The construction of a bathhouse requires a competent and responsible approach, because not only comfort, but also health, as well as the safety of the premises, depend on the result of the work.

In addition, one should take into account the material component, construction costs and the costs of further maintaining the building in working condition. It should be taken into account that these buildings are operated in conditions that are associated with sharp fluctuations in air temperature and regular exposure to large amounts of water and steam indoors.

Traditionally, Russian baths are built from wood, and wood is used for the construction of the main load-bearing structures, and as a finishing material, it is generally unrivaled.

Installation of the floor is an important stage in the construction of a bathhouse. This structural element experiences heavy mechanical loads and exposure to water during operation. Therefore, a competent choice of materials and correct installation will be the key to reliability, as well as convenience, when visiting the bathhouse.

The installation of floors should begin after all major construction work has been completed, including the installation of windows and doors.

Features of the problem

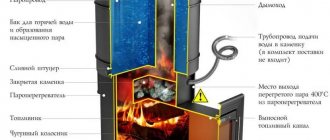

As you know, a Russian bathhouse consists of several standard rooms: a steam room, a washing room, a dressing room, a relaxation room, which have their own specific conditions. The most aggressive environment is present in the steam room. Here, high humidity is ensured (up to 60-65%) using water vapor heated to a temperature of 55-70 degrees. Below at floor level the temperature drops slightly (to 45-50 degrees), but heated water and steam condensate appear. To this should be added mechanical loads when moving participants in the bath procedure.

In a washing room, the main impact on a wooden floor is associated with flowing water (shower or dousing from containers), often mixed with detergents (soap, shampoo, etc.). In addition, clouds of steam may escape from the steam room. In the dressing room, problems are usually associated with the firebox of the sauna stove located here, in the area of which the material is heated. In addition, it is necessary to take into account temperature differences and dirt brought in with shoes. The most favorable conditions are provided in the relaxation room, where comfort and aesthetics come first.

The above analysis of bath conditions is important for developing an approach to choosing a flooring material. The fact is that different types of wood have different properties, and therefore the question of which board to make a floor in a bathhouse from has its own characteristics. When choosing a material, not only the dimensions that provide mechanical strength are important, but also the characteristics of the wood itself.

Preparing the foundation

First you need to carefully prepare the foundation.

At this stage, it is recommended to follow certain instructions:

- Floor joists are laid and fixed. It is best if the floor is made of larch in the bathhouse, but the more familiar pine is also suitable for this.

- Boards made of the above materials are attached on top.

- The lags must be laid out along the minimum distance between the walls, positioning them transversely to the direction in which the used water flows out.

- It is best to install support posts made of brick or wood under the joists so that the floors do not “walk” and are more rigid. For greater stability of the supporting elements, a reinforced concrete base can be installed under each, with an area slightly larger than the cross-section of the support.

In strip-type foundations, the upper support levels are adjusted to the top of the bath base; in other cases, the crowns of the embedded group are taken as supporting elements under the logs.

When placing the logs, it is necessary to maintain a slope in a certain direction in order to create the desired direction, guaranteeing the free flow of water. For this reason, it is best to place them with slight excesses, without adhering to the same size. When arranging a leaking structure, there is no need to maintain an inclined angle, because water will flow out through the cracks between the boards.

Choosing a wood species

Which board is best for a bathhouse floor?

On a note! When choosing a wood type, the following basic properties are taken into account: moisture resistance or degree of hygroscopicity, which is largely determined by the density of the structure; mechanical strength; tendency to deform when drying; presence of harmful resins.

The latter characteristic is especially important in a steam room, where under the influence of superheated steam at a sufficiently high temperature, resinous substances are released from the wood and inhaled by humans. In this regard, some coniferous trees containing large amounts of resins pose a danger to the body.

What board should I use for the floor in the bathhouse? The most commonly used tree species are:

1. Larch. It belongs to the coniferous species and has high strength and density. Essential oils contained in wood can have a healing effect, especially for disorders of the cardiovascular or immune system. The structure contains a natural antiseptic that combats microorganisms that cause rotting. Resinous substances are actively released at first, but later they stop evaporating. One of the main disadvantages is the high cost of the material.

2. Oak. This breed has unique strength, resistance to high temperatures and moisture, but it is used, as a rule, in the form of a finishing material. Oak flooring boards are not widely used due to their increased specific gravity, difficulty in processing, and tendency to crack due to temperature changes.

3. Cedar. It has a peculiar fibrous structure, which provides an important property: very low deformation and no cracking. There is practically no rotting of such wood, and the appearance is admirable. The advantages include increased heat capacity, which ensures long-term heat retention. The use of cedar boards is limited only by the high cost.

4. Pine. Main positive properties: low cost, ease of processing. Proper drying of wood eliminates the risk of cracking and deformation. Main disadvantage: low resistance to rotting. Fungi and various microorganisms actively develop in pine products. When deciding which board to lay the floor in a bathhouse, pine floorboards are most often rejected. At the same time, pine is widely used as joists, intermediate and supporting elements of wooden floors.

5. Linden. The classic Russian bathhouse was always based on this type of wood. It has healing properties, and the texture creates a unique decor. As a floor board, its use is limited by such negative aspects as low heat capacity (a fairly cold surface) and a high tendency to rot, which requires careful processing.

6. Aspen. It is in many ways similar to linden. It has a relatively low cost and is easy to process. The main disadvantage: it begins to darken when exposed to high temperatures.

Summarizing the arguments presented in favor of a particular type of wood, it should be noted that the question of what boards are needed for the floor in a bathhouse is decided by financial capabilities and in which bathhouse room the flooring is being built.

On a note! Larch looks the most attractive, but when saving money, pine boards are still more often used.

Plank flooring is ideal for a bathhouse

Wood in bathhouse decoration is one of the most common environmentally friendly materials. Has unique thermal insulation properties. In addition, preference is given to wood for its natural aroma, which is most pronounced in conditions of high temperatures and high humidity, and the abundant release of active phytoncides and other beneficial substances imparts healing and health-improving properties, which are very beneficial for the human body.

But wood can be very vulnerable: constant temperature changes and high humidity create conditions for the material to rot and for the appearance and proliferation of various destructive microorganisms. Therefore, the choice of floorboards should be made according to several criteria, of which price, although it may be decisive, is often not the most important.

What is taken into account when preparing material

In addition to the choice of wood species, other characteristics also play an important role. First of all, it is necessary to take into account quality indicators:

- Grooved board. For the floor in the bathhouse, a regular or tongue-and-groove board can be used. The difference lies in the formation of the end. In the tongue-and-groove version, a longitudinal tenon is formed on one side, and a corresponding groove is formed on the other. As a result of the use of such products, a locking connection is provided, which makes it possible to tightly fit and create a leak-proof floor covering. Naturally, profiled boards have a higher cost, but the quality of the floor also increases significantly.

- Humidity. A very important parameter for any wood is the presence of residual moisture in the structure of the material. For the floor it is necessary to use only well-dried products, i.e. with minimal humidity. Wet wood will warp as it dries, causing an uneven surface. The optimal humidity value is considered to be within 7-9%, at least not more than 12-13%.

- Dimensions. The thickness of the board for the bath floor ensures its mechanical strength. In principle, it significantly depends on the properties of the wood, i.e. depending on the type of tree. So, when using an oak board, a thickness of 20-25 mm is sufficient; to ensure the same strength, a pine board with a thickness of 40-45 mm is required. Typical tongue and groove boards are offered in thicknesses ranging from 27-37 mm. The choice of this parameter is determined by real loads taking into account the area of the room.

On a note! The width of the board also affects the reliability of the flooring and the likelihood of deformation. The narrower it is, the lower the risk of its curvature in cross section.

The most commonly used board is 10 cm wide. If you use well-dried material, you can safely choose a width of about 17-20 cm.

Joists and flooring

Leaky flooring types are installed quickly and easily. The first board is rigidly attached to the wall with nails, and the rest are laid relative to the first in increments of 40 mm, which allows for sufficient gaps for water to drain out. This design does not require a specific method of laying joists, so you can start laying them from any wall.

A non-leakage floor requires a slight slope in the direction where the water drain is located. The installation of a leak-proof structure begins with a rough flooring, to which an insulation cushion is attached, including systems of vapor barrier, waterproofing and thermal insulation layers. A finishing coating is laid on top. These should be tightly fitted edged or tongue-and-groove boards, which are secured with nails or cap screws.

Specific Features

The quality of plank flooring in a bathhouse and its reliability depend on the following nuances:

- Carrying out acclimatization. If we are making a floor in a bathhouse from boards, regardless of the type of wood, it is recommended that the material be given the opportunity to acclimatize to the conditions where it will be located. To do this, the boards should be brought into the bathhouse at normal humidity and temperature and left for 3-5 days.

- Method of fastening the plank covering. It is customary to attach ordinary boards to the joists with nails or self-tapping screws at right angles. The caps of fasteners must be recessed into the wood. A tongue and groove board can be fastened along a tenon, which makes it possible to remove the head from the surface. Wide boards (more than 14-15 cm) will additionally have to be secured in the middle.

- Treatment. Any wood, even larch or oak, requires impregnation with a special antiseptic to prevent the activity of fungi and other microorganisms that cause rotting. All wooden parts are subjected to impregnation - both internal (joists, supports, sheathing) and finished floor boards. At the same time, modern compositions may include additives that change the tinting of wood for decorative purposes.

Underground

The choice of floor type and drainage of water in a bathhouse with wooden floors depends on the composition of the soil. If it easily absorbs water, like sandstones or sandy loams, then the issue will be resolved with little effort. It is enough to dig a hole and fill it with filtration materials. The filter can be ordinary crushed stone. Water will break against it and quickly seep to the drainage layer.

Clay rocks almost do not allow water to pass through. In this case, a hydraulic structure is installed in the underground from a tank and pipes leading into the pit. Water can drain by gravity or under the influence of auxiliary elements fixed in the structure.

For a non-leakage floor, drainage of drainage water is arranged in the underground, for which a hydraulic structure is used. Also of particular importance is the arrangement of floor ventilation, built on the presence of gaps and holes.

Technological features

Bath floor: which boards to use is only the first question. The next task is to choose its design. In practice, 2 options are used:

- Leaking variety. In it, the boards are laid with a gap through which free flow of water from the floor surface is ensured. This lattice system is considered traditional for a Russian bath. The drainage in such a design is produced directly into the ground under the bathhouse or collected underground by a drainage system and then discharged into special collectors outside the building.

- Leak-proof design. In this case, the boards fit tightly to each other, and additional waterproofing is provided to prevent water from seeping through the flooring. For such a system, tongue and groove boards are most suitable. The water drains through special drain holes, and the floor itself is made with a slope in the direction of these holes.

Thus, the question of how to lay the floor in a bathhouse from boards is decided taking into account the choice of design. In other words, the boards can be installed with a gap of 2-5 mm or fitted closely, sealing the joints.

Structurally, both options differ precisely in the way the boards are placed. The structure of the wooden floor itself is similar. Its installation is carried out in the following order:

- Leveling and compacting the soil. Backfill the cushion with sand and crushed stone with a compaction 10-12 cm thick.

- Laying roofing felt waterproofing.

- Installation of logs from wooden beams measuring at least 40x40 cm. The installation step is 40-65 cm, depending on the size of the room. Installation is carried out with the formation of a slope towards the drain holes.

- Laying or backfilling thermal insulation between joists. Expanded clay is usually used for this purpose, but mineral wool also works well. Do not use foam that can release harmful substances when heated. Then another layer of waterproofing and a vapor barrier with a foil layer are laid (for the steam room).

- After completing the formation of the base of the floor, rough flooring from boards can be applied, which increases the strength of the structure. However, this element is optional. In principle, the finishing board covering can also be attached directly to the joists.

The floor in a bathhouse made of boards has long been considered a traditional design. If all work is carried out correctly and protective measures are taken, it can serve for a long time even in extreme steam room conditions. It is important to choose the right type of wood and carry out the necessary preparatory work.

Racks

The first thing you will need to install wooden flooring yourself is joists and beams. The optimal size is 150x150 mm. This is the supporting floor onto which the decking is attached. The lags are laid on supports in the form of brick or reinforced concrete columns. The thickness of the posts should be more than 150 mm, which allows you to get a slightly larger area under the joists.

The height of the racks must correspond to the top line of the foundation if using the strip option. A columnar foundation or on screw piles requires laying the logs at the same level with the embedded crown so that the upper horizon of the beams coincides with the upper line of the supports.

Before installation, all wooden elements are treated with protective agents, including an antiseptic. Only after this the waterproofing is laid with roofing felt, roofing felt, bitumen or glassine.

Advantages of working with our company

We do it on time or for free. Construction is divided into stages with a specified completion date. "Full construction". All work is done by one company. Possibility of accepting payments in installments or on credit. No hidden fees. The price is final at the contract stage. Quality control is carried out at every stage of house construction by our competent services. Thanks to high-quality construction work. We have more than 300 successfully completed projects. Delivery of materials within 200 km from the Ring Road for freeGet a free estimateBriefly about the main thing

In the bathhouse, two building materials are used to form the floors: wood or concrete.

If boards are selected, then the floor can be assembled as a continuous covering or laid with a gap.

If concrete is chosen, it is better to insulate the floor using expanded clay or slab material in the form of penoplex. You can install a “warm floor” system.

If you decide to lay a wooden leaky floor, then underneath it you will need to organize either a drain towards the cesspool, or make a drainage layer of crushed stone.

Concrete floors are stronger, more durable, but much more expensive than wood.

Ratings 0