| № | Name | Rating | Nomination |

| Gas stoves for baths | |||

| 1 | Kutkin G–2.0 Premium | 4.65 | Popular manufacturer in Russia. Spectacular design |

| 2 | Troika No. 06-GT | 4.57 | The best ratio of price and quality |

| 3 | Kusaterm 10/20 kW | 4.48 | |

| 4 | Heat StandardGas | 4.31 | Better heat dissipation |

| 5 | TMF Taimyr | 4.25 | Signature steam preparation |

| Gas-wood stoves for baths | |||

| 1 | EasySteam Sochi K | 4.55 | Increased strength |

| 2 | Vesuvius Skif Forging 18 | 4.34 | Best price |

| 3 | Ermak Uralochka-20 | 4.24 | The most versatile |

| 4 | Koster-Potok 18 | 4.11 | The lightest and most compact |

| 5 | Termofor Taimyr Inox TSB ZK | 4.01 | |

Top 5. TMF Taimyr

Rating (2021): 4.25

36 reviews from resources were taken into account: Yandex.Market, Otzovik, 1000pechi

Proprietary steam preparation The optimal temperature for a “Russian bath” is considered to be about 60 °C and a relative humidity of 60%. These indicators can be achieved thanks to the proprietary technology of double steam preparation: first in a closed heater, and then in an open one.

- Characteristics

Average price: RUB 25,199.

- Country Russia

- Heated volume: 8 – 18 cubic meters. m.

- Power: 32 kW

- Gas burner: option

- Heater: closed, open (2 pcs.)

- Remote tank: yes

The TMF Taimyr gas stove is designed specifically to operate in a classic “Russian” bathhouse with a temperature of 60 °C and a relative humidity of 60%. To generate soft steam, a technology patented by the company is used: steam is generated in a closed heater and is pushed into the open heater at high speed, due to which the walls of the oven are heated to the required levels. Using an open heater, you can arrange aromatherapy sessions by spraying aromatic oils and herbal infusions on the stones. And although this is not the fastest oven to heat up, it maintains a stable temperature and is trouble-free to use.

Advantages and disadvantages

- Modern design

- Compact design

- Stable temperature support

- Use of proprietary technologies

- Warranty up to 5 years

- No gas equipment included

- Takes a long time to heat up

Installation

So, given: the gate for the fence made of corrugated sheets is welded, hung on awnings and sheathed with profiled sheets. Welding is at our disposal; There is also some three-millimeter steel sheet. In addition, it is worth getting out of your bins a drill, a grinder with a cutting wheel for metal, a square and a scriber (any sharpened object made of tool steel will do the job).

Factory-made metal scriber.

Overhead

How to install a padlock? The instructions are very simple if a cross member is welded at the height of the castle (usually 90 centimeters from the ground).

- Attach the lock from the inside so that one of the mounting holes rests on a horizontal profiled pipe, and the core and handle are below or above it. Mark future holes in the frame and a recess for the crossbar. If the post next to the gate is not wide enough or is made of a round pipe, you will have to weld a plate or corner under the lock mate.

- Drill holes - in the frame for fasteners, in the corrugated sheet for a key and, if necessary, for the handle. A hole in the profiled sheet is drilled along the contour and leveled with a roller cutter. In the same way, a groove is made for the crossbar in the column.

- All that remains is to secure the lock and install the core, handles and linings.

Another way is to drill holes of a smaller diameter and cut threads for the screws with a tap.

If the crossbar is located at an inappropriate height, installing a rim lock in a gate made of corrugated sheets will require welding an additional plate under it.

Mortise

How to embed a lock into a gate made of corrugated sheets?

If the frame of the gate is made of a thin pipe (for example, 20x40), the only way out is to weld a box made of steel sheet under the lock. Its dimensions should first of all leave minimal side gaps between the walls and the lock body. Material: three-millimeter steel.

From the end of the gate, a groove is selected for the crossbar and holes are drilled for the fastening screws. It is advisable that they be outside our box, otherwise we will again be faced with the impossibility of screwing the nut onto the screw thread. In the box, key grooves are selected on both sides (or for the entire core).

The counter part is mounted on a pole; as an option, a groove for the crossbar is selected directly in it.

Of course, it is also possible to install a lock in a gate made of corrugated sheets. However, you can’t call her neat; in addition, the mechanism will be exposed to rain and snow.

Finally, it is worth mentioning the most, so to speak, civilized scenario.

On sale for a long time you can find special mortise locks for gates made of corrugated sheets. They have a minimum width and are designed for installation in a profiled pipe measuring 40x40 millimeters.

This narrow-profile lock is designed for professional pipes measuring 40x50 mm.

Inserting the lock is simple and does not require welding.

- After marking, a groove for the body is selected at the end of the gate. Using a grinder, two vertical cuts are made and another one is made diagonally to the future rectangle; then the resulting triangles are bent outward and cut off. The edges are smoothed with a file.

- Holes for screws and a core are drilled in the side surfaces with a drill.

- To mark the mate of the lock, you can use a little trick. Coat the bolt with toothpaste, putty, or any other thick, colored substance. Then, with the gate closed, turn the key - and on the post there will be a clear imprint of the place where the groove should be.

Once all the holes have been selected, all that remains is to secure the lock with screws - and the job is finished. But how to install a fence from corrugated sheets? Read about this in other articles on our website.

The result of our work.

Top 4. Heat StandardGas

Rating (2021): 4.31

6 reviews taken into account from resources: Reviewer

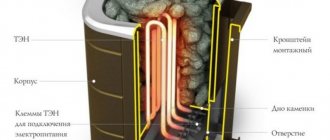

Better heat transfer The heat generator firebox is made of carbon steel ST 20, which is characterized by increased thermal conductivity. In addition, the design of the chimney eliminates the direct outflow of hot air, thereby increasing the heating of the heater.

- Characteristics

Average price: RUB 29,980.

- Country Russia

- Heated volume: 10 – 24 cubic meters. m.

- Power: 30 kW

- Gas burner: included

- Kamenka: closed

- Water tank: option

presents 3 gas stove models on the market: MalyutkaGas, StandardGas and SuperGas. They are designed for heating baths of various sizes, and the most popular of them is StandardGas with an average power gas burner of 30 kW. In the owner reviews there are no particular complaints about the operation of the unit. The excellent quality of welds, high heat transfer of the firebox, and impressive heating speed are often noted - up to 100° in less than an hour (the room is properly insulated). Conveniently, the water tank (optional) can be installed in various ways - on the stem, on the rear or side wall, on the pipe. There are also some shortcomings - the protective coating peels off quite quickly.

Advantages and disadvantages

- Long service life – 10 years

- Optional equipment with water tanks

- Heat transfer is 2 times higher than that of analogues

- Collapsible design of the gate unit

- Adding water to the tank without disconnecting it

- Small thickness of the firebox metal – 8 mm

- Poor coloring

Gas procedure, practical advice

The preparatory stage is the purchase of pipes, consumables and gas equipment. To gasify a bath according to the rules, you need to check the project and the received technical conditions.

The documents contain a calculation of the length of the pipes, an indication of their diameter, as well as the name and brand of permitted equipment. Experienced users advise purchasing pipes and consumables with a 30 percent reserve.

Stage No. 1 - installation of an external gas pipeline

Since it is recommended to install an external gas pipeline above ground, reliable supports will be required to secure the pipes. They must raise the gas pipeline above the ground by at least two meters.

The following requirements apply to supports:

- the distance between the supports is determined by the project;

- the strength of the structure should be calculated based on the gas pipeline’s own weight and the weight of possible ice with a coefficient of 1.2;

- the fastening part must correspond to the design dimensions of the pipe.

If the project specifies the installation of a gas pipeline with a slope, you can install metal spacers between the soles of the supports and embedded structures. The installation of such gaskets between the pipe and the support is prohibited.

The rules for placing supports also apply to the distance between them and the welds on gas pipes. This distance cannot be less than 5 cm

To protect against the effects of wet precipitation, the outer pipeline is painted with bright yellow oil paints. This is done by employees of the gas company that took over the installation.

But after they leave, many summer residents repaint the pipes in other colors that match the main palette of the site. This is prohibited.

Stage No. 2 - laying pipes inside

The internal gas pipeline must also consist of metal pipes. In places where they pass through the walls, it is necessary to drill holes and install embedded iron sleeves in them. Laying pipes through walls is permitted only through such sleeves.

When gasifying wooden buildings, this is extremely important, since any wood shrinks over time. And this is fraught with damage to the unprotected gas pipeline

Holes for the gas pipeline are prohibited from being made between logs or beams, at their junction. They must be located inside solid wood

Fastening must be carried out using the products specified in the project. It is better to purchase fasteners in specialized stores, since regular retail outlets often offer analogues that do not meet the requirements.

To implement turning moments, it is important to use an induction pipe bender - a device that allows you to change the angle by 90 degrees. Manual bending with heating is not suitable in this case, as it can damage the structure of the metal

At the points where gas equipment is connected, the end of the pipe is threaded. Filters are attached to this thread and shut-off valves are installed. During the final pressure testing, a specialist must check the tightness of these connections and the integrity of the welds.

Before performing welding work, you should make sure that you have a fire extinguisher, cover the wooden walls of the bathhouse and nearby buildings with asbestos or metal sheets

It is important to ensure that the gas pipes inside the bathhouse do not intersect with the electrical wire. The minimum distance between them is 10 cm

If water supply or sewerage is installed in the bathhouse, then it is necessary to maintain a distance of 2 cm between them and the gas pipeline branch.

Stage No. 3 - installation of the chimney

We have already discussed the rules for installing a gas stove. Therefore, the next step is the organization of the chimney. Gas companies also have special requirements for it.

During installation, it is recommended to ensure:

- lack of pipe joints in the ceilings - it is necessary to install the chimney so that the connections are located above or below the ceiling;

- the location of the pipes relative to the flammable elements of the building - the distance between them should not be less than 1 meter.

Above a flat roof, the chimney can protrude 1.2 meters or more. Above a roof with slopes, the minimum elevation value is 0.5 meters.

Top 3. Kusaterm 10/20 kW

Rating (2021): 4.48

- Characteristics

Average price: RUB 1,348,072.

- Country: Germany

- Heated volume: up to 20 cubic meters. m.

- Power: 20 kW

- Gas burner: included

- Kamenka: open

- Remote tank: no

A high-quality German stove is designed for small areas, so it is often installed in family baths and saunas. When choosing this gas appliance, you don’t have to worry about safety - the model is equipped with protective railings, and strong Foamglas foam glass reliably insulates the floor from heat. In general, the quality and class are confirmed by the CE marking. This mark is a guarantee of compliance with all EU directives. Reviews praise the model for its technology - the built-in fan has a low noise level, and all control is carried out via a digital panel. The highlight of the device is its universal design, which allows you to decorate it yourself with natural stone and thereby fit the model into any interior.

Advantages and disadvantages

- Low noise level

- CE marking

- Floor protection with foam glass Foamglas

- Small area work

- High price

Legal requirements for design, equipment, installation

The basic requirements for laying gas pipes inside the bathhouse, the design of the stoves and the parameters of the room are prescribed in SNiP 2.04.08-87.

The arrangement of the external gas pipeline and connection features are regulated by SNiP 42-01-2002.

Conditions for approval of the project by technical supervision

It is extremely rare that bathhouse owners manage to coordinate gas wiring, since their buildings do not meet the requirements. It is more correct to first create a project and then begin construction. Moreover, the building must be located on a solid foundation.

Old baths often have low ceilings. Due to this parameter alone, they are not suitable for gasification. A properly designed room has a distance between the floor and ceiling of more than 2 meters

The main criteria are the presence of an emergency exit, a transom for ventilation or an exhaust ventilation duct, and sufficient area. The volume of the room where the oven is located must be more than 8 cubic meters. And the passage next to it cannot be less than a meter wide.

Attention is also paid to the doors - each of them should open outward and have functional handles on both sides. The doors themselves can only be made of non-combustible materials

All this is taken into account when agreeing.

Equipment selection criteria

Not all types of stoves are suitable for installation in gasified baths. Only factory-made metal products are allowed, the design of which allows combustion products to be discharged into the chimney. Stone and brick-lined ovens are prohibited. Important points are the presence of a fuse that blocks the supply of fuel when the fire dies out and the tightness of the gas chamber.

It is worth noting that the leading Russian companies, Termofor and Teplodar, produce approved models with excellent automation and high-quality components. While the products of European factories do not always successfully pass testing.

When purchasing, check the quality and safety certificates, check the product passport filled out by the manufacturer. It must contain marks indicating successful completion of technical control.

The stove should be serviced not in the steam room, but in the dressing room. Therefore, the design must have an external fuel channel.

Particular attention is paid to the type of jets: when using a main gas supply, expanded nozzles are required; when using a propane mixture from a cylinder, narrowed ones are required

Rules for installing a gas pipeline, stove, chimney

The installation rules include requirements not only for laying a gas pipeline, but also for installing a fire alarm. Highly sensitive carbon monoxide sensors can play this role.

The pipe outlet from the house should rise 2 meters above ground level and enter the dressing room at the same height. Laying under or inside the foundation is prohibited.

A valve is installed at the end of the pipe, which, in the event of depressurization of the equipment, will immediately ensure complete shutoff of the gas pipeline.

When choosing equipment for a bath, you should always pay attention to the permitted operating temperature. For example, many Chinese CO sensors are designed for temperatures up to 55 degrees. Particular attention is paid to the placement of furnaces

Wooden walls next to them must be insulated with non-combustible materials. An acceptable option is sheathing with thermal insulation and steel sheets

Particular attention is paid to the placement of furnaces. Wooden walls next to them must be insulated with non-combustible materials

An acceptable option is sheathing with thermal insulation and steel sheets.

The fireproof distance from the insulated wall to the product body is 60 cm. All other objects, ceilings, wall shelves must be at a distance of at least 110 cm from the walls of the stove.

The supporting base of the furnace must also be made of refractory material, protruding beyond the boundaries of the product by 10 cm or more. It is allowed to connect the stove to the chimney only with steel pipes.

According to paragraph 5.1.4 of SNiP 42-01-2002, joints of metal pipes must be permanent, welded. Detachable connections are allowed in places where gas equipment elements are connected

The installation of the chimney itself is also regulated. In places where they pass through the ceilings and walls of the bathhouse, it is necessary to lay fire-proof cuttings.

Very often expanded clay is used for this purpose. Bulk material easily fills space and has high fire-resistant characteristics.

Top 2. Troika No. 06-GT

Rating (2021): 4.57

5 reviews from resources were taken into account: Reviewer

Best value for money The model is quite expensive, but is unique in that it is equipped with a spacious closed-type heater with a wall thickness of 10 to 20 mm. The package also includes gas equipment.

- Characteristics

Average price: RUB 131,120.

- Country Russia

- Heated volume: 40 – 70 cubic meters. m.

- Power: 80 kW

- Gas burner: included

- Kamenka: closed

- Remote tank: yes

The stove is ideal for lovers of a real Russian bath: in dry heat it creates abundant but light steam, and the brick design ensures good heating and long-term retention of the desired temperature. The average heating time from scratch is 160 minutes. Thanks to thermal inertia, the model quickly dries out the room, and the heat of the stones on 5 working sides allows you to quickly reach a high temperature, reaching more than 500°C in the lower layers. Such a device will last a long time, they write in reviews, because the walls of the heater are made of 20 mm low-alloy steel. This thickness is enough to hold up to 280 kg of stones without deformation and guarantee reliable protection against burnout.

Advantages and disadvantages

- Quick kindling

- Spacious heater

- Steel 20 mm thick

- Massive weight of the structure – 390 kg

How to choose the right gas stove?

The stove is the most important element of the steam room. It determines how comfortable and useful a visit to the bathhouse will be, and how much it will cost.

The design of a gas stove is not the last selection criterion. The volume of stones is also important; by splashing water on which you can adjust the steam hardness and other vaping characteristics.

When choosing a stove, take into account the requirements for gas baths, which relate primarily to operational safety. The manufacturer or seller must have official documents confirming that a particular model has been tested and meets government standards.

As for technical parameters, the main ones are:

- area of the steam room;

- rated power;

- firebox type;

- material of manufacture;

- control method;

- installation features;

- design.

If the power of the stove is too large for the volume of the steam room, the air will heat up quickly, and the stones will not have time to warm up. This means that getting decent steam will be problematic.

At low power, the oven will operate at the limit of its capabilities, which will lead to rapid wear and deformation. As a result, you will have to spend money on expensive repairs or even buy a new unit.

Therefore, it is necessary to determine the volume of the steam room and add to it the volume of adjacent rooms if they are also planned to be heated using the same stove. You can add 20-25% to the obtained value and, based on this data, select a model based on other criteria.

Facing a gas stove with bricks or slabs of natural stone significantly increases the heat transfer of the unit and protects bathhouse lovers from direct exposure to high and ultra-high temperatures

It is important to pay attention to the firebox, which must be made of steel grades that can withstand high temperatures and their significant differences.

It is desirable that the stove has thermal inertia, that is, it can retain heat after being turned off. This will not only save fuel during bathing, but also dry the bathhouse after completing all procedures.

If the stove will also heat water for the shower room, which is located outside the steam room, you should choose a model with a remote tank. Those who like wet steam need to buy a stove with an open heater. For connoisseurs of dry heat, you will need a unit with a closed heater, in which the heating of the stones reaches 500°C.

Multi-mode models will help you not to limit yourself to one thing and, depending on your mood, steam in either a Russian steam room or a Finnish sauna. Some stoves are capable of providing the conditions of an oriental hammam and an infrared sauna.

Additional equipment will allow you to control the unit from a distance and prepare the bathhouse for your arrival, being hundreds of kilometers away. All that remains is to wish you a successful purchase and easy steaming!

Top 1. Kutkin G–2.0 Premium

Rating (2021): 4.65

Popular manufacturer in Russia The popularity of stoves from the famous Russian inventor is facilitated by his personal active presence on thematic forums, the company’s readiness to provide high-quality after-sales service and the quality of the design.

Spectacular design The “Premium” version offers stove finishing with natural stones made of serpentine, soapstone or jadeite. In addition, the fuel channel door can be replaced with a fireplace insert. Together these details create a WOW effect.

- Characteristics

Average price: 50,500 rub.

- Country Russia

- Heated volume: 20‒25 cubic meters. m.

- Power: 20 kW

- Gas burner: option

- Kamenka: closed

- Remote tank: option

The inventor and owner of the manufacturing company Kutkin M.M. created a sauna stove capable of creating microclimatic conditions for all types of steam rooms - from an infrared sauna to a Russian bath. His brainchild managed to collect many awards. The main differences in the design are the mandatory closed heater, the absence of convection and the presence of several temperature conditions, including low temperature. Owners of heating units in their reviews emphasize other advantages - high heating dynamics, pleasant dry steam, modern design and several finishing options. There are also disadvantages: the oven can easily overheat; in order to achieve the ideal temperature and humidity ratio of 50/60 or 60/50, you need to gain experience.

Advantages and disadvantages

- High-quality materials - AISI steel, art. 3

- Inexpensive price compared to analogues

- Noble look of cladding

- Possibility of conversion into a fireplace stove

- Proven durability

- It takes time to master firebox skills

See also:

- 10 best hot tub manufacturers

to the beginning of the rating

"Legend" - notable characteristics

The Vesuvius Legend model is a reliable cast-iron version of a sauna stove. Design features and characteristics guarantee users increased efficiency - 80%. Cast iron options are characterized by accelerated heating of the room. The cast iron stove demonstrates resistance to temperature changes. Eliminating the slightest deformation at critical temperatures does not spoil the presentable appearance of the product.

The reliability of the stove is determined by the integrity of the seams. The volumetric mesh around the firebox holds 160 kg of material. With the same weight of the stove (160 kg), it is recommended to worry about a reinforced foundation. “Vesuvius Legend” lives up to its name and efficiently heats rooms from 10 to 28 cubic meters.

Top 5. Termofor Taimyr Inox TSB ZK

Rating (2021): 4.01

8 reviews from resources taken into account: Reviewer

- Characteristics

Average price: 17,650 rub.

- Country Russia

- Heated volume: 6‒18 cubic meters. m.

- Power: 32 kW

- Gas burner: option

- Kamenka: closed

- Remote tank: no

The compact stove with chrome elements is a modification of the “Angara 2012” model, popular among bath attendants. Like its predecessor, it is suitable for heating small rooms - from 6 cubic meters. But the declared maximum 18 cubic meters does not hold up, users share in reviews. According to them, the heat transfer of the device is rather weak, and the heat cools down quickly. This disadvantage is compensated by the low cost of operation - the design is adapted for firing with natural gas. It is equipped with a special funnel for supplying water to the lower layers of the heater, which produces light steam of 60 °C, which is ideal for the Russian bath mode. In addition, the model has an attractive design, and the burner is hidden behind an aesthetic screen.

Advantages and disadvantages

- Compact size

- Cheap to use

- Modern colors “terracotta” and “anthracite”

- Italian automatics

- Weak heat transfer

See also:

- 10 best skis for skating

The best wood-burning stoves for saunas

Wood-burning stoves were originally used to heat baths, but this heating option has not lost popularity even now. It is the wood-burning stove that allows you to fully experience the atmosphere of the steam room. The combustion of wood produces steam, and the air acquires a pleasant woody aroma. It is more difficult to maintain such a stove, and you will definitely have to build a chimney for it, but these efforts will fully pay off with improved well-being and mood.

Harvia M2

This wood-burning stove model has a stylish, discreet design, and thanks to its compact size, it can be installed even in small steam rooms. The body is made of high quality steel, the door is made of transparent heat-resistant glass and is equipped with a handle for ease of use. This design allows you not only to heat the steam room evenly, but also to enjoy the pleasant view of an open fire. The stove produces even heat and ensures good air circulation. Due to this, even remote corners of the bathhouse warm up. Since a wood-burning stove involves the use of a chimney, the manufacturer has provided two options for connecting it: from above and from the side.

| Heated area | 13 sq.m. |

| Power | 13 kW |

| Size (W/H/D) | 39x71x43 cm |

| Weight | 45 kg |

pros

- stylish black body;

- heats up quickly;

- economical fuel consumption;

- ease of operation;

- affordable price.

Minuses

- cannot be used without a chimney;

- Suitable for small steam rooms only.

Harvia M3 SL

The design of the wood-burning stove is thought out in detail and aimed at maximum ease of use. The steel body is painted black with special paint. Due to this, soot is invisible on the stove, and the device does not lose its attractive appearance even after long-term use. The firebox is covered with a glass door, so while in the sauna you can not only enjoy the aroma of firewood, but also watch the flames. If desired, the user can change the opening direction of the door by simply reversing it. The stove is designed for a maximum of 30 stones, but for a small sauna this amount is quite enough.

| Heated area | 13 sq.m. |

| Power | 16.5 kW |

| Size (W/H/D) | 39x71x65 cm |

| Weight | 50 kg |

pros

- ash box included;

- reliable Finnish manufacturer;

- high-quality assembly with careful fitting of parts;

- you can change the direction of door opening;

- The design allows you to additionally connect a water heater.

Minuses

- suitable for a Finnish sauna, but not for a Russian bath;

- high cost in comparison with domestic analogues.

Vesuvius Skif Forging 22 (220)

This wood-burning stove is worth buying not only because of its practicality, but also because of its attractive and original design. Externally, the device resembles a real stove that was installed in bathhouses before, while the functionality of the device meets all modern requirements. The device is equipped with an external firebox. This allows you to install the stove itself in the steam room, and the firebox in the next room. Unlike previous models made of steel, this stove has an additional cast-iron convector, and therefore has a long service life. The stone net is designed for 150 kg. Even if the fire in the firebox goes out, the device will still maintain temperature.

| Heated area | 24 sq.m. |

| Power | 22 kW |

| Size (W/H/D) | 52x74x71 cm |

| Weight | 84 kg |

pros

- original design;

- convenient and practical remote firebox;

- suitable for heating large steam rooms;

- durable body made of steel and cast iron;

- fireplace glass door.

Minuses

- It takes a long time to gain heat, but retains it for just as long;

- high price.

TMF Oca Carbon YES

Wood-burning sauna stoves of this model are available in a wide range of body colors, so everyone can choose a device to match the interior of the steam room. According to user reviews, the device is only suitable for small steam rooms. The design assumes a central placement of the chimney, which greatly simplifies installation and further operation. The heater is ventilated, and air flow helps to quickly warm up the stones. The manufacturer has provided several modifications to the device. For example, a consumer can choose either a stainless steel or heat-resistant glass door to allow viewing of the flame.

| Heated area | 9 sq.m. |

| Firebox volume | 26 l |

| Size (W/H/D) | 40.5x60.5x66 cm |

| Weight | 40 kg |

pros

- wide choice of body colors;

- affordable price;

- There are several modifications to choose from;

- perfectly supports the Russian bath regime with moderate temperature and high humidity;

- There are models with a built-in heat exchanger.

Minuses

- suitable only for mini-baths;

- designed for a weight of stones not exceeding 25 kg.

Top 4. Koster-Potok 18

Rating (2021): 4.11

21 reviews taken into account from resources: Reviewer

The lightest and most compact The wall thickness of the structure is 4 mm, which makes it light weight: only 70 kg. In addition, the oven is small in size - 609 x 354 x 798 mm. These parameters are important for arranging small-sized steam rooms without a foundation.

- Characteristics

Average price: 23,250 rub.

- Country Russia

- Heated volume: 11 – 18 cubic meters. m.

- Power: 18 kW

- Gas burner: option

- Kamenka: closed

- Remote tank: yes

The gas-wood device creates a stable and controllable microclimate in steam rooms. It differs from classic stoves in its high smoke collector and the location of the flame divider in the upper part of the firebox, which ensures stable heat transfer and heating of the stones. The radial fire holes of the burner completely heat the steam-generating surface, which, together with the heater, is at a minimum distance to the flame. Direct contact with fire is possible thanks to durable stainless steel 4 mm thick with 17% chromium and titanium in the composition. Among the disadvantages is the excessive consumption of firewood, because the stove is heated exclusively with an open vent. However, the manufacturer warns about this nuance in the attached instructions.

Advantages and disadvantages

- Powerful heating of stones

- Durable chrome and titanium elements

- High burner efficiency

- High fuel consumption

Electric heater in the sauna

If there is a source of electricity nearby, it is better to use it and install an electric heater. For good heating, a nominal voltage of 380 W is sufficient. The design is convenient, since you do not have to waste time and effort on preparing firewood, periodically cleaning the chimney of soot and performing other procedures.

An electric stove is suitable for a sauna for several reasons. Modern versions are equipped with a timer and remote control, which ensures comfortable operation. Heating elements are used to heat stones. At the same time, heating elements have several significant disadvantages. First of all, this is a limited resource, which varies from 2 to 5 thousand hours. It is easy to replace a worn or burnt part and install a similar one yourself.

You can also use a tape-plate as a heating element, which has a reduced temperature. The indicators in this case vary from 200 to 400°C, while the heating of the heating elements is much stronger and reaches 800°C. The working life of tape-plates is many times higher; they also create gentle indoor conditions and do not overheat the air. As a result, a comfortable stay in the sauna is created and energy consumption is reduced.

Safety precautions

During the installation of an electric heater, it is necessary to pay attention to safety precautions. First of all, it is necessary to arrange individual grounding. A simple neutral wire from a substation is not enough

If it is impossible to install your own grounding, the problem is solved by grounding. To do this, the zero terminal, which extends from the distribution board, is combined with a wire that is the grounding of the electric furnace

A simple neutral wire from the substation is not enough. If it is impossible to install your own grounding, the problem is solved by grounding. To do this, the zero terminal, which extends from the distribution board, is combined with a wire that is the grounding of the electric furnace.

Another important point is the emergency shutdown. A similar measure is necessary for every electric furnace, regardless of the type of structure. Emergency shutdown operates automatically and de-energizes the oven if a short circuit or any other problem occurs. Typically, cables that are resistant to moisture and temperature changes are used for structures. The dimensions of the stove are calculated in accordance with the area of the heated room. For example, for a sauna with a size of 1 m2 you will need an electric furnace, the power of which varies from 1.4 to 1.8 kW.

Top 3. Ermak Uralochka-20

Rating (2021): 4.24

22 reviews taken into account from resources: Yandex.Market, Otzovik

The most versatile Uralochka sauna stove can be heated with low-pressure gas or wood, and the breathable open compartment for stones allows you to get dense hot steam or a dry steam room.

- Characteristics

Average price: RUB 19,480.

- Country: Russia (manufactured in China)

- Heated volume: 10 – 20 cubic meters. m.

- Power: 20 kW

- Gas burner: option

- Kamenka: open

- Remote tank: yes

Ermak Uralochka-20 is a universal sauna stove. You can slowly burn it with wood, enjoying the smell of wood, or use gas. Gas equipment is capable of maintaining a constant temperature of 70 – 120°. The Uralochka-20 stove differs from other gas-wood-burning models at a similar price in its increased power, sufficient to heat not only the steam room, but the entire bathhouse. The open ventilated heater allows you to get hot steam. Users praise this model for its ease of installation, reliability and affordable price. There are also negative reviews about cases of firebox burnout, but this is usually a consequence of improper operation.

Advantages and disadvantages

- Dual fuel use

- Maintaining temperature in the range of 70‒120°

- Availability of spacious mounted and remote tanks

- Warranty up to 5 years

- No burner or stones included

See also:

- 10 best skis for kids

Criterias of choice

Choosing a gas furnace is a responsible task that requires preliminary calculations and knowledge of design features.

The selection criteria are usually:

furnace power

It is necessary to first calculate the required power, taking into account the volume of the room, correction factors for decoration, windows, number of rooms (compartments), etc. The power is selected based on the volume (on sale it is usually indicated for which rooms a particular model is suitable);

burner type

Manufacturers claim that the best option is a supercharged design. However, it has a lot of features that complicate operation. In particular, high-quality grounding and a voltage stabilizer are required. Therefore, atmospheric burners are more often chosen - they are unpretentious and only need stable draft;

water heating method

Double heating is preferable (in a container and in a flow-through method), but here they are guided by their own needs and considerations;

fuel type

Most designs can operate on both natural and liquefied gas. However, most burners require reconfiguration from one type to another, change of burner nozzles and other procedures. They can only be performed by specialists from the service center.

Expert opinion

Lovkachev Boris Petrovich

Bath master who knows everything about steaming

Taking these criteria into account and comparing them with the characteristics of commercially available gas furnaces, the optimal option is selected. An important factor is also the price of the stove, which many users consider the main selection criterion. Here any recommendations are useless - they are guided by their own financial capabilities.

Top 2. Vesuvius Skif Forging 18

Rating (2021): 4.34

19 reviews taken into account from resources: Yandex.Market, 1000pechi

Best price The manufacturer offers to gasify a bathhouse with high-quality equipment for only 17 thousand rubles, which is affordable to the general public even taking into account the cost of the project, gas automation and installation.

- Characteristics

Average price: 16,850 rub.

- Country Russia

- Heated volume: 10 – 20 cubic meters. m.

- Power: 18 kW

- Gas burner: option

- Kamenka: open

- Remote tank: no

Gas-wood stoves Vesuvius Skif are praised for their reliability. Thick steel walls and a heavy cast iron door prevent the structure from burning out, thereby ensuring its durability and safety. The entire heating surface is enclosed in a casing, also known as a convector. Thanks to it, the steam room heats up quickly, while infrared radiation is blocked, and the heat in the bath remains soft. A fairly spacious heater (130 kg) ensures a stable temperature. The power is enough to heat the steam room and heat the bathhouse. At the same time, the price is pleasingly affordable, but gas equipment is offered to be purchased separately.

Advantages and disadvantages

- Attractive design

- Robust design

- High power

- Thick steel walls

- Possibility of heating from an adjacent room

- No gas burner included

- No tray for stones

Advantages and disadvantages

Statistics show that gas models are the best-sellers among all types of sauna stoves.

This success is due to the many advantages of gas furnaces:

- rapid heating of rooms and water;

- fuel costs are lower than alternative models;

- gas consumption is much lower than the amount of solid fuel or electricity required to heat the same premises;

- there is no need to monitor the combustion process and constantly add fuel - simply, the combustion mode is adjusted, and the process proceeds automatically;

- the steam room (and the room in general) is clean, there is no soot or ash;

- the ability to quickly and accurately adjust the temperature;

- light weight, no need to build your own independent foundation

- the presence of heat-protected chimneys, passage units through the ceiling and roof;

- ease of operation. There is no need to constantly remove ash and clean the ash pan;

- small size, the stove does not take up useful space from the main room of the bathhouse;

- a large number of models of different capacities with a wide range of functionality.

Disadvantages of gas furnaces:

- the need to obtain permits for the operation of gas equipment and carefully follow the operating rules;

- accidents are possible caused by violations of operating rules or the use of low-quality devices;

- After turning off the stove, the temperature in the bathhouse drops quite sharply.

Despite some shortcomings, the demand for gas sauna stoves is steadily increasing. The undeniable advantages of such equipment make gas furnaces the most popular and preferred among all possible options.