The lack of the usual H2O in the water tap is a common everyday nuisance that is simply impossible to get used to. A person is able to adapt to the systematic shutdown of gas or electricity, but it is the lack of drinking liquid that he endures the hardest. Of course, you can collect life-giving moisture in bottles and cans in advance, but this is not a way out. It is much more reasonable to purchase a storage tank for the water supply system and install the container under the water.

Purpose of the water storage tank

The needs of a modern person are not limited to simply the supply of drink to the home. Every consumer of this resource wants H2O to flow from the tap under good pressure and ensure the uninterrupted functioning of household appliances. However, in a number of situations this is only possible if there is a water storage tank.

Installation is usually done:

- If there are no alternative water sources on the homestead territory or nearby. In this situation, a tank that is systematically filled from a tanker truck will be a real salvation.

- When liquid is supplied to residential premises through a centralized water supply system irregularly or in accordance with an established schedule.

- If you have your own well or well with low productivity. In this case, limited resources simply cannot meet all the needs of residents.

- During frequent power outages, without which pumping units are unable to function.

Main types of breakdowns

Modern manufacturers have learned to create excellent luxury water heating equipment. It uses gas to operate efficiently and rarely fails. However, even the best gas heaters cannot avoid breakdowns. The list of inevitable malfunctions includes:

- water leaks;

- poor heating of the liquid;

- discharge of power elements;

- weak water pressure;

- lack of gas.

Owners of gas boilers can repair some faults themselves. Anyone can change the batteries in the power supply. It is also easy to eliminate weak water pressure - perhaps excess scale has simply formed in the heat exchanger. To remove it, remove the heat exchanger and rinse thoroughly. For these purposes, you can also use special descaling liquids.

It is not difficult to solve the problem of poor water heating on your own. The main reason for such a malfunction is often contamination of the heat exchanger with soot. The solution to this problem is to remove the mentioned element and remove plaque. If more significant problems occur, you should contact a professional.

Using the Water Tank

To use the reserve supply of H2O at any time, the storage tank must be connected to the water supply. The connection must be carried out taking into account the supply of an aqueous solution in automatic mode (if there is not enough external pressure) or the activation moment must be set using a conventional valve. There are many ways to install water storage devices. To decide on a specific option, you need to take into account the following factors:

- source type;

- probable location;

- living space layout, etc.

In addition, it is advisable to familiarize yourself in advance with the design of different storage tanks for water supply and consider their connection diagrams. Once all the important nuances have been taken into account and the available information has been studied, you can choose the most suitable configuration.

Electrical part

The station motor is powered directly from the electric meter through a circuit breaker.

To protect the pump, quickly de-energize the engine in cases of unstable power supply or rotor overload, it is advisable to select a machine 10% more than the rated power. For the station motor used in the example, the rated power is 0.77 kW, taking into account the requirements, you need to use a 3.85 A circuit breaker ((770 W + 77 W) / 220 V), but the closest parameter is 5 A. You can use a circuit breaker with differential control.

As practice shows, conventional circuit breakers with similar current parameters cope with their functions quite well.

Features of the storage container

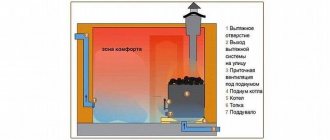

The water tank is designed to maintain the required pressure level (the same as an expansion tank). The optimal solution for these purposes is a storage tank with a closed type membrane. Such models are produced with a membrane base located inside. A mesh membrane divides the internal area into two halves. One section is occupied by air, the second by liquid.

Water storage tanks are used in individual systems. Their use is relevant in case of systematic interruptions in the supply of water to the home. The storage tank replenishes it from accumulated reserves. Water storage tanks are produced by manufacturers in a wide range of sizes and volumetric characteristics. Drainage and water supply adapters, filter elements, and ventilation outlets are located on the surface of the housing. There are also models equipped with pumping stations. They already belong to the category of expensive products.

The storage tank simultaneously performs a number of functions:

- stabilizes the pressure level when the supercharger is inactive;

- protects against water hammer occurring due to the penetration of air masses into the water supply system or power surges;

- maintains the set volume of liquid;

- ensures wear resistance of pumps.

Setting up the automation unit

The automation unit consists of a membrane with a working element, a contact group, a housing, and adjusting screws.

Under the influence of pressure, the rubber membrane expands or contracts, while its working element switches the contacts from the “On” position. to the "Off" position At the factory, the pressure switch is set to maintain a pressure of 1.8 - 2.8 bar, that is, when 1.8 bar is reached, the pump turns on, and when 2.8 bar it turns off. A timely inspection of the automation, which consists of cleaning the inlet (connecting port) and the contact surface, allows it to operate smoothly without adjustment. But since the relay contains adjusting devices, let’s consider how the unit can be switched to a different operating range.

Pressure switch.

If you turn the No. 1 stud nut clockwise, the upper response range will increase; if you turn it counterclockwise, this range will decrease. Nut No. 2 adjusts the lower response limit. To quickly achieve the best results, after small changes you should check the results of the adjustment. The device is very sensitive and every setting, even one that is not significant at first glance, leads to a change in the response limit of the device.

Types of reserve tanks (water storage tanks) for cold water

In accordance with the technical characteristics and configuration features, water storage tanks are divided into several classes according to:

- Form. They are produced in round, rectangular, cylindrical, and in the form of non-standard models.

- Design differences: closed or open.

- The material from which the tanks are made. The most common are metal, polypropylene, stainless steel, and plastic.

- Volume. Water storage tanks have a capacity from 7 to 500 liters.

- Purpose: for hot water supply, hot water supply, heating systems and irrigation.

- Installation method. Possible vertical or horizontal placement, underground or wall mounting.

Safety

It is imperative to ground the boiler.

Any water heater, regardless of model and type, requires compliance with operating conditions, as well as safety precautions. Gas models have an increased danger, as there is a risk of gas leakage.

Contact with water is the main risk factor when operating any electrical product. The boiler is equipped with an automatic shutdown system upon contact with liquid, but this does not negate compliance with the simplest fire and electrical safety requirements.

It is important to make grounding in advance. Installation of a grounding wire is a basic and mandatory condition for the safety of an electrical appliance.

Device and diagram for connecting a water storage tank to a water supply system

The liquid level in the storage tank is regulated by built-in level gauges, which are divided into float and electronic versions. The supercharger pumps H2O from the source to the backup storage. The aquatic environment fills the water storage tank to the set value, after which the float valve is activated and the water intake process stops.

When activated, the electric motor of the pump begins to fill the collection compartment of the reservoir. The air space compartment at this moment decreases. A decrease in air volume leads to an increase in pressure. As soon as a certain norm is reached, the injection unit is switched off automatically. It will work again when the atmosphere indicator drops to the minimum level.

MBFT-75 Membrane for 75GPD

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

Storage water heater

The design of a storage water heater is quite simple.

The main element of the device is a water container made of stainless steel or aluminum. If the tank is made of simple steel, then its inner surface of the tank is covered with special materials that improve its performance characteristics and corrosion resistance. A heating module consisting of one or several heating elements is installed in the storage tank. Heating elements can be “wet” or “dry”. In the first case, the heating element is in direct contact with the water, and in the second, it is placed in a tube, which heats the water.

This entire structure is placed in an outer casing and insulated from it with a special thermal insulation material. A thermostat and other necessary sensors connected to the automation system and information modules are installed in the tank. A control system, mechanical or electronic, is mounted on the outer shell of the device. Below is a classic diagram of a storage water heater in section with the minimum required set of elements.

The principle of operation of the boiler is based on the properties of water at different temperatures.

Warm liquid tends to rise, and cold liquid flows down. It is on this physical phenomenon that the work of all storage water heaters is based. Cold water is supplied from the bottom of the device and heated by a heating element. As it rises, it is removed from the tank through a high hot water intake pipe. The process itself is simple, but for reliable operation of the entire system, the installation of additional elements and systems is required both inside the tank and on the protective casing.

A magnesium anode is installed inside the storage tank, which is necessary to reduce the amount of free ions in the water. This element can significantly reduce corrosion of the internal parts of the boiler. A thermostat is also installed in the tank, allowing you to regulate the water temperature and turn off the heating elements when the required temperature is reached. The entire process of heating and extracting hot water from the boiler is shown in the following figure.

Most electric storage water heaters are equipped with temperature sensors, with readings displayed on an electronic display or mechanical thermometer.

Cold water is supplied through a tap with a non-return safety valve.

The boiler operating modes are controlled both by electronic modules and by mechanical regulators in simpler models.

The advantages of storage electric water heaters include the ability to heat large masses of water and low energy consumption, and the disadvantages are high cost.

Nuances of choosing a storage tank

When choosing a suitable water storage tank, focus on the needs of future consumers of the water resource. Determine how many people will use it. Also count the number of water intake facilities in the house or apartment. These include: kitchen taps, showers, various household appliances that consume H2O during operation. Plus, consider the possibility of use by several people at once. So that it doesn’t happen when one family member is washing, and the second cannot wash the dishes at that time.

Purpose

Tanks are used for collecting and storing drinking liquids and other non-aggressive substances that meet the food category. A variety of sizes of water supply storage tanks with and without a pump for water in an apartment allow you to save a sufficient amount of resource. A certain amount of reserves is especially relevant during systematic supply cuts. And also in cases where there is no source on the plot.

Shape and volume

Many who in practice have encountered the purchase of reserve capacity believe that the optimal displacement should be 250 liters. This is exactly the amount of liquid that will be sufficient for mass flow. For example, it will be spent cleaning the house, washing the car, filling the bath. The aqueous solution will constantly move without stagnating. 150 or 200 liters is not enough for this.

However, it is impossible to confidently recommend any specific parameters. The most common but valuable substance - H2O - is consumed differently by everyone. Therefore, when purchasing a storage tank, focus on the needs of your household.

Materials

Manufacturers produce devices of two types: metal and plastic.

The first option is products made of stainless steel, which is impervious to mechanical damage and rust. In this regard, metal models are quite expensive and are often made to order. To avoid the negative effects of corrosion when collecting and storing hot liquid, the tanks are coated on the inside with heat-resistant enamel.

Storage tanks made of plastic are the most practical and common. They are easy to manufacture, light weight and low cost.

How does an indirect heating boiler work?

Externally, an indirect heating boiler looks like a large tank with a cylindrical shape. And the boiler design itself consists of the following parts:

- boiler body;

- insulation;

- tank made of stainless steel;

- thermometer;

- heat exchanger;

- magnesium anode.

Diagram of a heating system with a direct circuit.

Due to the presence of a layer of insulation between the tank and the body of the boiler itself, the heat loss coefficient is 3-4ºC per day. The thermometer allows you to control the set temperature of the water in the tank. The heat exchanger is a spiral-shaped steel or brass tube, which is located inside the boiler itself. Very often this tube has a complex shape and is located closer to the bottom of the boiler. Manufacturers claim that it is thanks to this fact that it is possible to achieve uniform heating of water throughout the entire container. The magnesium anode is designed to protect the tank from galvanic corrosion. Almost all electrochemical reactions will affect the magnesium anode without affecting other parts of the water heater. Over time, this part of the water heater will have to be replaced as it is subject to constant wear and tear.

Almost all new models of modern boilers have an alternative heat source. Such devices are also called combined. In the summer, when the heating season is over, boilers use either electricity or gas to heat water. There are also models on the market that can heat water using sunlight.

Connection options

You can connect the storage tank to the water supply using two different methods: by placing it at a certain height or by placing it at ground level.

Upper placement is used mainly when there are no household appliances in the living space that are particularly demanding of good pressure. For the minimal needs of household members, such as washing dishes, cleaning the house, hygiene procedures, it is optimal.

The lower location is more efficient. Suitable for residential buildings that have all the amenities familiar to city residents. This type of installation requires mandatory equipment with a pump, since in its absence it will not be possible to obtain the required pressure.

SF-mix manual up to 0.8 m3/h

AMETHYST - 02 M up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

Principle of operation

Let's look at how an electric storage water heater works. Electric storage water heating equipment is distinguished by a special operating principle based on the movement of the hottest water layers upward and the shift of cold water, which has a high density, to the lower part of the tank with heating elements.

The initial connection of a water heating device to the electrical network is accompanied by turning on the heating element and heating the water to a temperature condition at which the thermostat contacts provoke the opening of the electrical circuit.

Operating principle of a water heater

The process of inversion of water heated to the specified parameters into the supply main system is prevented by the installed non-return valve device. It is thanks to the presence of such fittings that the water flow moves in only one direction.

Opening the supply tap at the water point causes hot water to flow to consumers through a special pipe, which is accompanied by a decrease in pressure inside the storage tank. As a result, the water heating tank is filled with cold water from the water supply system.

The presence of a functional divider at the inlet pipe does not allow hot water to mix with the cold water flows entering the water heating tank. The dissecting device distributes the jet and at the same time reduces the speed of its movement. It is for this reason that the flow of cold water is evenly distributed over the very bottom of the water heating device, which allows the installed heating element to carry out effective heating.

In normal mode, a decrease in the temperature of the water in the tank causes the contacts of the thermostat to close and subsequently connect to the electrical network.

Water supply schemes with storage

They largely depend on the location and type of source, the process of preparing hot water, as well as the selected pumping system that supplies water to the container.

So, if water is drawn from a 7-8-meter well, it is quite enough to purchase a surface pump. A check valve will need to be installed on the inlet pipe to prevent H2O from escaping.

It will be possible to lift the aqueous solution from a depth of 15-18 meters only with the help of a remote ejector, which must be equipped with a supercharger.

Well, for an artesian well you can’t do without a submersible device.

Centralized water supply

When installing a water storage tank, regardless of the type of connection, you will definitely need a shut-off element. It is this that prevents the stored liquid from escaping back into the water supply.

Upper connection

The storage tank is mounted under the ceiling above the pipeline or in the attic. At the initial stage, it should already have a falling and water intake fitting, as well as a pipe for discharging excess into the sewer.

Next, a coarse filter device, a check valve, a water meter, and a valve are installed. Only after this can a tee be installed that leads the tube to the inlet adapter.

A hose to remove excess H2O is lowered into a sewer pipe or simply taken outside the living space, for example, to a garden or personal plot.

To control the filling level, special float elements are used.

Leading from below

In this case, all manipulations are performed similarly to the previous method. But unlike this, a pumping station is installed at the outlet, creating a certain pressure in the pipeline. To use the liquid, you must first activate the pump.

Bottom connection of storage tank with membrane

When studying water supply schemes with a storage tank for storing water in an apartment, one cannot help but pay attention to this option. You can connect a water storage tank of this type using just one tube connected to the water supply through a tee and valve. The water storage tank must be installed after the cleaning device, water meter and check valve.

Main table dispenser AquaPro 919H/RO (hot and cold water)

Main table dispenser AquaPro 929CH/RO (cooling/heating)

Floor dispenser AquaPro 311 (empty, without cooling)

Autonomous system

Supplying H2O from an individual well or borehole source is extremely simple. It is lifted using a supercharger, the configuration of which depends on the height of the shaft and the depth of water resources.

Water tower

The storage tank is mounted 15-20 meters above the ground on an equipped tower or in the attic. The liquid from the pumping station is sent to a reserve tank, and from it is supplied to the toilet or kitchen in the living area. The necessary pressure is created due to the level difference between the water storage tank and the home tap.

Bottom connection

In this case, the storage tank is installed at the same height as the injection system or no higher than the first floor. Filling is carried out using a pump. The float switch acts as a control element. Optimal scheme for excessive H2O consumption.

Membrane design

Such a storage tank is installed immediately after the supercharger and the shut-off part (valve) through a lower connection.

Using a hydraulic accumulator

This device is designed to ensure the start of the pumping station. Can also be used as a reserve water tank. The more impressive the dimensions of the device, the higher the efficiency. However, the cost increases accordingly. Thanks to good tightness, it keeps the aqueous solution suitable for drinking.

Application of water heater

Installed for heating liquids in residential premises. At the same time it serves as a water storage tank. It is characterized by ease of installation and the ability to obtain heated H2O, regardless of the season.

Emergency overflow and drain

To protect against flooding of the room in cases of overfilling of the container, an emergency overflow is installed in its upper part, consisting of:

- transition with a diameter of 1 inch;

- corrugated hose with a cross section of 32 mm;

- siphon for washing;

- fastenings for sewer pipe 50 mm.

A tee with a 45-degree outlet was installed into the existing sewer system. The outlet pipe of the siphon is connected to the tee through a rubber transition from a diameter of 32 mm to a cross-section of 50 mm. For reliability, these components are treated with silicone sealant.

When it is not possible to supply liquid by the pump (breakdown, no electrical power), the water is drained through an emergency drain located in front of the suction line check valve.

In this case, the drain valve 26 is placed as close to the bottom as possible.

Where are water tanks installed?

The choice of location for storage tanks depends on many factors that must be taken into account when planning installation work.

- You can provide backup water supply to a private home through a storage tank by installing the tank in a utility room under the ceiling.

- Install a water tank in the attic or loft. If necessary, the structure will have to be insulated.

- Place it directly on the floor surface or in the basement. Without a pumping station, of course, such a scheme will not work.

Types

The storage tank can be a container with sufficient internal volume, made of a material that is resistant to corrosion and safe for storing drinking water. The following materials are used:

- polyvinyl chloride;

- cross-linked high or low pressure polyethylene;

- polypropylene;

- stainless steel;

- steel coated with waterproof varnishes and ceramic coatings.

Plastic Tanks

Although galvanized steel is corrosion-resistant and waterproof, over time the protective layer of zinc can wear thin, especially at joints and welds.

By design there are:

- open containers that have a neck with or without a lid, but with sealed walls and bottom;

- closed, completely sealed membrane-type containers.

In the first case, everything is simple: the entire internal volume is filled with water and, if necessary, drained through a pipe fixed at the lowest point.

In the case of membrane storage tanks, the useful volume is at least a third less than the volume of the entire structure. Part of the volume is allocated under the air chamber, separated from the water using a durable elastic membrane. As the container fills with water, the membrane presses on the air chamber, creating excess pressure. When it is necessary to get water back, the valve opens and it enters the water supply system under the influence of accumulated pressure.

Recommendations

When planning to purchase a storage tank and organize its operation in the house, it is worth enlisting the advice of experienced specialists:

- Combine the purchase of a water storage device with the purchase of a filtration device. This way you can get crystal clear drinking liquid. When considering offers on the market, you should pay attention to products. We manufacture and sell water treatment equipment and are ready to help you choose the option that suits you.

- When choosing a water storage tank, do not skimp on quality. If you buy a cheap product, you will probably spend more money on troubleshooting various problems.

- When doing the installation yourself, consider the possibility of dismantling the system for repairs or replacement.

- Be sure to consider grounding to prevent corrosion.

Repair

Small leaks in the tank can be easily repaired on your own. These are typical malfunctions that manifest themselves mainly in the places where the pipes exit and where they connect with the pipes. You won’t need a welding machine, especially for plastic tanks. When eliminating defects yourself, it is recommended to use special putties and adhesives. The nuance is that not every product is suitable for these purposes - we are talking about water, which is also used for drinking and cooking.

When choosing a composition, you need to carefully read the instructions for its use. Experts recommend eliminating leaks in storage tanks using “cold welding”, two-component glue (“Poxypol”) or similar properties. To increase reliability, after applying the first layer, you need to apply a patch (for example, a piece of gauze) to the damaged area and re-process it. Manufacturers always indicate means that can be used to eliminate minor defects in the tank body; you just need to carefully read the instructions.

You need a quality water storage tank. Don’t waste time searching - the website alfatep.ru presents various versions of tanks from well-known manufacturers at factory prices. Our online store also has everything necessary for their installation: pipes, shut-off valves, fittings, sealants. ALFATEP employees will help with calculations of the required tank capacity and recommend the optimal model, advise on the procedure for servicing and repairing the product, and advise which materials should be used. You can ask questions through the “Contacts” option or by phone (calls within the Russian Federation are free). Delivery of containers to the customer is carried out by the company’s representative offices in the regions, in a short time; We work all over Russia. Form of payment – at the client’s choice, it is possible to provide a loan on preferential terms.

Where else can plastic barrels be used?

They can be used for storing any liquid, granular media - neutral or aggressive, but:

- if the internal pressure in the tank (the product of the density of the stored material by the height of the column and the acceleration of gravity) does not exceed the calculated (declared by the manufacturer) tensile strength values;

- the material is inert to the substance loaded for storage.

Technical information: Thermoplastics of the polyester group, including polyethylene and polypropylene, are completely inert to ammonia, gasoline, acetone, butanol, acetic acid (CH3COOH only), ethyl chlorides, chlorine gas, hydrogen sulfide, mineral oils, propane, etc.

Installation process

The most affordable option for organizing an autonomous water supply system in a house or bathhouse is to install a container in the attic.

To do this, you need to make or purchase a bath tank of the required volume and configuration.

The container is installed on the top beam or in any convenient location in the attic.

Installation work is carried out in stages:

- The base under the water tank is being strengthened. The floor beams are covered with wide boards.

- The drive is installed on the prepared base.

- A float type valve is being installed. Step back 7.5 cm from the top edge, make a mark and cut out a hole of the required diameter. The tail part of the valve with a plastic sealing washer is threaded into the hole. A special stiffening plate is installed on the opposite wall of the container, another sealing washer is installed, and a nut is screwed on. All fasteners are securely fixed, a connector is screwed to the tail part, with which the water pipe is connected.

- Holes are made for outlet pipes of the required size. A connector with a washer is screwed into the finished holes on the inside of the container. The thread is strengthened with a special tape. Next, put on the washer and tighten the nut.

- Shut-off valves are inserted into the outlet pipes.

- Overflow is in progress. To do this, set a mark 2.5 cm below the location of the float-type valve and make a hole. The overflow pipe is led into the sewer system and secured to the walls of the tank using connectors using a similar principle. Next, the pipes are connected with compression fixation. The finished sections of the pipeline system are mounted to the walls of the tank and a wooden base.

- The connected tank is filled with water to check the tightness of the system, as well as to regulate the float valve.

- The container is insulated using polystyrene sheets or rolled mineral wool.

In this simple and reliable way, you can set up an autonomous water supply system, the main element of which is a storage tank for a bathhouse or home.

Popular models

It's time to understand the most popular models of heat accumulators for heating systems. We will consider products from domestic and foreign manufacturers.

Heat accumulator for heating boilers made in Russia Prometheus

The manufacturer of Prometheus heat accumulators is Novosibirsk. It produces models with volumes of 230, 300, 500, 750 and 1000 liters. The equipment warranty is 5 years. The heat accumulators are equipped with four outlets for connection to heating and heat sources. A layer of thermal insulation made of mineral wool is responsible for preserving the accumulated energy. The working pressure is 2 atm. maximum – 6 atm. When purchasing equipment, take into account its dimensions - for example, the diameter of a 1000-liter model is 900 mm, which is why its body may not fit into standard doorways 80 cm wide.

The price of the presented heat accumulator for heating systems varies in the range from 65 to 70 thousand rubles.

SPSX-2G 1000

Another capacious heat accumulator for 1000 liters of water. It is equipped with one or two smooth-tube heat exchangers, but lacks thermal insulation, which must be taken into account when installing it - it will have to be purchased separately. The diameter of the case is 790 mm, but if thermal insulation is added to it, the diameter increases to 990 mm. The maximum temperature in the heating system is +110 degrees, in the DHW circuit – up to +95 degrees.

Buderus Logalux P 500-1000/5

These heat accumulators are available in modifications with six or ten connections. Temperature sensor terminals are also provided on board. The tank capacity is 960 liters, operating pressure is up to 3 bar. The thickness of the thermal insulation layer is 80 mm. The use of liquids other than water as a coolant is not allowed - this applies to both circuits, and not just the heating circuit. If necessary, it is possible to connect several heat accumulators in series into a single cascade.