September 14, 2021 Stroyexpert Home page » Foundation » By construction project

The foundation of all structures must be reliable and warm. The foundation of the bathhouse is no exception. However, many bathhouse owners have the opinion that insulating the base of the bathhouse is an unnecessary waste that can be easily avoided. The main argument for this erroneous opinion is that baths are heated quite rarely (say once a week) and you can sacrifice firewood and time to heat them to the required temperature. But in fact, the essence of insulating the foundation of a bathhouse is to maintain its integrity for a long time. Insulating the foundation of a bathhouse with your own hands is quite simple, so every owner should think about this procedure.

How to insulate a columnar foundation of a house

The foundation pillars are sheathed around the perimeter with wooden blocks, boards or a profile to the full height (see photo above). A load-bearing base is necessary when insulating a columnar foundation with mineral wool and expanded polystyrene. We recommend using polystyrene foam, since the structure borders the ground and will be constantly exposed to moisture from the ground and precipitation.

When self-insulating a columnar foundation with polystyrene foam, insulation sheets are attached to a base made of bars or a profile on the base of the house. URSA XPS, like extrusion from other manufacturers, is frost-resistant, has high mechanical strength and moisture resistance. Seams and gaps between sheets of extruded polystyrene foam are carefully sealed with polyurethane foam.

On the outside, sheets of expanded polystyrene are protected from solar ultraviolet radiation and precipitation by base siding or PVC panels. To prevent moisture from the ground from rising into the house, the underground of the house is covered with a layer of rolled waterproofing and the foundation is backfilled.

Key requirements for insulation

The choice of insulation for the foundation must be approached responsibly. Mineral wool left over from interior decoration cannot be used for this purpose. Water will accumulate in it, which will lead to rapid destruction of the entire structure.

The material must meet the following requirements:

- low thermal conductivity;

- resistance to sudden temperature changes;

- sufficient mechanical strength;

- resistance to aggressive environmental influences;

- waterproof.

Vapor permeability does not play a big role. But it is better to give preference to materials with low throughput

Do not pay attention to the flammability of the insulation, as it will be covered with soil

Features of extruded polystyrene foam

Thanks to the properties of the raw materials and the closed-cell structure, which prevents water from penetrating inside, slabs made from extruded polystyrene foam have excellent technical characteristics and a long service life of at least 40 years. This makes it an excellent material for organizing thermal insulation of the foundation of a bathhouse.

In addition, it has been found that rodents like extruded polystyrene foam less than regular granulated polystyrene foam. They spoil it much less often, even if it is a barrier to water and food.

For use in the foundations of civil and industrial buildings, thermal insulation boards with high compressive strength are used as vertical thermal insulation. In private construction, it may be somewhat less, because the depth of the foundations here is less, and accordingly, the pressure of groundwater and soil on the thermal insulation material is significantly lower.

In personal construction, it is recommended to use slabs with a strength of at least 200 kPa, while in structures that require increased strength properties, for example, when installing loaded floors, slabs with a compressive strength of at least 500 kPa should be used.

Calculation of thermal insulation thickness

The required thickness of thermal insulation of a structure installed below ground level can be calculated using a special formula. For areas elevated above ground level, there is another formula. But for those who do not want to bother with complex mathematical calculations, tables have been created that indicate the thickness of thermal insulation made from extruded polystyrene foam, recommended for individual regions.

The range of these materials includes specially created thermal insulation boards equipped with a surface with milled grooves. This device allows it, together with geotextile fabric, to work perfectly as wall drainage. So it successfully performs three functions simultaneously: it insulates the foundation, protects waterproofing from mechanical damage, and removes water from the foundation in the drainage system.

Practical recommendations

You can determine what brand of concrete is needed for the foundation of a bathhouse without weighing and complex calculations. The method is based on meeting the conditions under which the most durable material is obtained. The cementitious emulsion should fill all the free space between the solid fractions of the mixture.

To do this, take a measuring container and a 10 liter bucket. The sand and gravel mixture is poured into a bucket and filled with water, measuring the volume using a measuring cup. When the water rises to the surface of the mixture, record the measured volume of water. This will be the volume of cement that needs to be added to the solution.

If you managed to pour 2 liters of water into the bucket with the filler, then to obtain concrete, mix a bucket of sand-gravel mixture and 2-liter measures of cement. The cement-mixture proportion will be 1/5. Water is added to the dry mixture in portions until a plastic mass is formed.

Why is such a procedure carried out?

Before you engage in sheathing, insulation of walls and foundations in a bathhouse, you need to understand why this is necessary. Thermal insulation allows:

- Keep the room warm.

- Prevent destruction of the building foundation due to exposure to moisture. Liquid penetrating into the micropores of the foundation under the influence of temperature changes expands small holes, forming cracks.

- Increase the rigidity of the base.

- Warm up the floors of the building.

- Reduce heating costs.

- Normalize the room temperature.

Insulation is not necessary when the bathhouse is built without a foundation (mobile or lightweight construction).

In addition to its practical purpose, thermal insulation of the base is necessary to give the building a finished look.

It is important to take care not only of insulating the base. The base also needs treatment

Materials

For thermal insulation of a bathhouse, the following are used:

- Organic insulation based on polystyrene foam;

- Mineral fiber mats and wool;

- Bulk insulation such as expanded clay, brick chips, sawdust, etc.

Mineral wool and thermal insulation materials based on it are more susceptible to moisture, and when exposed to high temperatures they can become a source of unpleasant odors, especially over time. Bulk insulation rather complements the main thermal insulation. Therefore, expanded polystyrene is considered the best material for insulation today.

How to insulate the foundation of a bathhouse - methods and methods

The method of insulation depends on the design of the foundation and the type of soil on the site. Let's consider the insulation of the most common types of foundations: strip, monolithic, columnar.

Thermal insulation of strip base

Insulating a strip foundation immediately solves two problems:

- the impact of soil heaving is reduced;

- heat loss through the base walls is reduced.

The work is carried out as follows:

- The foundation is cleared of soil along the entire perimeter. We dig a trench with a depth of at least the soil freezing level and a width of 50 cm. The soil freezing level can be found out at the local geocenter; for central Russia the figure is 1.5 m.

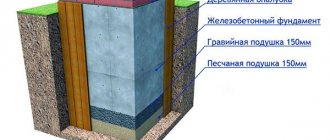

- A sand cushion of 15–20 cm is poured in. It is necessary to moisten and compact the sand as thoroughly as possible. It is better to use coarse sand, it goes less into the soil.

- The foundation is coated with bitumen mastic in 2 layers. The waterproofing is allowed to dry.

- Insulation is being installed. Its thickness is calculated separately for each region; for central Russia, mineral wool is taken 20 cm, polystyrene 15–20 cm. The seams are foamed with polyurethane foam. It’s easier to take foam plastic with L-shaped locking joints, so the seams will be more airtight. The foam is glued to a special adhesive composition and fungal fasteners.

- At the corners, the insulation is laid in a layer 1.5 times thicker, since heat loss is the highest there.

- Expanded polystyrene can simply be covered with sand on the side and compacted. Polystyrene foam and mineral wool must be additionally protected with a 25 cm brick wall. It is simply laid out along the entire perimeter of the base.

- A blind area from the base is made on top at an angle of 15 0 from concrete. The top of the blind area can be decorated with ceramic tiles.

The insulation of the strip foundation is ready. It will retain heat well and is not affected by soil heaving and moisture. Heat loss in the bathhouse will be reduced by 45%.

Scheme of insulation of a strip foundation.If it is impossible to insulate the foundation from the outside, you can do the work from the inside in a similar way.

Insulation of a monolithic base under a bathhouse

For subsidence and silted soils, a monolithic base for a bathhouse is selected. It is better to lay a monolithic foundation on a layer of hydro- and thermal insulator. But if the work is not completed, you can insulate the finished structure.

Insulation scheme for a monolithic foundation.

Protection of slab-type insulation from liquid concrete is carried out depending on the type of base reinforcement. when the reinforcement is made using wire and metal rods, a PVC film with a thickness of at least 200 microns is laid on top of the thermal insulation. All joints are glued using double-sided tape.

If the reinforcement is performed using a welding machine, then a screed no more than 15 cm thick is made of weak concrete mortar or cement on top of the insulation.

Along the walls, the finished structure is insulated similarly to tape.

Thermal insulation of a columnar base for a bathhouse

The most difficult thing to insulate is a columnar foundation. The free space under the bathhouse is ventilated and the floors quickly freeze. Ask how to insulate the foundation of a column-type bathhouse? The following steps:

- A trench 1.5 m deep and at least 50 cm wide is dug along the walls of the bathhouse.

- A sand cushion is poured into the bottom, watered and tamped down.

- A wall of red brick and half a stone is laid on top. The wall should barely reach the bottom of the bathhouse. This gap is foamed with polyurethane foam.

- The wall is coated with bitumen mastic.

- Further, the work is carried out similarly to the insulation of the strip base. During work, the posts must also be covered from the outside with insulation.

You can do the work yourself, but you need to be patient. More details in the video:

https://youtube.com/watch?v=7mNC4LIX75I

The work is labor-intensive and requires free time of at least a week. You will have to work hard, but it will be easier and faster to heat the bathhouse. And the steam room will last longer, which will please your family. And may the steam be light and the procedure useful.

Reinforcement

The armored belt is made of thick reinforcement (>12 mm longitudinal and 6-8 mm transverse, vertical reinforcement). To work, you will need a grinder, wire for tying the armored belt, a welding machine, and a tape measure.

Reinforcement

The belt consists of longitudinal (four or more), transverse and vertical reinforcements. In this case, the entire structure must be 5 cm away from the formwork, soil and the top point of the foundation, and be reinforced in the corners of the building. The cross section of the armored belt is a rectangle or square.

The reinforcement is cut to the required length. Longitudinal and transverse rods are laid out on the ground and tied with wire at the points of contact. Welding the frame is not recommended, since the welded frame may lose its integrity when compacting the poured concrete or operating the constructed bathhouse.

The longitudinal rods are laid out and tied to each other with an overlap of about 30 cm.

Knitting longitudinal rods

The distance between the transverse and vertical rods should not exceed 50 cm. If the strip foundation is up to 120 cm wide, then it makes sense to make the frame not from two, but from three longitudinal reinforcement bars. If the foundation height is high, it is also worth increasing the number of longitudinal rods. The frame is also reinforced on top with U-shaped clamps, designed to increase the strength of the structure and reduce the risk of cracking of the strip base.

Clamps

At the corners of the bathhouse, the frame is additionally strengthened with reinforcement located at an angle of 45 degrees relative to the horizontal rods.

Corner reinforcement

Corner reinforcement

The finished connected frame is installed on plastic supports. To prevent movement during the pouring of concrete, plastic fasteners are inserted between the formwork and the reinforcement.

Strip foundation reinforcement

Reinforcement and laying of communications

Why insulate the base of the bathhouse?

An uninsulated foundation has direct contact with the soil. The operation of the bathhouse leads to the formation of wet condensation on the lower surface of the floor adjacent to the foundation. Moreover, the outer side of the floor is a cold surface in contact with the air surrounding the bathhouse. You can easily understand that moisture will constantly accumulate on the underside of the floor and gradually undermine the base of the bathhouse, forming dampness, rot and mold.

When cold weather sets in, another problem arises. The moistened lower surface of the bathhouse and the foundation itself are a source of dampness in the soil. During the freezing process, moist soil layers form so-called “buoyant forces” - it is known that liquid expands when it freezes. And this, in turn, causes deformation of the base of the building, its distortion. It is not difficult to guess that such a foundation very quickly collapses under the simultaneous influence of “swelling” of the soil and dampness, mold and fungi from the inside.

When the owners insulate the foundation only from the inside, the outer surface of the building is practically given over to the freezing air. The uninsulated side is even more exposed to the influence of the swollen soil, freezes even more, which means it collapses faster

Therefore, it is very important to insulate the foundation, first of all, from the outside, and only then from the inside.

Insulation of foundations with foam plastic

For a bathhouse, such an option to insulate a structure involves several important features. First of all, a minimum amount of tools and materials is required. In addition to the foam itself, cement, bitumen mastic and elements for fixing the insulation are used.

- The surface on which work is carried out outside the bathhouse must be carefully leveled.

- After this, it is treated with bitumen mastic, up to a height of 20 cm above ground level. This affects not only the foundation, but also the lower part of the walls.

- When the mastic has dried and become hard, they proceed to the stage of installing the insulation from the inside. There are two ways to attach the material: using fungi or using a special adhesive.

- When the insulation is in place, you can cover it with paint mesh.

- The outside of the foundation requires mastic treatment and installation of a heat insulator.

In general, the work process is similar to the previously described activities. It is recommended to insulate the structure only after the foundation has been completely built and the flooring has been installed. to the begining

Best answers

Cat's smile:

There are two options: 1) Drain water from all pipes between the fireboxes. ,

2) Heat with electricity.

It is better to arrange a drain, but if this is a problem, arrange an insulated box for the inlet faucet and part of the inlet pipe up to the faucet, and place a low-power light bulb in the box; its heat will be enough to prevent the faucet from freezing. , Drain the rest of the water inside the bath itself.

VD-23:

asbestos cord or cardboard

Massi:

try filling it with foam

Alexander:

there are many materials. old glass wool, new fiber materials.

Yuri Morozenkov:

there is a wire. or, more correctly, a thermal cord. it raises the water temperature by several degrees. Type it into a search engine. I saw him with my own eyes. but dear bastard

Vasily Zadov:

You can insulate it with anything, BUT, if there is no heat supply, and this is either a constant flow of water (water from the ground +4 somewhere), or additional heating, you can try a heating cable if you don’t mind electricity. But if there is no additional heat supply, then even a meter of insulation will still freeze within a week. If there was a diagram, I would advise in more detail.

Insulation from outside

Insulation from the outside not only helps maintain the desired temperature, but also protects the structure from precipitation and cold air.

Wood holds heat very well on its own. But all the cracks between the logs must be carefully sealed with special rope insulation. Wood dries out over time, new cracks form, which also need to be insulated.

Wooden and other structures can also be additionally sheathed. To do this, you need to make a sheathing from wooden slats, lay and secure insulation between them, and then attach the trim from lining, block house, imitation timber, and so on.

You will read more about insulating a bathhouse from the outside in our next article.

The main reasons for the need to insulate bathhouse foundations

The foundation of the bathhouse must be insulated for the following reasons:

- To prevent the formation of condensation on its internal walls. In the warm season, heated air freely penetrates from the street under the uninsulated foundation. The inner walls of the foundation are quite cold due to contact with wet soil. When a cold wall meets warm air, water condensation begins to form on it. The result is that the internal surfaces of the foundation will be constantly wet all summer. Gradually, mold and mucus form on them, which subsequently leads to the destruction of the structure. Within two to three years, there may be a need for major foundation repairs.

- To maintain a comfortable thermal regime in the bathhouse. According to studies conducted, up to a quarter of all heat losses can occur through an uninsulated foundation.

- To eliminate the consequences of frost heaving. In winter, freezing of wet soil layers inside the space under the bathhouse and outside the uninsulated foundation leads to swelling of the soil. The result is the occurrence of cracks and deformations in the body of the foundation and the walls of the bathhouse.

- Protection of waterproofing from various types of possible mechanical damage.

The result is greater durability of the foundation waterproofing.

The bathhouse foundation is insulated from the outside and inside

Important: it is strictly not recommended to carry out insulation work on the inside if insulation has not been done on the outside. Because in this case, increased freezing of the outer walls of the foundation occurs in winter while enclosing the heat generated inside the foundation

Soil heaving begins to occur more intensely, which leads to rapid destruction of the bathhouse foundation structure. Internal insulation is carried out only in the most extreme cases, when it is not possible or very difficult to perform external insulation. Of course, when insulating from the inside, there will undoubtedly be a positive effect, but still, freezing of the foundation surface occurs from the outside. If there is a financial opportunity, then it is most rational to insulate the foundation of the bathhouse both outside and inside.

Types of wallpaper

- Paper ones are the most democratic. They are cheap, can be found in any repair store, they come in embossed and smooth. However, they have one significant drawback - they are not durable at all and cannot be repainted often (no more than 5 times during their service life). To increase strength, some craftsmen coat them with a special varnish composition. This adds durability and gloss. However, it exposes all the irregularities of the wall. In addition, to repaint, the varnish will have to be removed, which can lead to very disastrous consequences.

- Vinyl is more durable. Consist of vinyl and foamed PVC. They can withstand up to ten repaints without losing integrity, but are afraid of mechanical damage. On sale you can find this type of wallpaper with an interesting texture - a pattern or imitation. They are well suited for the kitchen or hallway.

- Non-woven ones - created on the basis of a more technologically advanced material than those mentioned above. The composition includes three or even four different layers, which make the material very durable and unpretentious. They are elastic, withstand wet cleaning, as well as repainting up to 15 times. You can also come across negative statements, which mainly boil down to the non-environmental friendliness of this type of coating. The fact is that when heated strongly, non-woven fabric releases a certain amount of formaldehyde vapor. However, if you stick them on the walls of the hallway or hall and do not plan to set them on fire, you have nothing to fear.

- Fiberglass wallpaper is the most expensive and most technologically advanced type of wall covering in our review. It is obtained by processing glass with special additives. The high cost is more than covered by its excellent appearance, environmental friendliness and durability. In addition, they do not burn and do not emit any odors or harmful substances. If you intend to surprise your guests and plan to change the color of the walls often, this is the best option for you.

Liquid wallpaper. To complete the picture of the possibilities of decorating walls in residential premises, this type cannot be ignored. Essentially, it is a dry mixture of various materials, which just needs to be diluted with warm water, spread on the wall and wait until it dries. In terms of painting, they can be compared with paper ones, i.e. They practically cannot be painted and are very afraid of being treated rudely.

Why is such a procedure carried out?

Before you engage in sheathing, insulation of walls and foundations in a bathhouse, you need to understand why this is necessary. Thermal insulation allows:

- Keep the room warm.

- Prevent destruction of the building foundation due to exposure to moisture. Liquid penetrating into the micropores of the foundation under the influence of temperature changes expands small holes, forming cracks.

- Increase the rigidity of the base.

- Warm up the floors of the building.

- Reduce heating costs.

- Normalize the room temperature.

Insulation is not necessary when the bathhouse is built without a foundation (mobile or lightweight construction).

In addition to its practical purpose, thermal insulation of the base is necessary to give the building a finished look.

It is important to take care not only of insulating the base. The base also needs treatment

Insulation methods

The specifics of insulation depend on the type of foundation and the complexity of the soil.

Tape base

Thermal insulation of a monolithic tape allows you to reduce soil pressure and minimize heat loss through the foundation walls.

Insulation of an already created foundation occurs in several stages:

- Release the tape from the soil along the entire perimeter to the freezing point of the ground. Trench width – 50 cm;

- Create a cushion of sand 15-20 cm high. Thoroughly moisten and compact;

- Treat the foundation with 2 layers of bitumen mastic. Let dry;

- Install insulation boards. The width of the layer depends on the seasonal characteristics of the region - in the middle zone it should be about 20 cm. Properly foam or glue the seams;

- Since the corners of the bathhouse are characterized by the highest heat loss, the thickness of the insulation here is taken 1.5 times higher;

- Cover expanded polystyrene with sand, reinforce mineral wool and polystyrene foam with a brick wall;

- Create a concrete blind area from the base at an angle of 15 degrees. If desired, cover it with ceramic tiles.

Insulation performed in this way will reduce heat loss through the foundation by up to 45%. If for some reason external thermal insulation is not possible, then the work is carried out from the inside according to the same scheme.

Slab foundation

Arranging a slab base for a bathhouse is justified on silty and subsiding soils. It is better to carry out hydro- and thermal insulation in parallel with its creation. If protective layers were not laid under the foundation, then the insulation runs on top of the slab.

The foundation is covered with PVC film of sufficient thickness and the joints are taped with 2-sided tape.

Columnar foundation

The columnar base is considered the most difficult in terms of insulation. Thermal insulation is carried out in several stages:

- Dig a trench along the walls of the bathhouse 50 cm wide, 1.5 m deep;

- Fill the bottom with sand;

- Lay out a brick wall that does not reach the bottom of the building. Fill the resulting gap with polyurethane foam;

- Coat the wall with bitumen;

- Carry out insulation in the same way as a strip foundation, not forgetting about the thermal insulation of the columns.

DIY thermal insulation

An individual application technology has been developed for each insulation. Before you get started, you need to study the step-by-step instructions.

Expanded clay and sand are similar in their characteristics and laying technology:

- Trenches are dug from the outside of the base. They are needed for soil drainage.

- The bottom is covered with geotextile, crushed stone is poured on top. Then perforated pipes are laid around the perimeter, connected and led into the prepared well. A layer of crushed stone is applied on top.

- The foundation is cleaned and dried.

- The trench is filled with sand or expanded clay. When placing, each layer is compacted.

Thermal insulation technology with mineral wool:

- Defects are removed from the surface of the base, cleaned, and dried.

- A frame is built from a metal profile.

- Mineral slabs are mounted on the structure.

- The open surface of the mineral wool is covered with a special film that protects the mats from wind, water, and steam.

- The mineral wool structure is covered with a brick wall (or ventilated slabs).

The technological process of applying bitumen mastic is simple - the surface of the foundation blocks is coated several times with a bitumen mixture, covered with a roll of waterproof material that will act as a heat insulator.

Foam application technology:

- Digging under the base, cleaning, drying, removing residual particles of oil, bitumen, fats.

- Applying a waterproofing layer.

- Foam boards are mounted using construction adhesive (dry mixture).

- Using the same glue, a fine metal mesh is applied to the surface of the foam plastic, designed to protect against pests. For reliability, the mesh is secured with plastic dowels.

- The foundation dug around the perimeter is covered with sand.

The technology of using sheet polyurethane foam insulation is similar to foam insulation. There is another way to protect the foundation from temperature changes - layer-by-layer application of polyurethane foam. In this case, a liquid polyurethane foam composition is used. The composition is applied in layers with a total thickness of 5 cm. Such a gasket is equivalent to a layer of extruded polystyrene foam 12 mm thick. Spraying polyurethane foam requires special equipment.

Working with tape base

Such a frame needs to be insulated from the outside, since it is important to preserve more free space for the underground room. Baths are sometimes equipped with basements, which serve as utility rooms. In this case, double-sided sealing will not hurt. To eliminate the unwanted greenhouse effect, the room is provided with vents.

The tape base allows the use of horizontal and vertical types of thermal insulation.

The insulation procedure requires a long time, since it involves following the instructions step by step:

- Undermining – 10 days of settling (moisture evaporation period).

- Cleansing, drying.

- Waterproofing - 5–7 days (drying).

- Treatment with mastic.

- Installation of EPS (extruded polystyrene foam) or polystyrene foam.

- Additional fastening of the above-ground part of the insulation.

- Reinforcement, treatment with plaster - 1–2 days (drying).

- Final leveling, sanding.

- Backfilling with sand, expanded clay, earth and compaction.

- Casting a concrete blind area - 1–2 days (drying).

How to make a foundation for a bathhouse?

The answer to this question depends on what type of foundation is chosen for construction, taking into account the geology and hydrology of the site, as well as the future load on the foundation. We will briefly look at the schemes for working on each type, and you will find detailed plans (what is done and how) in separate articles to which we will refer

In particular, we recommend reading:

However, there are general points in the work plan - they are the same and I don’t want to repeat them. Before you start marking the future bathhouse, you need to:

- remove trees, bushes and large stones from the territory;

- cut off the fertile layer of soil and transfer it;

- level out uneven areas in the building area - manually or using a bulldozer.

IMPORTANT! If there are large differences in relief, you can not level the area, but put the bathhouse on piles. Markup is another general point, but it's covered entirely in the chapter below.

And now we will consider the different stages of laying for each type separately

Markup is another general point, but the chapter below is devoted entirely to it. Now we will consider the different stages of establishment for each type separately.

Tape

Let's look at how to make a strip foundation for a bathhouse. There is no need to dig a pit under it; a trench is enough, the depth of which comes in two options:

- 20 cm below the level of fertile soil;

- 20 cm below the soil freezing level.

To strengthen the soil, they usually make a sand and gravel cushion with a height (most often) of 20 cm - this is the amount to deepen the trench by.

Having fallen asleep, spilled water and compacted the pillow, they proceed to installing the formwork. It is knocked together either from boards or plywood. Both materials need to be strengthened on the sides and top so that the concrete does not push through it. Some people cover the formwork with polyethylene, covering both the bottom and sides.

The reinforcement is tied into a 4-sided frame, the basis of which is 12 mm rods connected with 6 mm wire.

This is how the reinforcement for the foundation of a bathhouse fits together

IMPORTANT! The frame is not placed on the bottom, but on stands 7-10 cm high. Concrete is poured at one time

Why is this important >>>

Concrete is poured in one go

Why is this important >>>

Columnar

Now, how to make a columnar base for a bathhouse. Let's start with excavation work. For columnar, they involve digging or drilling holes in the ground in the form of truncated cones tapering downward. If the post is laid directly in the hole, then its diameter can be increased for convenience.

IMPORTANT! Do not forget to increase the depth of the hole by the height of the sand and gravel cushion. The pillow is always(!) spilled with water and/or compacted

The pillow is always(!) spilled with water and/or compacted.

Pillars are placed on the prepared base. Since they are different: brick, asbestos-cement, reinforced concrete, rubble and wood, we will not dwell on the technology of their construction, suggesting instead that you read an article where the laying of a columnar foundation is discussed from “a” to “z”.

Pile

How to properly make a pile foundation for a bathhouse. This type involves minimal disruption of the integrity of the soil. In a prepared and marked area, holes are either drilled in the ground for a bored type of pile foundation, or iron piles are immediately screwed in.

If we are talking about a drilled well, then the well is strengthened with sand and gravel, then a casing pipe is installed into which the reinforcement cage is laid. After this, all that remains is to pour concrete into each pipe and expel the air from it.

Slab

Now a little about how to build a slab foundation for a bathhouse.

- A sand and gravel cushion is poured into the finished pit in a layer of up to 30 cm.

- Formwork is placed on the compacted cushion, and space is allocated in advance for future communications.

- After this, it is necessary to isolate the future concrete slab from moisture from the soil. To do this, polyethylene is placed on the bottom and sides of the formwork. You can use another waterproofing material instead.

- The next stage is laying a mesh of rods from 8 to 12 mm thick (depending on the weight of the future building).

- Concrete is poured over the frame. After filling, you still need to remove air bubbles from it.

Formwork reinforcement

After hardening, concrete becomes completely inelastic; in order for it to withstand the effects of various natural factors well, it is necessary to give it additional rigidity and strength using reinforcement - steel rods connected according to certain rules.

Approximate layout of fittings

It is more convenient to install the reinforcement after the formwork has been assembled. To do this, pieces of reinforcement are driven into the bottom of the trench in two rows. They should be 5 cm apart from the formwork panels, and their height, after they are driven in, should be 5 cm less than the height of the foundation. Then horizontal reinforcement bars are placed on the bottom. They are tied with wire to vertical supports at a height of 7-10 cm from the bottom of the trench (to make it more convenient, you can place bricks under the reinforcement - this will be the desired height). The upper reinforcement belt should be buried 6-8 cm into the future foundation.

This is what foundation reinforcement looks like

After the reinforcement is completed, all that remains is to provide technological openings for the supply/discharge of water, light and ventilation. To do this, you need to cut a piece of plastic pipe and attach it to the reinforcement in the right place. To prevent the pipe from becoming clogged with concrete, it can be covered with sand.

After installing the reinforcement, it is necessary to provide technological holes

We equip the blind area with penoplex

- After insulating the foundation, we backfill it 15–20 cm below ground level. At a distance of one meter we assemble formwork with a height of 20-25 cm;

- Level and compact the soil. After this, Penoplex slabs are installed along the entire perimeter;

- A waterproofing film and reinforcing metal mesh are laid on top of the insulation with an overlap.

- After that, cement mortar is poured into the formwork. The surface is leveled so that there is a slight slope away from the house;

- After the time required for hardening has passed, the formwork is dismantled and the surface of the screed is covered with “street” material, such as tiles. Or you can treat it with a water repellent for concrete. This is a very effective means of “removing” moisture. Insulating the blind area together with the foundation reduces humidity in rooms located below ground level.

A few words about insulating the foundation in a bathhouse.

A very good thing. Its thermal insulation reduces heat loss, which means the bath warms up faster and cools down longer. The room will have a warmer floor. In addition, the level of humidity and the risk of condensation on the internal surfaces of the foundation are reduced. Well, biological destruction in the form of mold, rot, etc., slows down significantly. In the photo on the left, the photo was taken with a thermal imager. See the temperature difference.

That's probably all I wanted to tell you. As I promised last fall, I try to bring interesting material to the reader. Don't want to miss blog updates? Then subscribe to the news. Good luck to your family and a warm, cozy home! See you soon!

Wisdom Quote: The cruelest lies are often told in silence.

Features of insulating a frame bath from the outside

If you need to insulate the walls of a frame bath, it is best to use polystyrene foam for this. In this case, the lightness of this material plays a decisive role. Although there are other advantages, for example, hydro-repellent properties and low thermal conductivity.

You can insulate a frame bath from the outside using foam boards, even without having the skills to work with this material. The insulation simply needs to be glued to the wall or secured with self-tapping screws, and plaster or decorative facade cladding must be applied on top. The disadvantage of polystyrene foam is its fragility, which is why you need to be especially careful when working with this material.

How to insulate the base of a bathhouse with penoplex?

Thermal insulation of the base using penoplex, which is also called extruded polystyrene foam, will cost a little more. At the same time, this insulation is not afraid of contact with moisture and is much better preserved in the presence of mechanical loads. Thus, the use of penoplex allows you to achieve excellent results, but only if the work is done correctly. Another big advantage of using this method is that it does not require intensive waterproofing. It is enough to cover the base with the simplest waterproofing material from the outside.

Scheme of insulating the base with penoplex

- The foundation is covered with a waterproofing membrane;

- Penoplex up to 12 cm thick is applied to the surface of the base;

- The thermal insulation layer is covered with a membrane that acts as drainage;

- Geotextiles are laid, playing the role of a filter layer;

- Thermal insulation of the concrete blind area around the perimeter of the bathhouse is carried out.

Foundation slab

When insulating the foundation slab, thermal insulation boards are laid on top of the waterproofing.

When reinforcing a monolithic foundation slab in a bathhouse using knitted reinforcement, a polyethylene film having a thickness of 200 microns or more is used to protect the insulation from liquid concrete.

When performing reinforcement work using welding, a protective screed is made on top of a film of cement-sand mortar or low-grade cement. In this case, the film sheets are laid on double-sided tape with an overlap of 130-150 mm.

Only in this way can you save the foundation from freezing and premature destruction. Take care of it today, otherwise tomorrow may be too late!