strength. It is best to place 3 supports at different levels horizontally. It is important to consider the bottom as a substrate for the oven. The middle one is located where the ash pan door will be constructed. It is best to place steel caps above and below the pipe.

Heat exchanger welding

For a bath, a heat exchanger is often additionally used. This is a coil that you can choose yourself or buy ready-made. Copper is chosen as the material; it will best provide heating. It is worth considering that it is best to purchase a heat exchanger, because its manufacture will be too labor-intensive.

Assembly of the structure

At this stage it is necessary to assemble the entire boiler. To do this, a box is welded in, the firebox is brought outside or into the dressing room, and a heat exchanger is inserted. Be sure to immediately make an additional hole for the chimney.

Installation work

After manufacturing, your sauna boiler can be installed in the sauna. It's a fairly simple process:

- During the construction of the bathhouse or immediately after, the foundation is prepared.

- A concrete screed is used as the base.

- Install the boiler and connect it to the chimney.

- Brick can be used as finishing.

If there is a heat exchanger, it is connected to the heating system in the given room.

Sauna stove Kopeechka

view product

The Kopeechka sauna stove is made from 6 mm stainless steel and is coated on the outside with heat-resistant black matte enamel. It is perfect for small spaces with a combined washing and steam room with a volume of 6-15 cubic meters. m. Despite its structural simplicity and affordable cost, the wood-burning unit is reliable, highly efficient, and easy to install. The heater can hold 60 kg of stones, which warm up to comfortable steam in just 30 minutes. The presence of a retractable ash pan makes it possible to regulate the combustion power, as well as easily remove accumulated ash even while using the stove. If necessary, you can install a tank to heat 31 liters of water.

Advantages

- increased reliability is achieved by strengthening the combustion chamber and heater;

- durability - metal thickness is 6 mm;

- high efficiency and compactness;

- heating time for stones to produce steam – 30 minutes;

- deep capacious heater;

- The outer surfaces of the stove are painted with heat-resistant enamel.

Flaws

- no built-in heat exchanger;

- the tank is purchased separately;

- no remote firebox.

| Steam room volume | 15.0 (cub.m) |

| Firebox material | Steel |

| Mass of laid stones | 60.0 (kg) |

| Chimney diameter | 115.0 (mm) |

| Width | 320.0 (mm) |

| Height | 590.0 (mm) |

| Depth | 475.0 (mm) |

| Weight | 60.0 (kg) |

| Manufacturer country | Russia |

| Guarantee | 12 (months) |

2

Sauna stove made from a pipe or an old cylinder

The ideal material for production is special boiler steel. However, there is an opportunity to save money if you use cheaper materials. In the case when you plan to take a pipe or an old cylinder, the water tank should be placed above the firebox. It is important to take into account that the thickness of the metal cannot be less than 1 cm, otherwise the use of such material is unsafe.

Which boiler is better to choose?

As we wrote earlier, the first and most important selection criterion is the volume of the steam room in your sauna. Each model of a factory steel furnace is supplied with detailed documentation, which necessarily indicates the optimal dimensions of the steam room, at which the boiler’s operating efficiency will be greatest.

Why is this so important? The fact is that if you install a more powerful stove than necessary in a small steam room, you will encounter such an inconvenience. As the boiler gradually warms up, the temperature in the steam room will increase and the moment will come when it will be optimal for starting steaming. And it is logical that just at this time you should go into the steam room and start warming up, but there is one problem - the powerful stove quickly warmed up the steam room, but the stones inside it did not have time to heat up.

When you enter the steam room at this stage, you will pour water on the stones, but they are not warm enough and do not produce steam. Water ultimately evaporates only when it hits the surface of the metal, and the most pleasant feature of modern metal furnaces - finely dispersed light steam - will not be available. Therefore, for small steam rooms you should choose only small stoves and nothing else.

Horizontal boiler for a bath

The original horizontal boiler is quite common. Its production differs from the classical scheme:

- Holes must be cut in the pipe according to the diagram.

- It is necessary to create a heater in the upper part, it is very convenient.

- Such a stove is located on legs.

The chimney is connected to one side. Additionally, be sure to check the traction force.

Combinations

Let's consider several successful combinations of boilers that can be used for a bath and made with your own hands:

- Pellet and electric. The disadvantage of this solution is the cost of the equipment. Therefore, quite large initial costs are required. In this case, you will need to allocate quite a lot of space to place the devices. However, there are also advantages of this solution: the affordable cost of pellet fuel, the possibility of automating the process, reducing costs by turning on the electric boiler only at night if a two-tariff meter is installed.

Electric pellet boiler

- Gas and electric boiler. This is a technological solution that will allow you to fully automate the process, without fiddling with solid or liquid fuel, while always being provided with heat. After all, if there is a power outage, the gas supply is unlikely to be interrupted and vice versa.

Electric-gas boiler

- Coal and electric boiler. Under certain conditions, such a combination can be both beneficial and convenient. Of course, you need to be able to buy coal profitably.

Coal or electric boiler, which is used in baths

Types of heat exchangers for boilers

To heat water, as well as heat the room, if it is large enough and the stove cannot cope, it is necessary to consider a heat exchanger. They differ primarily in material. The best option is copper. However, such metal is not affordable for everyone. It is possible to replace it with carbon steel and get a similar result. However, it is best to purchase a ready-made option. After all, it is quite difficult to correctly assemble a heat exchanger with your own hands.

Tubular heat exchanger

In most cases, the heat exchanger is a kind of coil; it can also be spiral or composed of two pipes, when one is located in the other. It must be taken into account that one end of it must be connected to the heating system, and the other must be located directly in the boiler.

Where to install heat exchangers

The heat exchanger installation process provides several options for choosing a location:

- Inside the firebox;

- Near the body;

- In close proximity to the chimney.

Depending on the design of the boiler, as well as on the room itself, you definitely need to focus on the option that will be most convenient.

Sauna stove Vesuvius Legend Standard 16 (DT-4S)

view product

The cast iron bath stove Vesuvius Legend Standard 16 (DT-4S) is guaranteed to last at least 30 years. The forged steel mesh holds many stones, retaining heat for a long time and blocking infrared radiation. A remote firebox, made of two cast parts bolted together and sealed with a sealing cord that can withstand temperatures up to 1200°C, allows you to place the device in a room adjacent to the steam room. To change the direction of the flame, increase efficiency, and facilitate the removal of soot from the unit, it is equipped with a removable chipper tooth cast from cast iron. The door of the device is originally decorated and glazed, allowing you to admire the living flames.

Advantages

- made of high-strength cast iron;

- stylish appearance;

- the door is made of impact-resistant glass;

- large volume of heater;

- A minimum of welds guarantees a reliable structure.

Flaws

- regular cleaning of soot;

- heavy construction.

| Volume of steam room, m3 | 8-18 |

| power, kWt | 14 |

| Material | Cast iron |

| Chimney diameter, mm | 115-120 |

| Weight of stones, kg | 120 |

| Height, mm | 620 |

| Width, mm | 560 |

| Depth, mm | 760 |

| Weight, kg | 105 |

| A country | Russia |

| Guarantee | 1 year |

5

Summarize

Modern sauna boilers are sold in stores in a wide variety. Unfortunately, among a large number of models you can find too expensive options that are unaffordable. There are also economical options, but they are of poor quality, primarily due to the use of cheap material. As a result, it is the independent manufacture of boilers and their installation with your own hands that are becoming increasingly popular, especially considering that this is a fairly simple job if you prepare for it correctly and use all the useful recommendations.

Gas-only stoves

TMF Taimyr

The most comfortable temperature for a classic Russian bath is considered to be around 60 degrees combined with a humidity of about 60%. Such indicators can be achieved with the help of such a furnace, largely due to the use of unique technology for generating steam. First, it passes through the closed heater, after which it enters the open one and exits into the steam room already quite soft, providing maximum comfort.

The power of this stove is 32 kW, it is capable of heating a steam room with a volume of up to 18 square meters. m. The kit includes a remote tank, but there is no burner. An open heater is often used for aromatherapy sessions - aromatic oils and herbal infusions can be sprayed onto it. Such a stove does not heat up the steam room too quickly, but for a long time it is able to maintain a consistently comfortable temperature.

Advantages:

- Modern appearance;

- Compact overall dimensions;

- Maintains temperature at a stable level;

- The most modern technologies are used in production;

- The manufacturer provides a five-year warranty.

Flaws:

- Some items have to be purchased additionally;

- The steam room does not warm up as quickly as we would like.

TMF furnace Taimyr

Heat StandardGas

The heat generator is equipped with a firebox made of high-quality high-carbon steel ST20, which has a high thermal conductivity. The design of the chimney is carefully thought out, so there is no direct outflow of hot air. This approach makes it possible to ensure the highest possible heating of the heater and steam room with minimal fuel consumption. The maximum power of the furnace is 30 kW, the largest heated volume is 25 cubic meters. The design is equipped with a gas burner; the heater is closed; a water tank will have to be purchased additionally.

The quality of the welded joints is quite high, the stove warms up to 100 degrees in less than one hour, especially if the steam room is equipped with high-quality thermal insulation.

Advantages:

- Long period of operation – at least 10 years;

- Optionally can be equipped with water tanks of various installations;

- Heat transfer is approximately twice as high compared to analogues;

- The gate unit can be disassembled if necessary;

- You can add water to the tank without disconnecting it.

More: Top 10 best wood glues, how to choose wood glue?!

Flaws:

- The wall thickness is not very large;

- The paint layer peels off quickly.

Stove Heat StandardGas

Kusaterm 10/20 kW

It is distinguished by the highest quality of production, and also has a very long service life. The products have protective railings that prevent burns. The stove is equipped with very strong foam glass, Foamglass, which provides reliable thermal insulation of the steam room floor from heat.

The stove fully complies with all international standards; the design can be controlled using a digital panel. In general, users say that this design is universal - it can be decorated independently with natural or artificial stone, thanks to which it will fit perfectly into any interior.

Advantages:

- Works almost silently;

- Complies with major international standards;

- The floor is protected by Foamglass.

Flaws:

- Designed only for small areas;

- Very high cost of production.

Oven Kusaterm 10/20 kW

Troika No. 06-GT

Another rather expensive model, which has a unique design, there is a closed heater, the wall thickness of which ranges from 10 to 20 mm. The package contains all the gas equipment necessary for normal operation of the product. The product is quite powerful - 80 kW, it can reliably heat up to 70 cubic meters. A remote tank is included in the kit. When using dry heat, it is possible to obtain abundant but very light steam; the outer casing is stylized as a brick. With its help, you can provide high-quality heating, a comfortable temperature is maintained for a long time.

Thermal inertia technology is used here, which ensures quick drying of the room. The stones heat up on five sides at once, so the temperature in the steam room rises very quickly, while the stones themselves in the lower layers warm up to about 500 degrees. The furnace is made from low-alloy sheet steel 20 mm thick. This allows you to load up to 28 kilograms of stones into the heater without fear of deformation of the structure.

Advantages:

- Melts almost instantly;

- The heater allows you to accommodate a significant mass of stones;

- Made from thick sheet steel.

Flaws:

- The stove weighs a lot - about 400 kg;

- Expensive.

Troika stove No. 06-GT

Kutkin G-2.0 Premium

One of the most popular models among Russian consumers. The stove itself is decorated with natural stones made from materials such as serpentine, soapstone or jadeite. Instead of a standard firebox door, you can install some kind of fireplace burner. The product power is 20 kW, it heats up to 25 cubic meters. With the help of this model, it is possible to create a microclimate regime in the steam room, regardless of the type of bathhouse - from classical Russian to Finnish and even Turkish.

The heater here is closed, there are several temperature modes, there is no convection. The heating dynamics are very high - the room warms up to a comfortable temperature in about half an hour, the design is modern.

Advantages:

- Compared to analogues, it is quite affordable;

- Made exclusively from high quality materials;

- Original external design;

- Long service life.

Flaws:

- You will have to spend a certain amount of time mastering the firebox itself.

Oven Kutkin G-2.0 Premium

Knowledge and skills

First you need to decide on the fuel on which the boiler will operate, because many other parameters depend on this.

Note: Considering the safety conditions, accessibility and traditional nature of the procedure, it is better to choose a wood-burning boiler. Do-it-yourself solid fuel units are quite simple to build, lightweight and easy to maintain.

If you choose, for example, a gas boiler for a bath, this increases the danger of performing bath procedures. In addition, the installation of such a unit will require approval from regulatory authorities.

Therefore, solid fuel units are the best choice. And their organization should begin with the preparation of diagrams and drawings. Some elements today can be purchased at construction stores, the rest can be done with your own hands. And the result can be no worse than in the photo.

It is especially important to have the skills to use a welding machine. This is necessary to obtain a high-quality weld, ensuring the reliability and durability of the structure.

Tips and tricks

A separate base is built under the sauna stove from non-combustible building materials - brick or concrete. As additional protection for the floor, a steel or asbestos edging is installed around the stove.

Important! If it is not possible to install the most efficient stove, then a metal structure that is imperfect in terms of basic parameters can easily be improved by a brick casing and the installation of a well-thought-out ventilation system that allows you to temporarily stop convection flows inside a steam room. The standard distance from the heater to the nearest objects is 32-35 cm

All furnace elements with an increased degree of heating are separated by non-combustible layers. The combustion door is placed opposite the doorway with a distance from the nearest object of at least one and a half meters

The standard distance from the heater to the nearest objects is 32-35 cm. All stove elements with an increased degree of heating are separated by non-flammable layers. The combustion door is placed opposite the doorway with a distance from the nearest object of at least one and a half meters.

Selecting the size of the sauna stove

In order for a sauna stove to optimally heat the air in a steam room, it is necessary to make extremely accurate calculations of the dimensions of the structure. An axiom when arranging a bathhouse yourself is to take into account the following most important parameters:

- combustion hole in a ratio of 1:50 or 1:70 to the area of the room;

- firebox depth in the ratio 1:2 or 2:3;

- the proportion of the combustion chamber to the chimney section is 1:10.

The heater can have a corner installation, installation at the end or internal wall, so the dimensions of the structure may vary.

| Room area | Common stove surface in different types of rooms | ||

| With one corner | No corners | With two corners | |

| 8 m2 | 5.85 m2 | 3.74 m2 | 6.10 m2 |

| 10 m2 | 7.20 m2 | 4.50 m2 | 7.80 m2 |

| 15 m2 | 10.20 m2 | 6.90 m2 | 11.70 m2 |

| 20 m2 | 13.80 m2 | 9.60 m2 | 15.60 m2 |

| 30 m2 | 20.70 m2 | 13.80 m2 | 23.40 m2 |

What is stepsoning and why is it needed?

A shoot is a shoot that appears between the leaf and stem of a tomato. These shoots need the same macro- and microelements as the fruits. And the stepchildren take them away. Therefore, tomatoes may not have enough nutrition.

Pinching is the cutting off of shoots growing from the axil of a leaf. This process is also called bush formation, since during this procedure a certain number of stems remain. To prevent additional shoots from growing to the detriment of flowering and fruit formation, they should be removed. Bushes form throughout the growing season.

Room for installing a gas boiler

The volume of space for a gas boiler depends on the type of unit and its power. All requirements for the boiler room or other place where the device is located are specified in SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000 .

Gas boilers differ in the type of combustion chamber:

- units with an open combustion chamber (atmospheric);

- devices with a closed firebox (turbocharged).

To remove combustion products from atmospheric gas boilers, you will need to install a full chimney. Such models take air for the combustion process from the room in which they are located. Therefore, these features require a separate room for the gas boiler - a boiler room.

Units equipped with a closed firebox can be placed not only in a private house, but also in an apartment in a multi-story building. The exhaust of smoke and the influx of air masses is carried out by a coaxial pipe that exits through the wall. Turbocharged devices do not require a separate boiler room. They are usually installed in the kitchen, bathroom or hallway.

Boiler room requirements

The minimum volume of the room for installing a gas boiler depends on its power.

| Gas boiler power, kW | Minimum boiler room volume, m³ |

| less than 30 | 7,5 |

| 30-60 | 13,5 |

| 60-200 | 15 |

Also, a boiler room to accommodate an atmospheric gas boiler must meet the following requirements:

- Ceiling height – 2-2.5 m.

- The width of the doors is at least 0.8 m. They must open towards the street.

- The door to the boiler room should not be hermetically closed. You need to leave a 2.5 cm wide gap between it and the floor or make holes in the canvas.

- The room is provided with an opening window with an area of at least 0.3×0.3 m², equipped with a window. To ensure high-quality lighting, for every 1 m³ of combustion chamber volume, 0.03 m2 of window opening area should be added.

- Availability of supply and exhaust ventilation.

- Finishing from non-combustible materials: plaster, brick, tile.

- Electrical light switches installed outside the boiler room.

Note! Installing a fire alarm in the boiler room is not mandatory, but recommended. It is strictly forbidden to store flammable liquids and objects in the boiler room. There must be unobstructed access to the boiler from the front panel and from the side walls.

There must be unobstructed access to the boiler from the front panel and from the side walls.

It is strictly forbidden to store flammable liquids and objects in the boiler room. There must be unobstructed access to the boiler from the front panel and side walls.

Room requirements for installing a turbocharged unit

Gas boilers with a closed combustion chamber with a power of up to 60 kW do not require a separate combustion chamber. It is enough that the room in which the turbocharged unit is installed meets the following requirements:

- Ceiling height is more than 2 m.

- Volume - at least 7.5 m³.

- Has natural ventilation.

- There should be no other appliances or flammable elements closer than 30 cm next to the boiler: wooden furniture, curtains, etc.

- The walls are made of fire-resistant materials (brick, slabs).

Compact wall-mounted gas boilers are even placed between cabinets in the kitchen and built into niches. It is more convenient to install double-circuit units near the water intake point so that the water does not have time to cool before being released to the consumer.

In addition to generally accepted standards, each region also has its own requirements for the room for installing a gas unit

Therefore, it is important to find out not only how much space is needed to install a gas boiler, but also all the placement nuances that apply in a given city