One of the significant advantages of the technology for building baths from profiled timber is that it allows installation to begin at any time of the year. Including in winter, since there are no “wet” processes. However, the season when the frame assembly begins does not affect some important stages of construction and finishing. It is advisable to know about this in advance, since in some cases, if not insurmountable, then rather unpleasant difficulties may arise. This article explains how the construction of a wooden bathhouse differs in spring, summer, autumn and winter.

Construction of a timber bathhouse in the spring

Spring is the optimal season to start building with brick, foam blocks, aerated concrete, but not with timber. During this period of the year, several difficulties may arise at once. Firstly, melted and high groundwater in low areas prevents the construction of a foundation. Secondly, in early spring the daylight hours are not very long, which increases the construction time.

If the log house is assembled from profiled timber with natural moisture, then with the onset of hot and dry weather, problems with shrinkage and shrinkage may arise in a couple of months. Under such conditions, moisture will come out of the wood too intensely. If this is not foreseen and appropriate measures are not taken, shrinkage will occur unevenly, the timber will crack severely, and wide cracks will form between the crowns. The last two problems are very easy to deal with, but correcting uneven shrinkage is difficult and expensive.

Spring construction of a wooden bathhouse also has advantages. The weather is generally good - if there is any precipitation, it is short-lived. When building a log house from chamber-drying timber, after 2…4 months the bathhouse can be put into operation. Also, problems usually do not arise with access roads and storage of lumber. In early spring or late winter (in advance), there is every chance to buy timber from winter harvested forests. It contains less defects, biological damage and moisture.

Is it possible to build a bathhouse in winter - Features

You can build a bathhouse in winter from rounded logs, timber or simple chopped material. You can prepare logs in advance, but it is better to use winter forest. The main stages of building a bathhouse in winter include:

- Waterproofing a finished foundation or installing a new one.

- Assembling the box and roof.

You can do finishing and insulation after installing the finished roof; in winter it is better to do a rough one. Let's look at the features of each stage in more detail.

Foundation for a winter bath

The log house is placed on a pile foundation.

To build a wooden bathhouse in winter, you need to think through and prepare the foundation in advance. Installation work will be easier in the warm season. You can make a foundation in winter, for example, with a pile-screw foundation. Some craftsmen make tape, the price will be higher. Various additives are used to harden cement at sub-zero temperatures. It is difficult to predict how a strip foundation assembled in winter during the warm season will behave. In addition to all of the above, the ground will be frozen, making it difficult to do it yourself.

You can see more details on how to install a screw foundation in winter in the video:

Box assembly

You can assemble a bathhouse box in winter with your own hands. The installation process is no different from the usual:

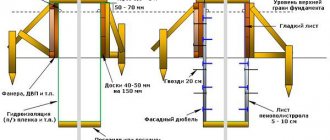

- The foundation is waterproofed by laying two layers of roofing felt.

- Rows of thin slats are laid, which will enable the lower crown to better stand on the foundation.

- A lower crown of larger cross-section made of moisture-resistant aspen or larch is mounted.

- A box is made of timber or logs. The links are connected to each other using wooden dowels.

- Jute insulation is laid between the links.

- The roof is going to be rough, because in the spring the soil will begin to move and the bathhouse will shrink.

Despite the similarities with conventional construction, winter construction has its own characteristics:

- At temperatures below -25 °C, wood becomes brittle, so all work is carried out to the required level.

- The weather can change at any time so you need to be prepared to stop the assembly at any time.

- You cannot leave the bathhouse box open, as it will be covered with snow and in the spring it will turn into water, and this will lead to rapid rotting of the walls.

- It is better to buy timber or logs that have already been treated with antiseptic compounds.

- It is better to purchase material from the winter forest since the trees “sleep” and the movement of sap in the trunk has stopped. The barrel is filled with a special paraffin-like substance. Wood has lower humidity and greater moisture resistance.

Construction of a cobblestone bath in summer

In the summer, there is only one significant problem for timber construction technology - abnormal heat. Now the climate is changing not for the better, and at this time of year the temperature rises to levels unusual for our region. Because of this, the timber in the log house dries unevenly and too quickly, which can lead to the formation of deep cracks. To be as safe as possible, in the summer it is recommended to build a bathhouse from dry timber, which has compensation cuts.

Otherwise, summer is considered the right time of year for building a wooden bathhouse. Daylight hours are long, the weather is almost always “flying”. With proper organization, by the coming winter you will be able to take a steam bath in your own bathhouse. If it is built from timber with natural moisture, then over the winter it will shrink evenly, and in the spring all that remains is to apply the “shine” and use it.

Types of foundations, which one is better to choose for winter work

The most common light foundations (light because the bathhouse is usually not heavy), which are installed both in winter and summer:

- columnar;

- grillage;

- tape;

- plate;

- pile

Since all types of foundations, except piles, are built using concrete, in order to make them in winter it is necessary to add a special anti-freeze additive to the solution.

Anti-frost additive

A pile foundation requires only unfrozen soil. If you are planning to build a lightweight structure, I recommend using screw piles if the ground is not yet frozen.

It is clear that if the ground freezes in winter, the technology for both concrete and pile foundations will have to be changed.

Winter construction of a wooden bathhouse

Compared to other technologies, construction from timber in winter is the most preferable. Yes, there are some difficulties. For example, the foundation must be ready in the fall or built on stilts. The roads are swept away. Daylight hours are short and so on.

However, only in the winter season does wood naturally contain little moisture, and it freezes out of it at an optimal rate. When frost sets in outside, the relative humidity also decreases. This promotes quick and uniform drying of the wood in the log house. Microorganisms and insects do not live in such conditions, which means there will be fewer lesions and defects on the timber by the next stage.

Plus, in winter there is a greater chance of finding lumber from winter-harvested forests, getting favorable discounts, and speeding up the start of construction due to less workload for specialists.

Features of work in winter

In addition to using anti-frost additives, if a slab is made as a foundation, it must be heated, because one of the components of the solution is water and if it crystallizes in the cold, the concrete will not “set” and will not acquire the required hardness.

Problematic foundations.

When building foundations by professional teams in winter, tents are usually erected above the foundation, which are capable of maintaining the temperature, and heat guns are installed inside the tents.

The most important requirement is a temperature above 3 degrees on the concrete surface. Another technological technique is to wrap the formwork in thermal insulation materials.

Tents protect the concrete surface from above, but if you are making a strip foundation, it must be insulated from the sides, for example, with mineral wool.

Since serious frosts have not yet begun, I ordered a concrete mixer with an anti-freeze additive from the factory. Now any concrete plant produces such concrete.

If I need to fill some niches, I will add such an additive to the concrete mixer when the ambient temperature at night is less than 5 degrees.

How much firewood do you need for the winter?

Snowy hello, dear blog visitors!

Do you want to build a welcoming house or a welcoming wooden bathhouse? Well, summer will come and then... What? Don't want to wait? But winter is just around the corner. How to be? What do experts think about this? Some people think that we need to wait. And others say that construction should begin immediately, since winter is the ideal time of year for the construction of any wooden structure.

What to do? Opinions differ! Well, we won’t torment the unfortunate daisy with the words: “To build or not to build.” Let's act like smart people and consider the pros and cons of this process. Do you agree? Wonderful! So, winter construction: to be or not to be?

Before we start discussing the advantages and disadvantages, I want to tell you what prompted me to write this article.

I decided to go to the dacha, and I saw that my neighbor’s construction was in full swing. He felt the urge to start building a wooden house in winter. I didn’t want to wait for spring and summer and that’s it. Just so you understand, it’s -15 outside and knee-deep snow. I, of course, approached him and the builders, found out everything that interested me, and decided to share the information with you, dear readers. I think you will find it useful.

After all, if you think about it, not everyone has the opportunity to build a cute Russian bathhouse or a lovely wooden house in the summer: a vegetable garden, conservation, renovation, a trip to the sea and all that. Is it true? Here you go. Therefore, construction in winter is very convenient. However, can certain objects built in the cold be considered high quality? Ha, I already know the answer! I hasten to share with you.

Winter, as it turns out, is the ideal time to build wooden structures! Why? I'll tell you now.

1.) Winter forest is the best raw material for building a wonderful cottage or wooden bathhouse. Is it true? Surely. Structures made from the so-called winter forest serve faithfully much longer than their relatives made from summer wood. This fact can be explained simply. Winter forest:

- not attractive to rodents, insects and microorganisms;

- gives much less shrinkage;

- does not become covered with cracks and gaps;

- does not change shade;

- does not undergo the process of rotting;

- becomes much stronger due to the narrowing of the annual rings;

- has a minimal shrinkage period (8–9 months, instead of 12–18);

- characterized by the absence of moisture;

- has a low price because it is “out of season”.

2.) Saving is a guarantee of wealth. In winter, as a rule, construction organizations cannot boast of an abundance of orders. Therefore, companies specializing in the construction of this or that structure offer very tempting discounts to “winter” clients. The benefits are obvious!

3.) Quality is the key to the durability of the structure. As I already said, construction organizations often sit without orders in winter. What does it mean? And the fact is that company employees work many times better, since they are not in a hurry to hand over the object to the customer as quickly as possible and start creating a new one. Fewer orders – more quality.

4.) Availability of materials – reliability of the structure. In winter, raw materials intended for construction are much cheaper than in autumn, spring or summer. As a rule, prices for materials fall by 15–30%, or even more.

5.) Non-conflict is a guarantee of a healthy nervous system. Friends, what usually annoys neighbors the most? Right. The construction of an object that causes noise and interferes with people's recreation. And in winter, few people go to the dacha, so no one will make a scandal.

6.) Speed – the faster they built it, the sooner they moved into the house. In winter, this or that structure is erected much faster, since today there are a lot of innovative winter construction technologies. They allow you to “decorate” your garden plot in the shortest possible time with a charming cottage, a friendly house, or a delightful bathhouse made of valuable wood species.

7.) “Healthy” soil is the key to active flower growth. Quite often, in places where heavy construction equipment has been “wheeling”, the vegetation does not want to be accepted for 5 or even 10 years, which upsets the housewives. And the frozen ground is not afraid of any wheels.

8.) Pouring the foundation – “minus” – is great. More than half of people believe that building a foundation in winter is impossible. This is not entirely true, here is an article for you. Experts say that the basis is damaged by heat, not frost. A foundation built during the cold period, on the contrary, has a long service life.

Pouring the foundation in winter

In general, both practice and theory prove that construction in the winter season is cheap and cheerful. By the way, frame houses are quite often erected precisely in the cold season. What do you think? The structures are very strong and beautiful.

It’s strange, why then are people not in a hurry to get a house in winter? It's simple. People live in the past. What do I mean? The fact is that earlier, when construction was carried out using primitive materials and technologies, structures built in the cold were not of high quality. But during times of innovation, a huge amount of various raw materials were invented that are not afraid of heat, frost, snow, or rain. In view of this, dear friends, build for health, even in winter, even in summer!

I would like to write that winter construction has no disadvantages (a very rosy picture emerged with its advantages). But employees of construction organizations, to whom I invited myself to visit, told me about upsetting negative aspects. I simply have to tell you about them.

- Highly qualified workers are the guarantor of a reliable home. Winter construction requires special skills and knowledge. Only a master of his craft can do the job efficiently. “Sharashka’s offices” are unlikely to cope with such a responsible matter. Agree, this is a very important point.

- Heating – increased winter construction costs. Since winter is a frosty time, workers need somewhere to warm up from time to time. This means that you need to build a shed with a heater. Where it leads? To greater consumption of electrical energy and an increase in the amount in the receipt.

- Lighting. Since daylight hours are short in winter, care must be taken to ensure the availability of artificial lighting at the construction site. Again, additional winter costs.

- A short day means a reduction in the amount of work. It gets dark early in winter, which means the workdays for construction workers are shorter.

- The weather is a capricious lady. A lot of time is spent eliminating the vagaries of nature: the snow needs to be cleared and the ice needs to be melted. In addition, as a rule, builders do not work at -20°C.

- Wood is also a finicky lady. A significant “minus” can lead to cracking of the wood when cutting. But the pros have already learned to deal with this problem, so the disadvantage is debatable.

This is where the negative points end. Perhaps some organizational and financial issues may unsettle you a little, but this will not happen if the contract is drawn up correctly. All conditions must be clearly stated (without small print and pitfalls). Be carefull!

Read also

What fruits can you grow at home?

What's New Year without fruit? And they all have seeds. They can be collected and sown in pots. And after some time there will be a real tropical forest on the windowsill! We tell you what exotic fruits you can grow at home from seeds

New items with weirdness: Orange cabbage and white beets

Active sales of seeds have begun in stores for summer residents. What interesting things are offered in the 2019/2020 season?

Choosing the best water heaters for a summer residence

The problem of lack of hot water in a country house is quite acute. KP has prepared for you the top 7 devices that can solve it

Picking peppers in 2021

Peppers take a long time to ripen, so seeds for seedlings are sown at the end of February

Why is the tinder fungus dangerous?

How to remove it and save trees after the fungus has settled on them

Why is the tinder fungus dangerous on the site and how to remove it?

Gardeners consider this fungus a parasite.

How to cover seedlings for the winter: step-by-step instructions from agronomists

How to properly cover seedlings for the winter and preserve them until spring if you didn’t manage to plant them on time, we tell you in our material

And in an ordinary two-room apartment, gardens can bloom! A Krasnoyarsk woman grew a crop of citrus fruits, pomegranates and avocados on her windowsill

With proper care, everything will grow, the girl is sure [video]

Effective remedies for garden pests

If you feed birds in the garden in the fall and winter, they will destroy most pests! True, not all birds are equally useful. And in order to attract the right people, you need to know how to feed them

Soil for seedlings: Why your own soil is better than purchased soil

In former times, all summer residents stocked up soil for seedlings themselves. Simply because there were no other options. Now soil is sold in all garden centers and even supermarkets. But is she any good?

Picking seedlings in 2021

Many heat-loving crops with a long ripening period are grown through seedlings

Preparing garden crops for winter

Lately our winters have become unpredictable. And even completely frost-resistant garden crops begin to suffer from bad weather. Therefore, it is important to properly prepare them for the harsh season.

Preparing perennial vegetables for frost

What needs to be done in October to get a good harvest next year and how to properly prepare perennial vegetables for frost

How to prepare perennial vegetables for frost

What needs to be done in October to get a good harvest next year and how to properly prepare perennial vegetables for frost

How to prepare grapes for winter

There are a lot of options for covering grapes, but how to cover them without harming them, as well as how to properly prepare them for winter, says our specialist

Winter garlic: planting, varieties, tips from gardeners

This crop can do without fertilizing and grows with minimal watering.

Grouse flower: planting secrets

Let's figure out how to properly grow this beauty

Harvesting cabbage: rules and secrets

Sometimes harvesting this vegetable must begin much earlier than October.

Root vegetables: when to harvest and how to store

Vegetables from your own garden are always a good help. They produce a decent harvest, but not everyone manages to preserve them all winter. This is often due to improper cleaning.

Bed question: choosing bed linen

Oddly enough, people approach the issue of choosing bed linen quite frivolously. Bright packaging and low price sometimes play a decisive role

Age category of the site 18+

Selection and procurement of building materials

The construction of a sauna can be made from various materials, but real lovers of the steamy spirit tend to use natural wood. As you know, wood is a living material characterized by certain features:

- During the period of growth and active nutrition, the humidity of the tree trunk is 60 to 70%;

- Natural wood contains starch, which causes it to rot;

- The tree is one of the favorite habitats of insects, which can significantly deteriorate its quality;

- Moisture, heat and oxygen cause the spread of mildew and mold.

Each of the listed processes is natural and can cause negative consequences for a wooden bath. They mainly occur during warm seasons. Wood harvested in the autumn-summer and spring periods is coated with a transport antiseptic. However, it cannot be guaranteed that it will be able to destroy all mold. During this same period, active evaporation of moisture occurs, which causes the formation of cracks in the material.

In winter, the tree almost does not grow, is characterized by a low content of starch and moisture, and is resistant to the formation of cracks and tears. During this period, all bacteria, bugs and pests die in it. A tree cut down in winter is not subject to rotting, it is stronger and more durable.

"Underwater rocks"

Firstly, at ambient temperatures below -20°C, lumber becomes very fragile. This significantly complicates their processing. In particular, during the manufacture of connectors, you may encounter excessive cracking of the material, chipping and other damage.

Secondly, the bathhouse must be built on a foundation, the arrangement of which becomes significantly more difficult in winter. If it is a monolithic strip, then pouring it requires concrete with modifiers and individual heating. And this always costs a pretty penny. In an area with frozen soil, even preparing a trench can cause considerable difficulties.

Thirdly, not every construction team will agree to work in such harsh conditions. The process may be repeatedly interrupted due to bad weather, which will result in loss of time and other resources.

Hire builders or do it yourself

I hired builders for my dacha several times. But every time they left a lot of “shoals”. Some of them can be corrected, but most are not even visible, since they are in hidden work (in walls, ceilings, foundations).

So I prefer to do the foundation and everything else myself.

If you do hire builders for foundation work, at least make sure that they work only in warm weather. If this is not possible, consider installing tents and heat guns.

When choosing builders, do the following:

- sign an agreement with a legal entity or individual entrepreneur;

- transfer money through a bank;

- do not pay more than half in advance to cover only the costs of materials;

- pay incrementally, in parts;

- invite an independent builder who will monitor the progress of construction, if you are not a “ruh” yourself; It’s better to pay him extra than to deal with a cracked foundation later;

- Before concluding a contract, look for reviews about this team of builders, look at the projects they have done and, possibly, contact their clients.

If you have ever poured a foundation in winter, please share your impressions.

Recommendations

In order for everything to work out as it should, and the winter construction of a bathhouse to justify itself as a good idea, you should use these recommendations:

- Build from truly winter wood. Dishonest sellers in the winter sell off the timber harvested in the summer, passing off one thing as another. This needs to be checked.

- Think about the foundation in advance. It is better to fill it before the onset of cold weather - in summer or autumn. If it’s winter, then give preference to a pile-screw one.

- Purchase material that has already been treated with antiseptics. Because it will be very difficult to process it yourself in cold weather.

- Do not leave the log box open. A sudden snowstorm will bring snow there, which will melt in the spring. The water will rot the tree.

- Leave the finished building under the rough roof. Make it permanent in the spring.

It is also better to start the further stages - caulking the walls, sheathing, laying out communications, finishing - as soon as the weather warms up. If you follow all the details and take into account the characteristics of the material, the “winter” bath will be of high quality and will last for many years.

How modern professionals work with logs

Experts share their experience:

- When preparing and laying the log house, we work on our own construction site. Here we use covered hangars, which allow us to prepare logs, debark them and prepare them for drying.

- Working under a roof allows you to exclude weather factors and build log houses in any season, without looking at weather forecasts and stereotypes.

- Indoor hangars make it possible to insulate the log house even in the rain using Euro-flax and flax-jute, as well as to perform rough grinding of the corners and grooves of the logs.

The use of special covered areas makes it possible to prepare logs for transportation and assembly in any weather. Depending on the size of the log house, work on the site takes only 2 to 7 days.