Polystyrene concrete blocks are used for the construction of residential buildings, as well as for the construction of outbuildings.

The use of this material has been successful in the construction of garages and bathhouses. To build a bathhouse from polystyrene concrete stone, you need to calculate all the consumables in advance, as well as prepare a project.

An important stage of preparation will be the study of all the pros and cons of such construction.

Is it possible to build?

Before building a bathhouse from polystyrene and concrete blocks, it is recommended to study the issue of relevance. Cases when construction is preferable :

- simultaneous construction of a house from the same material is taking place on the site;

- the goal is to build a warm room;

- I want to save money on materials.

If a residential building made of polystyrene concrete blocks is being built on the site at the same time, then it will be profitable to immediately build a bathhouse from this material. The owner will not have to spend additional money on transporting the stone, since it will be delivered in a total volume on one truck. You also won’t have to pay a second time to unload the goods.

Polystyrene concrete blocks have a low thermal conductivity coefficient , which means that the bathhouse will be warm inside.

If this is the indicator that is set as the goal, then this option is preferable. Blocks allow you to save on construction due to the fact that the volume of purchased materials is reduced.

If the wall thickness is 300 mm, then you can use a wide edge of stone for this.

It is not recommended to build a bathhouse from polystyrene concrete if the estimate does not include funds for finishing. Stone is susceptible to ultraviolet radiation , and in regions where sunny days occupy most of the year, such exposure will not benefit the house.

What polystyrene concrete blocks are suitable?

When choosing a material for building a sauna, you should pay attention to the density, strength class, size and thermal conductivity of polystyrene concrete blocks. Also, the frost resistance indicator plays an important role. It is recommended to select blocks according to the following parameters:

- dimensions 600x300x250 mm;

- density – D400-D600;

- strength class: B2;

- thermal conductivity coefficient - 0.105-0.135 W/mºC;

- frost resistance - F75-F100.

Since the material is not able to absorb water (this figure is only 4%) , it can be confidently used for the construction of a bathhouse. Density from 400 to 600 just indicates that the material is structural and thermal insulating, that is, universal. It is great for building bath walls. In terms of strength class, the stone must be no lower than B2, although this value is determined based on the height of the future wall.

We build a bathhouse from foam blocks - laying the floor

Where a place is planned for a washing room and steam room, the soil should be removed with a slope of 5-10 degrees towards the drain, and covered with a 5-10 cm layer of crushed stone on top. The reinforced mesh layer should be filled with concrete on top and beams (floor joists) can be laid. , pre-treated with an antiseptic against rotting. Then a finished floor is laid from planed boards, and a plinth is nailed around the perimeter.

Let's move on to insulating the walls. To do this, use linden, larch or pine, attaching ready-made sheathing beams with basalt wool between them. The sink can be finished with ceramic tiles or PVC panels.

External finishing of walls made of foam block for a bath is carried out similarly to the internal one.

Stages:

- Using self-tapping screws, a wooden sheathing (50 mm thick) is attached to the blocks.

- In the middle of the sheathing slats, it is necessary to lay insulation (mineral wool, basalt or stone material, polystyrene foam, polystyrene).

- The top is covered with foil for vapor barrier.

- The last thing is finishing the sheathing. For this purpose, false timber, block house, lining, vinyl, ceramic or metal siding, as well as decorative brick are usually used.

After the construction of a bathhouse from foam blocks with your own hands from the foundation to the roof is completed, the stove is installed according to personal preferences and structural features. Its power should be 1 kW per 1 m³ of the steam room volume. The main thing is to put a protective heat-resistant screen between the stove and the wall, and route the chimney through a specially designated non-combustible outlet in the ceiling.

Wall requirements

There are several requirements for bathhouse walls made of this material, including the thickness of the structure:

- to ensure normal load-bearing capacity of the wall, a thickness of 380 mm will be sufficient;

- to obtain the heat resistance of a room, calculations must be made;

- Each region has its own seasonal thermal conductivity coefficient.

You can read about the requirements for walls in official documents : this is SP 434.1325800.2018, as well as GOST 33929-2016. All standards and technical conditions for the condition of the material that will be used for masonry are indicated here. The parameters and requirements for building a bathhouse are also indicated here.

A warm home with dozens of advantages

We have already mentioned excellent thermal insulation properties. This is perhaps one of the warmest concretes currently available. Thanks to granules of excellent insulating foam, polystyrene concrete is even warmer than wood, therefore it provides significant savings on heating in the cold season and creates a special comfortable microclimate in the summer

And, importantly, the stability in the thermal conductivity of polystyrene concrete is ensured by the high moisture resistance of this material

What does it mean?

Imagine warm and dry clothes that you are wearing on a cool autumn day. Now imagine that it starts to rain. If your clothes are moisture resistant, they will not get wet. And if your clothes are soaked with water, then you immediately begin to freeze. This happens because water is a strong conductor of cold. Thus, in relation to materials: if the material is moisture resistant, then its thermal conductivity (heat saving) parameters remain stable under any conditions. Polystyrene concrete is a moisture-resistant material; grade D-600 has a moisture absorption of no more than 8%.

High moisture resistance enhances another advantage of polystyrene concrete - its durability. It is known that any building material that is capable of absorbing moisture begins to rapidly deteriorate in winter, as water expands when it freezes. Therefore, the more moisture-resistant the material, the higher its durability. For example, aerated concrete has a moisture absorption rate of 40 to 60%.

The durability period is measured by such a parameter as the “Frost resistance grade”, this is the number of cycles of freezing and thawing of the material without loss of strength. For polystyrene concrete, the state standard specifies a frost resistance grade of F300. This means that polystyrene concrete can withstand 300 cycles of complete freezing and thawing without losing its strength characteristics. In central Russia there are about two cycles. Accordingly, the conditional durability of polystyrene concrete is 150 years.

In addition, the long list of excellent characteristics of polystyrene concrete includes: biostability (not susceptible to mold and mildew dangerous to humans), high noise insulation (will not let in sounds from the street, from neighboring rooms and bathrooms), good vapor permeability (the house “breathes” no worse than wooden), non-flammability and elasticity (does not crack when the house “shrinks” and weak earthquakes, that is, you don’t have to worry about the finishing). And the most prudent builder and future home owner will be pleased with the economics of construction using polystyrene concrete.

How to make a project?

To make a bathhouse construction project, you can contact the appropriate company or try to do it yourself. Things to consider when designing:

- choose a construction site;

- develop planning solutions;

- draw a plan;

- coordinate it with the relevant organizations.

For construction, it is better to choose a hill near a reservoir , but if there is none, then the bathhouse must be built at a distance of at least 1 meter from the boundaries of the site, and also at least 5-6 meters from other buildings. The layout should include a vestibule, a dressing room, a washing room and a steam room. You can also make a rest room. You can develop a plan manually with a pencil on a piece of paper or use special programs on a computer.

flaws you didn't know about

Polystyrene concrete is a building material that is made from cement, foam balls, quartz sand and various additives. This material is not widely used, since there are much more negative opinions and properties of polystyrene concrete than advantages. Let's look at the disadvantages of the material in more detail.

Freeze and Thaw Cycle Limits

According to the developers, the number of freeze/thaw cycles is 100 times. In fact, it turns out that polystyrene concrete can withstand a maximum of 20 such cycles. In addition, foam balls gradually collapse under the influence of sunlight.

If the material is wet and then freezes and thaws, the blocks become brittle and chips and cracks appear. Because of this drawback, polystyrene concrete needs to be insulated from the outside, the facade of the block building must be plastered with a thick layer of plaster (at least 2 cm) and painted, which increases the cost of construction.

Low material density

One of the block materials is a foam ball. This material is flimsy, in addition, the balls fall out when cut, making low-density polystyrene concrete even less dense. The low density of polystyrene concrete blocks creates many problems during operation. On the one hand, this quality can provide good heat conservation, on the other hand, a structure made from this material is completely impractical. All fasteners (nails, anchors, dowels) integrated into the walls can be pulled out, so to speak, with bare hands. This is a significant disadvantage of polystyrene concrete when used in everyday life.

It is problematic to install doors in polystyrene concrete. During operation, the doors become loose within six months, regardless of the installation method.

The presence of foam balls and, as a consequence, low density give a high degree of shrinkage of a building made of this material - 1 mm/meter.

The low density of polystyrene concrete blocks also causes low thermal conductivity and vapor permeability of the walls. Thus, when building from blocks, it is necessary to take into account the need to install additional means of ventilation, as well as moisture removal. This significant drawback significantly increases the cost of constructing buildings made of polystyrene concrete.

Loading...

Other disadvantages of the material

- To ensure high-quality thermal insulation, the blocks must be laid precisely, with a joint width of 5-8 mm.

- Foam balls have low adhesion to concrete. They fall out from chips, therefore the strength and thermal insulation of the structure decreases every year, which is a significant drawback.

- When building with polystyrene concrete blocks, it is necessary to plaster with a thick layer not only the facade, but also the walls in the room. At the same time, plastering work is extremely difficult to carry out, since plaster does not adhere well to polystyrene concrete.

- The low fire resistance of the material (group G1) is considered a disadvantage. Polystyrene balls are destroyed at high temperatures, which means the concrete block becomes less strong and loses its thermal insulation properties. In order to avoid the destruction of granules, it is necessary to treat the walls of the building with special non-combustible materials.

- After production, the material must reach rest hardening within 28 days. Unfortunately, the buyer cannot be sure that such a procedure has been completed.

abisgroup.ru

Consumables and tools

To build a bathhouse made of polystyrene concrete, you will need the following tools:

- building level;

- cord;

- rubber mallet;

- plane;

- Master OK;

- spatula-comb;

- brush.

You also need to prepare consumables: cement, sand, water, glue for blocks. You need to calculate in advance how many blocks will be needed to build a bathhouse of the required size.

Reference ! It is better to order blocks from the manufacturer - this way you can save money.

Flaws

Aerated concrete is considered a reliable and decades-tested building material, but it also has its downsides.

The material, despite its low density, is quite fragile, so you need to work with it very carefully and should not throw it. Due to the porous composition, it is difficult to hold fasteners. Only through the use of dowels and anchors can this problem be solved. It easily absorbs water, therefore, if the outer side of the wall has poor-quality cladding, the walls will become saturated with moisture and mold may appear

In addition, if moisture gets inside the blocks, then with temperature changes the material will collapse from the inside. Read more about the moisture resistance of aerated concrete blocks here. The price of aerated concrete is higher than the price of other types of cellular material. Ideally even geometric shapes of aerated concrete blocks are guaranteed to be available only from well-known manufacturers. Working with aerated blocks when constructing walls requires strict adherence to masonry technology. When constructing load-bearing structures, the use of reinforcement is mandatory. Buildings made of aerated concrete cannot be built higher than 3 floors.

DIY construction instructions

To build a bathhouse from polystyrene concrete blocks with your own hands, you must follow the instructions:

Construction of the foundation.

The simplest type of foundation for such a bathhouse is strip. To do this, you need to dig a trench 60 cm deep and 30 cm wide around the perimeter, then make markings and arrange a sand cushion.Then the reinforcement frame and formwork are assembled, concrete is poured, having previously organized a sewerage supply. Foundation height 70-75 cm.

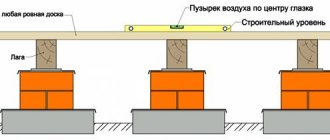

- Walling. The first row of blocks is laid on a cement-sand mortar. Then you can use special glue. You need to adjust the laid stone using a rubber mallet. It is important to check the evenness of each laid row using a level or building level.

- To arrange window and door openings, you need to use additional elements or lintels made of the same material.

- Construction of the roof. First, a frame is made, then the roofing material is attached to it.

- Do not forget about the construction of a straight chimney, which should be separated from the entire bath structure using heat-insulating material.

Why choose polystyrene concrete

If you need a warm bath, then using blocks made of modern building materials is a thoughtful solution. Laying is quite easy to do. Using blocks allows you to save up to 30%. They are easy to transport: three times more polystyrene concrete fits into a truck than ordinary bricks.

Bathhouse layout with dimensions of polystyrene concrete blocks

The dimensions of one block are 600 x 300 x 400 mm. In other words, it is capable of replacing 17 bricks. The speed of building construction increases several times. The products are in demand because they are easy to process. Communications are laid within the walls of the bathhouse. The structure is easy to make original. You can implement unusual design ideas using an arch or semicircular elements. If desired, the owner can build two floors with floors made of wooden beams. Polystyrene concrete is cut and processed with a hacksaw.

Possible difficulties and errors

Difficulties and errors may arise during the work process, especially if the work is performed by beginners. Here are some of them:

- incorrectly designed bath plan;

- the masonry mortar is not prepared according to proportions;

- no special masonry adhesive was used;

- there is no vapor or waterproofing;

- no foundation provided.

If you skip one of the stages of construction or neglect it, then in the future such a bathhouse will not last long. Its walls will shrink, and cracks may appear on the surface.

Cost of polystyrene concrete products

In general, the cost of PSB blocks is 10-15% higher than that of foam and aerated concrete analogues. The price of polystyrene concrete blocks is determined primarily by the size and grade of material (structural or thermal insulation). Products with decorative finishing are 20-30% more expensive than construction products.

For a block measuring 595x375x295 mm, the average price in the Moscow region (per 1 m3, excluding delivery costs, depending on the brand) is:

- D-250 - 3000-3200 rub.

- D-300 - 3300-3400 rub.

- D-350 — 3450-3550 rub.

- D-400 — 3650-3750 rub.

- D-450 — 3800-3850 rub.

- D-500 — 3750-3950 rub.

- D-600 - 4250-4300 rub.

Walls made of PSB blocks with claddingSource isd-group.ru

Advantages and disadvantages

There are several pros and cons of using this raw material for the construction of a bathhouse. First, let's look at the advantages :

availability;- low thermal conductivity;

- possibility of preparing the solution yourself;

- simple installation process;

- resistance to aggressive environmental conditions;

- durability;

- sanitary and hygienic safety.

In terms of availability, the material is considered the most acceptable, even when compared with brick or timber. It does not need additional insulation, since it itself is able to retain heat indoors. In addition, if it was decided to decorate the bathhouse to your taste, then the finishing materials fit very well on the base of the polystyrene concrete block.

Important ! Polystyrene concrete is resistant to rotting and infestation by insects, as well as mold. This gives it an advantage over the same timber from which saunas are often built.

To further reduce the cost of the construction process, you can prepare your own solution for the blocks . To do this, it is enough to adhere to technology and use special equipment. For comparison, it will not be possible to prepare bricks or timber yourself. You can also carry out the laying on your own, since the blocks have good geometry. In addition, a bathhouse made of such material can last up to 100 years.

But polystyrene concrete for baths is not without its drawbacks. Among them are a high degree of shrinkage and instability to temperature changes. In addition, the material belongs to group G1 in terms of fire safety class. This means that it is considered a low-burning raw material: within 90 minutes the material will not be affected by fire.

Owner reviews

After analyzing several construction forums, we can highlight the main pros and cons from owners of bathhouses made of polystyrene concrete blocks. Main positive points :

- does not absorb moisture;

- easy;

- there is the possibility of self-installation;

- good strength;

- affordable price.

But there were also those who were dissatisfied with this material for building a bathhouse. The opposition side claims that the material does not meet the standards, if we take European standards as a basis. They insist that even under plaster, polystyrene emits toxic gases, and if a fire starts, then at a temperature of +135 degrees the material will begin to release harmful substances into the atmosphere.

Reviews from owners of bathhouses made of polystyrene concrete can be read here and here.

Modern material for building a bathhouse

Thanks to its unique properties, it successfully competes with other modern building materials: aerated concrete and foam concrete. Advantages of polystyrene concrete:

- Minor shrinkage, about 0.1%;

- Density ranging from 150 kg/m³ to 600 kg/m³;

- Low operating humidity;

- Rot resistance;

- Strength;

- Fire resistance;

- Excellent sound insulation;

- Long service life, more than 100 years.

If the owner of a summer house strives to use every opportunity to save his money, then the use of polystyrene concrete blocks in the construction of a bathhouse is the right way to do this. Walls and ceilings may have a small thickness, however, the heat will not escape outside. When exposed to high temperatures, polystyrene does not emit harmful substances.

Structure of polystyrene concrete blocks

Therefore, people can safely take water procedures and steam without fear for their health. It takes a little time to build. All construction work can be done with your own hands.

Tips for laying blocks

Some builders lay polystyrene concrete-based blocks using a conventional mortar made of cement and sand, believing that this can significantly save money. The low cost of such a solution can only create the illusion of monetary savings.

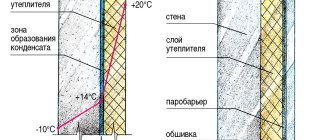

The cost of fine-grained special glue is approximately 2-2.5 times higher than the price of the solution. With all this, the consumption of mortar based on cement and sand per unit area of masonry is 6 times higher than the consumption of glue. Moreover, a tight fit of some elements is only possible when using glue. The use of such a solution, which is made on the basis of cement and sand, will lead to a significant increase in the thickness of the seams, as well as the formation of “cold bridges”, which are breaks in the wall material.

Such bridges have high thermal conductivity. Intense heat exchange in such areas will inevitably lead to the appearance of cold areas that will be located on the inner surface of the walls. This will increase heat loss, which will cause the formation of condensation, mold and dampness. Moreover, traditional cement- and sand-based mortars can increase the unevenness of masonry, reducing its flexural and compressive strength.