Over time, stove heating is replaced with a more modern one, and the old stove must be dismantled. This task is also present when replacing an unsuitable one with a new one. Partial analysis is also possible. This is how the structure is rebuilt into a fireplace. There may also be options where the main part of the stove is left, using it as a bed. Alternatively, use it for storage space. The technology for laying out the furnace masonry depends on the final goals.

How to disassemble the stove

Well, first of all, I’ll say right away that this matter is dusty and even very dusty.

Therefore, to prevent soot from flying in all directions, it is necessary to cover everything possible with plastic wrap and newspapers, including the floor. It will also be very cool if you, in addition to this, stretch plastic film around the entire perimeter of the stove from top to bottom. This way you will reduce a little space into which dust and soot can reach. Secondly, since soot will fly in all directions, as I already said, you should protect your respiratory organs from it, because it is very harmful to the body, and it will be very difficult to breathe from the dust.

A respirator will help you with this. It is best to wear old clothes. And you shouldn’t forget about gloves either.

So, now we move directly to the disassembly of the stove itself. You should start disassembling it from the pipe. After you have disassembled the pipe, you can leave the bricks in the attic. Well, if you don’t need them there, then you can remove them, of course, just suddenly you decide to install a new stove. They will be useful to you for a new pipe if they are in more or less decent condition.

Toyota Camry 1997, 140 l. With. - with your own hands

Cars for sale

Toyota Camry, 1997

Toyota Camry, 1996

Toyota Camry, 1996

Toyota Camry, 1995

Comments 18

I cleaned everything, there was compressed dust just like I pulled the felt out of there, this is the first time I’ve seen this... If you have a compressor, you can also blow it out with it!

So a toothbrush is not a problem, I asked the guy to go look for a bottle for me while I was at work! And there is a remedy called a thousand, can it replace this remedy if it is not available?

And of course, if you remove the dashboard and remove all the pipes and channels and rinse them with hot water in the bathroom at home, and blow out the radiator with a compressor - this is of course the best and most effective option!

How to disassemble a brick oven: procedure and features of dismantling oven equipment

Now let's start disassembling the stove in the room. To do this, open windows and doors to allow fresh air to enter. We take a bottle of water, put a spray bottle on it and spray water on each brick of the row that we will disassemble. Sprayed? We don’t spare water in this matter, it’s better for us, less dust will fly. Now gently tap with a hammer and slowly remove brick by brick. You can, of course, use a sledgehammer) This way the whole stove will quickly fall apart. BUT it’s too dusty, and suddenly you’ll need these bricks for something later, you never know what happens. The more carefully you do everything, the better off you will be. Well, and so on until the very end. The idea is simple: spray, disassemble. And yet, before you start directly breaking down the stove, take care in advance of where you will put the old bricks so that you don’t have to drag them from place to place later. That's basically all. After all this, all you have to do is clean up and take out all the trash. Good luck!

No matter how good the old stove is, sooner or later many of its owners come to the conclusion that it needs to be disassembled. The reasons are different: the desire to expand the living space, the acquisition of an alternative heating system, the desire to change the interior design. In general, there are many reasons. The stove can be partially disassembled by converting it into a fireplace or simply rebuilding several partitions.

If you decide to disassemble your old stove, inspect it carefully. Any work begins with the head; at the stove it is the chimney.

Open the ceiling above the stove and make sure nothing is resting on the chimney. Don't forget to cover or take things out of the room; there will be a huge amount of dust and ash. Carefully, starting from the roof, widen the hole around the chimney and dismantle the masonry brick by brick, gradually descending into the house. Be careful not to stack too many bricks on the roof, otherwise you risk falling. In the attic and indoors, masonry can be broken with a sledgehammer or something heavy, but be careful not to damage beams and walls that will still be useful. Carefully fill the holes in the ceiling and roof left by the chimney with bricks.

Next, we proceed to disassemble the central and largest part of the stove, on which many people liked to soak up the heat when the stove was still in use. The main part of the oven can not be completely disassembled; just one wall can be removed. Adapt the remaining walls for niches or shelves.

If you decide to disassemble the entire stove, then again check whether the body of the stove is supported by something, and also dismantle the floor around the stove and inspect its foundation. Check how the walls are folded and how the bricks are connected to each other (clay or cement). If you later plan to build a new stove, you will need a price list for building bricks. If the oven is lined with clay, then everything is simple, the walls are quite easy to disassemble, but if cement is involved, then you will have to sweat.

Dismantling car heaters

If the stove has ceased to function well, then it is imperative to identify the cause of the poor performance. The initial stage is not disassembling the device, but checking the stove. The most typical problems that negatively affect the operation of the device:

- airing of the cooling system

- radiator malfunction

- Incorrect installation/dirty cabin filter

- poor quality/delayed replacement of antifreeze

- thermostat malfunction

Thus, for the smooth operation of the device, every car owner must regularly diagnose the stove.

Dismantling a car heater in Moscow

Where to disassemble the stove - in a big city such a question does not arise, since in Moscow there are quite a lot of inexpensive car services that offer this service. The price of the issue is not high - about $50. All that remains is to choose a suitable service, where, if necessary, they could not only disassemble the device, but also carry out high-quality repairs of the stove.

It is believed that the stove works well if, at an outside temperature of 25 degrees below zero, the car warms up to a temperature of +16 in 15-17 minutes.

Do-it-yourself car heater disassembly

If it is not possible or there is no desire to seek help from service specialists, you can try to disassemble the car’s heater yourself. The entire process of removing the stove can be briefly described as follows:

- the shield is removed from the instrument panel;

- all LEDs and lamps are removed, screws are unscrewed;

- the heater control unit is removed, including the switch for this device, etc.;

- The stove is removed.

To disassemble the car heater itself, you will need the following tools: a hammer, wire cutters, screwdrivers of various types, pliers, wrenches, etc. First, the torpedo is removed from the device, all cables and hoses are attached. The next stage is removing the heater (by the way, if everything is not in order with the stove, it is recommended to disassemble the car heater for preventive purposes). By unscrewing the nuts connecting the heater cap to the electric motor, the cap is removed and the fan and sealing gasket are removed. The final stage of disassembling the stove is removing the resistor and protective casing.

As you can see, disassembling this device yourself is not difficult.

Dirty cabin filter

A clogged cabin filter greatly affects the operation of the air conditioner in the summer, but can be the reason why the stove does not heat in the winter. It is good when the filter is located in an accessible place (for example, behind the passenger glove compartment) and is changed regularly. But sometimes it is hidden deep in the depths of the center console, and the car owner does not even know about its existence. As a result, instead of a filter, a “bed” of dust, leaves and insects is formed there.

Regularly replacing the cabin filter is important not only for the heater, but also for human health, because passengers breathe the air passing through it. Car manufacturers recommend changing the cabin filter every 10,000 km. And if you often drive on dusty dirt roads, then the replacement interval should be halved.

How to dismantle an old brick stove

Disassembling a car heater

During self-disassembly, this process can be divided into the following stages (condition: the heater has already been removed):

- the brackets holding the front casing of the device are unfastened, the lower screws are boiled;

- the casing is removed, the electric motor is released;

- remove the brackets and unscrew the screws holding the heater air intake housings;

- the housing is removed (first the front, then the rear);

- the brackets holding the rear casing are unfastened;

- The radiator and damper are removed.

If you do not have the appropriate skills, then you can contact any car service center to disassemble the heater in Moscow.

So, high-quality stove care implies constant monitoring of its operation, and diagnostics should be carried out before the onset of cold weather. Often, it is during preventative work that hidden problems are revealed. In older cars, experts recommend monitoring the operation of the stove more closely, since timely elimination of breakdowns allows you to avoid replacing the stove motor and its other components.

How to disassemble the stove

Over time, stove heating is replaced with a more modern one, and the old stove must be dismantled. This task is also present when replacing an unsuitable one with a new one. Partial analysis is also possible. This is how the structure is rebuilt into a fireplace. There may also be options where the main part of the stove is left, using it as a bed. Alternatively, use it for storage space. The technology for laying out the furnace masonry depends on the final goals.

Advice on the job

As an option, you can suggest not completely disassembling the central, largest part of the stove, which was used as a stove bench. You can remove just one wall and use the remaining ones for niches and shelves. Here a lot will depend on your imagination. Perhaps you get excited about the idea of building a fireplace and use part of the design of an old Russian stone stove.

The final stage is dismantling the furnace foundation. If the design is such that the base of the stove can be removed from the support and taken out without completely disassembling it, this should be used. You'll have to find helpers, because you can't do it without outside help.

If the furnace foundation does not interfere with your plans, then you can leave it. Holes in the floor should be patched with boards. The work of dismantling the furnace ends here.

How to disassemble a brick oven: procedure and features of dismantling oven equipment

Now let's start disassembling the stove in the room. To do this, open windows and doors to allow fresh air to enter. We take a bottle of water, put a spray bottle on it and spray water on each brick of the row that we will disassemble. Sprayed? We don’t spare water in this matter, it’s better for us, less dust will fly. Now gently tap with a hammer and slowly remove brick by brick. You can, of course, use a sledgehammer) This way the whole stove will quickly fall apart. BUT it’s too dusty, and suddenly you’ll need these bricks for something later, you never know what happens. The more carefully you do everything, the better off you will be. Well, and so on until the very end. The idea is simple: spray, disassemble. And yet, before you start directly breaking down the stove, take care in advance of where you will put the old bricks so that you don’t have to drag them from place to place later. That's basically all. After all this, all you have to do is clean up and take out all the trash. Good luck!

No matter how good the old stove is, sooner or later many of its owners come to the conclusion that it needs to be disassembled. The reasons are different: the desire to expand the living space, the acquisition of an alternative heating system, the desire to change the interior design. In general, there are many reasons. The stove can be partially disassembled by converting it into a fireplace or simply rebuilding several partitions.

If you decide to disassemble your old stove, inspect it carefully. Any work begins with the head; at the stove it is the chimney.

Open the ceiling above the stove and make sure nothing is resting on the chimney. Don't forget to cover or take things out of the room; there will be a huge amount of dust and ash. Carefully, starting from the roof, widen the hole around the chimney and dismantle the masonry brick by brick, gradually descending into the house. Be careful not to stack too many bricks on the roof, otherwise you risk falling. In the attic and indoors, masonry can be broken with a sledgehammer or something heavy, but be careful not to damage beams and walls that will still be useful. Carefully fill the holes in the ceiling and roof left by the chimney with bricks.

Next, we proceed to disassemble the central and largest part of the stove, on which many people liked to soak up the heat when the stove was still in use. The main part of the oven can not be completely disassembled; just one wall can be removed. Adapt the remaining walls for niches or shelves.

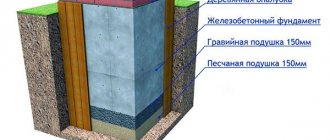

If you decide to disassemble the entire stove, then again check whether the body of the stove is supported by something, and also dismantle the floor around the stove and inspect its foundation. Check how the walls are folded and how the bricks are connected to each other (clay or cement). If you later plan to build a new stove, you will need a price list for building bricks. If the oven is lined with clay, then everything is simple, the walls are quite easy to disassemble, but if cement is involved, then you will have to sweat.

Preparation

The job of dismantling the stove is dusty and dirty. Furniture and things from the room must be removed or covered with film. If repair work on the floor is not planned or it is new, it should also be covered.

Before disassembling a brick stove, you need to inspect its chimney. It can be iron or brick. The technology for dismantling it depends on the design of the furnace. If the stove is old, then there is a chance that its chimney is being used as a support for the ceiling. They did this before, building Russian stoves at the same time as the house. If this is the case, then you won’t be able to disassemble it yourself. A specialist is needed here.

Return to contents

Advertisements on NN.RU - For children

Children's playground for the dacha. Children's play complex made of natural wood is for sale. Can be supplemented with slides and stairs. Price: 48,000 rub.

Romper size 62. Excellent condition Shipping within Russia is possible Price: 50 rub.

In excellent condition Shipping within Russia is possible Price: 430 rub.

Price for all 3 pcs. In excellent condition. It is possible to sell individual items. Possible delivery throughout Russia. Price: 420 rub.

Tools

The set of tools depends on what solution was used when making the stove. For comfortable dismantling, you should wear gloves and a respirator, because there will be a lot of dust and ash, and they can make breathing difficult. You need to take care of your work clothes, which would be better to throw away later. Clay masonry is easier to disassemble. To make work easier, it can be moistened with water. Then she will be more pliable. If the brick is laid on cement mortar, then soaking will not help. Here you will need a hammer drill, since dismantling will be difficult.

To disassemble the structure you need a sledgehammer.

For cutting you may need the following equipment:

Return to contents

Subtleties of dismantling a brick oven

First of all, you need to decide on the scale of work and assess the current situation. In cases where it is planned to replace the stove with a new one, you should inspect the chimney and consider the option in which it will remain. If it becomes possible to supply gas, the stove equipment can be completely dismantled or a small fireplace can be built based on the chimney.

Where to start: the preparatory stage of work

Work begins with a careful inspection of the structure in the ceiling area. In old houses, Russian stoves, as a rule, were built along with the house and used as additional ceiling supports. You can begin dismantling only after making sure that the roof does not rest on the chimney, and its structure will not be damaged after dismantling the ducts.

Outdated stove

Dismantling a stove is a dirty and dusty job. If you have to do it not at the stage of a major overhaul, you need to remove everything that is possible from the room and cover the remaining pieces of furniture with film. You can also build something like curtains from thick polyethylene, separating the desired area from the rest of the room.

Tools: necessary tools

The set of tools for dismantling brickwork depends on the composition used for the construction of the mortar. Here is a list of tools that will most likely be needed for the job:

- heavy hammer or sledgehammer;

- scrap;

- pick;

- chisel;

- perforator;

- steel wedges.

It is recommended to work in a respirator and use gloves to protect your hands. It’s better to choose clothes that you don’t mind throwing away. During disassembly, not only dust will fly, but also soot, and washing it off is very problematic.

Helpful information

The easiest way to work is with buildings made of clay, which becomes pliable after preliminary soaking. Depending on the strength of the masonry, a suitable tool is used in the work, for example, a chisel and a hammer. The point should be directed into the masonry joints - this will not only simplify the work, but also reduce the amount of debris, and also help preserve building materials for later use.

The most difficult thing to disassemble is cement masonry; in this case, soaking the seams will not help. For dismantling, steel wedges are driven into the horizontal seams with a sledgehammer, violating their integrity. After this, the masonry is dismantled row by row using a hammer drill, and if there is no such tool, then they use a crowbar.

The easiest ways to remove

The choice of the optimal method for removing whitewash from the ceiling depends, first of all, on the total area of the room in which the work will take place. If its square footage is small, the traditional dry method is quite suitable.

Dry

A spatula is the simplest and most effective tool in the fight against outdated whitewash

It requires the use of a wide metal spatula, thanks to which it will be possible to remove the whitewash from the ceiling layer by layer. In this case, any irregularities that arise can be smoothed out with sandpaper. The advantage of this method is its simplicity and the absence of the need to purchase additional means for removing the old coating. But the disadvantages are labor-intensive, time-consuming and a huge amount of dust.

However, you can get rid of them:

- placing a special box on the spatula. It can be purchased at a hardware store along with the spatula or scraper itself, or you can make it yourself. The uniqueness of this device is that it allows you to avoid dust settling on all surfaces. You can replace it with any container.

- using a grinding machine. It allows you to speed up the whitewash removal process without losing quality and is ideal for large areas.

- gradually applying water with a spray bottle or a wet sponge to the layers of whitewash. Once they are soaked, they can be easily removed with a spatula, thus avoiding the appearance of a cloud of dust. In this case, you can replace the spatula with a scraper.

When choosing this method, you should not soak the entire ceiling area at once. It is much wiser to divide it into several sections and process them in turn. As a rule, the process of wetting the whitewash layer takes 5-10 minutes.

This method is best used in small rooms or in rooms with a small layer of whitewash to avoid the appearance of a large amount of dirt. Meanwhile, its occurrence can also be prevented by simply wiping the swollen layer of whitewash with a damp cloth.

- “tapping” evenly with an ordinary hammer on the old whitewash, especially if it is calcareous and thick. Peeling pieces can be easily removed with a spatula.

Wet

For many years, a wet sponge has remained one of the most popular tools for removing whitewash.

Features of dismantling

Dismantling the chimney pipe

Dismantling work starts from the top. First - the chimney. It can be simple and come from the roof or wall, or complex where the smoke passes through ducts in the interior wall of the house. A complex option is used as additional heating of the room. The iron pipe coming out of the house is removed by loosening it at the base. If it is made of brick, then we dismantle the masonry brick by brick, gradually going down.

After the external chimney, the part in the attic is dismantled, having previously closed the resulting hole with slate or a metal sheet. Here the work will go easily, since this area is done with sand-clay masonry mortar. To prevent the plaster from falling off the ceiling during work, it is worth placing a board on the beams, on which it will be convenient to stack the disassembled bricks.

Return to contents

Destruction of the structure itself

The masonry of the building begins to be dismantled from the top, moving to its bottom.

Next you should start cutting the central and most massive part of the furnace. The work is also carried out - from top to bottom, moving in a circle. The part near the pipe is disassembled first, gradually expanding. It is better to clean the plaster. If the stove is tiled, that should also be removed. For the job to go better, the chisel should hit the seams between the bricks. The wall, under the influence of vibration from a blow with a hammer or sledgehammer, will collapse. If you plan to use the resulting brick, you should be careful, because the wrong blow can break the brick.

The difficult part is cutting the vault. To prevent it from collapsing ahead of time, it is recommended to use the following trick: place a sheet of iron on supports under the arch. It is better to start disassembling work from the back wall and gradually move towards the front of the oven. The iron plate and doors are dismantled last. Don't rush or remove them prematurely. It is better to keep them closed, this will reduce the amount of soot that gets into the house.

Return to contents

How to disassemble the base of a brick oven?

The last stage remains - dismantling the furnace foundation. There are stoves that stand on supports. Their base can be simply removed and stored without disassembling. But here one person cannot cope. Others need to be dismantled, since their foundation is also laid with bricks. If the base does not interfere with the interior, it can be left alone. The top is simply covered with linoleum.

Fault diagnosis

You can diagnose the condition of the stove yourself , without involving a professional stove maker. Troubleshooting methods include:

- inspection of external damage ;

- assessment of the operation of a flooded furnace.

Diagnosis of faults begins with an external examination. The joints in the masonry, walls, foundation, firebox, chimney in the house, attic and roof are subject to assessment. The condition of metal parts and components (hob, valves, firebox door, grate, firebox lining) is checked.

Then the furnace is flooded and its “in operation” condition is assessed. The heating structure is faulty if:

- the stove cannot be lit due to poor draft (or lack thereof);

- smoke comes from cracks in the masonry, from the door, through the gaps of the hob, through the holes for the valves ;

- Carbon monoxide ( CO accumulates in the house .

You cannot heat a stove whose foundation is deformed or tilted .

In this case, the chimney, walls, and cutting are under stress, which can lead to sudden destruction of elements of the house or stove. If this happens while burning wood, a fire may occur.

It is especially difficult to determine the accumulation of carbon monoxide in the home , which causes fatal poisoning of people and animals.

This gas is heavier than air, it accumulates underground, near the floor in rooms. The gas has no odor; it accumulates in the house if the firewood is not completely burned out (they no longer emit smoke, but the fire glows in the ash) and the valve is already closed. Carbon dioxide can accumulate if a bucket of hot ash is left in the house overnight. Coal ash is especially dangerous.

Dismantling stove heating in a private house

The article describes the process of dismantling stove heating in a private house. I will share my observations about why gas heating is better than stove heating, and why the decision was made to dismantle stove heating. After reading the article, everyone will be able to decide for themselves whether they need stove heating, and if so, gas heating. If the choice is in favor of dismantling stove heating, then the knowledge gained from the article will help you do the dismantling yourself.

In Soviet times, most houses were heated by stoves. Now the situation has changed and many have switched to gas or steam heating. Therefore, the choice is whether to leave stove heating in the house when switching to alternative gas heating? In my case, there was no choice as such, because the house was uninhabited for a couple of years, which affected the stove heating system. Due to dampness and cold, the structure became unusable. An attempt to light the stove ended in clouds of smoke in the house. Smoke came from all the cracks, even from under the floor. It was impossible to enter the house for a couple of days; everything was saturated with smoke. The house was not previously famous for its successful implementation of stove heating, and over time it completely fell into disrepair. At first there was an idea to make a fireplace with heating, but in the end it was decided to install gas heating in the house, so dismantling the stove heating was on the agenda.

In my house, I do almost everything with my own hands. Armed with a pair of gloves, a change of clothes, a crowbar, a shovel, an ax and other equipment, I got to work. First I disassembled the stove itself. To do this, I removed all metal structures. If they are in good condition, then they can be sold. If it is in poor condition, then send it for scrap. My option is the second one.

Then, brick by brick, from top to bottom, I dismantled the stove. Brick has a specific smell, so when dismantling the stove, it is better to open all windows for complete ventilation. The brick should be immediately taken out into the yard so as not to clutter the space.

We had a homemade stove with a bed that my grandfather made... I took everything apart from the top row to the bottom row. There is more space in the room, and fewer unnecessary structures. He took construction material out into the yard.

The next stage was dismantling the wall with the furnace heating passages. Using a crowbar and an ax, I completely dismantled the wall where there is a stove heating duct. Moving from top to bottom, dismantling one row, he moved on to the second. He took the brick out into the yard.

In the future, the brick will not be suitable for construction work in residential premises and even for courtyard buildings; it is completely saturated with smoke. But in my case, it found a use - I subsequently made a sewer hole underground from it. Therefore, the smell of brick was not a problem.

I did not dismantle the pipe that goes to the roof. It doesn't play any role in the house, there is no smell from it. So I decided not to complicate my life and leave it. If desired, you can then use the chimney and create a fireplace for beauty and comfort in the house.

When all the stove heating structures were dismantled, the house became one large room. Convenient, but not practical. It is necessary to build interior partitions. There are many options for partitions: from reliable brick to walls made of plywood or plasterboard. I chose reliability, so in my case the walls will be made of brick. To save money, I bought a used brick rather than a new one. But it is suitable for partitions.

Subsequently, it was decided to redesign one of the room partitions, in the direction of enlarging one of them. Therefore, the foundation for the partition was laid along the outer edge of the former bench, and was made to a depth of 50 centimeters, using ordinary bricks and fittings.

I connected the 10-centimeter reinforcement to the main foundation of the house using holes made with a hammer drill. All other places, under the dismantled furnace structure, were filled with screed, to the level of the existing floor in the rooms, using beacons. The surface was leveled and left to dry. In the summer it took about three days. The resulting hole in the ceiling (chimney) was hermetically sealed with a metal sheet of the required diameter. I took it from the decorative lining of the stove. This sheet should be slightly larger than the diameter of the chimney. Along the perimeter of the protruding parts of the sheet, from the chimney at a distance of five centimeters, into pre-made holes, screwed 100 mm self-tapping screws.

To prevent moisture from entering the house and the formation of drafts, the chimney on the roof was sealed with old concrete tiles of the required diameter.

Next it’s time to lay out the interior partitions from brick. There are a lot of video tutorials on the Internet on how to do this. I turned to an expert in this matter - my father-in-law. In a couple of days he laid out the partitions. Finished partitions must dry before plastering. This took less than three days.

Then you can start plastering the walls. This is not an easy task and it is better to entrust it to professionals so that the wall is level. There is an auntie living next door to me who makes a living from this business. In one day, she did her job, and the walls were plastered. The plaster dries faster; after just a couple of days it was possible to prime the surface and glue wallpaper.

Now the walls look smooth, beautiful and have no smell, as they did with stove heating. Gas heating does not cause inconvenience, but rather makes life better. Just as I started the system during the heating season, I turned it off at the end. I only regulate the temperature. It’s not even worth comparing with stove heating. There are no foreign odors in the house. Walls with wallpaper look great even after five years. Therefore, the decision to dismantle the stove heating was successful and justified.

Mechanical and manual cleaning

For mechanical cleaning of chimneys today, the same tools are used as 200 years ago. The technology itself has also not undergone major changes. Cleaning is carried out from the roof side and from the stove side.

Tools and materials

To clean the roof side use:

- rope or steel cable;

- hard metal brushes and weights;

It is important that the load has the correct center of gravity. Otherwise it may get stuck. It is ideal to use a round metal core as a load. It is they who break through the blockage. And only then do the brushes come into use.

If you don’t have a suitable brush at hand, you can make one yourself from an old plastic bottle. Step by step instructions below.

How to make a ruff with your own hands?

- Take a plastic bottle and cut 150 mm from the top. Make cuts along the top part in 15 mm increments. The length of the cut is selected depending on the diameter of the pipe. If the pipe diameter is 100 mm, then the brush diameter should be 130 - 140 mm.

- Drill a hole in the center of the plug. Screw the plug into place and bend the petals.

- The first brush is ready. Now we do the second one in exactly the same way.

- Find a suitable load. Its weight should be sufficient for the brush to pass through the chimney.

- Tie the load to a strong cord or steel cable. Thread the other end of the cord into the brush plugs. The brushes should be positioned towards each other.

- Take the rest of the bottle. Cut off the bottom. It turns out to be a cylinder. Cut it lengthwise. Insert it between the brushes. The length of the cylinder should be about 150 mm. Give it a diameter equal to half the diameter of the brush. Secure with a stapler.

- Tie a knot over the top brush plug. The tool is ready.

Minor problems

Heating systems should be inspected regularly. This will allow you to detect minor defects in time and timely repair the stove in the house, without waiting for serious damage. There are several types of small problems. You can handle all of them yourself. To do this, you will need tools - a trowel, hammers, a plumb line, a tape measure, a level, a container for preparing repair mixtures.

Lack of traction

Such a defect can occur for various reasons. Most often, traction is lost due to violation of operating rules. For example, the stove has not been used for a long time, and a plug of cold air has formed in the chimney.

Interesting video of restoring an old stove with your own hands:

Failure may also be caused by:

- Insufficient air flow. If there is a lack of oxygen, the wood will not burn.

- There is too much wind outside, causing reverse draft.

- The chimney is thoroughly clogged with soot.

If there is no draft, you can try to solve the problem using simple methods or clean the chimney.

Getting rid of an air lock is very simple. You just need to light the firewood not with paper, but with rubber or dry fuel. Until the defect is eliminated, it is prohibited to use special ignition fluids.

If the chimney is clogged, the firebox is first lit, and then a handful of coarse salt is thrown into it. It is important to remember to close the damper immediately. After this, lumps of soot will fly out into the chimney.

If this method is ineffective, you will have to clean the chimney manually using knockout bricks. They can be identified by their special location - they always protrude slightly from the general masonry.

Violation of seam tightness

Detecting a defect is as easy as shelling pears: smoke enters the room, and soot stains appear on the masonry. Stove repair begins with identifying the exact location of the defect. To do this, you need to thoroughly heat it and mark the places of damage.

If the room is filled with smoke, this may indicate cracks in the walls

Repair activities are carried out in the following order:

- The seams are soaked with ordinary water and cleared to a depth of several centimeters.

- The walls around the defect are thoroughly washed with a brush. The water needs to be changed several times during the cleaning process.

- A solution is prepared from sand, clay, salt and asbestos fiber. The resulting mass should have medium viscosity. You don’t have to make the solution, but purchase it ready-to-use.

- The seams are filled with the prepared mixture and sealed. It is important to fill in all existing voids.

After repair, the seams need to dry. The oven must not be used during this time. After drying, the walls of the structure can be plastered or tiled.

Laying fallen bricks yourself is not difficult

In old heating appliances, bricks often fall out or burn out. The damage appears severe, but repairing the brick kiln will not be difficult. The problem area is cleaned, moistened and covered with a clay cake. Then a new brick is prepared. It is also wetted and coated with the same solution as for repairing seams. The new block is placed in place of the old one and securely fixed.

.

Average defects

For more serious damage, more effort will have to be made to repair the stove. It may be necessary to strengthen individual structural elements.

Gaps around the firebox

This element is constantly exposed to physical stress and temperature changes. Over time, cracks appear around it, dangerous because carbon monoxide from the firebox can begin to penetrate into the room. To prevent trouble from happening, it is important to repair the brick oven in a timely manner. We are talking about compacting damaged areas.

The cracks must be sealed as quickly as possible to prevent carbon monoxide from entering the room.

You need to act in the following order:

- Thoroughly clean the surface around the door.

- Remove all old solution.

- Prime the cleaned surface with heat-resistant glue.

- Lay asbestos cord around the door. It will act as a thermal protector and prevent the destruction of the clay solution in the future.

- Seal the cracks with repair mortar.

After restoration, the stove cannot be used for 24 hours. After this, you need to heat it thoroughly and check that the door is securely fastened.

Using exactly the same principle, gaps around the hob are eliminated. The only difference is that the asbestos cord can be replaced with other fire-resistant materials.

Strengthening the frame and replacing the grate

If cracks appear around the entire perimeter of the oven, its walls will need to be strengthened. The most reliable way is to completely go through the masonry, but for many people this work is beyond their capabilities, so you can resort to tightening the frame with metal wire.

The screed is carried out as follows:

- Horizontal channels with a depth of no more than 20 mm are cut into the outer walls of the furnace.

- Wire is pulled along the grooves.

- The required quality of the screed is ensured by the beard. You need to act carefully so as not to damage the wire.

After the work is completed, the wall is plastered or improved in any other way.

After completion of the repair, the stove can be plastered or tiled to suit your taste.

When replacing the grate, you should pay attention to the fact that you need to leave a gap between it and the walls of the oven . The new element should not differ in size from the old one. After installing the grate, the gap between it and the brick walls must be filled with sand.

Maintenance

If you notice that the heating system has begun to function incorrectly, then you should carry out a step-by-step solution to the problems. This must be done in a timely manner so that the structure is not damaged and operation occurs without a negative impact on the atmosphere in the room. Let's figure out how to quickly repair frequently occurring problems of a Russian stove, which is also called current, since it is constantly necessary.

Lack of traction

The draft inside the chimney can disappear precisely because of insufficient care of the stove structure. To prevent this problem, aspen wood has been used since ancient times for heating, which helps clean the chimney. Light the stove with aspen chips, make sure that the smoke coming out of the chimney changes its color from black to light gray.

Chimney contamination

The formation of soot inside the chimney occurs due to the use of low-quality raw materials when heating the stove. The greatest danger comes from garbage burned in the structure, so it is strictly prohibited to use it as fuel. Burning raw wood can also lead to the formation of large amounts of soot.

You can clean a brick oven through a special metal door, or using a special device through the chimney pipe on the roof of the building, which is presented in the form of a long cable with a heavy load and a brush at the end.

Cracks

Due to the occurrence of cracks and crevices in the furnace structure, serious problems may arise during its operation:

- Cold air enters through the holes and the efficiency of the heating system is significantly reduced;

- Carbon monoxide may escape from the openings, which can cause poisoning and suffocation for those in the room;

- Small cracks can expand and if they are not corrected in a timely manner, a major repair of the structure will be required.

But on the building materials market today you can buy a special solution for brick stoves and fireplaces, which is used to cover up the holes that appear. The most popular are: “TerraKot”, “Pechnik”, “Parad”. The correct consistencies are indicated on the packaging.

Crevices

If visually visible damage appears in the furnace structure in the form of cracks, breaks, crevices or other holes, then you should not panic - these problems can be easily solved without calling specialists. Purchase in advance a spatula and a special composition intended for repairing fireplaces and brick stoves, then you can begin routine repairs to the heating system structure.

- Clean any dust damage that appears;

- Prepare a solution of the required consistency from the purchased mixture, in a small amount, so that the excess solution does not harden;

- Using a spatula, seal the previously cleaned cracks;

- Allow the solution to dry; for visual beauty, the areas of the repair work can be treated with whitewash or special paint.

Sealing of the combustion door and hob

Under strong mechanical loads and high temperatures, gaps may appear between the masonry and the fire door or hob, which allows gases hazardous to human health to enter the room. To fix this problem, it is necessary to seal the furnace door or hob with a special cord and repair solution. All this can be purchased at a hardware store.

Eliminating the gap between the door and the stove

The Russian stove is a unique structure, one of the features of which is the possibility of self-repair, without the involvement of a stove-maker, whose services are quite expensive. Sealing the holes between the masonry of the fire door and the cooking platform is one of the easiest jobs to carry out:

- Clean the area between the metal element and the masonry from dust and dirt;

- Wash the gap, prime and treat with heat-resistant oven glue;

- Purchase a specialized fire-resistant cord in advance;

- Insert the cord into the hole between the masonry and the furnace door or hob - it will compensate for temperature changes and protect the solution from cracks;

- After this, fill the hole with repair mortar using a spatula;

- Let the composition dry for at least a day.

Serious problems

Sometimes the damage to the brickwork is so serious that in order to restore the functionality of the heating system, individual parts will have to be completely replaced. Most often, craftsmen have to change the lining of the firebox, which consists of fireclay bricks.

If there are serious faults, you should entrust the repair to specialists

If the damage is not global in nature, then you can cope with the task directly through the firebox window. For restoration you need to use a fireproof mixture. All defective areas are carefully covered with it.

In case of serious damage, some of the bricks will have to be replaced. This must be done in the following sequence:

- Prepare the repair mixture in advance.

- Soak and remove the old mortar in the area where the brick will be replaced.

- Remove damaged lining elements.

- Thoroughly clean the vacated areas, moisten them with water and lubricate them with the repair mixture.

- Install new fireclay bricks and carefully seal the seams with refractory mortar.

When replacing individual lining elements, you need to ensure that the new brick is homogeneous with the old one. Otherwise, due to the difference in thermal expansion, the destruction of the furnace protection will continue.

It is possible to completely replace fireclay bricks in a firebox only by completely disassembling the wall. This is a difficult job that should not be performed without experience, as there is a risk of serious damage to the underlying masonry.

Serious repairs also include repairing the chimney and switching the brick stove to a different type of fuel. In the first case, you will have to go through the masonry and re-plaster it. In the second, you will need to completely redo the firebox.

What requires more attention: a stove in the country, a wood-burning stove in the countryside, or a sauna stove?

Furnaces in which coal and brown coal are burned .

A few years after construction, repairs are required for bathhouse and country stoves. Heating appliances in which tin bread, loaves and pizza are baked .

Italian Pompeii ovens are built in many countries. Pizza baked in such facilities has a special taste and smell. This oven is usually built outdoors. Food is cooked under a brick vault, under the influence of fire and the heat of heated bricks. There are two types of Pompeii ovens - Neapolitan (with a low arch, intended mainly for baking pizza) and Tuscan (with a high arch, which allows you to put a pot or pan inside and cook not only pizza, baked meat and fish, but also soups).