The modern consumer is accustomed to the fact that new insulation materials regularly appear on the construction market, and it is difficult to surprise him with anything. Polynor can also be classified as a new product, and nevertheless, it has already taken its rightful place among other insulating materials. Due to its excellent characteristics and ease of use, polynor has received high consumer ratings and also won the title of “people's insulation.” The polynore installation technology is so simple that any beginner can handle it, which is one of the distinctive features of this material. In this review, we will look in detail at the characteristics of the heat insulator, and also tell you how to insulate a house with polynor.

Consumer properties

Like any insulating material, Polynor has a number of advantages:

- Features excellent heat conservation. These insulation indicators are higher compared to expanded polystyrene and mineral wool.

- Non-toxic. Consumer reviews about Polinor are quite good, since it is not poisonous and does not require protective equipment when using it.

- Ease of use. When using POLYNOR, a heat-insulating layer is created, which does not require a frame for fastening. Also, no tools or auxiliary materials are required.

- Excellent grip. The composition quickly adheres to any surface - brick, wood, plastic, stone, concrete, which significantly expands the scope of its application.

Polynor insulation is very popular due to the fact that it is applied by spraying. This affects better adhesion of different surfaces, even if they are not very smooth. Very often this insulation is used to finish hard-to-reach places, for example, where pipes or cables are laid.

Disadvantages of polyurethane foam compositions

In terms of its technical indicators, Polynor is ahead of most traditional insulation materials. It has a lower thermal conductivity than mineral wool, extruded polystyrene foam or polystyrene foam. Accordingly, its properties as insulation are much better. However, this material also has its drawbacks.

The finished layer of thermal insulation needs additional protection, since it quickly collapses when exposed to direct UV rays and moisture. The structure of the insulation depends on the temperature before application, the range is within +15-25*C. The difference of five degrees is quite noticeable. When carrying out work, this fact also has to be taken into account, especially if insulation is carried out in cold weather.

Polyurethane insulation is highly toxic, so spraying is carried out only with protective equipment (mask, gloves, goggles). The enclosed area must be ventilated after work. The smell after hardening lasts for several days.

“Polinor” is applied in a layer of no more than 6 cm, as recommended by the manufacturer of the material. It should be noted that it is quite difficult for a beginner to apply uniform spraying; this requires some skill.

Another significant point is the flammability of the material. Polyurethane foam has the property of self-extinguishing, but only in the absence of an open flame. During combustion, it releases toxic compounds.

Where is it used?

One-component POLYNOR is widely used for heat and sound insulation of the following elements:

- facades;

- loggias;

- terraces and verandas;

- attics and attics;

- basements;

- residential premises - apartments, houses;

- production premises;

- pipeline systems, utilities;

- thermos vans.

Features of application

Consumer reviews about Polinor insulation are quite common, which is explained by the ease of its use. The principle of working with it comes down to the following:

- Preparing the working surface for further finishing. To do this, you need to rid it of stains, dirt, and thoroughly moisturize it.

- The cylinder with insulation must be in the room at a temperature of at least 18 degrees.

- Before work, you need to put the special nozzle that comes with the kit on the cylinder until it clicks.

- Remove the cover from the cross and screw the gun onto the base. By the way, it is not included in the package. During this procedure, the balloon must be held vertically.

- The container is thoroughly shaken.

- Sprayed insulation is easily applied by dosing by pressing the gun trigger. You need to spray a layer no thicker than 5 cm.

It is recommended to shake the container during operation. To clean the gun after completion of insulation, you need to use a special liquid PULP Cleaner.

Due to its ease of use, Polinor insulation is very popular in everyday life. The instructions for its use are simple, so even a novice user can handle it. As already mentioned, the material can only be applied to a cleaned surface. Moreover, if you are working with a galvanized profiled metal sheet, you must first wipe its surface, remove all stains and oil film, which is always present on the metal due to the peculiarities of the technological process. Heating the aerosol is necessary so that the mass in the container does not freeze and is sprayed evenly.

Liquid foam

This type of insulation includes almost all foam materials based on polymer resins. The quality of the final product, including its environmental friendliness, largely depends on them. There are raw materials whose use is not permissible for residential premises due to the high toxicity of the polymer and its long-term emissions. At the same time, such materials are quite suitable for insulating technical structures or isolated building elements (if there is confidence in their insulation and the conscientiousness of the working specialists).

At the moment, such types of liquid foam as polyurethane foam, penoizol, as well as a number of products in compact cylinders are common.

Polyurethane foam (PPU)

Viscous heterochain polymers in a liquid state are used as the main component of this insulation. During chemical reactions, urethanes foam, which leads to their increase in volume by more than 50 times.

In its frozen state, polyurethane foam resembles ordinary polyurethane foam, the main difference in the structure is less porosity.

Mainly used for:

- Insulation of walls of frame buildings;

- Roofing structures;

- House facades;

- Thermal insulation of basements and lower floors.

To apply polyurethane foam, you need a special unit that first mixes and foams the insulation components, and then delivers the finished mixture under pressure to the surface to be treated. Final polymerization occurs within 24 hours, after which the finishing can be installed. Polyurethane foam is suitable for treating surfaces made of brick, concrete, wood, metal, cinder blocks and gas silicate blocks.

The average cost of work including material is 1000-1500 rubles per m2, with a layer thickness of 50 mm.

Penoizol

A budget analogue of polyurethane foam insulation, since it is based on relatively cheap, but more toxic urea-formaldehyde resin. The structure of this insulation is very similar to ordinary foam plastic, but its use is more preferable due to the absence of cold gaps in the insulating layer, characteristic of sheet and roll materials.

The density of penoizol, even in a liquid state, is noticeably lower than its urethane analogues, which does not allow its use in loaded structures. Otherwise, the scope of application is similar to polyurethane foam. Thermal insulation qualities are also not exceptional and are comparable to mineral wool, and two times less than that of the polyurethane foam described above.

Apply under pressure after pre-mixing the components and foaming. Increases in volume by no more than 30 times relative to the original mixture.

Roof insulation with foam insulation

Work together with the material costs approximately 2000 rubles per 1 cubic meter.

"Polinor"

This is a liquid insulation based on polyurethanes. A common form of release is small cylinders, similar in appearance to those for polyurethane foam. Using one cylinder you can insulate about 1 m2 of surface with a layer thickness of 6-7 cm.

The strength and thermal insulation qualities are similar to polyurethane foam, but unlike it, “Polinor” is more suitable for household use, since it does not require special equipment for application. The relatively high cost (about 500 rubles per cylinder) makes its use inappropriate over large areas.

The insulation is applied by spraying, which allows it to be used on almost any surface, for example, for thermal insulation of pipelines located outdoors.

As for filling voids in the walls, this procedure cannot be completed due to insufficient pressure in the cylinder.

"Polinor" has the following technical characteristics:

- Thermal conductivity – 0.025 W/(m*K);

- Moisture absorption coefficient – no more than 0.03;

- No toxicity, non-flammable;

- Solid density – not less than 28 kg per m3;

- Retains all operational properties for 50 years;

- The operating temperature should not exceed +121°C;

In addition, the mixture is quite chemically stable and does not interact with most reagents common in everyday life. Chloroform, dichloroethane, and high concentration hydrochloric acid have a negative effect (promote swelling) on Polinor. Nitric and sulfuric acids react with polyurethane, thus destroying the insulating mixture as a whole.

Current prices for your city:

Using the attachment

“Polinor” is a sprayed insulation material that is applied with a special plastic spray nozzle. It is attached to the tip of a regular mounting gun, and to do this you need to remove the nozzle from the sprayer, press it against the tip of the gun, then insert it into the spray nozzle until it clicks. The main thing is not to allow too much stress, as this can lead to cracking of the nozzle body. The nozzle cannot be used to work with regular polyurethane foam.

After the insulation has been applied, you can treat it with water using a regular garden sprayer - this will speed up the polymerization and better foaming of the newly created thermal insulation layer.

Difference from polyurethane foam

Both polyurethane foam and Polinor are essentially polyurethane foam, but they have different qualities:

- A) Thermal insulation: polyurethane foam has open cells, in Polinor 70% of the cells are closed;

- B) Moisture absorption: polyurethane foam absorbs and then releases water, Polinor does not absorb it;

- C) Polinor is a self-extinguishing product in relation to combustion, i.e. does not support combustion;

- D) The main distinguishing feature of Polynor sprayed polyurethane foam is the “torch” for high-quality spraying.

We follow the rules

As already mentioned, consumer reviews about the Polinor product are common. Given the ease of use, you need to approach this process as responsibly as possible. Firstly, when spraying, the mass in the form of foam that has not yet hardened can irritate the skin, eyes, and respiratory organs. To avoid this, you need to use traditional safety equipment in the form of gloves and glasses. And if the finishing is done from the inside and it is difficult to ventilate the room, you need a respirator when working. If foam gets into your eyes or skin, you need to treat them with warm water.

There are good reviews about Polynor insulation, but when using it, you should remember that the cylinder contains gas, which is a foaming agent. It is heavier than air and is flammable. Therefore, spraying should ideally be carried out in well-ventilated areas. Important: when using Polinor, you should not smoke and/or work near open flames indoors.

Installation

When using Polinor there is no need to purchase expensive spray equipment. To get started, just put a specialized gun on the cylinder and press the trigger. The mixture has a high spray speed, it can be easily applied to flat surfaces such as walls and floors, and also squeezed onto the ceiling without fear of leakage or falling off.

It is important to note that after the first pull on the trigger, strong pressure is created, as a result of which too much of the spray mixture may come out. To avoid this, it is recommended to make the first descent within an interval of no longer than 1-2 seconds

A good performance quality of Polinor is that the user has the ability to independently regulate the thickness of the applied mixture. With uniform spraying, you can achieve a layer of any size without seams.

There is no need for special surface treatment before applying polyurethane spray; it is enough to simply clean it of visible large contaminants.

Nuances

It is important to apply the mixture after shaking the container. Moreover, it must be at room temperature! It is best to spray the insulator onto a damp surface, which guarantees excellent adhesion

Applying 1 layer is usually not enough, so after it has dried, you should spray a second one so that the total thickness is around 40-50 mm. During operation, the cylinder should be shaken regularly, and at the end of the action, remove the gun and wash it, which makes it possible to use it on new containers with a heat insulator.

If, after the protective layer has dried, any damage or chips are found, they can be easily eliminated by applying a new layer of polyurethane insulator on top of the defective area. To increase fire-fighting properties, the material is treated with a special composition that will provide the surface with flammability class G1.

After applying the material and completely drying, it can be painted or plastered, as well as covered with plasterboard.

POLYNOR is an excellent innovative high-quality material, through the use of which it is possible to achieve effective insulation of structures and reduce heating costs.

"Polinor" for the floor

This spray-on insulation is ideal for indoor comfort. Thanks to proper thermal insulation of floors, you can make the room warmer, while saving on additional heating. Moreover, you can use Polinor yourself - this does not require special knowledge. The peculiarities of its use are that it is sprayed onto an already prepared surface and easily adheres to any material - from brick to wood and plastic.

Polinor received positive reviews as insulation:

- A comfortable room temperature is maintained.

- The low degree of water absorption makes it possible not to install a vapor barrier layer.

- The material promotes good vapor, hydro and noise insulation.

Cellar insulation: cheap and high quality

When decorating a house or apartment, we look for high-quality materials that are also economical. One of the materials that meets these requirements is Polinor insulation. The price starts from 400 rubles per spray bottle. That is why it is often used when it is necessary to insulate the cellar. When carrying out this work, the dimensions of the foundation and the height of the base should be taken into account. Most often, polystyrene foam is used to insulate the basement, but it is not easy to work with, so many people prefer the more economical option - Polinor. The distinctive features of its use include:

- There is no need to construct a frame, since the insulation is sprayed directly onto the surface. The material fills all microcracks, thereby ensuring reliable thermal insulation.

- “Polinor” has high thermal conductivity, so it can be applied in a small thickness.

- Simple installation allows you to do the insulation yourself without using special tools.

- “Polinor” does not absorb moisture, therefore it serves as an excellent waterproofing layer.

- After applying the insulating layer, it can be further processed - painted or plastered.

Major manufacturers of liquid insulation for buildings (structures) or utility networks

Today, a very large number of manufacturers have begun to produce ultra-thin liquid thermal insulation. However, many of them sell ordinary paint as liquid insulation. How to make the right choice? Let's look at this issue together and present a rating of the most popular manufacturers of this thermal insulation material.

Liquid thermal insulation Astratek

This material is produced by Russian. All products of the concern have appropriate quality certificates and a positive conclusion from the fire service and sanitary and epidemiological station. Liquid insulation Asstratek easily has the consistency of mastic and is easily applied with your own hands to any surface using a roller, sprayer or brush.

- It is not destroyed when exposed to precipitation because it has hydrophobic properties.

- There are no “cold bridges” unlike traditional insulation.

- Non-toxic and meets environmental standards.

- Does not support combustion, and is completely safe from fire safety.

- Completely preserves the architecture of the facade and does not steal useful space.

Liquid insulation RE-THERM

The insulation of this class consists of silicone and ceramic microspheres, which are located among a binder based on acrylic and latex. Thanks to this structure, this material has excellent waterproofing properties and, at the same time, high elasticity and particular strength.

The manufacturers of this product promise that the thermal conductivity of 1 mm of RE-THERM liquid insulation corresponds to 5 cm of mineral wool.

- This liquid insulation can be used on various surfaces, from concrete and brick to glass and plastic.

- Demonstrates ideal characteristics in the temperature range from −470 to 250 C.

- Quick drying, which ranges from 3 to 24 hours.

- High resistance to various mechanical influences, as well as to ultraviolet and infrared rays.

- Can be used both outside and inside buildings and structures.

VIOTERM Metal ALLUMA

This type of coating is specially designed for processing metal structures and engineering structures. Thanks to its structure, liquid insulation VIOTERM Metal ALLUMA gives the surface a glossy tint and reliably protects the surface from corrosion.

In addition to the above advantages, this ALLUMA coating perfectly retains heat in hot water supply and heating systems.

- It is used exclusively for treating metal surfaces as waterproofing.

- Demonstrates effectiveness at ambient temperatures from −50 C to 250 C.

- Low consumption, which is only 1 liter per 1 m2 with a layer thickness of 1 mm.

- When insulating water supply systems for hot water supply and heating systems, heat losses are reduced by 30%.

- The service life of this coating is 10-15 years.

How to soundproof a ceiling?

Noise in an apartment no longer surprises anyone, but it can be minimized using Polynor construction sprayed insulation. Consumer reviews about it are enthusiastic, not only the affordable price and ease of use are noted, but also high levels of noise insulation. What are the benefits of using this particular material? Firstly, it needs to be applied in a very small layer, so your ceilings will hardly lose any height. Secondly, peace and tranquility will finally reign in your home, since the level of noise-absorbing characteristics, as well as due to its high density and elasticity, the material perfectly absorbs all noise.

“Polinor” is an insulation material whose price is good news. When installing it, again, the construction of a frame is not required, since, when it hardens, it forms it itself. And after the foam has hardened, you can treat the surface with plaster or paint. Another important point is that to install this building insulation, you no longer need to call in professionals - you can do the sound insulation yourself!

Which variety to choose

In many ways, the choice will depend on the specific situation and what area needs to be treated. Using an example, we can consider the most common cases when a house needs foam insulation:

- If you need to seal cracks or eliminate any other defects on the surface, then polyurethane is suitable. But such material should not be exposed to sunlight.

- If you need to fill a large volume, then penoizol is suitable. But an ordinary cylinder will not be enough; you will need to purchase a special device with high pressure. You don’t have to buy it at all - you can rent it or borrow it from friends, because no one will use it often.

- If you need to seal small cracks and carry out thermal insulation in small areas, you can buy a cylinder with regular polyurethane foam. It does not support combustion, after hardening it is particularly hard, and it has an ecological composition.

- If defects are found on the outside of the wall, then you need to apply a composition based on polyurethane. It is applied directly using a special cylinder or apparatus.

It is worth remembering that foam insulation creates errors inside the layer that need to be eliminated.

To do this, you will need a long hose to push the material inside. If it is necessary to fill air gaps inside the insulation, then holes are made in the wall with something sharp. Polyurethane foam is not suitable for insulating the entire external facade - it does not have the appropriate characteristics necessary for this. Therefore, you should not choose it for these purposes, even despite its more economical cost.

We insulate the roof

“Polinor” is a universal material with which you can perform a whole range of insulation work in the house. As for the arrangement of the roof, experts advise paying close attention to this process and not choosing too cheap materials. However, many modern builders prefer materials such as Polinor. Its price is affordable, but in terms of surface quality it is not inferior to expensive analogues. In order for the roof insulation to be carried out correctly, the order of work must be followed.

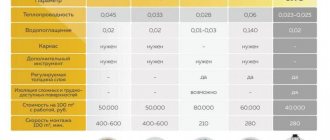

Features for comparison

Everything is learned by comparison, right? Therefore, in addition to Polinor, its potential rivals for our wallets are indicated. We look at the table and compare.

I don’t know about others, but insulation with Polinor will cost approximately 400 -450 rubles per square meter. Of course, there are not a few more indicators here

However, I decided not to bother your attention. I think this is enough

But... there remains one more important point - the price. It would be correct to name the price for a “rough” thermal insulation coating with an area of 1 sq. m.

I hope the information presented looks objective and will be useful to someone.

Insulation of walls from the inside

A parable about insulating a roof with your own hands: Once upon a time there lived a pitched roof and one day she decided to insulate herself with her own hands. But back and forth, my hands don’t get there all the time. Then the roof decided to become flat. And so she did. And soon winter came, snow fell, then more, more and more... As a result, the insulation of the flat roof happened without the help of hands.

That's all for now. Read and subscribe to the blog, recommend to friends.

Good luck and light spraying! See you in the next articles...

Quote of wisdom: Women without male company fade, and men without female company become stupid.

https://youtube.com/watch?v=kU5FQ8WIr7U

Stages of roof thermal insulation

As you know, any roof consists of several materials:

- Directly roofing material in the form of roofing felt, metal.

- Wooden sheathing.

- Vapor barriers.

- Waterproofing.

Most often, mineral wool or fiberglass is chosen as roof insulation, and this is understandable: they have a breathable structure, good vapor permeability, are resistant to fire and are ventilated. On the other hand, these materials can sag and, accordingly, cold bridges will form. Secondly, due to changes in temperature and humidity, the insulation can collapse and lose all its protective properties.

Insulation with modern materials

Polinor is an insulation material whose price and characteristics cannot but rejoice. Firstly, when using it, you do not need to call experienced specialists for help, since spraying can be done independently. Secondly, this insulation fully meets the requirements of vapor permeability and at the same time serves as reliable protection against moisture. Thirdly, when spraying Polinor, joints and cold bridges do not form, and the insulated roof becomes single and integral. Accordingly, it will be provided with good waterproofing.

Points of sale

You can buy our products at your nearest point of sale.

Your privacy is very important to us. We want your experience on the Internet to be as enjoyable and rewarding as possible, and for you to feel comfortable using the wide range of information, tools and opportunities that the Internet offers. Personal information collected when ordering services (or in another form) on the site is used to prepare services in accordance with your needs. Your information will not be shared or sold to third parties.

What data is collected on the site?

When voluntarily submitting data using forms, you submit your name, e-mail or phone number.

For what purpose is this data collected?

The name is used to address you personally, and your e-mail or phone number is used to conduct a dialogue with you about the possibility of providing our services. At the same time, we do not send SMS or e-mail messages; all offers and promotions are advertised only on the website. Your name, e-mail or phone number are not transferred to third parties under any circumstances, except in cases related to compliance with legal requirements. However, while we strive to keep your personal information secure, you must also take steps to protect it. We strongly recommend that you take all possible precautions while surfing the Internet. The services and websites we operate include measures to protect against the leakage, unauthorized use and alteration of information under our control. While we make every effort to ensure the integrity and security of our network and systems, we cannot guarantee that our security measures will prevent third party hackers from unlawfully accessing this information.

To contact the site administrator with any questions, you can write a letter to the e-mail specified in the “Contacts” section.

Insulation of a house or bathhouse

One of the most reliable and easy-to-use insulation materials is Polinor. Its characteristics as insulation are always positive, which is due to many factors. The use of this material is advisable and profitable because the insulation process can be made competent and efficient, which means you can significantly save on heating costs. When insulating houses, bathhouses and any residential buildings in general, much attention is paid to achieving the following goals:

- preventing drafts indoors,

- insulation of various structures from exposure to cold air,

- protection of buildings from the negative impact of environmental factors.

All these requirements are met by “Polinor” - a modern insulation material that is easy and convenient to work with. Unlike classic polyurethane foam, it is resistant to moisture, does not deform during operation, and allows you to insulate structural elements. Before starting work, you should prepare the surface for them, and then arm yourself with an ordinary household spray bottle. When insulating a bathhouse or a country house, it is necessary that the polyurethane foam insulation be at a certain temperature. This will ensure fast and high-quality polymerization of the surface. Also, when using an aerosol, you should shake the can thoroughly so that the spray is carried out evenly and efficiently.

Compliance with the stages of applying insulation plays an important role. So, first you need to apply the first layer to the surface - its thickness should not be more than 0.5 cm. There is no need to increase the insulation layer, since it will expand as it hardens. Once the first layer becomes harder, you can apply the second layer. “Polinor” is a unique material because it can be used to conveniently process the most inaccessible places, for example, the corners of apartments and houses. The final layer of insulation is applied to obtain the final thickness, approximately 5-6 cm. Many will say that POLINOR is the same polyurethane foam, but in fact the chemical composition of these materials is significantly different. Accordingly, the technical and operational properties of the material will be different. Due to its plasticity, reliable adhesion of the material to the surface is ensured.

Where to buy Polinor? In any stores that offer construction and finishing materials. Reviews about this Norwegian insulation are mostly good, since it is easy to use and allows you to treat hard-to-reach places. Among the disadvantages, users note a persistent odor that lasts quite a long time; moreover, if a large surface area is processed, too much material will be required, which is not very profitable.

Release form

Sprayed insulation has been known since 2013. It is a one-component self-expanding mixture with a closed-cell structure.

In construction stores, this thermal insulation is sold in cylinders similar to conventional foam for a gun.

It is applied in the same way as construction foam. According to reviews, one cylinder is enough for a 5-centimeter layer of insulation over an area of one square meter. The manufacturer's instructions state that the service life, in the absence of exposure to negative factors, will be at least 35 years.