Chimney lining is carried out in cases where the previously built brick chimney of a stove or fireplace began to lose its throughput, often becoming clogged with combustion products. At the same time, the draft is significantly reduced, due to which smoke periodically fills the rooms of the house, and the heating efficiency sharply decreases.

Chimney lining

There are several ways to solve this problem. But one of the most effective is to “ennoble” the internal surfaces of the brick walls of the chimney shaft with special liners. These sleeves have smooth internal surfaces, so that smoke does not encounter obstacles and does not linger in the channels. It smoothly “slides” along the smooth walls, coming out, while leaving virtually no fuel combustion products on the surface of the liner.

Types of lining

Lining with a sandwich pipe

The principle of behavior of lined liners and their placement in the channel is the same, but the sleeves differ in material, so there are certain nuances for each type.

Specialized stores offer inserts:

- made of polymers;

- of steel;

- from corrugated pipe;

- polymer sleeve;

- made of stainless steel.

Polymer sleeves

A plastic pipe is installed inside the operated chimney. PVC products are reinforced with fiberglass fabric and, when heated, acquire plasticity. As a result of this property, irregularities and spaces on the clinker surface are filled. After hardening, the internal area becomes smooth, and the wall has a thickness of 2 cm.

The downside of the application is the temperature limitation. Lining a chimney made of brick with plastic is done with exhaust flows up to +250°C, so they are installed to work with low-power units.

Application of steel elements

Corrugated pipe lining

A structure made of a rolled pipe is placed in the straight section of the chimney, or rectangular, square, oval and round shapes are made with your own hands. Sheets are taken with a thickness of 0.5 to 1.5 mm. In channels made of steel materials, it is possible to provide the required modules for cleaning, inspection, and containers for accumulating condensate in accordance with the standards.

Steel products are used for fireplaces using various types of fuel. The material resists acids and is not subject to plaque deposits. The disadvantage is that only straight sections can be lined with this method; winding pipelines cannot be equipped.

Using corrugated pipe

Manufactured using various types of stainless steel, the pipe shells are made of two layers. The positive thing is that flexible liners are used for complex channels with turns. The products do not require connecting elements. Double-layer inserts significantly reduce the diameter of the air duct; this must be remembered when choosing.

Polymer sleeve

Polymer sleeve for chimney lining

The sleeve is made of copolymer resin and reinforced with fiberglass. The insert is used to combat condensate drops; it is used to treat low-temperature chimneys and those coming from powerful boilers.

Types of polymer products:

- Fitfire is a liner containing two layers, the maximum element has a length of 60 m. After installation, the chimney duct has a diameter of 80 - 500 mm. The manufacturer specifies a service life of 50 years; the hose is used to remove low-heat gases.

- Fitfire HT 1000 is used in pipelines of sauna and fireplace hearths with high smoke heating. The sleeve consists of three layers, the middle one is a reinforcing mesh.

When lining the chimney with a polymer sleeve, the internal protection is obtained without seams, with a smooth surface.

Stainless steel pipe

The material is one of the most popular types. The products work for many years and do not deform due to high temperatures or corrosion. Lining a brick chimney with a stainless pipe is often used because... There is a large assortment of ready-made inserts for sale, sometimes products are made by hand, taking into account the dimensions.

The inserts are made from stainless steel sheets with a thickness of 0.8 - 1.5 mm. To connect and turn the channel, standard tees and pipes are used, but to install them you need to know the exact layout of the chimneys. Sleeves with a rectangular cross-section are installed only on straight sections of chimneys.

General description: what is Furanflex?

To understand what Furanflex is, let's start from the very beginning. A chimney is a duct (pipe) that runs from a stove, fireplace or boiler through all of these to the top and out through the roof. Very often the chimney duct is made of brick.

A sleeve (sleeving) is an insertion of a pipe made of a different material into a brick chimney. At the exit we have a pipe in a pipe, and in this case the smoke will not come into contact with the brickwork, but with an additional pipe placed (a sleeve, which is usually made of ceramics, steel and a polymer sleeve).

Pipe lining with Furanflex

A correctly installed sleeve protects the chimney channel from fouling with soot, and also protects from condensation and exposure to high temperatures. As a result, the service life of the channel is significantly extended, and the likelihood of its breakdowns and blockages is reduced.

During installation, it is unwound, lowered into the chimney channel, straightened along the entire length and secured at the top (at the pipe outlet) and at the bottom (at the place of attachment to the stove). Next, a plug is placed on the hose from below (it is blocked), and a special installation is connected from above, through which hot steam is supplied to the hose.

Under steam pressure, the hose expands along its entire length, pressing against the walls of the air duct. Under the influence of temperatures, the sleeve becomes elastic and is then glued to the brickwork, at which point the installation process ends. At the same time, both fireplace and stove chimneys can be lined in this way.

Where and what is it used for?

Furanflex is used for lining, that is, to protect the main chimney channel. Moreover, even if the protective liner fails, replacing it is both cheaper and easier than replacing the main chimney duct.

The use of Furanflex is justified in the following cases:

- To protect the smoke channel during its construction.

- To protect an existing smoke channel.

- To restore a smoke duct that has become unusable (and it usually doesn’t matter what exact reason led to the failure of the smoke duct).

Typically, lining in this way is used for lining chimneys located in low-rise private buildings. Somewhat less often - for channels located in baths or saunas. But there is no prohibition on the use of this technique for chimneys in industrial systems.

Material and characteristics

The Furanflex protective sleeve consists of several structural elements (layers or segments), so it makes sense to consider them all.

Sleeve segments:

- internal segment - made of thermoplastic polyethylene, used exclusively at the installation stage and used to hold the middle layer (segment) - after installation it is immediately removed from the channel;

- middle segment - made of thermosetting polymer resin using fiberglass (330 g per square meter), and there are usually several layers of fiberglass (about four);

- outer segment - made of polyester fabric (if we are talking about Furanflex Black or Ventiflex), or from fiberglass with Kevlar reinforcement (if we are talking about Furanflex RVW).

General information about Furanflex material

Product Specifications:

- Basic length: up to 30 meters.

- Basic sleeve diameter: from 60 to 1000 millimeters.

- Wall thickness: from 2 to 3 millimeters.

- Tensile strength: exceeds 400 N/mm.

- Maximum smoke temperature (with prolonged exposure): up to +250 degrees (if we are talking about Furanflex Black), or up to +700 degrees (if we are talking about Furanflex RVW). One-time short-term temperature rises up to +500 for the Black model and up to +1000 for the RVW model are allowed.

- Maximum channel bend angle: 45 degrees.

- Minimum ambient temperature: no more than -50 degrees.

- Service life: from 10 to 30 years with proper installation and subsequent operation.

Briefly about the manufacturer

The Furanflex company is based in the Russian Federation, and its products are aimed specifically at the CIS market. The company has a representative office in Ukraine.

Considering that the described products are rare in the construction market of the CIS countries and the choice of them is small, the Furanflex company can be called a fairly large manufacturing company of such devices. This is the largest manufacturer of chimney hoses and the most popular in Ukraine, Russia and Belarus.

What is lining a brick chimney?

During the operation of brick chimney channels, soot accumulates in them, which affects the deterioration of draft in the system. Brick chimneys have rather rough walls, so they are prone to soot accumulation. Brick communications for the removal of combustion products are easily destroyed due to various negative factors affecting them. Consider these factors:

- temperature changes;

- condensation that appears due to temperature differences during operation of brick chimneys;

- aggressive chemical compounds contained in smoke.

As a result of the accumulation of soot, the draft in the system deteriorates, which, in turn, affects the performance of the heating structure. As a result, a reverse draft effect may occur, which will lead to smoke in residential premises.

This effect poses a great danger to the health and life of the owners of the house, therefore, to ensure safety, it is very important to carry out preventive checks and cleaning measures on time

Installing a liner in a chimney does not entail the same costs as completely replacing the chimney

There are two main ways to solve the problem of soot formation in a brick chimney duct:

- chimney lining;

- complete dismantling of the old channel and installation of a new chimney communication.

Since the second option is much more labor-intensive and entails large financial costs, many people line the chimney.

Is there a need for a sleeve?

It is better to install the sleeve during the construction phase of the building. The insert is bricked up as the shaft is laid out from brick. If you didn’t do this initially, you will have to return to the process over time. Cladding a completed house is more difficult. We will have to partially destroy the masonry, break the decorative cladding and restore everything again.

The urgent need for lining brick chimneys is caused by the following reasons:

- Initially, the combustion product removal system was designed and built with errors;

- constant use of a fireplace or stove connected to a brick chimney is assumed;

- long channel length;

- if according to the project the mine should be lined, but this was not done;

- the shaft passes through a cold attic and due to the temperature difference, condensation forms;

- the chimney is made of brick inside the outer wall of the building;

- condensation streaks appear from the seams of the brickwork of the shaft;

- depressurization of the smoke channel;

- the shaft quickly becomes clogged with soot and requires frequent cleaning;

- The smoke exhaust passages were laid not by professional stove makers, but by inexperienced masons.

In all other cases, the owner performs the sleeve at his own request.

Main rules for lining

Lining a brick chimney with a stainless pipe is not such a complicated process. But let's talk about everything in order:

So, as a rule, this method is used to smoothly restore the removal of processed gases. This is especially true when the owners do not have the opportunity to remodel the entire chimney duct.

There are two sleeve methods:

- Stainless steel sleeve;

- Liner using the FuranFlex system (here a special polymer liner is used, which is “blown” into the chimney, and which, when hardened, becomes a new chimney).

https://youtube.com/watch?v=VAFq-N889jY

Key mistakes when lining

The main mistakes include:

- Partial liner (not along the full length of the shaft).

- Using a knee instead of a special support element.

- Crumpling of the edges of pipes (if we are talking about stainless steel) during transportation, connection (of segments to each other) or lowering into the shaft.

- Jerks of the cable when lowering the sleeve.

- Narrowing of diameter.

- Too sharp turns (if we are talking about a polymer liner).

- Use of bulk thermal insulation (between the sleeve and the brick shaft).

- The absence of a U-shaped water seal - if the condensate is discharged directly through the hose into the sewer.

Please note: every mistake is quite serious. If you allow them, you can complicate your task in the future (if you need to replace the liner), or worsen the operation of the boiler.

Let's rationalize heating: how to use a heat exchanger on a chimney, and how is it useful?

How to clean soot from a chimney using potato peelings?

Related Posts

Work rules

In this article we will look at how chimney lining should be done. This is not very difficult, but necessary work. As a rule, chimney lining is used to restore the unhindered removal of exhaust gases when it is not possible to redo the entire chimney duct. The chimney liner can be made in two ways:

- installation of steel sleeves (preferably stainless);

- use of the FuranFlex

, which is suitable only for gas boilers with low combustion product exit temperatures.

Preliminary work

Additional measures before chimney liner:

- Identify all damage, including brickwork. Check the strength of the entire structure.

- Inspect for tightness and integrity, the degree of clogging of the chimney.

- Inspect the cross-section of the pipe and the absence of any obstacles along the entire length of the channel.

- Determine the cross-section of the pipe and compatibility with the intended sleeve so that the chimney itself does not narrow.

- Before carrying out, determine the complete design of the future sleeve.

- Provide free access to the work site.

When carrying out pipe laying work, you must:

- Dismantle the brick wall of the channel in the place where the heat generator will be installed. The length of the disassembled surface must correspond to the length of the elements that ensure the collection of condensate, provide for the installation of a hatch for cleaning and a smoke exhaust pipe.

- Install the specified elements in the channel (see).

- Attach ropes of the required length that have sufficient strength to the straight part of the pipe (which has hooks).

- Place the inserted pipe in the brick channel at a height so that it is possible to insert another nozzle.

- Lowering the rope, fasten the following pipes until the channel distance is completely covered.

- Fill the voids between the pipes and the walls of the brick channel with non-combustible heat-insulating material.

- Install the pipe on the head of the brick channel. Attach an umbrella to protect from precipitation.

- Make a brick backfill for the dismantled chimney opening.

Lining with flexible stainless pipe

The chimney can also be lined with a flexible stainless pipe. True, this will not be the best option. This pipe has its disadvantages:

- the corrugated surface does not interfere, but helps the accumulation of condensation and soot;

- small wall thickness reduces the service life of the structure.

So it's not ideal.

They also line the inner surface of the channel with a fire-resistant mixture

. It fills all the cracks and levels the brick surface of the chimney. In this case, the channel practically does not decrease.

If the height of the chimney duct is high, a technological hole is made in its lower part, which is laid after finishing the lining work. The cost of such work will be significantly lower than lining, but will never guarantee good tightness of the channel.

The simplest option is to install a liner during the installation of the chimney, during the construction process. This will increase the reliability of the channel at no additional cost. But many do not take this issue into account during the construction process, and this is a significant mistake.

These problems in brick houses are completely solvable. Remember, the safety of your home and the health of your family depend on the proper operation of the chimney.

During the operation of chimneys, you may encounter the problem of deposition of combustion products, or simply soot, on its walls.

A bathhouse in which cracks appear in the chimney, or, worse, partial destruction, ceases to meet fire safety requirements.

This can happen due to improper use, errors in choosing the material from which it is made, or deviations from building codes during its construction.

Another of the most common signs of malfunctioning chimneys is the appearance of “backdraft”, which is not just annoying, but deadly due to possible carbon monoxide poisoning.

System calculation rules

The purpose of their implementation is to select the optimal height and cross-section of the gas exhaust channel to ensure effective traction. The last characteristic is very important. If possible, it is best to have professional calculations done. If not, you can use averages. There are three main sizes that are widely used:

- Six. This is a square-shaped pipe having a row of six blocks. The dimensions of the internal channel are 250x250 mm. Used for Russian stoves and fireplaces, where minimal resistance to the flow of heated gases is required.

- Five. The chimney with a rectangular cross-section is formed by five elements. Section 125x250 mm. It is used for heating and cooking-heating devices.

- Four. A structure made of four bricks in a row. Size - 125x125 mm. Installed for low-power solid fuel boilers and kitchen stoves.

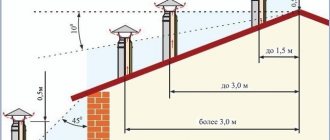

When choosing the height of a future structure, the following standards should be taken into account:

- If the roof covering is fire hazardous, the structure is placed at least 150 cm above it. For non-flammable materials, this value is 50 cm.

- The minimum distance between the grate head and the grate is 500 cm.

- When constructing a chimney on a ridge or at a distance of no more than 150 cm from it, the height of the part is 50 cm above the roof level.

- When installing a structure at a distance of 150 to 300 cm from the ridge part, its length is equal to the height of the ridge.

- If the structure is further than 300 cm from the ridge, it is allowed to be built below it. But the line drawn conditionally through the ridge and deflector should have a slope of 10°.

Causes and consequences of chimney pipe destruction

Artificial destruction may include: poor-quality illiterate masonry; low-grade materials used in the work; improper operation; low qualification of the stove master; non-compliance with the rules and construction plans.

This chimney is in need of repair.

If work is carried out incorrectly, condensation may form in the chimney pipe, and with temperature changes and freezing of water, ice will rupture the mortar in the masonry and destroy the bricks. After such processes, it is possible that the draft may be disrupted, which means that it will be impossible to light a fireplace or stove, since the smoke will not go up the chimney, but will go into the room.

Obvious delamination of low-quality bricks

If low-quality or untempered brick is used, it can be damaged by sparks or ignition of gases emanating from the firebox. In the future, these destructions can lead to damage to the entire stove heating system or even to a fire.

Repair of a brick chimney is carried out in cases where it is damaged for other reasons - for example, due to the consequences of natural phenomena or mechanical impact, which led to a violation of the integrity and solidity of the masonry.

Fatal effects of time and nature

Natural causes of destruction include the above-mentioned long-term use, and, as a consequence, the general aging of the structure.

Requirements for the exhaust duct

Good traction is maintained due to the tightness of the structure, as well as the condition of low soot accumulation and condensation formation. These parameters are the basic requirement for all chimneys. It is important to correctly calculate the cross-section so that there is no smoke inside the room.

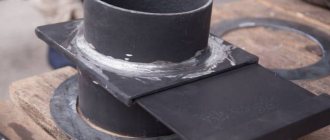

Stage 3. Head construction

After the main installation work on lining the chimney with your own hands, we proceed to the design of the mouth of the lined chimney. This process requires adherence to the following rules:

- The sleeve/case insert must rise above the smoke shaft;

- A cover plate should be installed around the sleeve that protrudes (if there is none, a tile is made of metal or of cement-sand mortar with a slope away from the pipe itself);

- It is necessary to install a cuff near the pipe to prevent moisture from getting between the pipe and the shaft. Or arrange a mortar ledge with a gap for expansions;

- The direction of the pipe mouth is vertical, cut is horizontal;

- The protruding part above the roof and in the attic must be thermally insulated;

- It is advisable to install an umbrella that will prevent precipitation from entering the pipe (which is especially important when the condensate drain is not connected to the sewer);

- To increase the height of the pipe and further design it, it is better to use sandwich pipes with factory-made parts;

- Thermal insulation of sleeves should not be carried out with bulk materials, this is not permissible;

- To make ventilation channels, a cuff with a cone is used, or vents are made in the surfaces of the shaft (side), below the cover plate.

How to liner

Progress:

- First, the lower section of the chimney, which is connected to the boiler, is dismantled to install a tee with compartments for condensate outlet and monitoring the operation of the system.

- A rope is attached to the mouth of the pipe to lift and lower the sleeve; the work will go faster if the rope is secured on both sides.

- The complete structure of individual elements is assembled on the ground, then tied with strong ropes and lifted to the roof and lowered into the chimney.

- The sleeve is laid to the height of the shaft so that the top rises above its mouth.

- The empty space between the outer side of the sleeve and the chimney is filled with non-combustible material, basalt wool is suitable.

- After installation, the edge of the pipe is covered with a cap or a horizontal pipe is installed, this will prevent precipitation from getting inside.

- All elongated bricks are inserted into place.

In principle, installation is not difficult, but if you do not have confidence in your abilities, so as not to create an emergency situation, it is better to invite a specialist. Any homeowner who is responsible for their home should check the condition of the chimney on the eve of the heating season. Timely lining will ensure the safety of the house and the health of its inhabitants. Ideally, the installation of modules is carried out during the construction stage, so that there are no problems with the chimney in the near future.

vote

Article Rating

Why do you need a chimney?

You can look at the photo of chimneys for a solid fuel boiler or traditional fireplaces with stoves. They are, in fact, very similar, because they have the same purpose - eliminating combustion products during operation of the heating boiler.

This happens due to the draft, which is created due to the difference in temperature and pressure of the air that is inside the heating boiler and outside.

In the winter season there should be no problems with this, and absolutely none, because the temperature outside will be very low, mostly sub-zero, but the temperature inside the boiler can in some places exceed 300 degrees Celsius.

In the case of gas boilers, we simply get air without oxygen - carbon dioxide, which we cannot breathe, but it becomes terrible only in high concentrations.

If in the case of gas the chimney is more of a ventilation duct, then in a solid fuel boiler there are many substances that exit through the chimney, outside the system and the house.

Holes in the chimney can pose not only an aesthetic threat, but also be really hazardous to health, because carbon monoxide and smoke flow through it, in fact.

Features and design of the chimney

The design of a brick chimney coming from a fireplace, stove, solid fuel and gas boiler is a shaft that forms a straight channel or a channel with turns. The upper part of the structure is raised above the roof, and a protective cap is placed on top.

Principle of operation

When the boiler is burning, the temperature at the bottom of the duct is higher than at the outlet. Due to the difference, a pressure difference is formed. The higher this indicator, the better the traction. Combustion products are freely discharged to the street, and oxygen enters the firebox to support combustion.

Approximate cost of work

The cost of rehabilitation depends on the materials and design of the future chimney liner. For installation of a 1 m long liner you will have to pay approximately 2.5 thousand rubles. After measuring the length of the shaft and multiplying the results by the cost of the selected liner, you can roughly calculate the cost of rehabilitation.

We hope that the information provided will help you choose the appropriate sleeve method and complete all the work yourself. We invite you to subscribe to other useful articles. Share information on social networks. Maybe some person is similarly looking for ways to solve a similar problem.

Features of installation of liners made of different materials

In modern construction, stainless steel, ceramics or a polymer sleeve are used to reconstruct the chimney. Ceramic liner and polymer are difficult to install. Most often, when lining chimneys with your own hands, stainless steel is used.

Preparatory work

Regardless of the type of liner chosen, a number of preparatory measures are performed before starting liner:

- Using a powerful flashlight, they inspect the smoke shaft from the inside. The degree of destruction, soot contamination, the presence of fallen pieces of mortar, bricks, and bird nests are determined.

- Use metal scrapers, brushes and other devices to clean the chimney. Bricks protruding from the masonry will prevent insertion of the liner. They try to knock down all the protrusions with a hammer or pry bar.

- Measure the length as well as the diameter of the chimney. The dimensions are transferred to the diagram, indicating all rotations and degrees of angles.

- The part of the chimney adjacent to the boiler or stove is dismantled. The installation of the shaped element will begin from this place.

- The bottom of the smoke shaft is cleared of debris and leveled if necessary.

After the preparatory measures have been carried out, the inserts necessary for the sleeve are purchased.

Installation of a stainless steel liner of round, rectangular or oval cross-section

Sleeving a small shaft with stainless steel without turning is carried out according to the following principle:

- All elements of the sleeve are assembled into one structure. The joints are treated with heat-resistant sealant, and the top is wrapped with aluminum-based adhesive tape.

- Two belts, cables or strong rope are secured to the bottom of the pipe with a clamp.

- The sleeve is carefully lowered down the shaft until it touches the bottom. If the length of the chimney is short, a lightweight stainless steel pipe is immersed by hand without using cables.

- The liner from below is connected to the inlet of the boiler or furnace and a condensate collector is installed. The sleeve is removed from the street above the brickwork of the chimney, and a protective cap is put on top.

Stainless steel lining of a long chimney with turns is carried out differently:

- The smoke duct is dismantled at the entrance to the boiler, as well as all areas where shaped connectors will be installed.

- First, the lower part of the sleeve is assembled from flat sections of the pipe up to the first shaped connector. The liner is lowered to the bottom of the shaft, connected to the inlet of the boiler or furnace, and a condensate collector is installed below.

- A shaped connector is installed on the second free end of the steel sleeve. A flat section of stainless steel is connected to it until the next turn of the shaft. The procedure is repeated until the sleeve is removed from the shaft.

More about sleeve methods

Lining the chimney can also be done using a flexible stainless steel pipe. It is worth noting that this will not be the best option. Such a pipe has its drawbacks: the corrugation will not be an obstacle, but on the contrary will help condensate and soot accumulate + the service life of the structure is reduced due to the small thickness of the walls.

There is another way to “level” the chimney: line the inner surface of the channel with a fire-resistant mixture. Thanks to this, the brick surface of the chimney pipe is smoothed, because the mixture closes all the cracks. In this case, the smoke channel does not decrease significantly in size. If you have a large smoke channel height, you should make a technological hole at the bottom. After the lining work is completed, it must be laid. This will cost you less than lining a chimney; in this case, the price will be much lower. However, it will not provide guarantees of tightness.

It is easier to install the liner when the chimney is being installed, i.e. at the construction stage. This will be both more reliable and save your family budget. Therefore, be sure to take this issue into account during the construction stage. Don't ignore him!

The main thing to remember is that the correct lining of the chimney is, first of all, the safety of your home and the health of your loved ones!

Service price

The cost is calculated individually based on the length of the pipe and the type of material used to make the inner liner.

By consulting with our specialists, you can find out how much cladding will cost for your home. You can be sure that it will cost much less than installing a new pipe. The ideal condition of the smoke exhaust channels is not only a mandatory requirement that must be met for the legal operation of heating equipment. This is a matter of safety for people in the premises. According to statistics, carbon monoxide poisoning occurs quite often during the heating season. This substance has no odor, so people do not notice the problem and quite often end up in the hospital in serious condition. If there are children in the house, then poor draft in the chimney can be fatal.

Specialists from Ventgazservice LLC will restore the patency of smoke channels using special inserts. This will provide good traction and prevent the rapid accumulation of soot. Our priorities are compliance with industry standards and safety.

Installation of a smoke exhaust duct

The simplicity of the chimney design allows, if you have some experience, to calculate and make it yourself. Laying a brick chimney with your own hands will significantly save financial resources.

A short instruction will help you design and build a chimney correctly, as well as line it.

- At the first stage of the work, it is necessary to correctly calculate the main characteristics of the smoke exhaust duct:

- traction force;

- pipe diameter and height.

With the correct diameter, as the height of the chimney increases, air circulation also increases. The basic requirements for how to build a brick chimney, as well as provisions for the choice of material, structure size and installation procedure, are set out in the main regulatory document SNiP 41-01-2003 “Heating, ventilation and air conditioning”.

- Before making a chimney out of brick, it is necessary to provide for its lining at the construction stage;

Installation of smoke exhaust pipes

- Installation of smoke exhaust pipes begins from the heating facility. Each subsequent pipe link is inserted into the previous one. To protect the structure from moisture, it is necessary to use a special heat-resistant sealant;

- All joints are fixed using clamps;

- When laying, it is necessary to completely prevent the pipes from coming into contact with other communications (gas, water, electrical wiring, etc.);

- It is necessary to provide for the installation of a door for cleaning the smoke exhaust duct during its operation;

- If pipes are planned to be located near flammable finishing items, they must be insulated;

Brick chimney laying diagram

- When laying a stainless pipe through the roof, it must be insulated with mineral wool;

Insulating the pipe from the roof elements using mineral wool

When laying bricks, special attention is paid to the evenness of the walls and the accuracy of the corners; During laying, it is necessary to provide technological holes and a place for installing the door to clean the channel from the formed soot; The outer part of the fireplace (stove) chimney can be lined with tiles or decorative bricks;

Photo of how to build a brick chimney, taking into account all the important structural elements

- It is necessary to build the chimney as vertically as possible. The fewer turns and inclined sections, the more efficiently the smoke will be removed from the brick fireplace (stove) to the outside. The length of horizontal sections should not exceed one meter.

Sleeve installation steps

Below we will look at how to properly perform sleeving in different ways (according to the type of materials discussed above). Please note: it is quite difficult to do this kind of work yourself if you do not have extensive experience in construction.

Preliminary work

Before you start lining, you need to prepare the existing smoke channel.

Step-by-step actions ( the instructions are relevant for any sleeving methods

):

- The condition of the chimney from the inside is assessed. To do this, you need to visually inspect it with a flashlight. Attention should be paid to the level of contamination and damage, if any.

- It is checked to see if there are any obstacles inside: protruding bricks, sagging mortar, protruding pieces of reinforcement, or contamination - bird's nests and other debris. If problems are found, they should be eliminated.

- Just in case, you can double-check the length and cross-section of the channel.

- The channel is cleaned mechanically (with a brush). Optional but recommended item.

- Part of the smoke shaft from below is disassembled (the area adjacent to the boiler/fireplace and the areas in which the fittings will need to be installed.

- The bottom of the shaft is leveled.

Next, we will consider the features of the sleeve in each method.

Lining with a ceramic pipe (video)

Stainless

If the chimney is small and has no turns, the work looks like this:

- Only the lower section of the main shaft is being dismantled.

- The sleeve is assembled from its component elements. The elements are fastened together with aluminum tape. For gas and liquid fuel boilers, a high-temperature sealant (intended for temperatures up to 300°) is additionally used; for solid fuel boilers, a heat-resistant sealant is used (for temperatures up to 1200°).

- A rubber strap or crimp clamp is attached to the bottom of the sleeve.

- There are 2 cables attached to the belt or clamp.

- On the cables, the sleeve smoothly lowers to the bottom of the shaft.

- If the total length of the sleeve is small, and the elements are connected to each other reliably and firmly, it can be lowered into the chimney, holding it from above with your hands (then this point will replace points 3-5).

- A floor element with a condensate drain is mounted below.

- The pipe is brought out above the masonry and the head is mounted.

If the chimney is long and/or has rotating sections and shaped elements:

- The main shaft is disassembled from below, at the places where the shaped elements are installed.

- The lower piece of the sleeve is assembled from several elements and immersed in the shaft (with a rubber belt/clamp, on 2 cables - as described in the list above). A floor element with a condensate drain is mounted in the lower part. The lower segment must be lowered through the disassembled hole above (not through the very top of the chimney).

- The shaped element is installed.

- The next (higher) segment of the sleeve is assembled from several elements and descends through the hole (disassembled shaft) located above.

- The segments are fastened to each other (with aluminum tape and sealant).

- In a sequential manner, the sleeve is assembled from several segments, from bottom to top.

- The pipe is installed above the masonry.

- The head is mounted.

If corrugated hose is used:

- The sleeve is cut into segments of the required length (if it is necessary to use shaped elements), or into 1 piece along the full length of the chimney.

- The lower part of the shaft is dismantled.

- If shaped parts will be used, the masonry in the places where they are installed will be dismantled.

- The sleeve descends from top to bottom, to the bottom of the shaft.

- At the bottom, a rigid section of stainless pipe with a steam trap is added.

- The corrugation is brought out 20-30 cm above the mouth of the shaft. Ideally, the upper section (extending outwards) should be made of a regular (not corrugated) stainless round pipe - for this it is attached to the upper end of the corrugation on an adapter.

After the work has been done, the disassembled masonry is put back together and the head is mounted.

How is sleeving done with a round stainless steel pipe? (video)

Polymer

The installation steps are as follows:

- The lower part of the shaft and the places where the shaped elements will stand (if any) are disassembled.

- The rolled up sleeve rises to the top of the roof.

- A special segment with a pressure gauge and a valve is attached to the upper part of the sleeve, through which air will be released during installation.

- The sleeve is immersed in the chimney and goes down to the bottom.

- An air compressor is connected to the hose and air is supplied. Under its pressure, the polymer stocking straightens, taking the desired shape.

- After straightening the stocking, instead of air, steam is supplied, under a certain pressure and temperature, and remains inside for the required time (determined by the manufacturer, depends on the length of the chimney and on which product is used). When exposed to steam, the stockings harden.

- The compressor and the upper mounting element (with pressure gauge and valve) are turned off.

- A condensate drain is mounted below.

- The upper end is cut to the level of the shaft, and the tip is mounted on top.

How is sleeving done with Furanflex polymer stocking? (video)

Sleeving methods and materials

There are several ways to line a brick chimney using various materials and technologies.

Stainless steel pipe

The solution is relevant for smoke mains of any shape and length. Stainless steel sleeves provide excellent resistance to high temperatures and condensation. The structure is easy to install; no special equipment is required. Most often, owners of private houses line the chimney with a pipe with their own hands.

Stainless steel inserts of various designs are available on the market:

- round pipes. Perhaps the most popular liner option. Models are made with a cross section of up to 100 cm. The wall thickness varies between 0.5-1.5 mm, this design parameter depends on the characteristics of the base material,

- rectangular pipes. A stainless steel insert of this category is used less frequently than an analogue with a round cross-section. Models with dimensions of 14x27 cm are relatively common,

- oval pipes. The thickness of the material is 0.5-0.6 mm, common sizes are 20x10 and 24x12 cm. The cross-section of the oval-shaped stainless steel liner of the required sizes corresponds to a round pipe with d15 and d29 cm,

- corrugated stainless steel sleeves. The corrugated pipe is presented in the form of a two-layer model made of different grades of stainless steel with a cross-section of up to 35 cm.

As practice shows, the potential of a corrugated stainless steel liner provides a service life of no more than 4 years, since the ribbed walls become clogged and the liner burns out under the influence of temperature loads.

Polymer sleeve

The liner is made on the basis of fiberglass mesh with polymer impregnation. Models are made up to 60 m long. Thickness parameters vary within 50 cm. The polymer solution provides a long service life - up to 30 years. The material is resistant to condensation.

The chimney can be lined with a polymer sleeveThe convenience of installing a flexible tab lies in the fact that a one-piece hose is inserted into the smoke channel, which can bend at an angle of 30°, which is important when there are bends in the brick main. At the same time, shaped elements are introduced into the design if necessary.

They note that without special equipment and certain skills, it is impossible to install a polymer hose into a smoke shaft yourself. It is noteworthy that models of polymer sleeves for high-temperature and low-temperature heat generators are manufactured using various technologies.

Ceramics

Ceramic liners come in round and oval shapes, the diameter varies from 12 to 45 cm, the length of straight elements is 33, 66 and 133 cm, and the wall thickness is 4-20 mm. Reliable ceramic sleeves are often used in the reconstruction of mines with significant deformations. The material does not react to soot combustion and is valued for its durability. When lining with a ceramic insert, it is necessary to disassemble the smoke shaft. The high cost and impressive weight of the product are the main disadvantages of ceramic sleeves.

Nuances and requirements for lining the chimney of a gas boiler

Before lining, you need to clean the brick chimney from soot.

A chimney lining is a necessary solution if the pipe is made of brick. The presence of the insert does not protect against the appearance of condensation drops, but with the help of the lining it is possible to ensure organized moisture removal.

Before lining a brick pipe, you need to prepare:

- inspection of the chimney outlet;

- checking the section shape;

- identifying the degree of contamination;

- pipe cleaning;

- checking for tightness and functionality.

The cross-section is most often represented by a rectangle with dimensions of 14 x 27 cm; before installation, the dimensions of the sleeve, its length and shape are determined. Attention is paid to the cross-sectional area, because the insert in the channel narrows the outlet.

Troubleshooting a brick chimney ↑

While repairing steel chimneys is fairly quick and easy, repairing brick chimneys requires a more serious approach. It can be performed in several ways and largely depends on the reason that caused the problems. When the working element of the heat generator becomes cracked or collapses, the brickwork is repaired.

The main task of the master in this case is to restore the damaged area as efficiently as possible. To do this, it is necessary to disassemble the chimney to the point of damage and re-lay it using new brick. If the chimney design is done correctly, during its repair you will not have to dismantle the entire masonry. If mistakes were made during the installation of the gas and smoke exhaust system, it is easier to completely redo it.

Repair of brick chimneys can be carried out in several ways; the choice of a particular one largely depends on the reasons that caused the problem

When a brick shaft needs to be reworked, the chimney is lined. This repair method will help to avoid labor-intensive and dirty work, which will subsequently lead to the need to repair the roof and the entire room; it is used exclusively when problems arise with a straight chimney, without bends or displacements, and involves the installation of a ceramic or steel pipe of a certain diameter, corresponding to the needs of the heat generator. The result of chimney lining is improved draft, increased tightness of seams and joints, and prevention of soot formation on a smooth surface.

If you need to repair a chimney quickly and efficiently, it is best to resort to lining it. This method does not involve dismantling the masonry. It is based on finishing the chimney duct with special refractory compounds made from granite chips, cement and lime or perlite rocks, characterized by high adhesion to brick and concrete surfaces.

Lining chimneys using Mordax mass

The main features of chimney lining include:

- versatility: this method can be used both for repairing chimneys and ventilation ducts;

- improving draft and simplifying channel cleaning due to the formation of a smooth surface inside the chimney;

- resistance to temperature and atmospheric influences;

- minimal labor costs when performing repair work;

- increased fire safety and minimal risk of leakage of combustion products due to the solidity of the internal surface of the chimney;

- speed of the process (repairing a chimney this way will take a maximum of five hours);

The process of lining the chimney channel begins with preparatory work. It is first of all cleaned of soot, loose pieces and debris, then moistened with a special aqueous solution and a special composition is applied in three layers using a blowing brush wrapped in fabric, which is lowered into the chimney on a winch.

It is important not to forget that each subsequent layer must be applied after the previous one has completely dried.

Chimney lining with polymer liners

Another effective way to repair brick chimneys is to line them with polymer liners. Despite the fact that it has not yet managed to gain particular popularity, experienced craftsmen recommend resorting to it during the work. Lining of polymer liners involves installing special polymer liners developed using new technology into the chimney duct. They not only allow you to quickly restore the chimney, but also minimize the risk of its further destruction.

Repairing a chimney duct using this method is carried out as follows:

- the polymer liner is inflated with compressed air, then steam and mounted in the internal channel of the chimney;

- under the influence of pressure, the liner takes the shape of the chimney channel, fits tightly to the walls and hardens, as a result - a smooth and durable layer of polymer is formed inside the chimney without seams or cracks, resistant to precipitation and high temperatures, soot and condensation do not accumulate on it.

Maintenance of a chimney repaired in this way is quite simple and quick.

Do-it-yourself smoke channel lining

First of all, before lining the old brick chimney duct, it is recommended to carry out preparatory work. Preparatory work before lining the chimney includes the following steps:

- it is necessary to check the brick smoke exhaust duct for contamination and damage;

- it is imperative to determine the dimensions and cross-sectional shape of the sleeves for a specific case;

- The third thing that needs to be done before starting installation work is to prepare the workspace.

After the preparation for sleeving has been completed, you can proceed directly to the installation process itself, which is performed in the following sequence:

- First, part of the smoke exhaust duct is dismantled. The dismantled part of the channel depends on the specific case and is made according to the length of the sleeve. Dismantling part of the chimney is necessary so that it can be lined and, in addition, for installing an inspection hatch in the future.

- Next, you need to install the liner inside the chimney structure. It is installed at a height that does not interfere with the smooth installation of the next sleeve.

- At the third stage, the sleeves are joined together. The joining seam is usually coated with a special sealant. Experts recommend using heat-resistant sealants that can withstand high temperatures without losing their qualities.

- Then the structure of two sleeves joined together is raised to the required height and the following elements are installed. This activity is carried out until the smoke exhaust channel is lined along its entire height. The lining, which is carried out from the bottom up, is only relevant for smoke exhaust ducts of small height, since the resulting pipe structure will have too much weight in the case of a long duct. For long channels, it is recommended to line the liner from top to bottom. In this case, it is also worth remembering that you need to place bricks or a refractory block under the lower sleeve.

- At this stage, the space between the outer wall of the shell structure and the inner surface of the smoke-emitting brick structure is filled. The material for this can be any fireproof heat insulator (for example, basalt wool).

- Then the previously dismantled chimney opening is filled with bricks. This operation is the final stage of sleeving.

A chimney liner is one of the options for reconstructing brick communications. The features of this process depend on the specific case, however, it is necessary to remember that all work is recommended to be carried out taking into account fire safety standards and regulations in order to avoid the occurrence of unwanted emergency situations.

Stage 5. Advantages of chimney rehabilitation (liner)

Lining a chimney with your own hands or with the help of specialists has many positive aspects:

- optimal (even ideal) channel cross-section for gas movement,

- smoothness of the internal surface of the chimney, its minimal roughness,

- non-wetting and non-moisture-absorbing material of the chimney walls,

- low thermal conductivity + minimal cooling of gases over a period of 1 meter of pipe,

- maximum safety in case of insert depressurization,

- high heating rate of the chimney pipe in the cold season,

- protection of brickwork in case of condensation formations,

- possibility of replacing inserts,

- ease of cleaning the channel due to the smoothness of the surface.

The main advantages of sleeves

- The draft improves and the operation of the heating device becomes more productive.

- This design is sealed, reducing the risk of fire hazards.

- There is no need for frequent cleaning of the chimney. Compared to brick walls, which can often be uneven, have cracks and ledges in which condensation and soot accumulate, contributing to the formation of congestion, the walls of the liner are smooth and even.

- The chimney pipe will last longer. Due to the acid resistance of liner materials to condensate (especially in gas ovens) compared to brick, which is much more susceptible to mechanical and chemical destruction.

- The design includes elements for condensate removal and cleaning.

- The sleeve reduces heat loss from the system

Advantages of a steel chimney pipe

Chimney pipes are made of metal, ceramics and brick. Metal pipes are currently in greatest demand. Of all the varieties of this material, it is recommended to choose steel. Steel pipes for chimneys are coated with special solutions that make the material resistant to all adverse effects of the internal environment of the chimney.

When choosing a pipe, it is necessary to take into account the parameters of the heating devices and the fuel used. The material from which the pipes are made must withstand higher temperatures than the fuel can create.

When using some types of heating devices, chemically active substances are found among the under-oxidized combustion products. They can damage a chimney that is not sufficiently resistant to chemicals. Some unburned particles can ignite, creating sparks. Therefore, the material from which the pipe is made must be fireproof.

The advantages of steel pipes are:

- Easy to install. Steel pipes do not require the installation of a special foundation; they do not require complex engineering solutions or special installation tools. You can install them yourself without prior preparation. Due to the plasticity of the material, complex technical structures can be created.

- Light weight. They are easy to transport, you can lift and move them yourself without a team of workers, which also simplifies installation.

- High temperature resistance. Steel products are suitable for appliances operating on any fuel. They do not melt at maximum temperature loads.

- Chemical inertness. Steel does not interact with chemical reagents that can form as under-oxidized combustion products. These substances are not capable of destroying it.

- Corrosion resistance. This advantage applies to pipes that have a special coating and stainless steel. The material itself quickly corrodes. It is worth considering that in addition to the internal environment, the chimney pipe is affected by external unfavorable factors, for example, precipitation. Preference should be given to coated pipes.

- Smooth inner walls. Combustion products settle on the rough surface, turning into soot, which gradually reduces the clearance. This reduces the draft in the chimney. Steel is completely smooth, the risk of soot settling on their surface is minimal.

Positive aspects of sleeving

Chimney liners have many advantages:

- proper removal of condensate from the mouth of the smoke exhaust structure into the sewer system or a container specially installed for this purpose is carried out;

- there is free access to cleaning the chimney from soot;

- the tightness of the chimney increases;

- heat loss is reduced;

- the presence of a metal pipe head and a horizontally located protective plate reduces the ingress of moisture onto the inner surface of the brick or stone masonry.

Selecting materials

Only solid fire-resistant blocks are suitable for building a chimney. Recommended brands from M150 to M200. The material is available in three grades.

- 1st grade. With normal firing time. Even, smooth and dense. No crumbled areas. The color is bright red. When tapped, the sound is clear and clear.

- 2nd grade. Unburnt parts are pale orange. Porous, loose, with defects. They sound dull when tapped. They are characterized by weak frost resistance and heat capacity, low density.

- 3rd grade. Burnt bricks. They are distinguished by their dark red color. Pores, burrs and chips on the surface are visible. When tapped, the sound is excessively ringing. They are fragile, not frost-resistant, and do not retain heat well.

The chimney should be assembled only from first grade material. It is allowed to use the third, but only for arranging the foundation. The use of the second grade is excluded.

Instagram brigadir74

For the construction of the chimney, only high-quality first-class bricks are used

- Decoration Materials

Cladding the facade of a house with bricks: how to do it right

Brick pipe repair

To put the pipe in order, you can go in two ways: restore the masonry or perform lining - treat the channel inside with special means.

Reconstruction of masonry

In case of minor damage to the chimney masonry, they act quite predictably - instead of destroyed bricks, they install whole ones. To do this, the crumbled elements are carefully cleaned of the solution and removed. The empty cell is scraped out, after which a new element is placed in place of the taken brick, using a fresh mixture of clay and sand.

In case of minor damage to the masonry, it is restored by replacing individual bricks with new ones

Sometimes a situation arises when cracks appear in the pipe, through which moisture seeps in during heavy rains. In these cases, the outer surface of the pipe above the roof is primed and then plastered.

When the bricks in the masonry are damaged by more than 20%, partial repair of the chimney is out of the question. The smoke channel with severely damaged elements is completely dismantled to create a new masonry.

The effect of condensation on the chimney

When gas fuel is burned, hot steam enters the chimney from a gas boiler, which, when cooled, condenses on the walls of the chimney, creating a moist environment on its inner surface containing acidic components of nitrogen, carbon dioxide and water vapor, the so-called condensate.

Over time, condensation saturates the brickwork, passes through it, appears on the walls in the form of dark stains and destroys it. If the problem is not identified and corrected in a timely manner, the brickwork is completely destroyed.

Let's sum it up

Metal chimneys, unlike brick ones, can be assembled with your own hands. It is better to do this “by condensate”, since assembly “by smoke” will lead to accelerated wear of the pipes.

How to install a chimney correctly:

- starting from the heating device and always with a damper;

- using an adapter if sandwich pipes are used;

- with a minimum of deviations from the vertical;

- with passage through walls, roofs, ceilings at a safe distance from flammable materials (250 mm or 500 mm depending on the type of pipes).

What are the reconstruction methods?

There are two ways out of this situation:

- Reworking the chimney shaft.

- Lining (sleeve, insert) of the smoke exhaust channel.

Let's consider each option separately.

Relaying a smoke exhaust pipe involves significant financial investments: dismantling or disassembling the channel, purchasing new material, delivering it to the reconstruction site, loading and unloading work and paying for the services of a good stove-maker.

Believe me, the amount is very significant. An additional disadvantage is that the premises where such work is carried out will not be usable for some time.

Option two: reconstruction of the chimney using the lining method.

In simple terms, lining is the insertion of a piece of new pipe into the smoke exhaust ducts. This is permitted by the rules for installing chimneys.