Author: Yuriy Fedorovich Kolesnikov, thermal power engineer

The gas furnace is currently of particular interest. Let us immediately make a reservation that what follows does not mean gas cookers and hot water boilers; These are certain types of heating devices using gaseous fuel. Also a special topic is technological gas furnaces for industrial purposes. We are interested, simply put, in household gas stoves.

The cost per unit of heat obtained from natural gas is today much lower than from other sources , including electric heaters. In terms of ease of delivery and consumption, natural gas is second only to electricity, but it can be stored for future use without fear of dampness, bituminization, spontaneous combustion, and other disadvantages of solid and liquid fuels. This situation will continue in the coming decades; in any case, for a time several times longer than the estimated service life of gas heating devices. If you come up with a way to distribute heat throughout the rooms without pipes, radiators and coolant, then gas heating will turn out to be not only economical during operation, but also require 1.2-2 times lower initial costs than traditional water heating. And this method is already known, see below.

We will also take a closer look at gas sauna stoves. A city dweller of average and above average income can afford a maximum of a mini-sauna in his apartment, see fig. But they are produced mainly electric, the steam costs a pretty penny. And to get permission for gas - as they say, it won’t be late at night. Plus - destruction in the apartment from construction and installation work.

In general, those who like to take a steam bath in their bathhouse no longer go there, but go out on weekends. But firewood “from the forest,” alas, is a thing of the past. In the vicinity of holiday villages, everything is picked clean. At least scrape together enough for barbecue, but for a sauna you need several armfuls of firewood. And there’s also the time factor: it takes at least 2-3 hours to heat the bathhouse with wood until it’s ready. Steam as a family in shifts – 3-4 hours. You can’t fuss around while you’re steaming, otherwise the bath will only do harm; that’s another 2-3 hours of rest. How much is left for other chores and entertainment if an overnight stay is not planned? And even if it is planned, then out of 2 days off, only 1 is left for household chores. What does a gas sauna stove provide in this case? Quite a few:

- Lighting up the stove is instantaneous; About an hour is saved on fuel transfer alone.

- Women and children can steam already 30-40 minutes after starting the stove (if it is of a special design for gas, see below), and 1.5-2 hours will be enough for the whole family; the total gain in time is 3-4 hours, i.e. an extra half day for housekeeping.

- The price of gas for a bathhouse is comparable to that of solid fuel, but what is more convenient to carry – a propane cylinder or a bag and a half of coal? The question is rhetorical.

What is often forgotten

Gaseous fuel has a remarkable property: its combustion rate can be arbitrarily high, even to the point of detonation. They fight the danger of an explosion by adding a fragrance to household gas: the human nose literally smells mercaptan molecules, and the unbearable stench will force you to take the necessary measures, as physicists put it, many orders of magnitude before the gas concentration in the air reaches a dangerous value.

In this case, something else is more important: with the correct design of the burner, the gas burns completely, down to CO2 and water vapor, within a few centimeters from the burner nozzle at any value of its supply. As a result, firstly, in a gas sauna stove you don’t have to worry about clogging the flow-through (open) heater with soot and soot.

Secondly, a gas furnace for heating a house is capable of maintaining maximum efficiency of up to 5% and even 3% of the nominal power; For solid and liquid fuel stoves, when the power drops below 10-15% of the nominal value, the efficiency drops sharply. Since in mid-latitudes during the heating season the heat loss of a building varies depending on the weather by more than 10 times, the savings in fuel heat equivalent are almost double.

Thirdly, the risk of burning decreases sharply. Carbon monoxide, carbon monoxide, has no odor, and the first symptoms of poisoning appear when it is quite severe. Fragrance - mercaptan burns more difficult than saturated hydrocarbons, and if the fuel does not burn out, its smell will make your eyes water long before the fumes begin. A person can withstand CO2 concentrations of up to 2% by volume without harm to himself (in the atmosphere - 0.04%; in residential premises up to 0.6% is permissible). These circumstances make it possible to organize gas mobile and temporary heating, for example. for a summer residence, see below.

Gas stove heater

For some small rooms, a small tabletop heater may be sufficient for heating. The device is assembled using quadrangular flat tiles, which are initially equipped with a grid.

The structure is assembled by connecting the tiles to a metal casing. The casing is equipped with a combustion chamber and a fan. Assembling such an installation yourself is not difficult.

First of all, you need to measure the length and width of the future body. In this case, you need to rely on the size of the tiles. After making the casing, it must be secured with hook strips.

On one side you need to make a movable bar. This is easily done using a spring that is attached to the lift arm. This measure in the future will ensure the possibility of removing the housing if necessary.

Despite the apparent complexity of assembling gas heating devices, their design is not a difficult task. It mainly consists of correctly, step-by-step and carefully following all pre-written instructions

This design has a pre-provisioned ventilation system. There is no need to use any unusual materials for its construction. A handy fan will be enough. For example, from a window air conditioner. The blades can be carefully trimmed and given the desired shape and size. The fan is mounted on the back of the case.

To create draft inside the housing, it is necessary to secure a metal combustion chamber. Many holes are made on the surface of the combustion chamber at a small distance from each other.

Thanks to the ability to connect such a heater to cylinders of different sizes, this homemade device is very mobile and easy and convenient to transport. That’s why such mini-stoves are often taken on hikes.

The device effectively heats rooms even in winter and has a high efficiency. If you insulate the room in advance and install reflectors, then such a heater will perform its task as efficiently as possible.

But why oven?

Well, the reader may say, we already know about gas. Perhaps more than yours. But why put it in the oven? Natural gas is already widely used by industry and public utilities.

Heating residential premises using individual stoves can be a lifesaver for the environment. And it’s not just that up to 30% of heat is lost in the mains of thermal power plants. Nature manages to process small emissions of combustion products, extended over time and distributed over a large area, before they cause harm. And of the same or even smaller magnitude, the burst emissions from the pipes of thermal power plants, which also burn gas to CO2 and H2O, partially reach the stratosphere and add to the greenhouse effect.

For comparison: during a summer thunderstorm in the Moscow region, energy is discharged to 2 Mt of TNT equivalent. Within a few minutes, over an area of about 10 square meters. km. And over Hiroshima there were 20 times fewer explosions, but instantly and at one point.

Manufacturers of gas heaters

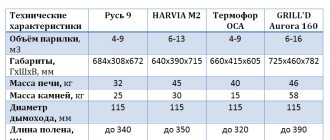

Currently, many Russian companies are producing gas stoves for baths and saunas. It is worth noting that domestic equipment in its technical and operational characteristics is in no way inferior to expensive European units. Let's look at the most popular models.

| Manufacturer | Short description | Approximate cost, rubles |

| Furnace "P-20GT" | Gas-wood appliance. At the request of users, it can be equipped with a fuel receiver or a gas burner of the GGU-20 “Spectrum” or UGOL-22 type. Power - 20 kW. Designed for steam room volume up to 22 m³. Efficiency when operating on gas is 80-90%. Chimney diameter - 122 mm. Oven dimensions: width - 535 mm, length - 1200 mm, height - 800 mm. Weight - 85 kg. It is possible to additionally equip a hot water tank. | 12 000-16 000 |

| Zhara-Malyutkagaz | This model is considered one of the most compact. Power - 16 kW. Capable of effectively heating a steam room ranging in size from 4 to 12 m². Dimensions: width - 400 mm, length - 725 mm, height - 575 mm. Weight - 54 kg. The diameter of the chimney pipe is 114 mm. | 13 000-15 000 |

| Termofor Urengoy Carbon | Compact gas stove-heater. Capable of efficiently heating a room up to 12 m². The oven walls operate on the principle of convection. The stove is made of high-strength steel. Dimensions: width - 450, length - 650, height - 705 mm. Weight - 44 kg. Chimney diameter - 115 mm. | 16 000 |

| Termofor Taimyr INOX | In many respects, this model is similar to the previous one. Suitable for steam rooms with a volume of 8 to 18 m³. The main difference is that this stove is equipped with a double steam preparation system, which includes external and internal heaters. Dimensions: width - 450 mm, length - 645 mm, height - 860 mm. Weight - 45.5 kg. | 19 000-22 000 |

| Ermak Uralochka-16 | Universal gas-wood stove for a bath. Capable of heating a steam room with a volume of 8 to 16 m³. Made from structural stainless steel. Central location of the chimney pipe. Remote fuel intake window. Thanks to this, it can be placed in the dressing room. Dimensions: width - 445 mm, length - 550 mm, height - 730 mm. Weight - 60 kg. | 14 000-16 000 |

| KUTKIN Standard G-2.0 | The model is quite expensive. The body and firebox are made of AISI 430 stainless steel. Operating modes: Russian, Finnish, Turkish bath. Chimney diameter - 115 mm. The heater is hidden in the body. Dimensions: width - 450 mm, length - 620 mm, height - 900 mm. Weight - 90 kg. | 27,000-65,000 (depending on the presence or absence of finishing) |

Thus, a gas stove for baths and saunas allows you to effectively heat the room, and using such a heater is very convenient.

Buy or make?

The first thing you need to know if you are interested in gas stoves is that homemade gas appliances are not certified by the Ministry of Emergency Situations; their use is expressly prohibited. At the same time, buy a good gas stove for constant heating of 1 room up to 120 sq. m of domestic production is possible for an amount equivalent to 800-950 US dollars. A “firm” will cost 50-150 USD more, but this is money “for a star”; the quality of Russian gas appliances is recognized all over the world.

A mobile gas heater with a power of up to 12-15 kW costs up to 350 USD; you can find a good certified one for 150 USD. Separate heating elements (more details below) for 8 sq. m of constantly heated area costs about 100 USD, i.e. a heating system for an average-sized house will cost less than 1000 USD, including installation of pipelines and fittings. This is several times, that’s right, cheaper than building a conventional furnace, and does not require complex construction work in the building; pipelines can be laid under a suspended ceiling.

Gas burner for heating and cooking stove

Can I do this work myself? No, only certified specialists are allowed to work with gas. The contracting company itself will draw up all the documents for gas heating. This, together with the work, will cost about another 600 USD, which is still much cheaper than building a wood-burning stove that heats 1-2 rooms.

You can gasify an existing stove with your own hands by purchasing a special stove burner for it (see figure) for 200-250 USD (in rubles). Such burners are equipped with an automatic system that shuts off the gas when the flame goes out, the stove and surrounding air overheat, gas leaks, etc. More expensive models are equipped with automatic ignition.

Note: only forced-air burners are suitable for household stoves! The burners are atmospheric, without pressurization, and are intended for other purposes. Their use in household ovens is unacceptable!

Gas stove burners are supplied with a certificate of suitability (don’t forget to ask the seller!) and are sold as separate devices. They are installed in the opening (creation) of the firebox and do not require alteration of the stove. Thus, a gas-wood stove is obtained.

DIY metal gas sauna stove

To achieve good steam in a sauna, you need a good brick stove. It will keep you warm for as long as possible. However, such a furnace requires a serious foundation. This requires additional money and time.

In order not to spend money on pouring the foundation, you can make a metal stove yourself. Creating such a furnace does not require an in-depth study of the circuits, and its effectiveness has been proven in practice.

Although a metal stove heats up quickly, it cools down just as quickly. This is its main drawback.

In order to assemble such a structure, you will need a metal container, sheets of metal or pipes of various diameters, a gas burner, an angle grinder, and a welding machine. Those who do not know how to use a welding machine can make a body from an ordinary pipe. This will not make the stove any worse.

Gas cylinders and pipes can be selected in other sizes. The size of the required parts depends on the size of the heated steam room. If its area is large, then it is worth making the stove larger. She will cope with her task as efficiently as possible

The result will be a stove about 80 centimeters wide and about one and a half meters high. A heater and platforms for installing a container with water are mounted on top. Thus, to create a steaming atmosphere in the steam room, you will need to pour water on the stones.

When drawing up a conditional drawing, you need to take into account the exact dimensions of all parts. Initially, you need to find a pipe or gas cylinder with a height of 180 centimeters and a diameter of 80 centimeters. In this case, the walls of the pipes must be quite thick - from 0.4 cm or more.

You will also need a metal sheet one centimeter thick, a steel rod with a diameter of one centimeter, cast iron or steel doors, a chimney pipe, a gas burner and a tap. All material can be purchased at a hardware store. You will also need tools: a grinder and a welding machine. You can rent them or borrow them from friends.

First of all, the base is prepared at the place where the metal stove will be installed. It needs to be made even and level. It is necessary to cover the foundation with fireproof material.

Two rows of refractory bricks are laid on top. Do not forget that the ceiling and all walls at a meter distance from the stove must be covered with fire-retardant material.

The manufacture of the furnace is carried out in several stages. First you need to cut the pipe into two parts with a grinder, one of which will be the furnace body, and the second will be used to heat the water barrel.

In the lower part of the first section of the pipe, a rectangular hole measuring 20x5 centimeters is made with a grinder. This method provides access to the gas burner.

The vast majority of gas furnaces have approximately the same structure and sequence of assembly and installation. The water tank is installed on top or welded to the side. If you want to install an advanced model, you can additionally install a number of elements and devices that will automate the control of the furnace.

In the middle of the first section of pipe, another rectangular hole of the same dimensions is cut. The brackets on which the mesh will be held are welded. The mesh cells should be smaller than the size of the stones that will be laid on it.

A tap is welded at the bottom of the second pipe. Then the second piece of pipe is attached to the heater. In this case, it is necessary to check the seam for leaks. Next, you need to weld one door and hang the second on its hinges.

The pipe is insulated using refractory bricks or other material. After welding all the elements, the burner is installed and the stove is ready for use. It is worth remembering that a metal oven heats up to high temperatures, so it is imperative to cover all nearby surfaces with refractory material.

Assembling a gas stove for a sauna with your own hands is not difficult. To implement such an idea, you need to observe safety precautions and follow recommendations. Thanks to self-assembly, you can save a lot of money, and the efficiency of this design is not much inferior to store-bought models. Before you start assembling the stove, you need to carefully prepare the room.

Which stove is suitable for gas?

Natural gas, as already mentioned, burns very quickly and produces a lot of heat. Brickwork is simply not able to immediately perceive and transmit such a flow into the room; a gas burner is an instantaneous device, and a brick oven is a heat accumulator. Therefore, only metal furnaces are clearly suitable for gasification; their efficiency with gas increases. If you still want to gasify your grandfather’s stove, then the brick gas stove must satisfy the following conditions:

- Without an extensive combustion chamber and massive masonry, a Russian stove is no longer needed.

- The stove must be made according to a duct design with a developed smoke circulation system, Dutch or Swedish.

- All heat release must occur in the firebox, i.e. all bell-type stoves without exception are eliminated: natural gas is too energetic for them, the exhaust gases from under the bell arch will be forced out into the chimney without having time to transfer heat to the body of the stove.

In any case, accelerating a brick kiln on gas requires a very long time, 4-6 days. During this period, the gas supply is gradually increased from minimum to nominal. Hence the corollary: it makes sense to gasify a brick oven only if it will be heated continuously for a long time. But what kind of masonry is needed that can withstand constantly large amounts, over 450 kW/cu. m, thermal stress?

Note: however, traditional stove makers do not give up attempts to develop brick stoves for gas. There is a point in these searches - a brick oven breathes, which creates a healthy microclimate in the room. Among the successful samples, we can note the heating and cooking stove AKH-14 designed by Yu. P. Sosnin; its advantages are confirmed by operating experience; there are more than 10,000 copies in operation in the Russian Federation. But still, the cost and weight of it are “brick” plus additional construction work - a foundation for the stove is needed.

Advantages and disadvantages of gas furnaces

The market offers consumers a wide variety of energy resources. At the present stage of economic development, gas is one of the most profitable and efficient fuel options.

The use of gas as a power source for heating equipment is advantageous in that its cost does not break the consumer's pocket. In addition, gas has a high efficiency factor. The operation of gas heating devices is easy to use, economical and safe.

This kind of homemade heater is often used for a wide variety of purposes. It can be used to heat greenhouses, garages, and boxes. Thanks to mobility and low assembly costs, portable heaters can even be taken on hiking trips

When installing a gas stove indoors, the best option for owners would be a situation where a gas pipeline is directly connected to the building. However, in modern realities this is a very rare case. Many will have to purchase gas cylinders and other containers for storing and supplying fuel to the stove.

The advantages of using gas furnaces include:

- fast, efficient and high-quality heating of the room;

- mobility and compactness of gas equipment;

- the ability to quickly move the oven to the desired location;

- independence from government communications, power outages and many other factors.

Gas equipment, like any other, has its drawbacks. However, they are relative and easily avoided.

The disadvantages include:

- the use of gas is strictly regulated by regulations;

- owners of non-residential premises will have to obtain a number of agreements and permits from the gas industry and other government bodies;

- drawing up the necessary project can cost a lot of money;

- the use of reduced and bottled gas requires compliance with safety measures.

In order for a gas stove to perform its function as efficiently as possible in a room, it is necessary to have protective screens. Such structures are equipped with reflective surfaces, thanks to which warm air does not escape, but is reflected and heats the entire area of the box.

Craftsmen are constantly improving their skills and using new techniques to design homemade units. Some modern handmade gas heaters are equipped with special blowers that allow you to control the flow of warm air

Open combustion stoves require the design and installation of a ventilation system and provision of air humidification. When the device burns oxygen, the air becomes dry. This often leads to headaches and sore throats.

What do you need besides money?

First of all, you need to check whether the burner certificate is valid. The easiest way to do this is to make a copy of it and show it to the gas service inspector. He can also advise in advance which model is better to take. The burner power for a sauna stove is calculated based on the value of 1.5 kW per 1 cubic meter. m to warm up the steam room to 80 degrees (where did the 252 kcal/0.4 cubic m circulating on the RuNet come from? To make it inconvenient to count, or what?); for household - according to the thermal engineering calculation of the building or taken equal to the power of the existing stove.

Note: there is no need to struggle too much with the heat loss of the bath by turning the steam room into a thermos. A proper, healthy bathhouse must breathe.

Gas sauna stove installation diagram

Next, you need to check your stove: the firebox opening must have a metal frame. The dimensions of the opening itself are height 470-550 mm, width 350-450 mm; together with the overlay, 615-680 mm and 515-665 mm, respectively. Then - the room. Installation of a gas stove is allowed in rooms with a volume of at least 8 cubic meters. m with a ceiling height of at least 2.2 m. In a room with a stove there must be an opening window at least 60 cm wide, with an area of 0.6 sq. m, and the gap under the door is at least 40 mm for air flow. Instead of a gap, there may be a ventilation grill on the door. The distance from the stove to the nearest wall made of flammable material is from 500 mm. Removal of the refractory base of the furnace is from 100 mm in any direction.

For a bathhouse, an additional condition applies: the firebox door should not open into the washing room or steam room. Therefore, the fireboxes of gas sauna stoves (see below) are made elongated so that the door opens into the dressing room. So keep in mind that it’s better not to even think about gasifying a potbelly stove with a heater standing right in the steam room. A typical installation diagram for a gas sauna stove is shown in Fig. it is also suitable for other cases, only it is no longer necessary to take the firebox into the next room. For more information about the construction of the bathhouse, see the video below; everything shown there also applies to gasified baths.

Video: bath structure

Note: automatic boosters require power. Therefore, in regions with unstable power supply, you should not seal the gas burner tightly into the stove so that you can heat it with wood/coal if necessary.

After installing a burner or a new furnace, a gas inspector is called for inspection; if necessary, eliminate the observed deficiencies. Next, the furnace is connected to the gas main; this should be done by specialists. When powering the burner from a cylinder, you can connect it yourself using the hose and reducer included in the burner kit (don’t forget to check!) and present everything for inspection at once. Then - walking through the authorities with papers, the description of which is a separate topic; It all ends with the issuance of permission to operate the furnace.

Note: a hose with a reducer and other fittings can be purchased separately, but obtaining permission in this case becomes very difficult, because Certificates are required for each separately purchased unit.

When papers are not needed

Homemade gas stoves, without worrying about permits at their own risk, are often used by home craftsmen for technological purposes in non-residential premises. The gas allows you to obtain a chemically neutral flame with a temperature, when pressurized, up to 1600 degrees. Craftsman jewelers use microburners made from medical needles of different diameters with supercharging from an aquarium compressor. In any case, the room in which the stove/burner is operated must be equipped with ventilation providing at least 2 complete changes of air volume per hour.

Features of homemade gas stoves

A gas stove differs from a wood stove in that it uses gas for kindling. Therefore, in such a device, instead of a window for storing firewood, a cavity for the burner is mounted. However, you can also make a gas-wood stove with your own hands.

A metal sauna stove is often lined with brick. The lining is made to increase heat transfer. In addition, a metal structure with a brick casing cools much more slowly

Most gas furnaces have the following design. A pressurized or atmospheric gas burner is mounted in the device body. Fuel is supplied through a sealed gas hose or pipe.

At the top of a homemade gas stove there is a closed heater or an open tray with stones that are heated by a burner, as well as a device that removes combustion products.

When assembling it yourself, be sure to take care of installing a thermostat and a fuse that cuts off the gas supply if the burner goes out. The gas chamber containing the combustible gas is usually located under a tray with stones.

The advantages of homemade gas stoves for baths include:

- compact size, because gas stoves do not have a firebox or ash pan;

- rapid heating to the required temperatures;

- economical resource consumption;

- there is no need for constant maintenance of the device;

- When installing a water tank, you can also heat the water.

The disadvantages include the need for a gas source. For example, if the bathhouse is located outside the city in a non-gasified area, some owners will have to buy gas cylinders or install a mini-gas holder. However, there is an advantage to this - there is no need to obtain permits.

It is worth remembering that when working with gas you must always follow safety precautions.

When choosing a gas burner for a sauna stove, it is worth considering that the efficiency of atmospheric burners does not exceed 90%, and the efficiency of forced-air burners is more than 95%. However, the first option wins in terms of independence from electricity

When installing an open combustion stove, it is necessary to design and install a ventilation system and chimney. Also, when oxygen is burned, the air becomes drier, so you need to take care of humidifying the air.

To end the baths

Among the household stoves that go on sale, gas bath stoves are perhaps the most popular product, so you need to add something about them. Namely: a gas sauna stove is definitely suitable for a sauna with absolutely dry steam; It’s difficult to steam in a bathhouse with such a Russian-style stove, with a birch broom and topped up with kvass.

The reason is the same too rapid combustion of gas. A gas burner, without blazing into the pipe in vain, is capable of “burning” the heater properly at the rate of 6 kg of river pebble per 1 cubic meter. m of steam room, and for vigorous Russian steam you need at least twice as much stone. Experienced manufacturers (Termofor, Tulikiivi, for example) find a compromise, firstly, offering to purchase a heater made of stones that combine high heat capacity with high thermal conductivity, for example. steatite and other rocks from the soap chlorite group. However, a considerable additional payment is required.

Secondly, this is already a domestic idea, the heater is made double: the main large heat-accumulating one is closed and the smaller one is open specifically for adding heat; The diagram of a gas stove with a double heater and its appearance are shown in Fig. The configuration of the convector (it is needed to speed up the heating of the bath), the size and location of the holes in it are precisely calculated.

Modern gas sauna stove with double heater

You can add heat to such a heater made of ordinary stone about once every half hour, and only with water. Restrictions are also imposed on the broom: only birch and only dried. Adding kvass and steaming with a freshly cut birch broom turns out to be a bit difficult even for a strong, non-drinking man, but it’s probably better not to experiment with an oak broom even for the heroes.

Sauna basket stove

The second possible option is to gasify the basket heater like “Vesuvius”, see fig. on right. However, the heating time of the bath will remain “wood-burning”, and the gas supply, so that the heat does not waste away into the pipe, will need to be smoothly and gradually increased from the minimum to about 0.7 nominal over 1-1.5 hours. And most importantly: basket sauna stoves are not available with an extended firebox, i.e. According to safety rules, gasification is not subject to gasification, because the firebox door with the burner base cannot be brought into the dressing room.

Heat gas gun

Heat gas guns are distinguished by their high power and high level of energy output. Usually the structure is equipped with a chimney.

To make such a device yourself, you will need the following materials:

- meter pipe with a diameter of 18 cm;

- meter pipe with a diameter of 8 cm;

- pipe 30 cm long and 8 cm in diameter;

- metal plates for future fastening;

- a metal sheet;

- gas burner equipped with piezo ignition;

- axial fan with round flange.

In addition to the materials listed, you will additionally need to acquire a welding machine, a tape measure and a level with two ampoules. Some craftsmen advise using old gas cylinders or fire extinguishers instead of pipes. Their bottom and top are first carefully cut off with a grinder.

If you collect all the necessary materials and tools, then assembling a gas gun will not take much time.

The first step is to drill two holes in the first pipe with a diameter of 18 cm. They should be located opposite each other, and their diameters are 1 cm and 8 cm. The second meter pipe with a diameter of 8 cm is used to make the combustion chamber. For this purpose you will need about 30 cm.

The essence of the operation of a thermal gas gun is as follows. First, the gas supply to the burner starts. The fan moves air through the heat exchanger, where it heats up. The output is warm air, which very effectively heats large rooms.

The mounting plates must be welded to the second pipe. A hole with a diameter of 1 cm is also made on this pipe. After this, the pipe must be inserted inside the first pipe.

The next step is cutting out a plug from a metal sheet, which will be used to cover the space between the heat gun frame and the combustion chamber.

Then you should use a welding machine and weld the pipe from which the combustion chamber will be made to the internal frame. After this, a pipe through which hot air will be exhausted is welded to a hole with a diameter of 8 cm. Next, a plug is welded.

The gas burner must be firmly and firmly installed in the chamber. It is necessary to check the rigidity of the fastening. After this, a hose is passed through the drilled centimeter holes in the two pipes. Then a fan heater is attached to the heat gun. A chimney must be installed on the front of the chamber.

To prevent the device from turning over and to stand stably on a flat surface, you need to weld the legs. You can also use your imagination and attach wheels or other parts to make the structure easier to transport.

Heating a room with a heat gas gun is convenient and simple. Moreover, it is economical. However, there is always a risk of structural failure. Therefore, you should be very careful and thoughtful in the process of assembling the device.

Which oven is better?

So, since we are talking about gas, you still need to buy a stove. In this case, naturally, we need the best gas furnace. How to choose it? Popular rumor, that is, consumer ratings, is essentially true, but it would be strange if advertisers did not gradually try to use such a powerful tool for promoting goods in the interests of their customers. In addition, a quiet, imperceptible revolution has recently occurred in the gas furnace business, but entailing far-reaching consequences. We will talk about it below, but for now we will discuss how to choose a better oven yourself, regardless of the principle of its operation.

Quantity

In this case, this concept refers to the efficiency of the furnace. To calculate it, in addition to your own initial data, you need to know the higher calorific value of the fuel, or its calorific value. For flammable gases used in everyday life, it is as follows:

- Natural gas in the Russian Federation – 34-38 MJ/cu.m. m; average – 36 MJ/cubic. m.

- Pure methane – 34.67 MJ/cu.m. m.

- Pure liquefied propane (density 0.51 kg/l) – 25.54 MJ/cubic meter. m

- The same, butane, density 0.58 kg/l - 28.61 kg/l.

- Propane-butane mixture summer (50%/50%), density 0.545 kg/l - 27.09 MJ/kg.

- The same, winter, 90% propane and 10% butane, density 0.517 kg/l - 25.85 MJ/kg.

Note: for those wishing to determine the heat of combustion of gas from their pipe by measuring the boiling time of a kettle, etc. you should know that the efficiency of a kitchen gas stove does not exceed 65% And what exactly this specific stove will have in this specific kitchen with this specific vessel with this specific water on this specific burner at this specific atmospheric pressure is known specifically only to the local specific Drum, and to no one except.

Now let's determine the heat and fuel consumption. Let's take, for example, a country bathhouse with a steam room for two with a volume of 12 cubic meters. m (2x3 m in plan and with a ceiling height of 2 m). It will require 1.5 kW x 12 cubic meters. m = 18 kW of heat, or 18 kJ/s of heat flow from the furnace. Per hour - 18 kJ x 3600 s = 64.8 MJ of heat. Next, we assume that our bathhouse is gasified. Then an hour of bath procedures at 80 degrees will take 64.8/36 = 1.8 cubic meters. m of gas.

Here you need to take into account the fact that stove manufacturers give the gas consumption in them based on heating the steam room to 60 degrees; Doctors say that at higher temperatures, it is dangerous for women and children who are at least a little sick (including temporary malaise after yesterday and euphoria from recent libations). The heat loss of a room generally depends on the difference in temperature inside and outside according to a power law, but since temperatures are measured from absolute zero (-273.16 degrees Celsius), then within 80-60 Celsius it can be replaced by a linear one without a noticeable error.

So, at 60 degrees and the efficiency of the furnace at 100% gas, you will need 60/80 = 0.75 x 1.8 cubic meters. m = 1.35 cubic meters. Choosing a stove turns out to be generally simple: the closer the fuel consumption declared by the manufacturer to this value, the better the stove. You just need to remember to look in the specification for what volume of the steam room it is stated for, and bring it to 12 cubic meters. If it is stated that there is less than 1.35 cubic meters of gas per 12 cubic meters of steam room, it means that you are a swindler. Or he invented a perpetual motion machine, but he himself doesn’t know about it.

Now let’s check independently, according to popular rumor. For example, in the Russian Federation, the Termofor Urengoy stove is in 1st place with a decent lead from the rest. Perhaps because of the price of only 12,000 rubles? Let's look at the declared gas consumption for 12 cubic meters of steam room - 1.71 cubic meters. m/hour. We calculate the efficiency of Urengoy: 1.35 (theoretical ideal consumption) / 1.71 (real for this furnace) = 0.79 or 79% A very good and very similar indicator to the truth; It's probably worth getting this stove.

Roughly offhand

compact infrared gas heater

As for infrared gas heaters, which will be discussed below, their market and culture of use have not yet developed properly, and a unified method for determining efficiency has not yet been developed. These devices, unlike sauna stoves, are designed for long-term continuous use, so you need to somehow take into account the cost of heating and its reliability. Therefore, it is possible to choose more or less definitely only by comparison.

First, without worrying about dimensions and other physics, we multiply the “consumption” parameters: the hourly gas consumption stated in the specification by the cost of the device. Let's get a certain carelessly abstract value A. Then we multiply the “economical” indicators: thermal power by the duration of the company warranty in months; we obtain a similar value B.

The following is also nothing complicated: C = B/A. The higher C, the cheaper heating will cost. This is enough to compare different models, and you can calculate the exact cost of heating if you know the amount of heat required, the calorific value of the available gas and its consumption according to the specification for the selected sample.

Quality

It remains to understand such consumer parameters as reliability and functionality. here is to compare popular rumor with the sales rating. The leaders in sauna stoves in the Russian Federation are the already mentioned domestic Termofor and the Finnish Tulikivi; for continuous infrared heaters - also domestic Bee Car and American Master. Recently, Russian-Chinese Comfort has emerged quite well. They say good things about it, but they won't be on the market for long. Therefore, having looked at the Comfort gas stove, it is advisable to consult with real users.

Conclusions and useful video on the topic

Anyone can assemble a gas heater according to the schemes discussed at home. You just need to follow safety precautions and not neglect the instructions for putting the devices into operation. If you assemble the heater yourself, you can save money. In addition, the efficiency and performance of such devices is not inferior to store-bought ones.

If you plan to heat a small room or tent, and also take the device on trips and hikes, then it is better to make a heater from a gas burner or from a gas stove. They are more compact, take up less space and are easy to transport. Gas heaters are suitable for heating larger spaces, produce more heat and require an electrical connection to operate the fan.

For heating small, remote non-residential premises, a homemade heater made from a gas burner and a heater made from a gas stove are suitable. To provide sufficient heat to medium-sized rooms, you should consider installing a gas heat gun or gas fireplace.

All devices considered can operate both from gas pipes connected to the room and from gas cylinders. It is worth remembering that when connecting to a gas pipe, it is necessary to install a meter and officially register the procedure with the gas control authorities. When installing a self-made structure, this procedure will become much more complicated.

If you use gas cylinders, you can effectively heat your room in the winter. It is important to remember that following safety precautions is the key to successful work with any gas devices.

Tags: gas, stove, hand, homemade, your own

« Previous entry

Gas stove revolution

This revolution is associated with the advent of gas infrared emitters, or infrared burners; both are designated by the abbreviation GII. There is a difference between them; which one - let's see below. For now, it is worth noting the fact: in terms of a set of parameters, including price, GII is ahead of conventional heating stoves, just like Porsche is ahead of the pre-war Emka. For example, a 1.5 kW GII heats an area of up to 12 square meters. m, it weighs about 7 kg, and costs up to 5,000 rubles. Let us emphasize: this is not an analogue of an electric fireplace; we are talking about constant heating of residential premises. The price of a gigacalorie of heat turns out to be 1.5-2 times lower than from any other source. In addition, household gas stoves based on GII turn out to be significantly better than other heating devices in terms of sanitary and hygienic indicators.

Towards the principle of infrared heating from above

How is this achieved? Due to heat distribution similar to underfloor heating, see fig. The comfortable zone is where people are, and heat loss through the ceiling is sharply reduced, which is especially noticeable in one-story houses. Plus, the floor can be insulated from the inside; the flow of heat from above will prevent the dew point from entering the room. But, unlike a heated floor, complex construction work is not needed, there is no thin winding tube embedded in the floor that can become clogged or leak (how can you repair it without breaking the floor?) Unlike electric heating, it is not expensive electricity that heats, but gas, a unit of energy is several times cheaper. Another plus is that the flow of warm air from the heated infrared floor is uniform over the area of the room; the inhabitants live as if on a warm island with an even climate.

GII device

GII burners are open type devices. In them, the gas-air mixture is blown through narrow channels in microdoses; air is sucked in naturally without pressurization. In ceramic GIIs (diagram in Fig. yb;t), nozzle channels are made in a ceramic (usually carbon) plate, which itself heats up to 900 degrees. Due to the high temperature in the microcombustion chambers, the efficiency of the device exceeds 90%, and 70-75% of the gas energy is converted into infrared radiation.

Diagram of a ceramic gas infrared burner

In catalytic GII burners, the combustible mixture passes through a catalyst mesh. The combustion catalyst itself is either platinum coating (eternal, but expensive), or nickel coating with additives (cheaper, but gradually burns out). Anyone who has used a wind-resistant gas lighter is familiar with catalytic combustion.

Ceramic GIIs are cheaper than catalytic ones, but their power is limited to 12-15 kW, because It is difficult to make the flow of the mixture through narrow nozzles very intense. The dimensions of ceramic GIIs cannot be very small; For effective radiation, a fairly large plate area is needed. Catalytic GIIs with power up to 30 kW and more weigh several kg; they can be made miniature, but are expensive.

Open GII in residential premises is of limited use, because emit carbon dioxide, although in small quantities. In practice, if there is supply and exhaust ventilation for 2 air changes per hour, open HII with a power of up to 12 kW can be used for temporary heating under constant supervision.

Gas infrared emitter device

GII emitters, or gas heating elements (diagram in Fig.) do not have this drawback, and therefore can be used for constant heating of residential premises. They require pressurization, therefore they are energy dependent, but, on the other hand, any modern gas hot water boiler is also energy dependent. And one and a half hundred years ago, pipelines for gas lighting were stretched like a web throughout the houses, and there were no widespread emergencies, although the gasification technology then was compared to the current cave technology. Also, gas heating elements require a gas flue, but the standard ones in new buildings are quite suitable: there is nothing at all in the exhaust gases (it’s hard to call them flue gases), and their temperature is up to 400 degrees.

Purpose and evolution

The first to go on sale were open ceramic GIIs for temporary heating of garages and outbuildings, pos. 1 in Fig. Probably, it was the need to create a comfort dome in a room with large heat losses, without burning exorbitant amounts of fuel, that prompted the creators of the first GII to develop them. GIIs for garages are successfully used to this day: sellers offer them in a wide range, and prices have dropped from 800 to 90-150 USD in 7 years; Certification and a separate permit for the operation of garage GII are not required. In everyday life, ceramic GIIs have also found application for replacing electric fireplaces, pos. 2, but this is just a mechanical transfer of a principle capable of much more.

Gas infrared heaters

GIIs, as powerful, relatively inexpensive, reliable and energy-independent heat sources, immediately attracted the attention of participants in field and expeditionary work, hunters, fishermen, tourists, yachtsmen and others who faced the problem of heating far from civilization. But these categories of users required a large specific power in relation to their weight and size, so they gave preference to catalytic GIIs.

The first samples (item 3) were similar to their non-catalytic counterparts. In the end, the “suburban” branch of the evolution of GII gave birth to a gas mini-oven (fig. on the right), which can be carried with you while moving on foot. However, there are few of them on sale: they are expensive, from 200 USD, and refueling requires expensive lighter gas.

Gas mini oven

The development of GII towards constant heating turned out to be much more productive. The high specific power of the GII, now per unit of radiating surface, made it possible to organize warm islands directly in the open air; for this it was only necessary to assemble the radiating panels under the reflective umbrella and place it on a stand, pos. 4.

The efficiency and cost-effectiveness of heating with GII “umbrellas” turned out to be so high that the question arose about using them for permanent heating of housing. At this time, the heated floors were wide open; their sanitary and hygienic properties were not in doubt, but the issue of complexity of installation in existing buildings and maintainability became acute. You already know the solution: GII burners were replaced with gas heating elements, and the umbrellas were removed from the stands and hung directly from the ceiling. Here, a large reflector is not really needed, and ceiling GII emitters are often made in the form of flat panels; in multi-storey buildings on floors below the topmost, the overall efficiency does not noticeably deteriorate from this.

Gas oven thermostat

In order for the oven to work correctly and food to cook within the specified temperature range, a thermostat or thermostat is installed inside the cabinet. They can be mechanical, electromechanical, or electronic; to control a given mode, a rotary knob, button, or other, more complex and highly accurate devices are used. What is a thermostat in a household gas stove and how does it regulate the operating mode of the oven?

Gas stove thermostat diagram:

Diagram of a dilatometric oven thermostat: 1 - tubular rod, 2 - movable wedge, 3 - ball, 4 - pusher, 5 - spring-loaded valve, 6 - spring.

How does a gas oven thermostat work?

The operating principle of such a thermostat is very simple. The dilatometer, which records the temperature increase in the oven, heats up, causing the linear rod to expand. It activates a mechanism that ultimately acts on the spring-loaded valve. The stronger the heating inside the oven, the further the spring-loaded valve will move and close the gas supply hole. Accordingly, as the temperature decreases, the linear rod decreases and the system works in the reverse order, opening a larger hole for gas access and increasing the temperature inside the oven.

Gas oven thermostat

The maximum temperature inside the oven is limited by a switch knob installed on the front panel of the gas stove.

How to check if the thermostat is working

Having figured out what a thermostat or temperature controller is in a gas stove, you need to make sure that this device is working properly.

Significant errors in the instrument readings can ruin any culinary masterpiece. In one case, the food will simply burn, in the other, it will remain raw. To check the thermostat, it is best to invite a specialist who, using precision instruments, will identify any deviations in temperature readings, up to 1 °C. If this is not possible, and a difference of 3-5 °C is not of great importance, you can check it yourself:

- Turn on the oven at 150°C,

- Place a mechanical thermometer inside the oven, designed to measure temperatures in the appropriate temperature range,

- Leave the oven on for 20-25 minutes until the temperature reaches the desired level,

- After 20 minutes, check the temperature readings on the thermometer and thermostat. If the difference in indicators exceeds 5-10 °C, the temperature controller needs to be repaired.

Important: to repair a gas stove, you must invite a specialist, since the problem may not only be a damaged thermostat, but also noticeable heat loss due to a loose door.

Gas in cooking

Gas baking oven

The next area where gasification of ovens is not only useful, but simply necessary is culinary and technological equipment. A gas baking oven, for example, takes up only about 10 square meters. m of ordinary, non-production space and without requiring an industrial supply of gas and electricity, allows you to bake up to 100-200 loaves of bread at a time, see fig. Individual bakers take full advantage of this circumstance and those who know how to bake bread really well run a good business at home with always guaranteed demand.

The second culinary device where gas is more than welcome is the pizza oven. Already a household tabletop (left position in the figure on the right) produces a product that even an unpretentious eater immediately distinguishes for the better from one baked with an electric grill. In this case, the role played by the greater heat flux density generated by the gas compared to the electric one.

Gas pizza ovens

A completely unexpected result was achieved by gasification of the traditional Pompeian pizza oven, right pos. Inveterate gourmets cannot distinguish the taste of real noble pizza from a wood-burning or gasified Pompeian oven. But the productivity of the unit (and the income of restaurateurs) has increased by almost one and a half times. In this case, the high energy intensity and gas combustion rate ensure accelerated and more uniform heating of the furnace roof, which increases its productivity.

How to properly connect a muffle furnace to an energy source

If you have no experience working with electrical devices, it is better to contact a professional electrician. To connect the device to the network you must purchase:

- thermostat;

- large terminal block made of heat-resistant plastic;

- small terminal blocks made of heat-resistant plastic for splicing wires;

- contactor (electromagnetic starter);

- two-core electrical wire;

- electrical plug;

- standard casing for electrical panel.

For this oven, a single-channel thermostat M-1-K was selected, which regulates the temperature of the working chamber up to 1300 degrees. The device is capable of working according to a complex schedule; it is used to set the heating time and temperature.

Reference. The cross-section of the nichrome wire and its length, the diameter of the spiral turn, the cross-section of the connecting wires and other parameters of the electrical circuit are calculated from reference books and selected in advance.

The element has 7 connectors for connection (two terminals for power wires, two for connecting a thermocouple, three for a relay). The device is controlled by four buttons. When the thermostat is turned on, the indicator light is on. The device comes with two brackets for mounting in a panel and detailed connection instructions.

Block installation

The block is installed in the following order.

- The contacts of the thermocouple and the spiral are insulated and connected with terminal blocks to two-core wires.

- A plug is connected to the power cord.

- The thermostat, contactor and large terminal block are mounted in the panel.

- A thermocouple, a muffle spiral, and a power wire with a plug are connected to the thermostat via a contactor and terminal block.

An electric muffle furnace must be grounded.

Gas in the workshop

Gas heating stove from a tin can

The high achievable temperature and the absence of chemically aggressive substances in combustion products make the gas flame very attractive for home craftsmen. You don’t need much here: a heating furnace for heating small metal parts is made from... an empty tin can, see fig. Just remember to leave a gap at the bottom for air access!

Small-sized muffle and melting furnaces on gas, incl. desktop ones are also available for sale. But a home-made worker or self-employed individual entrepreneur will have to be disappointed here: the fire department and gas service do not issue permits to individuals to operate them. And for legal entities - only those provided with appropriately equipped production space. So in unsuitable rooms you will have to make do with electric stoves.

Fire safety requirements

When installing any sauna stove, it is necessary to strictly comply with fire safety requirements, since the walls of the device heat up to fairly high temperatures during its operation. In order to ensure maximum safety and not have problems with regulatory organizations, it is recommended to install the stove in accordance with the provisions prescribed in SNiP 41-01-2003 (Chapter 6.6).

- The first thing that needs to be done is to equip a reliable foundation for the main structure of the stove, which will be adjacent to the wall dividing the room. The foundation should be covered with heat-resistant material and then with metal sheet. Asbestos sheets were previously used as heat-resistant insulation. Today on sale you can find panels of pressed mineral wool, which is less dangerous from an environmental point of view, sheets of foam glass or EZHKAKH (heat-resistant structural mica plastic).

- It is also necessary to provide a metal flooring in front of the combustion door, which will prevent the wooden floor from catching fire and simplify debris removal. The size of the pre-furnace sheet must be at least 400×800 mm.

- If the partition between the steam room and the dressing room is wooden, then the opening through which the fuel channel will pass must be separated from the wood by brick or stone masonry. The distance between the stove and wooden walls should be 400÷450 mm.

In the version shown, the owner chose to fill the opening with bricks

- Provided that an opening is installed along the end part of the wall through which the combustion channel will pass, a gasket made of heat-insulating material (mineral basalt wool or cement-fiber sheet) with a thickness of 40÷50 mm, the distance between the part of the wall built from combustible material and the outer wall oven can be reduced to 250 mm. If thicker thermal insulation material is installed, the safe distance can be 125 mm.

- The distance between the ceiling of the bathhouse and the surface of the stove should not be less than 1200 mm.

- The distance from the edge of the combustion door to the nearest door must be at least 1250 mm.

- If you purchased a non-factory-made stove, or the device is independently made from sheet metal, then it is best to cover it with brick. Thus, it is possible to protect the structure of the bathhouse from fire, and people taking water procedures from burns. Factory products, as a rule, are made with double walls, between which thermal insulation material is laid or convection channels pass through.

About gas fireplaces

Gas stove-fireplace

The remarkable properties of natural gas gave rise to attempts to make a gas fireplace stove. However, they cannot be considered successful: the blue light is beautiful in its own way, but it is still not a living flame. Manufacturers, being clever with burners, sometimes create something similar to it, supposedly in a modern style, see the figure on the right. However, the psychological and aesthetic significance of the fireplace traces its ancestry to a well-fed primitive tribe in a cave around a fire after a successful hunt, and without chaotically dancing tongues of fire, a fireplace is not a fireplace. It's like putting a mast with mainsail and jib on a Predator with a 400-horsepower Merccruiser. It will float, since it floats on the water, but there will be no romance of sailing.

Operating rules

A gas stove is the main assistant in the kitchen of any housewife. But when using it, you must strictly adhere to certain operating rules:

- If there is no electric ignition, the match is brought close to the burner and only after that the gas supply valve is opened. It is necessary to ensure that the fire burns in all burner holes,

- The combustion should be smooth, without jerking, the flame should be blue or purple. If small flashes and extinguishing occur, it is necessary to check the burner - water or food residues may have gotten on it. If the flame is yellowish, with signs of soot, you should reduce the gas supply by turning on the burner,

- The size of the cookware must correspond to the selected burner, the flames should not escape from under the pan,

- Do not turn on the stove with the burners removed. In this case, gas combustion does not occur completely, which can lead to poisoning.

Important: before using the oven, you need to ventilate it by sharply opening and closing the door several times. This procedure will allow you to get rid of the gas accumulated inside if for some reason the tap is open or a leak occurs.

Under no circumstances should you use a gas stove to heat a room, as this can lead to carbon monoxide poisoning. It is very important to properly clean your household appliance. It doesn’t matter what your household gas stove is made of, whether it has built-in automation and additional protection against electric shock, before cleaning and other maintenance operations it is necessary to disconnect the equipment from the network.

Watch a video about installing and connecting a gas stove

Disadvantages of combined models

- Modern manufacturers produce only floor-mounted universal gas-wood boilers. They weigh quite a lot, so transporting and installing them yourself is quite difficult. Under them it is necessary to build a solid foundation, and this is an additional expense.

- For installation of combined installations, you will have to allocate a separate room. And this is not always possible in conditions of cramped, compact housing.

- The more powerful the hardware, the fewer functions it can provide. For example, a high-efficiency boiler does not have a frost protection system. A second circuit for supplying hot water is not installed everywhere.

- “Sophisticated” models are quite expensive. They are difficult not only to buy, but also to maintain later, using service advantages.

- You can obtain the required performance in one single case - by correctly calculating the power of the unit. Experts recommend using the following formula for this: 1 kW of power is spent on heating every 10 square meters. For double-circuit boilers this figure increases by 30%.

Wiring requirements for an electric furnace in a bathhouse

Consider the following points:

- For a single-phase network, use a three-core cable, for a three-phase network, use a five-core cable.

- A prerequisite for wires is the presence of a grounding wire.

- Attach the wires to the wall using conventional cable ducts.

- The cable between the control panel and the oven must be in special rubber insulation. Sometimes this cable is supplied with the oven.

- Reinforced insulation wires are expensive, so it is recommended to reduce their length. To do this, install a metal mounting box near the stove (no closer than 1 m), on the wall. Between the box and the remote control, covertly lay ordinary wires in vinyl insulation, and from the box to the oven - wires with reinforced insulation. Pull the heat-resistant wires through a metal hose or pipe, which you ground.

- Under high temperature conditions, strands of copper and aluminum wires oxidize, so all wires in the building must be copper.

What materials and tools are needed

To make a garage or sauna stove from a gas cylinder, choose a steel, seamless propane (household) cylinder with the following dimensions:

- Case length: 1660-1755 mm. Diameter: 219 mm.

- Wall thickness: 5.2-8.9 mm.

The gas must be removed from the container Source f12.pmo.ee

Dimensions may vary, but maximum deviations (especially in thickness) must comply with GOST 949-73 standards. The tools you need to prepare are:

- Welding machine (200 A). Protective equipment (welding mask with light filter, gloves). Electrodes for welding structural steels (diameter 3-4 mm).

- Grinding machine (grinder). It requires cutting and cleaning discs for metal (diameter from 180 mm).

- Workbench with a vice.

- Drill and set of drills.

- To clean up welding slag: metal brush (with metal bristles), sandpaper.

- Tools: pliers, chisel, hammer.

- For marking: tape measure or folding meter, chalk (marker).

The range of materials depends on the size, shape and purpose of the structure. The middle list includes the following items:

- Pipe for chimney. Approximate dimensions: cross-section 120-150 mm, length 400 mm.

- Sheet of steel (thickness minimum 3 mm). The oven door is made of steel.

Stove with a horizontal heating device Source usamodelkina.ru

- Steel reinforcement or rod. Suitable for making a grate, you can make a handle for a door or a heater (if the stove is intended for a bathhouse).

- Metal corner or profile pipe. The materials will be useful for making legs.

If you plan to use a gas cylinder sauna stove, you will need a brick - this is used to build the foundation for the sauna structure. Diabase is ideal for filling the heater. Granite is not recommended; under the influence of high temperature it will quickly collapse.

If you do not have the opportunity to make a grate or other parts, you can purchase them ready-made. At this stage, you need to decide on the type of potbelly stove in shape. Taking into account the orientation of the housing (whether it will be located vertically or horizontally), all working operations are carried out.

Design features and operating principle

Structurally, gas heating equipment for a bath consists of a housing with a built-in burner-nozzle. The device is equipped with shut-off and relief valves, a fuse, filters, and a compartment for mixing gas with air. Here are the control mechanisms that regulate the fuel supply mode. Using a burner, the air in the combustion chamber is heated, then the thermal energy is transferred to the generator housing with a tray for stones. The functionality of the equipment, the efficiency of the device and safety depend on the characteristics of the gas injector.