Studio kitchens have gained great popularity in the modern world, where, thanks to different floor coverings, it is possible to effectively zone the available space. Most often, tiles and laminate without a threshold are used - this combination of two practical materials looks beautiful and original, and does not cause any particular difficulties during installation. It is important to know what methods of combining them exist and to adhere to a certain technology for laying tiles and lamellas.

Tile and laminate - a beautiful combination in a modern design

How to seal the transition between floor coverings:

The nuances of joining without a threshold Basic design recommendations How to join seams Grout:

- Sealant

- Liquid plug

- Cork compensator

How to join sections without a seam When a threshold is needed Types of thresholds Video: how to join hexagon tiles

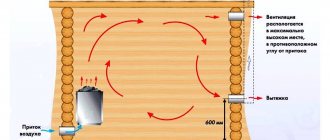

Two coatings are usually used for zoning rooms. For example, to visually separate the hallway from the corridor, or the living room from the kitchen, if they are combined. In this case, the transition line between materials can have a complex shape and a large length. It is advisable to design such a joint between tiles and laminate without a threshold.

It looks more attractive, dirt does not accumulate at the junction and no one will trip over it. But this technology is considered more complex than delimiting a room using a protrusion.

Advice from professionals

To achieve the desired result when using two different floor coverings, you need to adhere to the following recommendations:

- Ceramic tiles and laminated boards must be in the same plane. In this case, it is worth taking into account both the thickness of the tile composition and the size of the substrate used.

- First you should draw a line, then apply ceramics and lamellas to see the final result.

- First you need to lay the ceramics, and then adjust the laminated board under it.

- It is better to make a figured cut using a grinder. But you should use a tile cutter for an arcuate cut, and an electric jigsaw for a curved one.

The nuances of creating a docking without a threshold

There are several things to consider when planning your renovation.

- Laying height. The thickness of the laminate and tiles and the method of their installation are not the same. To seal the transition from tiles to laminate, you will have to level the floor levels in the rooms with a plywood backing or even at the level of screed formation. The maximum height difference can be 1 mm.

- Different properties of materials. Some coatings expand when exposed to moisture or heat. There should be a technological gap between the two types of finishing - approximately 5-10 mm.

- Hygroscopicity of chipboard and fiberboard. The edges of such flooring are almost always treated with a sealant so that they do not absorb excess moisture during installation or subsequent use.

- Floor

The best options for combining laminate and tiles on the floor in different rooms (60 photos)

Joints with threshold

Thresholds are rigid or flexible slats of various profiles. Made from plastic, metal, rubber, solid wood or wood materials. The outer surface has different decorative coatings, so choosing the right option for the floor is easy.

Advantages of docking thresholds:

- due to wear resistance, they can be used in places with high traffic, while maintaining their appearance for a long time;

- there is no need to perfectly process the edges of the coatings before installation;

- you can cover gaps of uneven width and with a slight difference in height;

- Most profiles have a smooth or flat shape, making them safe to walk on.

Fastening can be carried out in an open or hidden way. In the first case, the threshold is screwed through the holes with self-tapping screws, which remain visible. In the second, the lower part is installed first, then the upper part is fixed to it.

How can you connect the transition?

To neatly design the gap between functional areas, four materials are most often used.

Grout

An easy way to seal winding, shallow seams. Such thresholds are difficult to find, and other fillers will not look so organic. Often in modern interiors there is an interesting way of finishing the floor: polygonal ceramic parts “incline” a little into an area with a different coating. This separates the hallway area from the rest of the house and the kitchen area from the living room. In this case, the transition is also carried out using grout. Do it in the following order:

- Carry out preparatory work.

- Treat the edges of the second material with silicone compound.

- Fill the resulting seam halfway with it.

- Wait for it to dry.

- Dilute the grout, spread it on top and level it with a spatula.

- Wipe the finished dried layer with a damp cloth and cover it with clear varnish to extend its service life.

Photo: Instagram @remont100lvl

- Decoration

Colored grout for tiles: 8 pros

Silicone and acrylic sealant

Joining two sections with elastic sealant is even easier than with grout. The advantage of the method is that there is no need to additionally treat the boards to protect them from moisture. But there is one point - you need to take into account that after drying the filler will turn light brown. The acrylic filler can be painted in a suitable shade after it has dried. Both expansion joints are suitable for renovation work in new buildings, as they are able to adapt to the shrinkage of the building.

Sequence of work:

- Place masking tape on both sides of the seam so you don’t have to waste time scrubbing it off later.

- Make a hole in the silicone paste tube so that it can be squeezed out, or insert it into a special gun.

- Fill the gap so that the sealant extends slightly above the floor surface.

- Use a spatula to remove excess mixture. If you don’t have a spatula, you can wait until the mixture dries and cut off the excess.

Keep in mind that it takes one or two days for the sealant to dry completely. Silicone expansion joints are recommended for use in rooms where the flooring is secured with glue or fasteners.

Photo: Instagram @42m2.ofhappiness

Photo: Instagram @42m2.ofhappiness

Photo: Instagram @42m2.ofhappiness

Photo: Instagram @prinesite_pechenki

Liquid plug

Liquid cork for laminate and tile joints is a moisture-resistant mixture of an adhesive base and cork chips. It has an unusual texture and looks good in seams no larger than 7 mm. On wide crossings it will look alien. This is a simple connection method for areas of any shape.

The hole that is filled with the mass is first cleaned of dust and degreased.

Rules for working with the mixture:

- The coating levels must match. If there is a slight difference, the glue is aligned along the higher edge.

- Do not let the cork get on the floor, as it is difficult to wipe off and, once dry, almost impossible. You can pre-coat the floor with oil or apply masking tape to it.

- The material must be sanded a day after pouring, until it hardens.

The layer turns out to be very durable and it is almost impossible to remove it.

Photo: Instagram @centraparketarf

Photo: Instagram @parquet_design

Cork compensator

One of the most popular ways to design boundaries between two floor coverings. The filler is a soft, pressed lath or whole sheets with the same characteristics. The compensator has several advantages:

- Possibility to choose the appropriate color.

- Ability to withstand building shrinkage and dimensional fluctuations of laminated strips.

- Suitable for wide seams.

- Looks beautiful in the interior.

For this material it is also desirable that both areas are at the same level. Otherwise, the result will not look aesthetically pleasing.

Sequence of working with the filler:

- Adjust the rail to the desired size or cut the part from the sheet.

- Apply adhesive to the entire width of the laminate or tile, and a thin layer of sealant to the bottom.

- Glue the compensator and cover it on top with an antiseptic and clear varnish.

- The rail can be tinted, but you need to take into account that it absorbs paint well and the color turns out saturated.

Photo: Instagram @centrpola.ru

Photo: Instagram @centrpola.ru

What do we end up with?

As the experiment shows: foam copes with prolonged exposure to moisture and does not allow it to pass through. But there is one BUT here. Polyurethane foam is exposed to ultraviolet radiation. When exposed to solar radiation, the foam loses its properties and turns into a kind of brown sponge. Therefore, builders say: under no circumstances should foam be left without sealing with mortar. Although foam copes with hermetic properties, but only when it is protected from exposure to UV radiation.

Some secrets of polyurethane foam:

If you are sealing joints and cracks with polyurethane foam to prevent moisture from entering, treat it with a solution, hiding it from exposure to the environment. Otherwise, it will not be polyurethane foam, but a substance that has lost its fastening and insulating properties.

How to join tiles and laminate flooring without a seam

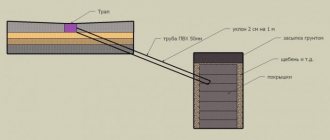

This method of joining is possible only if the two sections are perfectly aligned. Most often, this can only be done at the stage of housing construction, when workers are laying the screed. It is necessary to calculate in advance the height of the tile and the glue on which it will be attached. Then add the width of the parquet sheet, the backing underneath and the glue underneath. The resulting difference is equal to the difference between the screed levels. In addition, it is important to cut materials with pinpoint precision. It is very difficult to do this on your own.

Materials and tools

The required working set depends on what materials are selected and how the threshold will be installed. Both self-tapping screws and high-quality adhesives are suitable for wooden and plastic thresholds.

But the profile and retainer are not enough to perform installation work on joining tiles and laminate. The complete kit includes the following tools:

- Drawing supplies (pencil, ruler or tape measure) for leveling the edges of the flooring;

- An electric jigsaw or grinder with a disc or cutting blade that is coated with diamond (will protect the tile from chipping);

- A set of dowels and screws (at least one for every 10 cm) for fastening the thresholds;

- A screwdriver or drill with replaceable attachments for tightening screws;

- Phillips screwdriver to fit the thread size on the fastener;

- Rubber hammer. The usual one will not work - it can seriously damage the appearance of the flooring;

- For straight joints, you can use sealant or glue instead of screws.