The Buleryan heating system is an all-welded steel structure, on the sides of which there are multiple pipes. Cold air comes from the floor, it penetrates through the lower pipe pipes and heats up. And then it moves through the pipes pressed against the firebox of the heating device.

Already heated air comes out of the upper pipes, which is evenly distributed throughout the room. Already 15 minutes after lighting the stove, the air reaches a temperature of 120 °C.

Reviews about the main benefits

User reviews about the Buleryan stove will allow you to understand what the described design is. It is quite compact, but can easily cope with heating a room up to 100 m2. If you purchase equipment of greater power, it will be able to heat a room up to 400 m2. The period between stacking firewood reaches 12 hours. According to users, during operation you will only have to add firewood to the firebox several times a day so that the stove maintains a constant temperature in the room.

If you want to purchase a Buleryan heating stove, you should definitely read the reviews about it. From them you can find out that firewood burns out at a certain speed, which is affected by the set power. The type of wood also influences this. In just 3 hours after the device starts operating, the room warms up and the air in it reaches an acceptable temperature.

If the area is large, it is recommended to install several furnaces or purchase one unit, the size of which will satisfy your requirements. Such a stove, according to users, is not only convenient, but also versatile. It does not create smoke or soot in the room, saves firewood, and also has a convenient door for storing firewood, which simplifies operation.

Heating with “Buleryan” several rooms

These long-burning units are also used to heat several rooms. To do this, there is no need to remodel or modernize the Buleryan boiler.

You can assemble air ducts and a heat chamber into a single structure. An air heat supply system created in this way is no less effective than a water heat supply system, and the costs of its arrangement are several times less.

To assemble a thermal chamber with your own hands, use ready-made diagrams. In this case, galvanized profiles intended for drywall, as well as galvanized sheets, are used.

A frame is built from the profile, and holes are cut out in sheets of metal for grilles and inspection doors. Then they are attached to the finished frame. The galvanized surface is covered with mineral wool mats. Then the chamber is decorated as desired.

Air ducts are connected to the air outlets located on top. They are made from plasterboard, but you can use metal pipes of the desired diameter or square shape, similar to standard air ducts. This solution is more effective than installing corrugations on heat exchange pipes.

As a result, all the heat produced by the stove accumulates in the thermal chamber, and then it is distributed through the air ducts. When arranging heating with Buleryan, it is necessary to take into account the following nuance - the shorter the air ducts, the more effective the heating of the rooms is.

By the way, some property owners are trying to adapt this stove for water heating. But the principle of its operation and the heating of water do not coincide due to its greater heat capacity compared to air. Therefore, for water heating it is better to install a modern pyrolysis boiler or a long-burning unit of another type.

Main disadvantages

If you decide to install a Buleryan stove in the garage, experts recommend reading reviews about it. Among them, we should highlight the ability of the equipment to operate exclusively using firewood. It should also be mentioned that a large volume of generator gases does not burn, flying out into the chimney.

The firewood does not burn completely, the stove produces smoke, and the soot goes into the chimney pipe. This entails the need to extend the pipe 3 m from the height of the furnace. All these are additional costs, to which must be added the fact that the pipe needs thermal insulation. It does not matter whether the structure is made of metal or brick.

Reviews of the Buleryan long-burning stove also indicate that condensation from water, soot and tar accumulates in the chimney during operation. This happens because the fuel does not burn completely. The pipe cokes, and during kindling an unpleasant odor is formed, which is especially important after a long period of inactivity.

Consumers point out another disadvantage, which is that dust burns on the hot metal of the structure. This does not improve the atmosphere of the premises. The operating principle of the heating device leads to such consequences: the design is designed for heat transfer from the surface. It is not so easy to ensure long combustion and maximum heat transfer on one tab. To do this, you will have to master the skills of adjusting the damper. Reviews of the Buleryan dacha stove indicate that smoldering combustion causes many side effects.

Buleryan stoves and their design

The solution to the problem came from Canada, a country known for its harsh climate. Truly Siberian frosts constantly reign there, but seasoned Canadians do not pay much attention to the cold. In addition, they invented the Buleryan stove - a wood-burning stove that allows you to warm up a large room or building in a matter of minutes. Today Buleryan has become famous all over the world. It is produced by many manufacturers, despite the presence of a patent from one German manufacturer.

The Buleryan stove is a unique combination of the advantages of a classic potbelly stove, pyrolysis combustion and a convection heater. The combination turned out to be simple and very effective. In fact, the developers added convection tubes to a regular potbelly stove and managed to make sure that the generated heat almost completely went into the air ducts and not into the chimney.

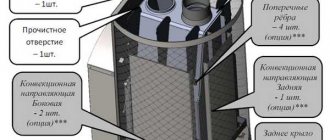

The Buleryan solid fuel stove consists of the following parts:

- Combustion chamber - its volume is approximately ¾ of the total internal volume. This is where the initial ignition of the fuel occurs when Buleryan is just starting up. And here the generation of pyrolysis products takes place;

- Afterburner chamber – in terms of volume, it occupies approximately ¼ of the internal space. Here, under the influence of draft, pyrolysis products enter, which ignite and burn to form a high-temperature flame;

- Injectors - small tubes through which atmospheric air enters the afterburning chamber, are necessary for burning pyrolysis products;

- Convection pipes - the Buleryan stove is a powerful convector, and convection is formed due to thick metal pipes. The inside of these pipes comes into direct contact with burning wood and flames. Due to the large contact area, they select a huge amount of heat, sending it into the premises in the form of powerful convection currents;

- Regulators - these include a slide valve and a throttle on the loading door. Thanks to them, the pyrolysis reaction is maintained in a Buleryan-type furnace - the control elements limit the draft and oxygen supply. At the same time, they are responsible for the intensity of combustion and maintaining a particular temperature;

- The chimney is the simplest part, often equipped with a container to collect condensate. Combustion products are removed through the chimney.

The design of the Buleryan stove is really very simple. Its most important part is the firebox, formed by convection pipes. Most of their area is exposed to heat, which ensures high efficiency of the unit.

Typically, chimneys are purchased or manufactured separately from Buleryan itself. We recommend that you equip the chimney with a condensate collector, building it in a T-shape with a faucet at the bottom.

The principle of Buleryan’s work is incredibly simple and is well illustrated by this picture.

Buleryan is a potbelly stove from Canada, from a country with a cold climate. This means that it has high performance. Initially, such stoves were used by lumberjacks to heat their houses - a comfortable atmosphere in them was achieved due to powerful convection generated by a large amount of heat. Thanks to the simplest scheme, Buleryan can be made independently, using auxiliary tools. But let's see how this oven works.

Reviews about the analogue of "Buleryan"

When you have read the reviews about the Buleryan heating stove, it’s time to study Breneran. This equipment is an analogue of a convection device and was developed by Professor Butakov. The unit is identical to the Buleryan, but the latter is the fruit of German developments, while the Breneran was first released in Russia.

The design differs from the Buleryan in the large cross-section of air pipes and their impressive number. They are hidden in the housing, and the air intake occurs at a right angle. According to users, the case is made in the shape of a parallelepiped. The chimney is introduced into the upper plane.

For ash, the design has a built-in drawer, the system is complemented by a grate. It is the chimney entry point that makes using the stove not very convenient. When changing the position of the valve on a pipe, you can easily get burned on the top of the body or the base of the pipe. As consumers emphasize, the rotary damper does not have a lock, and when you try to set the blower yourself, it moves under the weight of the handle.

In the stove, the wood burns almost completely, leaving only a minimal amount of it. According to consumers, defects can be found in Russian-made convection ovens; they are expressed in the absence of elements, as well as poorly executed seams. If you read reviews about the Buleryan long-burning wood-burning stove, you will be able to understand that it does not have such shortcomings. The smallest models of units cost approximately 9,000 rubles.

Recommendations

And finally, we decided to leave you with some useful tips from experts:

- This heating system can be used for houses with one or two floors. It is not customary to use it in houses with more floors.

- The place for installing Buleryan-Aqua with a water circuit must be covered with metal sheets.

- The stove should be no closer than 50 cm from the walls.

- It is forbidden to heat this type of stove with coal, since it is wood-burning. It is permissible to use only firewood.

- For efficient heat transfer, special corrugated pipes can be used.

- To prevent freezing of the coolant in the heating system, there is an electric heating element with a power of 1 kW. Don't forget to make sure it's working properly. To be on the safe side, completely drain the coolant from the heating system, and then the stove and pipes will be able to withstand temperatures even down to -50 degrees.

- Try to install the device in a separate boiler room or at least not on the street. Although the street option is possible (but only if it is constantly burning), it is better not to risk it.

Like other types of pyrolysis equipment, Buleryan-Aqua is sensitive to the quality of the fuel used, as well as errors that can be made during installation and features of the operating process. In general, the stove has good thermal characteristics, and I often use it for heating domestic and even industrial premises.

Reviews about the features of using Buleryan in a residential building

For temporary residences and country houses, Buleryan is the ideal solution. However, many consumers, in their words, doubt whether it is worth installing such equipment in residential premises. Here the opinions of buyers differ, so it is worth taking a more serious approach to studying this issue.

After reading reviews about the Buleryan stove, you can understand that such an installation can have a negative impact on the healthy atmosphere at home. With a portion of air, ordinary dust is drawn into the structure, which first heats up and then begins to burn. Thermal decomposition does not require too high a temperature. Buyers emphasize that combustion products of dust particles are present in the air and can have a negative impact.

In order to get out of this situation, you need to purchase “Buleryan” and a regular stove. The first will heat the house, and the second will maintain a constant temperature. Experts emphasize that if the Buleryan is positioned correctly and the basic rules and frequency are observed, it is permissible to use such an installation in a residential building.

Universal Soldier

Autonomous heating of your premises with wood with minimal costs and maximum output - this is Buleryan or Breneran. Cottage, garage, construction site, workshop, service station, warehouse, greenhouses, workshops, retail and public premises, and most importantly, the properties of Buleryan allow it to be installed even in residential buildings as a constant heating system.

The only nuance that needs to be taken into account is choosing the appropriate size and type of stove so that the room is evenly heated. It is also important to choose the right place for the stove, and to install the chimney responsibly and not forget about cleaning it. Then you can avoid the main problems that Bullerian users face.

Carpentry shops are simply an ideal place for Buleryan - there is plenty of fuel in the form of scraps of wood, which are also perfectly dried.

Reviews about use

You will be happy with your stove if you are careful when using it. Manufacturers claim that the described design is universal. Sometimes it is even compared to a solid fuel boiler. However, this belief is not entirely true.

The best fuel for a stove is wood. It is recommended to use non-resinous rocks. This should include:

- birch;

- poplar;

- acacia

Pallets and briquettes are excellent. According to consumers, kindling is best done with logs, but briquettes are perfect for the combustion process. Do not use flammable substances when igniting. Reviews about the Buleryan stove say that before laying firewood, it is recommended to dry it on the stove, then its combustion will be more efficient.

The above-mentioned period of operation on one load of fuel will be relevant only when the furnace is fully loaded. Do not make the chimney pipe shorter than recommended. In order to ensure successful combustion, good draft is necessary, which is only possible with a total chimney height of 5 m.

Consumers emphasize that the pipe should be assembled against, and not in the direction of, the movement of gases. This will prevent resin from getting on the floor, which flows out of the furnace openings. If the chimney is installed correctly, the resins will return and burn. Owners of private houses who successfully use Buleryan note that you should check the smoker twice a year. This will eliminate problems with heating equipment.

How to make a Buleryan stove with your own hands

There can be seven or more pipes.

If you have definitely decided that you do not want to buy a ready-made structure and are confident in your skills in working with metal, then you can make a pyrolysis oven with your own hands. Previously, we talked about how to make a simple stove from a gas cylinder.

Before you make a Buleryan stove with your own hands, you should take care of the tool; you can’t do it without it. In addition to what any craftsman has on the farm (hammer, pliers, file, etc.), you will need three tools that not everyone has:

- pipe bender;

- welding machine;

- Bulgarian.

If this kit is not there, things will not go further than desire. The manufacture of a homemade Buleryan stove is carried out according to the following algorithm:

- bend the pipes with a pipe bender, radius 220 mm, you choose the quantity yourself;

- we assemble the pipes together and sew up the structure with sheet metal;

- We make a compartment from steel sheets in the upper part - this is a secondary combustion chamber;

- two pipes cut into the air ducts to supply air to the afterburner;

- we make a chimney with a condensate collector from a metal pipe of larger diameter;

- we make two control valves: one for the air supply, and the second for the smoke exhaust;

- we make doors and weld a control valve and a locking mechanism to them;

- putting the structure together.

On the left is a valve for the chimney, on the right is for air supply.

Now let's look at the important points in the design of Buleryan stoves. The chimney should be in the shape of the letter "T". It is separated from the firebox by a smoke exhaust valve. If you use metal sandwich pipes, then collect them “by condensate”. Ceramic chimneys, and especially asbestos pipes, cannot be used. When you sew up the body with steel, there should be a protrusion in the front part. It will then fit into the groove on the door so that it closes hermetically. You simply cover the back part with steel, in which there should be a hole for the chimney.

Two rings of different diameters are welded into the lid from the inside, and an asbestos heat-resistant cord is placed in the gap, which will serve as a seal. In the damper that supplies air, you need to make a small cutout on the edge, so that even when completely closed, there remains a small loophole for air. In the chimney valve, you need to cut a segment to 25% of the area of the entire damper, like a piece of cake cut into four parts. To make it more convenient to remove soot, you can attach a plate to the bottom of the firebox, but this is not necessary.

Reviews about installation features

The Buleryan 100 stove, reviews of which you could read above, according to consumers, should be installed at some distance from flammable objects and materials. The distance should be 1 m. If the surfaces are covered with plaster, then this parameter can be reduced to 75 cm.

“Buleryan” is usually installed on a pedestal, which acts as decoration and serves as a functional element. Inside, consumers advise making a niche for firewood. Usually the base is made of piles.

Reviews about cleaning features

After reading the reviews and disadvantages of the Buleryan stove, you can decide whether you should purchase such equipment for your garden or home. But if you have already made your choice, then you need to learn more about how cleaning is carried out. No matter how high-quality heating equipment is, it requires preventive maintenance from time to time. "Buleryan" will begin to show signs of contamination over time. According to consumers, they are expressed as follows:

- lack of traction;

- deterioration of melting;

- Difficulty closing the gate.

For cleaning, you can use one of several technologies. The main thing is that it is safe. Reviews and disadvantages of the Buleryan stove indicate that such equipment can become a source of increased danger. Consumers do not recommend using the so popular burning cleaning method. This method is dangerous, although effective. Some daredevils decide to take this extreme move.

Its essence is to heat the pipe to a temperature where the metal turns red. Under such conditions, the resin simply burns out, and the chimney is cleaned. Cleaning, according to stove buyers, can also be done mechanically. To do this, a special rod is used, with which you need to get into the pipe from the roof.

The length of the chimney above the surface should be approximately 3 m, so this approach is no less dangerous without the use of insurance. In winter, such manipulations should not be carried out. After reading the owner reviews about the Buleryan stove, you will choose another method for yourself - through a glass. If the smoker is thoroughly clogged, and it is impossible to clean it from above, then you can knock on the pipe. However, some of the resin will still remain in place.

The smoker is sometimes cleaned from the inside, although this option is quite complicated. From scrap materials you should make something like a folding meter with a ruff at the end. You can use an aluminum angle or pipe. The design should be quite light. The height of the pipe is decent, and if the device is heavy, then cleaning, according to the owners of Buleryan, will be quite difficult.

It is more economical and easier to use a rigid but flexible wire or cable. Its end must be rolled into a ring along the diameter of the pipe and the chimney must be cleaned through the condensate glass. According to homeowners where Buleryan is installed, this procedure has one drawback. It is expressed in the fact that a lot of dirt is formed in the process, but you have to spend no more than an hour on cleaning.

Step-by-step instruction

Materials:

- Pipes;

- 4mm. 50x50 – 27 m;

- 2mm. 30x20 – 0.76m;

- 2mm. 40x25 – 2 m;

- Diameter 15mm – 0.6m;

- Diameter 95mm. (5mm.) – 1m;

- Steel – 5mm. – 3m2;

- Sheet metal – 100mm. – 0.1m2;

- Wire with a diameter of 10mm – 0.5m;

- Garage hinges – 2 pcs.

Step-by-step instructions for making Buleryan:

- We cut the pipe, which is 27 meters long, into 18 one and a half meter sections, from which we make pipes characteristic of Buleryan (two bends of 120 each).

- 15mm nozzles are welded into 4 of them. tubes (tube length – 15 cm).

- The pipes are folded together in the shape of the future Buleryan and secured by welding. Parts with nozzles are placed two on both sides (later they will act as a blower). Everything is finally boiled down.

- To make the gas afterburning chamber we use 5 mm. steel. We cut out 2 blanks (370x700 mm with a jagged edge 50x60mm to fit the pipe size).

- The parts are welded inside the contour formed by the pipes. Pipes with nozzles should be located in front of the partitions.

- Frame. From the same metal as for the afterburning chamber, we cut plates that will close the gaps between the pipes: 18 pieces for the middle part (400mm x 50mm). 36 pieces for all lower and upper spaces (350mm x 50mm).

- We cover the ends with two 6-carbon plates from the same 5 mm. metal (side 40cm). We make a hole in one of the plates for the chimney. It should be 85 mm in diameter. and located in the afterburning chamber.

- And a hole for the door is cut in the front plate. Approximately 25x25cm. We weld both plates into place.

- The chimney will be a 95 mm pipe, 50 cm long. A valve is installed in the pipe on a wire axis (similar to a throttle valve in a carburetor), with a quarter cut out.

- A pipe frame (40 x 25mm) is made around the perimeter of the door opening.

- We cut out two squares from 10mm metal. The first is 330mm, the second is 246mm. We weld the smaller square with a profiled pipe (40x25), so that it fits into the frame onto the hole for the door (see points 8, 10).

- The blower will be similar to the chimney, only the valve in it will not have a selected quarter. Pipe for 95, 140 m long.

- A 95 mm hole is made in the finished lid, and a blower is welded there.

- Canopies. The door is fixed (by welding) and at a distance of 40 mm from its top and bottom, 2 professional pipes with a length of 380 mm are welded horizontally. Where there will be awnings, the ends of the pipes should protrude 5 cm beyond the hatch. Garage hinges are welded to them.

- Constipation. You can make the lock yourself, or you can order it from a turner. After welding it to the door, the fixing welding is removed.

- All welds are ground.

- You can weld the legs.

Don't be tempted by narrow water pipes. For efficient operation of Buleryan, pipes of 50-70 cm are better suited.

Reviews of "Buleryan" with a water jacket

Reviews from owners about the Buleryan stove make it clear that a design with a water circuit can be found on sale. Using such an installation, rooms are heated due to active circulation in heat exchangers. Such a stove, according to buyers, is an unusual and at the same time simple device. The body is cylindrical and consists of two levels. It resembles an ordinary barrel.

Reviews of the Buleryan stove make it clear that the lower level of the structure is the firebox, which is necessary for pre-ignition and raising the temperature to the level of the combustion chamber. The upper compartment is necessary for burning wood gas. The main task of the furnace is to heat large volumes of water. According to buyers, the device has elements that distribute energy for heating water and heating.