Pouring concrete at an angle is a fairly common task, especially when it comes to individual construction and landscaping of the local area. Most often, platforms, driveways to garages, blind areas and floors in different rooms are poured on a slope.

The process differs significantly from conventional pouring of cement mortar and has a number of features. In this case, the concrete screed compensates for the difference between two mating surfaces, which are at different levels. And to ensure sufficient strength and reliability of the inclined mass, eliminating the risk of cracking and deformation, it is necessary to strictly adhere to the established rules.

Where inclined concreting is required

Concreting inclined surfaces is not done as rarely as it might seem. If a flat screed is usually installed in premises for different purposes and operating conditions, then filling an inclined plane most often becomes necessary on the street. However, the need to lay concrete on a slope may be relevant: when arranging interior work inside utility and residential premises, when carrying out outdoor events in natural conditions.

Where is an inclined screed needed:

- Floors in baths, saunas, shower rooms

- Paths, sidewalks, areas on the territory

- Creation of blind areas running along the perimeter of the building

- Arrangement of entrances to the territory of industrial structures and private facilities

- Drain trays for water drainage

- Arrivals for freight transport

- Access to underground garages and parking lots

- Wheelchair ramps

The main task performed by arranging an inclined screed is the formation of a reliable, durable monolithic coating with the required strength characteristics.

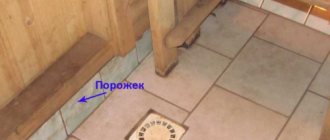

Non-leakage floors

Layout of a leak-proof floor with a slope

Laying wooden floors with a slope is required only if a leak-proof base is installed. How to lay floorboards at a certain angle to the drain?

- The rough coating is cleaned of dirt and a drainage system is installed;

- Then the concrete screed is supposed to be poured, which is done using the technology described below;

- After the screed hardens, the tongue and groove board is laid;

- The finished floorboards are positioned at a slight angle to the drainage system due to the previously formed screed slope.

Unlike pure concrete, wooden floors can be installed in a sink, steam room or shower, as they are not prone to dust formation.

Required materials and tools

Before pouring concrete on an inclined surface, you need to take care of all the tools, fixtures, and building materials that will be needed for the work. The process of pouring concrete at an angle is not easy and requires the most precise adherence to the proportions, conditions, norms and standards that make up the pouring technology.

Tools for pouring concrete at an angle:

- Construction level and cord for marking the surface and controlling the tilt height

- Concrete mixer for preparing mortar

- Several beacons installed as a guide during the concreting process

- Vibrating bar, mop or surface leveling rule

- Steel reinforcement to strengthen the screed

- Buckets and entrenching tools

Materials for pouring concrete at an angle: high-quality cement mortar (made independently from sand, cement, crushed stone and water or mixed from a purchased dry mixture).

Pit

A pit is nothing more than a container for wastewater, installed directly under the washing room. It is worth considering that the use of this system is rational only for small baths that are rarely used.

The construction of the pit must be carried out in the following sequence:

Alternatively, the floor board does not need to be nailed to the joists, so that they can be removed at any time and taken outside the bathhouse for faster drying.

The pit can be arranged in another way, in which the wastewater, having reached a certain height, would be discharged into the sewer or septic tank. This system is usually installed under “leaking” floors.

To install such a system, you will need to perform a number of works:

Stages of work

Before pouring concrete at an angle, you need to study the main stages of the work and strictly follow the order of their implementation. Ignoring even minor operations can ultimately lead to poor quality of the sloped covering and its inability to perform its functions.

Sequence of actions when pouring concrete at an angle:

1) Preparation of the base: thorough cleaning, marking the area

2) Installation of beacons, fixing them at the required distance from each other

3) Performing reinforcement to strengthen concrete

4) Preparation of a solution of the required brand, the consistency and strength of which are adequate to the degree of load of the future site

5) Pouring the concrete mixture at an angle, creating conditions for its effective setting and drying with strength gain

Purpose of slope for rainwater drainage

The roof of each building must be equipped with a drain, which ensures the timely removal of precipitation and its disposal into the storm drain. The presence of gutters and pipeline systems on the roof prevents the facade and foundation from getting wet. As a result, these structural elements last longer and retain their performance qualities.

Properly organized water drainage helps save on repair and restoration work. Sediment runoff will occur effectively if there is the correct slope of the drainage gutters and the system as a whole. This is due to the following reasons:

- Without proper slope, small gutters will not be able to do their job effectively. Water will constantly flow over the sides, which will lead to deterioration of the system.

- A drain angle that is too steep will make downspouts and pipes ineffective. They will not be able to cope with the rapid flow of water that comes from the gutters.

- An incorrectly chosen slope will lead to the accumulation of leaves and dirt in the system. Such a drain requires frequent cleaning and may periodically fail.

It is equally important to maintain the slope of the trays to drain rainwater from the yard. Its accumulation in the area around the building leads to flooding of basements and wet foundations. When covering with asphalt and paving slabs, the materials gradually degrade under the influence of large amounts of water.

Preparatory stage

The main task of preparing the base when pouring concrete at an angle is to remove everything that will interfere and mark the site. Remove stones, vegetation, debris and, if possible, dust. Then the surface is compacted, markings are made, and covered with sand up to 5 centimeters thick. It is advisable to compact crushed stone into the sand cushion in a layer of about 5 centimeters.

Now you need to install the beacons: you should definitely use a level so that the screed is made at the correct angle. The beacons act as landmarks and are located at different edges of the site, then a nylon cord is pulled between the beacons. It will form the geometry of the inclined concrete, showing the correct location of the screed and the correct angle of inclination.

To make formwork, take plywood or boards, cutting them according to surface measurements. The side walls should be in the shape of a triangle. They are installed on the sides of the platform, supported by supports made of boards and wooden stakes. If the difference is small, you can start filling.

When the difference in slope is significant, the upper part of the formwork structure will have to be additionally sheathed with plywood, which prevents the solution from leaking out. In this case, it will not be possible to obtain an ideal, even coating, but it can be corrected with cement mortar after dismantling the formwork. Such options are suitable for arranging a ramp for an entrance, entering a garage, etc.

Complex structures are made for pouring inclined floors. In such cases, as a rule, collapsible metal formworks are used, which are sold ready-made.

Dialogue with the customer

— Rafis, I wanted to clarify, are you planning to lay some kind of wooden flooring on the floor in the washing room and steam room?

— I definitely didn’t plan to go to the washing room.

- It's clear. As I understand it, the floors were poured and the drains were not installed under the tiles?

— What does “drains not under tiles” mean?

- Look, I see several problems here:

: Slopes too large. 5 cm by 1.5 m is a lot. And there is a risk of falling.

The slopes are organized without taking into account that the tiles will be laid here - there should be 4 trapezoidal perfectly flat planes, not to mention the fact that the screed is poured without reference to the layout of the tiles.

The drains are located asymmetrically and without any logic. By the way, I don’t understand this drain—what is it for?,” I asked, pointing to the drain in the left corner of the washing room:

“I planned a shower in this corner, so I decided to organize a drain here so that water would not run through the entire washing area.

- I see... It’s not clear how to make it all function correctly... The drains are on the same level, right?

- And what between the plums - should there be a rise?

“Well, yes... The water from the shower drains here, and the rest here,” Rafis said, first pointing to the drain in the left corner, then to the right.

— Curious... The layout of the tiles will most likely be along the washing area and dressing room? Not diagonally?

— And there should be a connection between the seams between the washing room and the steam room?

— By the way, what tiles would you recommend?

- The main thing is that it is not slippery. As for the size, it’s also better not to take a large one. Up to 30 cm.

ADDENDUM AND QUESTION TO SPECIALISTS + HAND PLAN OF THE PREMISES IN THE COMMENTS

Gain Setting

Reinforcement allows you to increase the strength of the concrete screed at an angle, provide better adhesion to the base, and will not allow the layer to deform and slide off this surface. Strengthen inclined surfaces using steel reinforcement with a cross-section of 4-5 millimeters. First you need to cut the blanks to the size of the future concrete base.

Then the reinforcement frame is assembled from the blanks using knitting wire, connecting the rods located perpendicularly. The result is a grid with a cell of 50-80 centimeters. You can also use a ready-made mesh for reinforcement.

The structure is laid between the beacons, on prepared non-metallic pads, which will ensure the required distance between the concrete and the reinforcement. The concrete will be evenly distributed under and above the reinforcement, which will protect the frame from corrosion and the effects of external negative factors.

Reinforcement

Additional strengthening of cement through reinforcement is an important process, since the use of steel rods prevents cracking and destruction of concrete over time. The simplest and most practical option for increasing the strength of a cement screed is to lay reinforcement in concrete between the beacons. Instead of steel rods, you can use a metal mesh. The reinforcement stage is mandatory for dosed concreting.

Return to contents

Preparation of concrete solution

To pour concrete at an angle with your own hands, you need to use high-quality materials. The grade of concrete is determined by the operating conditions of the surface and the magnitude of the load.

Selecting a concrete grade according to the intensity of use:

- Cement grade M400 – for indoor screed

- Brand M500 – for paths, blind areas, recreation areas

- M600 mixture – for driveways in areas where there is constant traffic movement and garages

To fill inclined surfaces, cement, fine crushed stone, sifted river sand and water are used. If M400 cement was chosen, then the following proportions are followed: part of the binder to four parts of a mixture of gravel and sand. There is no point in saving on cement, because it provides strength and other characteristics - this is important so that the base does not crack and can withstand all loads in the future.

First, mix all the dry ingredients, then pour in water portionwise until a thick paste is obtained. It is best to mix concrete using a concrete mixer - this way you can make a large volume of the mixture at once. Visually, there should be no noticeable inhomogeneous inclusions or sand in the finished concrete.

Pouring concrete at an angle - All about concrete

At different stages of construction there is a need to use concrete. Due to properties such as strength and durability, it is used not only to strengthen the structure of buildings, but also to fill floors, paths and blind areas. In most cases, there is no replacement for this building material. The only requirement is compliance with the instructions for its manufacture, violation of which may lead to loss of its quality characteristics.

To fill the floor at an angle, it is necessary to use auxiliary beacons.

Making the mixture

First of all, you need to decide for what purpose concrete is needed. Since its main component is cement, the grade will accordingly depend on the brand of cement. Determining the type of cement is not difficult: its brand is indicated on the original packaging. For production, in most cases, cement grades 400, 500 and 600 are used. Accordingly, the most durable concrete is produced using grade 600 cement.

At the same time, for the construction of private houses and improvement of courtyard structures, as a rule, 400 grade cement is used. It should be taken into account that production from cement that has lain for several years is not recommended. Caked cement, even grade 600, can cause the concrete to be brittle and will likely lose its strength. Other components are sand and crushed stone. Ideally, it is better to use a sand-gravel mixture.

Mobility depending on the angle of the vibrating chute.

As practice shows, making concrete with your own hands is not such a difficult task. The most difficult stage in its production is mixing. If resources allow, it is best to purchase a concrete mixer. It greatly facilitates the production of large volumes.

If grade 400 cement is used, then the ratio of cement to sand and gravel is usually 1/4. It is not recommended to skimp on cement, otherwise strength will suffer. As for water, it must be added gradually until the mixture resembles a thick porridge. The batch is considered ready for use when no sand is visible in its homogeneous mass.

If all requirements are met, the complete drying time (up to maximum load) will be about 1 week.

Sometimes it becomes necessary to pour concrete at sub-zero temperatures. In this case, it is very important to heat the prepared mixture.

In order not to overdry the concrete, it must be heated to a maximum temperature of 30 degrees, no more.

Pouring the solution at an angle

DIY concrete mixer from a barrel.

By and large, pouring in itself is not a difficult task. Difficulties usually arise during the preparatory stage. There are many nuances to consider here. For example, is it necessary to equip a drainage system, eliminate uneven ground or prepare beacons. Typically, angled pouring can be divided into the following steps:

- Installation of beacons for concreting.

- Reinforcement (if necessary) of the poured area.

- Direct filling.

Materials and tools:

- Cement, sand, crushed stone.

- Lighthouses.

- A thread.

- Concrete mixer.

- Mop (vibrating screed).

- Level for thread.

- Bucket, shovel.

First stage

Lighthouse installation diagram: 1 - frieze lighthouse row; 2 — intermediate auxiliary beacons; 3—reperior beacon on the wall; 4 - rows of rows; 5 - mooring cord for laying the lighthouse row.

https://www.youtube.com/watch?v=FYFIMiChz10

Since pouring at an angle is a rather specific task, we don’t have to remember about all the possible levels; we’ll only touch on the main thing. The best option is to set up auxiliary beacons, which during pouring will help create the surface at a certain angle. Basically, the need for pouring at an angle arises when constructing a blind area around the house.

In this case, you will need to prepare 4 pins and install them on the corners of the area to be poured. Depending on the direction of inclination, 2 pins must be higher than the other two, so that in the end the threads stretched between those that are higher and those that are lower create the required angle with the ground.

These threads must be taut because they will need to be connected by two other threads, which will need to move freely along the threads stretched between the pins.

As a result, the movement of the transverse threads will describe the plane. It is at the level of this plane that the concrete needs to be poured. The height of the pins must correspond to the maximum and minimum height of the area to be poured. If there is a need to more accurately orient the thread by level, then in this case you need to use a thread level.

Using a small hook, it is secured to the thread and then raised or lowered to achieve the required position relative to the ground. After the frame with the threads is oriented at the desired angle, you need to begin installing the beacons themselves (formwork).

Formation of concrete surface

When arranging a concrete screed at an angle, it is best to pour concrete in two layers: first, use a mixture with a large content of crushed stone without careful leveling, in the second go, cover it with concrete after a maximum of 24 hours, pour the mixture almost without crushed stone, in a layer 2-4 centimeters thick - the concrete should be liquid and easily distributed over the surface. This will reduce the consumption of materials and significantly reduce the cost of all work.

The procedure for pouring concrete at an angle is simple: when the solution is ready, it is unloaded between the beacons, evenly distributed over the base so that the level of concrete does not exceed the height of the beacons. Excess mortar is removed with special vibratory slats: they are placed on the formwork and driven along the concrete, as if on rails, performing reciprocating movements and gradually compacting the mixture. The procedure is repeated at least 2-3 times.

Poorly mixed concrete is immediately visible - it does not want to shrink properly. Therefore, the next batch must be prepared with a large amount of water. A poorly mixed mixture will also be immediately visible. Compacting the concrete must be done to remove air bubbles.

After pouring at an angle, the concrete is left to dry, periodically spraying water to moisturize and prevent the appearance of microcracks.

Features of arranging a screed slope in a shower room

In shower rooms and baths, screeds at an angle are performed with certain nuances. Here it is important to take care of laying a heat and waterproofing layer under the concrete. For the thermal insulation layer, use penoplex with a thickness of 30-50 millimeters with a density of at least 35 kg/cm2. Foam plastic with a thickness of 50-100 millimeters and expanded clay 150 millimeters are also suitable. It is better not to use mineral wool.

To protect concrete from moisture, roofing felt or waterproofing film (thickness more than 200 microns) is usually used. And plasticizers are added to the concrete mixture to make the inclined plane more durable and resistant to moisture.

Before pouring concrete at an angle in such rooms, a reinforcing frame is also made - a good choice would be a polymer or metal mesh with a cell of 50-80 centimeters, made of a rod with a diameter of 3-4 millimeters. Clamps or knitting wire are selected for it. It is also worth taking care of the drainage elements in the inclined surface, which are planned to be installed in the shower.

Pouring

For pouring thin layers of 1-2 centimeters (we start from the thinnest ones), a regular cement-sand mortar will not work. We need special mixtures that allow such thin layers; there are currently a great variety of such mixtures. Both tile adhesive and special floor levelers, allowing a layer of 0-5 mm, are suitable.

As a rule, you can use a section of the PN profile, placed with sharp edges on the beacons. The convenience lies in the fact that at any time the rule can be shortened with minimal effort, but this will definitely have to be done.

An improvised rule from the profile is taken with a small margin in length, so only the first plane or half of the entire screed is leveled (in the first method). In order not to damage the already formed adjacent plane, the rule should be cut almost “end-to-end” in width between the beacons, with a margin of only 1-2 centimeters. When pouring with the second method, the rule is shortened many times as you move from the edge to the drain.

When it is not possible to level some places with the rule, for example, near the ladder in the first method or there is a protruding pipe on the way, a solution with a reserve is applied to the inaccessible area on the “eye”, after the mixture has set, the tubercle is removed with a sharp spatula. When removing the influx, you need to focus on the adjacent planes aligned with the rule. It is important not to delay cleaning the deposits; this must be done no later than the next day, otherwise it will be problematic to clean off the excess later.

On this note we end our publication. We received a ready-made screed with slopes for drainage, and in the next publication we will tell you how to tile our creation.

Features of arranging an inclined entrance to the garage

The inclined approach to the garage is arranged in the same way as creating a ramp for the entrance or blind area. In this case, we are talking about pouring a gently sloping platform for the passage of cars and other vehicles from one high-altitude level to another. The flatter the ramp, the easier it is to make; the entrance can be direct or with a descent, a turn, or an ascent (curbs are installed).

The width of the ramp is usually made equal to the width of the garage door + 30 centimeters; to simplify entry, the inclined platform is widened at the far end. The optimal length is 5 meters, but the owner decides everything here. A drainage system is installed in the ramp, a surface slope is installed, and a groove with a grate is installed in front of the threshold (to drain water). A gentle ramp (counter ramp) is often installed on the side of the garage floor.

When pouring an inclined driveway to a garage, a blind area in the form of a concrete or asphalt strip at an angle from the building is required to drain water. Usually they create an inclined floor with an angle of 15-20 degrees, the width of the blind area ranges from a meter to the optimal value.

The entrance slope should be no more than 10% - that is, if there is a height difference of 10 centimeters, then the lower part of the entrance should be 1 meter long. For shallow foundations on heaving soils, part of the soil under construction is removed and replaced with materials that allow moisture to pass through, with additional installation of expanded polystyrene. Optimal standards: entry height of 20 centimeters, slope at an angle of 25 degrees.

Stages for concreting an inclined ramp:

- Excavation of soil by 40 centimeters according to the size of the inclined screed.

- Laying the first layer of sand 15 centimeters thick, compacting, spilling with water, laying a second layer of sand of the same thickness, compacting, spilling with water.

- Laying fine crushed stone to the top of the pit (about 10 centimeters).

- Separating the foundation and screed with a strip of linochrome (if the screed will not be tied to the base of the garage). You need to leave a gap of about 3 centimeters between the gate frame and the screed.

- Production of three-sided formwork from plywood or boards with a thickness of at least 25 millimeters. Installation of the structure.

- Laying insulation on a crushed stone cushion - usually extruded polystyrene foam 5 centimeters thick.

- Installation of the reinforcement cage, pouring the bulk of concrete 15 centimeters thick with a vibration compactor. Concrete is prepared from materials in the following proportions: part cement, 3 parts sand, 5 parts crushed stone.

- Installation of a mesh with a cell of 5 by 5 centimeters, pouring with concrete without crushed stone (proportion: part cement, 4 parts sand). Leveling with a board, ironing the concrete (sprinkling dry cement onto a wet screed).

- Concrete will gain strength within 15 days; for the first 5-7 days it is advisable to water it with water, again covering it with film. Then you need to install a drainage system near the inclined screed.

Example

Let's calculate what the sewer slope should be for shower pipes in a bathroom measuring 1.7 by 1.7 meters.

- Given: The base floor of the bathroom is considered zero;

- The riser level d=50 is raised above the base by 30 mm (we count the bottom of the pipe);

- The distance from the riser to the ladder is 1500 mm;

- This means that at the place where the drain is installed, the sewer pipe should be raised by: 1500 × 0.03 + 30 = 75 mm.

- If this is critically high, you can reduce it by 1500×0.02+30=60 mm.

- This means that the screed in the shower tray will be around 6-8 cm, which is quite acceptable.

Pour concrete floors in a bathhouse with a slope for drainage - step-by-step instructions

To perform a high-quality inclined surface, you first need to remove the fertile layer of soil, clean everything, and compact it. The hole in the drain pipe is plugged with a plug, and a fence made of boards or roofing felt is mounted around it. The area needs to be covered with sand in a layer of 10-12 centimeters and compacted. Pour gravel or crushed stone on top so that it is compacted into the sand (layer thickness is about 15 centimeters).

Next, you need to dismantle the box that encloses the sewer drain pipe and fill the space around it with concrete and foam chips. Cover the roofing felt (or waterproofing film at least 200 microns thick) with an overlap of 12-15 centimeters, coat the joints with warm bitumen mastic, add a layer of roofing felt, glue it along the perimeter of the room to the wall at a height of about 20 centimeters. For the drain pipe, leave a hole in the waterproofing and immediately install the lower part of the drain ladder.

A metal mesh is mounted on the roofing felt with knitting wire for reinforcement with cells of 5-8 centimeters. Beacons are placed on the grid (on a gypsum slide) with a level step of no more than 2 cm.

To fill an inclined surface, concrete is prepared with special additives - the construction industry today offers high-quality waterproofing additives (Crystal, Penetron, etc.) that will improve the structure of the solution and protect it from moisture.

Concrete is poured at an angle, the solution is leveled with a rule and a trowel, and distributed among the beacons. Concrete must be compacted to remove air pockets. Then the inclined screed is given the opportunity to gain primary strength (about 7-10 days) and insulation is laid, and another layer of reinforcing mesh is placed on it. Then the beacons are installed again and the leveling screed is poured with a layer of concrete of 50-60 millimeters and compacted.

Waterproofing impregnation is applied to the dried concrete, and decorative finishing is laid (usually ceramic tiles).

What to consider?

Sloped floors in the bathhouse allow you to quickly dry the surface of the floor materials. To properly organize your work, you need to adhere to the following recommendations:

- First of all, you need to calculate the height difference between the drain and the contour coverage area;

- To ensure the correct degree of inclination of the ramp, cords are pulled from the corners of the room to the ladder;

- The tiles are laid according to the following principle: its perpendicular side must correspond to the direction specified by the cord, and the horizontal side must be parallel to the ladder.