For a long time, the ability to build a house from timber was considered a respected profession among the peoples inhabiting the northeastern part of Europe. Skilled carpenters were valued in Rus' and the Scandinavian countries. The secrets of the profession were passed down from generation to generation. Every man knew how to harvest wood and build a house; boys were taught chopping wood from childhood. The owner who built the house with his own hands received universal recognition. The respectful attitude towards such people has been preserved in our time - a person who built a house from timber with his own hands is respectfully called a master.

The art of wooden architecture is based on a set of rules; this knowledge is still relevant in our time. Laying a log frame with your own hands has its own characteristics. Before you start construction, it is advisable to familiarize yourself with the advice of experienced craftsmen.

How to organize your workplace?

A workplace for the construction of a log house is organized after the completion of the foundation shrinkage process. The construction site includes: the foundation of the future house, a lumber warehouse and a place where carpentry work will be performed.

The lumber is stacked at a distance of 4-6 meters from the foundation and protected from rain; the stack should not come into contact with the soil and is located on a pallet. Between the foundation and the lumber warehouse, a work area for marking and cutting with a workbench 1.0-1.5 m high is equipped. When using power tools, it is necessary to supply power.

All carpentry work is performed in the work area. The assembly of structures and laying of timber is carried out directly on the walls of the log house. Working on ladders is inconvenient and unsafe; for convenience, industrial scaffolding is used. You can make the scaffolding yourself - place the ceiling on vertical posts and securely fasten the structure with consumable lumber.

The cut parts from the timber are lifted along inclined logs using a rope. All work can be done together.

Foundation preparation

For building a house, the optimal foundation is considered to be a strip foundation. To arrange it, stones and vegetation are removed, mounds and holes are leveled. When the site is leveled, the territory is marked. After this, a trench is dug, the depth of which depends on the height of the future building and the soil, the width is at least 25 cm. The profiled beam is quite light, so for a one-story building you can use a shallow foundation.

For multi-story construction or construction on unstable soil, the foundation must correspond to the freezing level of the soil. On average, this figure reaches 1.2-1.5 m.

The following materials are needed for the foundation:

- concrete, sand, crushed stone;

- formwork;

- reinforcing rods.

Any house begins with preparing the foundationSource penza-press.ru

The trench is filled with sand and crushed stone, and a mesh is laid with rods to reinforce the foundation. It is recommended to use tying wire rather than welding to connect the rods. The formwork is laid out, and then everything is filled with concrete. To make concrete mortar, cement, sand and crushed stone are used - all components are thoroughly mixed. The ratio of materials is 1:3:4, cement grade is at least 400. The foundation stands for about 2 weeks.

How to properly lay the crown molding?

The first and most important operation is laying the first (flashing) crown. The dimensions of the first row of the frame are determined at the design stage; they are commensurate with the length and width of the foundation. Using a building level, a basic horizontal line is applied to the flashing crown to control the current height of the masonry.

The foundation material and wood have different physical properties: the concrete base freezes and forms moisture when it thaws, dew also forms in the summer, concrete has a loose structure and is easily saturated with soil moisture. If waterproofing is insufficient, mold and mildew will appear on the lower beams and under the floor. The trim crown is reliably isolated from the negative effects of moisture.

To waterproof the base of a log house, roofing felt, fiberglass or woven geomaterial with bitumen impregnation are used. To adhere to the foundation, eliminate cracks and air cavities, the waterproofing layer is treated with open fire.

Material selection

Shrinkage is a proportional decrease in the linear dimensions of a beam under the influence of mechanical loads (primarily weight) and due to uniform loss of moisture.

And warping is the shrinkage that distorts the geometry of parts. It happens due to uneven drying, without regard to mechanical loads.

Shrinkage is standardized for different types of wood and different types of lumber. And warping is an unacceptable defect for high-quality commercial wood. Raw wood can be dried properly without warping. But seasoned wood, if stored incorrectly, can seriously fail the builder.

Considering all of the above, it is easy to conclude that a good house can be built from the following types of timber:

- Wild or wild wood. That is, from wood that had lain on the stock exchange for an indefinite period of time before sawing. This material is the cheapest, its humidity is not standardized, and its shrinkage is 10%. And we must keep in mind that if storage conditions are poor after purchase, it is not guaranteed against cracking and warping.

- Edged, seasoned. This one goes into sawing after being brought to air dryness (20%). Moreover, it is not much more expensive than wild timber, if we are talking about regions with a developed timber industry and active logging. However, its shrinkage is only 7%, its tendency to crack is normalized, and warping is not allowed under adequate storage conditions.

- Seasoned profiled. The properties of this material are almost the same as those of seasoned edged timber. But it is much more convenient to use. It is the most popular type of construction timber today, although it is more expensive than those described above.

- Glued. This timber is glued and pressed from individual lamella boards, pre-seasoned and impregnated. It can be profiled (more expensive) and seasoned (cheaper). In all technical and operational parameters it is superior to the above types of building timber and has only one drawback (for some it may be significant): the adhesive seams on such material are noticeable, and it becomes obvious that the house is not built entirely from natural wood.

- Rusk. That is, made from crackers - high-quality dead wood. The shrinkage of this building material is 0%. Cracking, warping and the formation of rot are also completely eliminated. However, cracked timber is very expensive, since the industrial production of cracked timber (that is, cutting the bark at the butt of a living trunk) is prohibited by law in all civilized countries. And Russia is no exception. The method is considered barbaric, and its use is criminally punishable and punishable under the relevant article of the Criminal Code of the Russian Federation.

How to collect crowns correctly?

The crown of the house is the main element of the log house; the crown is understood as a closed contour of timber, forming a structure with corners meeting at 90 degrees. The most common standard size for buildings made of solid timber is 250 mm, for buildings made of profiled timber – 150-200 mm. There are the following methods of joining into a crown:

- Cutting into oblo (joining into a bowl);

- Laying in the paw;

- Fastening in a bandage with a main tenon (assembly on a tenon).

Cutting into the claw and laying in the paw are universal joints; this technology can be used in construction from logs and timber. You can do it yourself by attaching it to a headband or a paw. Tenon assembly is used only in timber construction; tenoning is more complex and requires special skills.

Log cutting is the best way to lay a log house for a bathhouse and outbuildings; residential buildings are built in a claw and on a tenon.

How to lay a corner of a house?

After the casing has been laid, you can install the corner of the house. Most often, individual developers ask the question: how to properly lay timber in the corner of a house.

Assembling corners is the most difficult and time-consuming operation; the easiest way is to lay a corner from crowns assembled into a head or paw. The disadvantage is that in both cases significant gaps are formed, depending on the accuracy of cutting out the connecting elements. The corner joints are sealed and insulated.

More practical is a tenon mount, called a “warm corner”; such a connection is more labor-intensive, but has a number of advantages:

- The ends do not protrude beyond the edge of the building, the masonry is called “no residue”;

- The structure has no through gaps, the corner does not require insulation;

- The castle is located inside the structure, the facade takes on an attractive appearance;

- The building can be erected from timber of smaller sizes.

Types of laying load-bearing walls

Laying timber is carried out in two ways:

- "with the remainder";

- "without a trace."

How much it costs to lay timber depends on the amount of waste generated. The more the workpiece is cut, the more waste there is.

In the first case, the workpieces are processed in such a way that grooves are cut out in the upper and lower parts. The depth should be ¼ of the thickness.

A simpler option is to make the groove on only one side. The most complex but reliable is four-sided processing.

Connection "with remainder"

Advantages of styling “with remainder”:

- warmer corner;

- ease of construction;

- sustainability.

Flaws:

- the material is not used rationally, a lot of waste remains;

- The area of the room decreases, and the cost of laying timber increases.

Houses with convex corner joints look very beautiful and antique, but covering them with siding or insulation is almost impossible.

The corner connection of the timber “without remainder” implies that the walls have no protruding parts. All parts are in the same plane, facilitating further finishing of the house.

Advantages:

- modern type of construction;

- a warm corner is ensured through a reliable connection using additional materials;

- the interior space of the house increases.

Minuses:

- If you don’t follow the technology, the house will be drafty.

When installation is done independently, you need to choose the simplest, but at the same time reliable option.

What is a half-tree angle?

Half-wood masonry simplifies the corner connection as much as possible; in this case, the end of the beam is cut in half with a horizontal cut, and one of the parts is removed. The remaining parts are overlapped at an angle of 90 degrees. The reliability of joining the timber in this connection is ensured with the help of dowels.

This construction technique is used for lightweight buildings made of logs and log buildings. Half a tree is used to build country houses, bathhouses, outbuildings and other buildings not intended for permanent residence.

Craftsmen recommend: regardless of the construction method, the crown molding should always be laid in half a tree.

Design errors

When independently calculating a project, there is a risk of unprofessional design. For the same reason, one should not very much demand from the project developer significant savings in construction. It has been established through repeated experience that the attic provides a large increase in living space, but does not lead to a significant increase in construction costs.

By including a basement in a house construction project, you do not significantly increase its cost, but you significantly improve the quality of life in this home. Try to make the house proportional. The abundance of small rooms in a large house and vice versa will make living in it not very comfortable. Consider zoning in advance. You, most likely, will not really like it when smells from the kitchen hover in your bedroom.

How to securely fasten the crowns?

Deciding how to lay and fasten the crowns depends on the type of lumber chosen. The profiled timber is reliably connected by its own tongue-and-groove system; for reinforcement, wooden dowels are used; on one side of the building it is enough to install 6-7 such fastenings. When building from solid timber, dowels are installed every 500 mm.

Simultaneously with the laying and fastening, the inter-crown seams are sealed and insulated. For a log house for shrinkage, this operation is performed after completion of shrinkage.

How to control the assembly of a log house?

During the construction process, a number of parameters are monitored; the following are subject to control:

- Verticality of corners;

- Horizontal masonry;

- Current wall height.

To control verticality, a vertical line is applied to the end of each beam. The line is located at an equal distance from the edge of the corner and is marked using a construction square. When laying the next row, the lines of the bottom and top rows must be aligned. The resulting vertical is controlled using a plumb line; a violation of the integrity of the vertical indicates deformation of the masonry.

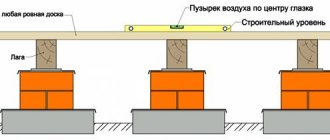

When laying the next row, the horizon is set using a building level. The height of the walls is measured from the base horizontal line marked on the rim.

Base insulation

Before laying the first crown, the upper foundation surface is leveled even if there is a centimeter deviation of its level from the horizontal plane. Afterwards, waterproofing material must be laid.

The upper surface of the base must be without slope, drops, and perfectly leveled. They check this with a laser or water level, or a construction level. Leveling is often performed with cement-sand mortar. It can also be used to close a gap if there is one between the lower crown and the foundation surface. Recently, construction foam has been mainly used for these purposes. After hardening, its excess is cut off with a knife. At the end of the work, the sealed area is covered with a decorative strip or ebb.

As a moisture-proofing coating, roofing felt is often used simultaneously with glass insulation. The materials are laid on the base so that they protrude beyond its edges by approximately 0.25 m. It is recommended to make a waterproofing coating of two layers. Boards are placed between them. In the corners, roofing felt or other material used is overlapped.

How to use dowels?

The dowels are installed under tension in specially drilled vertical holes and hammered in with a wooden mallet, the upper ends are recessed to a depth of 20-40 mm. Each dowel connects three rows of masonry. For timber up to 200 mm thick, dowels with a diameter of 25 mm are used, for larger thicknesses - 30 mm.

When temperature and humidity change, wooden dowels and wall beams change their dimensions proportionately without loss of adhesion; metal dowels do not have this property.

How to lay the interventional seal?

The slot seal performs the functions of heat and sound insulation and is used in the construction of any wooden structures. The type of sealant and laying technology depend on the size of the lumber. When building from solid timber, a layer of sealant is laid when laying each row. When building from timber with natural moisture, this operation is performed after shrinkage by sealing the cracks. The profiled timber has special grooves for the seal.

The seal for solid timber is produced in the form of a strip of tow, flax, natural moss, for profiled timber - in the form of strips of felt, foamed fine-pored rubber and polyethylene foam. The sealing tape is available in sizes from 100 to 250 mm, the sealing strip is selected according to the standard size.

Mold may appear in a seal that is wet or saturated with atmospheric moisture; it is recommended to recess the seal into the gap to a depth of 20-25 mm, and treat the gap with liquid sealant.

Roof construction and ceiling installation

Many materials can be used to cover the roof, including roofing felt and metal tiles.

Ceiling beams and rafters need to be installed after the builders finish cutting down the walls. Ceiling joists should protrude 50 cm beyond the wall. The material for the joists should be 150x100 timber. They are laid edgewise at a distance of 100 cm. After this, a rafter system is formed from the boards. This structure can be called the skeleton of the roof, so its fastening must be rigid. Next comes the laying of the fronts, which are best made from 150x150 timber. Afterwards the floor is installed.

Installation and assembly of the ceiling in a log house will largely depend on the preferences of the owners. The main thing that must be done is waterproofing. Laying and waterproofing must be completed before the ceiling screed. For a wooden house, it is recommended to use rolled or poured waterproofing.

The ceiling is considered the main detail that plays a big role in the interior design. The aesthetics of the room and the interior design will depend on its appearance and assembly. Today, the construction market offers a large number of coatings that can be used in a log house.

How to install internal partitions?

The classic design of a wooden house is “five-walled”. The fifth internal wall is a load-bearing partition and forms a single structure with the external walls. Such a partition is installed on its own part of the foundation and is erected from the same material as the log house. The timber in the partition is interlocked using dowels, the ends are joined to the outer walls in a tongue-and-groove lock.

Lightweight partitions for zoning space, installed after shrinkage. Partitions are made from lightweight lumber of solid or frame construction. Such partitions are attached to load-bearing walls with staples or nails.

Features of laying profiled timber

The technology for laying 150x150 timber assumes that the workpiece is completely ready for use. Its side can be flat or convex - you can choose either one, both for the outer and inner sides. Each subsequent crown is laid on a layer of jute insulation, tightly interlocking with each other using a tongue-and-groove system.

Manufacturers usually produce blanks 6 m long, but the wall can be much longer. In order to lay the beams efficiently, it is necessary to splice them together. It is important to prevent cold penetration.

To do this you should do:

- at the junction of two wooden blanks, a cut is made along the beam;

- the clutch is carried out “in a dressing” - on one side there is a long tenon, and on the other there is a groove, with jute between them;

- hammering the dowels at the joints provides additional strength;

- in each subsequent row, the joint location shifts slightly - this is necessary for the reliability of the structure.

The price of construction in this case increases due to the large amount of waste after cutting the workpieces. If the house design assumes a size of 6x6 m, then the cost will be significantly lower.