To ensure reliable removal of combustion products outside the house, you need a high-quality chimney. For its installation, a special sandwich pipe is used, which has a number of effective characteristics that allow its operation at high temperatures.

Sandwich pipe chimney

To install it, various methods are used to ensure a safe transition from a brick stove or fireplace pipe to a metal sandwich pipe. You can use industrial adapters or build a chimney yourself.

Transitioning from a brick pipe to a single steel pipe and a “sandwich”: how it’s done

A Russian stove, with crackling firewood inside, is a symbol of good family traditions and comfort. Masters of their craft passed on the art of laying brick chimneys to new generations. Modern building materials and technologies make it possible to install chimneys that can resist corrosion. So, for example, when it becomes necessary to replace the upper part of the chimney structure, a transition is made from a brick pipe to a sandwich.

Switching from a brick duct to a metal one may be necessary when installing a new chimney or when repairing an old one

Brief conclusion

The stove in the house performs a number of important functions. The heating system must be cleaned of combustion products in a timely manner. The modern building materials market offers a wide range of alternative elements for chimney systems. Often the usual masonry is combined with lighter sandwich pipes. In this case, it is important to connect the two elements hermetically using one of the transition methods, observing building codes and regulations. Don't forget about safety. Smoke flows must be freely removed from the system.

Pros and cons of sandwich pipes

They produce ready-made chimney installations from stainless steel. In order to prevent the formation of condensation, basalt insulation is attached between two metal layers. The main disadvantage of the chimney blank is its relatively high cost. The tightness of the system for removing combustion products from the furnace may be compromised. Main advantages of sandwich pipes:

- ease;

- resistance to environmental influences;

- multi-layer structure, preventing the accumulation of moisture and combustion products;

- high temperature resistance;

- quick installation;

- do not deform when exposed to chemicals;

- rarely get dirty.

A metal chimney pipe can be installed for all types of stoves and boilers.

Brick chimney design

The power of the stove is directly related to the cross-sectional size of the chimney duct:

For small stoves, a square section with an edge of 120-150 mm will be sufficient.

Most often, this is a channel that has four bricks in a row, so the size of this section is often called a four; For a bathhouse of 15-20 cubic meters or a fireplace, you will need a chimney with a cross-section of “five” or 125x250 mm. When laying, five bricks are placed in a row; For Russian stoves and large sauna heaters, use the “sixth” size with a channel of 250x250 mm. This is a very large cross-section, and should only be used for low-lying pipes or a very large furnace firebox.

Structurally, the laying of a chimney is no different from the laying of the stove itself. The only area that requires the hands and skill of a professional is the top pipe. At this point you need to properly bandage the brick being laid. For a simple tower chimney structure, the pipe can be made of alloy metal and connected to the main brick duct, as shown in the figure.

How to make the transition without an industrial adapter?

It is possible to ensure a safe transition without a special adapter, however, this may take longer. The chimney is arranged as follows:

- Pour a round hole in the brick pipe. You need to ensure that its diameter is slightly larger than the diameter of the inner cape of the sandwich pipe.

- The inner part of the structure is inserted into the resulting hole. It is better to seal the gaps that have formed at the joints with oven mortar or non-flammable sealant.

- The outer casing must rest on the brickwork. The junction also needs to be sealed.

- Install the chimney system along its entire length, inserting its elements one into the other.

- Secure the sandwich pipe using cut-offs and self-tapping screws in the places where it passes through the roof. Fixation of the structure should be carried out with a plumb orientation.

Adapters allow you to reduce the labor intensity of the process and make the transition point more reliable.

Whatever installation method is chosen, to ensure the chimney has good draft and safety, you need to use a sealant.

How to make a transition using a steel platform with a pipe

This method combines the advantages of the two previous methods, as it allows you to equip a chimney without a special adapter, and get rid of the labor-intensive filling of a brick opening.

Place of transition to sandwich pipe

Installation includes the following steps:

- Cut a platform from a metal plate so that its size matches the size of the brick part. It is better that the plate does not extend beyond its edges.

- Mark the places where the platform will be attached to the brick opening. You need to make sure that the fasteners are not located on the seams or on the edges of the brick.

- In the designated places of the sheet you need to make holes for self-tapping screws, and in the brickwork - holes for dowels.

- Insert the dowels into the holes made.

- Apply fireproof, silicone sealant to the surface of the brickwork.

- Place the metal platform on the sealant layer.

- Pull it evenly to the surface of the brick using self-tapping screws.

- After the sealant has dried, proceed with the installation of the air exhaust system from a sandwich pipe.

Approximate cost of work

The cost of installation work for installing a sandwich depends on:

- length of the assembly channel;

- height of the house;

- type of roofing;

- roof configurations.

Thus, the fee for a standard installation of a chimney for a private house with a roof ridge height of up to 6 m will be from 26 thousand rubles. As a rule, the price is clarified by the master directly on the spot.

Often the installation price is set per linear meter, on average from 1,700 rubles per linear meter.

Options for connecting a brick chimney to a sandwich pipe

According to fire safety regulations, the connection between a brick chimney and a sandwich duct must be sealed and well insulated. This transition can be mounted using several different devices.

With adapter

The easiest way to install a transition from a brick pipe to an iron pipe is to use a ready-made metal adapter. Its lower part is square, corresponding to the standard dimensions of a brick channel. The top one is round, the diameter of a sandwich. The finished adapter is already filled with a reliable heat insulator and complies with all fire safety rules and requirements.

The square part is installed on a brick section so that the masonry is inside the box. The remaining gaps are filled with building material for masonry

The sandwich pipe is mounted on top, also inserting it inside the adapter. The gap is sealed with sealant and further strengthened with a tightening clamp.

Without adapter

The transition without using a ready-made adapter is carried out by installing a metal platform on the brick part of the chimney. The dimensions of the platform are exactly along the outer edge of the brick channel section.

A hole is cut out in the center of the metal platform equal to the outer diameter of the sandwich pipe into which it is inserted.

The platform should be firmly fixed to the top of the brickwork. To do this, holes are prepared in the metal for self-tapping screws. Holes for dowels are drilled in the brick, symmetrically. Before fastening, the platform is coated with oven sealant and laid on the brick. Secure with self-tapping screws.

Installation using a factory blank

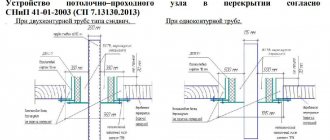

The sandwich chimney is mounted on a special cylindrical adapter with a rectangular base. This blank is installed on a brick pipe to ensure the tightness of the structure. The butt joint is made from fire-resistant stainless steel. To prevent moisture accumulation, heat-resistant basalt insulation is installed inside the adapter. Installation of a butt blank consists of the following steps:

- Mount one adapter on the ceiling above the chimney masonry.

- Attach the second element to the attic floor.

- Build an installation platform and secure clamps if you need to switch from a square section to a round one.

- Install pipes. Building codes allow a slight immersion of the sandwich blank inside a brick pipe.

- Seal the seams with sealing mortar.

Pipe head protection

Over time, a brick pipe is destroyed by temperature changes and precipitation. Our products help to protect and sometimes restore it - a chimney and a cover for the pipe:

The main functions of the chimney smoker:

- Protection against precipitation and debris getting into the pipe

- Protection from birds (they can make a nest in the pipe)

- Increased traction

- Protecting the chimney from destruction.

In addition, the chimney on the roof is simply beautiful - forming a single whole with the roof, the chimney gives the pipe a finished look.

Main types of stove chimneys

All chimneys can be divided based on the material from which they are made. Currently used:

- brick chimney. The main advantages of such chimney ducts are high fire resistance and a long service life. The main disadvantages of a brick chimney include the roughness of the internal surface, on which a large amount of foreign substances accumulate, and the need to install a separate foundation. The accumulation of substances affects the frequency of chimney cleaning, and an additional foundation increases the cost of installing the system;

View of a finished brick chimney

- iron chimney. It is most susceptible to corrosion and therefore requires additional protection. The design is quite light and cheap. It does not require a separate foundation. Builders most often use chimneys made from stainless steel and assembled into modules. Otherwise, such pipes are called sandwich. Sandwich pipes are assembled from two layers of metal, and non-flammable insulation, for example, basalt wool, is laid between them;

View of a finished chimney made from sandwich pipes

- stove chimney made of ceramic pipes. It is heavy and requires the installation of an additional foundation. However, ceramic pipes are heat-resistant and durable. From such pipes it is possible to construct both internal and external chimneys;

External chimney made of ceramic pipes

- chimneys made of polymer pipes. They are characterized by durability, low cost and ease of installation. Most often, polymer chimneys are covered with decorative overlays, for example, made of brick.

Polymer chimney decorated with brickwork

The choice of material for the chimney is determined by the characteristics of the heating device and the desire of the owner.

Expert advice

The design must include tees and plugs for collecting condensate and checking the chimney.

If the roof is made of flammable materials, it is mandatory to install a spark arrestor with a fine mesh.

When the head rises more than 1.5 meters above the roof, the chimney is additionally secured with braces.

Step-by-step DIY connection technique

When deciding how to install a metal pipe with insulation with your own hands, the condition of the existing brick structure is assessed. If signs of destruction are visible, it is recommended to dismantle it. When you plan to install a metal product using the fitting method, it is necessary not only to dismantle the collapsing section of the chimney, but also to build a new structure afterwards.

Required tools and materials

To work you will need:

- perforator;

- chisel;

- sledgehammer;

- Circular Saw;

- fireproof mixture;

- sealant;

- screwdriver;

- self-tapping screws;

- Master OK.

Installation rules are followed, and components are selected taking into account the chosen mounting method.

Work progress

After dismantling the old structure, a new brick superstructure is erected on the roof. To fix the steel product in the ceiling, a through-type pipe is used. The transition of a brick pipe into a sandwich is made using a sealing material. In this case, a reinforcing platform is used, it is secured with self-tapping screws. Special clamps are used to connect sections of metal pipelines.

Installation features

When you plan to disassemble the chimney close to the stove, then in order to avoid overheating, a thick-walled stainless steel pipe should be used as the first link of the transition structure. There should be no insulation inside. Installing a sandwich pipe can lead to through burning of the metal.

To properly assemble the chimney, it is necessary to carry out the installation sequentially. During the completion of the work, a cap is installed on top of the metal pipe. However, the deflector causes a lot of controversy regarding the installation of this element on top of the sandwich pipe. This measure helps to increase traction. However, an earlier version of the regulatory documentation mentions a ban on the use of such products when installed on chimneys. This is due to a decrease in the pipe lumen and accelerated formation of a soot layer on structural elements.