Lining is one of the most popular finishing materials. It is environmentally friendly, durable, and has beautiful external characteristics. You can install lining slats using different fastening devices. But the most convenient and reliable of them is the clamper. What kind of hardware is this, what are its advantages and disadvantages, how to install it - you will learn about this from our article.

Tools and materials

In order for the process of installing eurolining to be quick and high-quality, you cannot do without a certain set of tools.

Among them must be:

- perforator;

- jigsaw, it is better if it is electric;

- drill;

- hammer;

- ruler and level;

- thread for checking plumb line;

- self-tapping screws that are suitable for woodworking;

- clampers.

Using a hammer drill, it will be possible to prepare holes for dowels into which screws will fit when screwing the board. You can use a jigsaw to saw off the necessary pieces of material, especially if there are windows or other non-specific protrusions on the wall. For greater efficiency and faster pace of work, it is better to use a jigsaw.

A drill is necessary in order to attach wooden slats or a metal profile to the wall, into which the eurolining will be driven. You can use a hammer to hammer in dowel nails if they are used in the work, or tap the slats so that they sit completely in place without forming gaps or uneven seams. You need to work with this task carefully so as not to spoil the edges of each slats. A ruler is necessary to draw an even cutting line for the material to minimize inaccuracies. In addition, sometimes you have to cover a wall with windows, switches and other additional elements that need to be bypassed on both sides. Using a level, guides are lined up for the eurolining. The result of the finished masonry on the wall depends on their evenness.

When part of the lining is installed, you need to check it using a plumb line with a thread, if everything is fine, then you need to continue working, but if there are strong deviations, you need to get rid of them. The fastening of the boards to the guides is done using self-tapping screws. Their size is selected taking into account the thickness of the eurolining and the distance to the wall.

One of the fastening options is a clamp, which is a small bracket into which the lining is driven. Using a clamp, you can fasten one board to the sheathing and install a second one on top of it, which will fit into the groove of the already fixed part. This fastening turns out to be reliable, because each part is attached to a solid base. When planning the installation of eurolining, it is best to initially decide on the installation method and purchase only the necessary materials. If the procedure is to be done for the first time, then you can try each of the methods on a small area and determine for yourself the most convenient option for fastening materials, according to which you will need to select tools.

How to work with connections

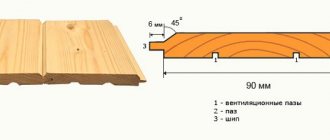

If the task is to attach them to these brackets, then they must first be inserted into the existing grooves, and screwed to the sheathing using self-tapping screws. There are clamps of various sizes. You can choose them from 1 mm to large ones, up to 6 mm. The choice directly depends on the thickness of the building material used in the process of finishing the room. It can be either plastic, wood or lining. When using such hardware, it is possible to significantly increase the speed of finishing the room. In addition, the main advantage of using clamps is the absence of damage to strips or individual sheets when installing fasteners for materials such as lining.

Scheme of fixing the lining

Fastening

You can select clamps for installing lining and plastic according to the dimensions of the panels and their materials. Brackets are classified by the size of the tab or tab that is used to support the mounting plate. There are these types:

- For installing chipboard. The thickness of the elements is 4 mm;

- For installation of plastic lining and MDF. Up to 2 mm;

- To fasten eurolining panels, staples up to 4 mm thick are used;

- For classic wooden lining, 5 mm fasteners are used;

Also, in some cases, sheet sizes are selected individually, depending on the thickness and material of the panels, as well as the location of their installation. It is most convenient to buy fasteners in bulk, this will significantly save your time and money.

In construction stores, the classification of clamps is carried out by numbers. For example, when installing aspen panels, brackets 5 and 6 are used for the ceiling, and for eurolining 4. Check the information directly with the seller so as not to confuse the fasteners.

Photo - steel clamp

The first step is to install the frame for future cladding. The surface for mounting the clamps must be perfectly flat, so when attaching bars and beams, be sure to use a level or laser pointer. Tips before installing the frame:

- Wood must be treated with an antiseptic solution, which will protect it from rot, mold and pests;

- Metal profiles can be taken the same as when installing drywall, i.e. CD, UD, CW and UW;

- If the paneling is done in a damp room (bathroom, sauna, etc.), then a waterproof film must be installed on the frame, which will protect the base from destruction due to moisture.

How to install clamps and how to attach them to the lining:

The tongue of the clamps is so thin that it does not interfere with the further installation of the lining. But at the same time it has excellent rigidity and does not deform when sheathing. After finishing the work, no additional actions are required (putting fasteners, priming, etc.), with the exception of coating the lining with antiseptics on the outside.

If installation of several layers of lining or a solid board is required, then not an ordinary bracket is used, but a so-called House block. It is more durable and wider, its tongue height can reach 10 mm.

Photo – House block

In the process of choosing clamps, a prerequisite is that you need to take into account the thickness of the material used for finishing work

It is very important to use only those brackets for lining that correspond to the dimensions of the product that you plan to use for cladding a particular structure

Fastening the lining to clamps is carried out most reliably if the builder used a type of hardware that has a thickness equal to half a millimeter, and the material for its manufacture was galvanized steel. This choice is not accidental, since this raw material cannot be subject to rust, unlike other metals.

The described fasteners for lining are so common among consumers today for many reasons. Among others, we can highlight the possibility of carrying out installation work in a room whose conditions are characterized by a high level of air humidity. Among other things, such fasteners are quite simple to use; even a worker who does not have enough experience can perform the manipulations.

Using these elements, you can choose in the store exactly the type that is suitable for a certain type of lining. The master will not need to purchase additional components. The clamps are distinguished by the presence of an anti-corrosion coating, which ensures durability and reliability.

Marking the base

In order to install each panel evenly, it is necessary to make markings on the base in advance. Installing wooden lining on clamps requires perfect precision to make it easier to monitor the level of the panels.

The marking method will depend on the direction of the panels. If the lining panels are placed vertically, the distance of the outer plank from the wall should be equal to its size. In the case of a horizontal installation method, the clamp should be located 1-2 mm from the floor.

To highlight the interior of a room, a mixed type of installation is often used, when a simple pattern is built from panels. Sometimes they are placed diagonally. Both methods require a certain skill, and if the vertical and horizontal methods do not require special skills, then difficulties may arise with the combined options.

The choice of panel placement may depend on the purpose of the room. Combined methods are more often found in living rooms, where decorative design is important. The vertical placement of the panels plays rather a practical function.

It is often found in bathhouses and helps preserve the lining from rotting (moisture does not accumulate in the seams between the panels, but flows down them).

How to fasten lining with clamps

Clamps are metal plates that have holes for nails/staples and a tongue of a certain shape that holds the lining by the groove. Clamps are used not only for lining, but also for exterior finishing systems - ventilated facades, plastic panels or MDF and chipboard panels. These are fairly reliable devices that provide reliable and hidden fixation of finishing materials.

Clamps for lining

For installing lining in a bathhouse, clamps are good for two reasons:

- The clamps are made from high-carbon steel and then galvanized on top. So such products can withstand difficult bath conditions (high temperature and humidity) for a long time.

- The special design allows you to mount the trim covertly and at the same time reliably (if you choose the right clamp size).

When installing eurolining of a standard profile, you need to use clamps with a tongue height of 4 mm; when using staples and a construction stapler, the tongue should have a length of 5 mm. To install a block house (lining with a rounded front surface imitating a rounded log), the height of the tongue should be 6 mm.

On average, there are up to 20 clamps per square meter. Knowing the total area of the walls and ceiling, you can estimate the amount of fasteners needed.

Plastic slats are a more popular type of material for finishing balconies and bathrooms than their wooden counterparts for a number of reasons:

- lighter weight, which reduces the load on the base plate;

- affordable cost;

- ease of installation;

- resistance to temperature and humidity changes.

Fastening plastic lining with self-tapping screws

Using lining, you can relatively easily and quickly give an auxiliary room an attractive residential look. Knowing the installation features will help you make the right choice of mounting method depending on the type of panel material and the purpose of the room.

Price issue

Q: How do I identify strong mounting brackets?

A: If it is possible to familiarize yourself with the product passport, all the characteristics of the product should be there, including the boundary load, installation method, type of lock on the lining, etc. If the purchase is made in a retail store, you can try bending the tab of the staple with your hands. Durable ones (for wooden lining) will not give way under the force of your fingers and will retain their shape.

Q: Choosing self-tapping screws for clamps - how not to go wrong?

A: The product passport must indicate the type of fastening of the bracket to the mounting frame. Usually these are standard galvanized self-tapping screws 10-20 mm long. Only the cap plays a big role here - it should be flat, without protrusions. When choosing self-tapping screws, you can try on different types on a regular clamp. The screw head should not extend beyond the upper plane of the bracket.

Q: What tools are needed to install panels on brackets?

A: Water or laser level, tape measure, mallet, self-tapping screw, screwdriver or hammer (depending on the method of attaching the clamp to the frame), drill. To accurately drill holes, a center punch is sometimes used to mark the location.

Q: How can I save on installation?

A: Staggering the mounting brackets, replacing self-tapping screws with nails, and using traditional installation methods can reduce the overall cost of repairs. However, safety is an important factor - poor fasteners will cause wall destruction, sheathing deformation, chips, and cracks. It's better not to save money on this.

Q: Is a special coating required for fasteners?

Oh no. There is no need to apply protective agents to any type of installation. The main thing is to take into account that the nails, staples, and screws were coated with a layer of zinc or powder paint at the factory. Only this material can be used in conjunction with sensitive wood or MDF panels. Plastic is not afraid of rust - you can use ordinary nails for it.

Q: What form of clamp is preferable for wooden lining?

A: Rectangular or square. The optimal number of holes for self-tapping screws is 2. For light types of finishing, installation on a clamp with 1 socket for a self-tapping screw is possible. In this case, you should take care of maximum adherence of the sheets to the frame.

Q: Is it difficult to install lining for a beginner?

A: If you have sufficient knowledge of power tools, understand the algorithm and choose the right fasteners, it’s quite simple. PVC sheets are best suited for amateurs - they are light in weight, can be mounted in different ways, and allow a lot of play. The most difficult thing to install is wooden slats - the problem is their heaviness and low margin for error.

How justified is the overpayment compared to finishing nails? The answer is in the table below.

| TYPE | Price, rub. * |

| Kleimer thick. 2 mm 100 pcs. packaged | 88 |

| Claymer for thick lining. 3 mm 100 pcs. packaged | 120 |

| Clamp for lining thick. 4 mm 100 pcs. packaged | 128 |

| Copper-plated finishing nails 1.2x25 price per 100 g | 45 |

| Galvanized finishing nails 1.4x30 price per 100 g | 40 |

* Prices are valid for autumn 2021.

As you can see, the cost of clamps is 2-3 times more expensive than finishing nails.

Is it worth overpaying? After all, many take on the cladding of bathhouses and balconies on their own just because they want to save on work.

It's still worth paying extra for several reasons.

Fastening the lining with clamps

Finishing nails are available in various types of coating and are selected depending on the location and type of finish:

- black – steel fasteners without an additional anti-corrosion layer for work in completely dry rooms;

- galvanized - the inexpensive and most popular variety, the zinc layer provides reliable protection, the products are suitable for use in all types of structures that do not have direct contact with water;

- with copper, brass, chrome or bronze coating - more expensive types of fasteners that can be used in rooms with high humidity and in open spaces, with increased requirements for aesthetic finishing, when working with expensive types of wooden lining.

Any novice craftsman who knows how to use a hammer can handle the job. Also during the installation process, a hammer is used - the device allows you to drown the head of the nail without damaging the material.

Using a Finishing Nail Puncher

When the panels are positioned vertically (the sheathing must be horizontal), installation is carried out in the following sequence:

- Place the first part with a tenon in the corner (for reliability, it is better to fix the first and last parts through with self-tapping screws, cover the caps with decorative caps to match the panel).

- Attach finishing nails to the sheathing beams through the groove at an angle of 45 degrees using a hammer with gentle blows.

- Insert the second panel with a tenon into the groove of the first, lightly tap the panel with a hammer through a piece of clapboard or block. Check the evenness of the masonry with a level.

- Attach through the groove with nails to the sheathing, etc.

Fastening in a horizontal position is carried out using a similar technology.

When using nails, they are driven into the groove of the lining at an angle, completely recessing the head into the wood. To avoid damaging the bar, you can use a hammer. Screws are screwed in in the same way, also making sure that they do not protrude and interfere with “planting” the next board.

Installation of lining with finishing nails. Options

Is it possible to fasten the lining in a bathhouse with finishing nails?

There is another option - simply hammer the nails into the lining, recessing the heads deeply (with or without drilling). Cover the resulting indentations with wood putty. It’s much easier to do this, but not everyone is happy with this option from an aesthetic point of view: making nail/screw marks completely invisible is quite problematic.

You can make your own wood putty that perfectly matches the color. To do this, mix the smallest shavings, or better yet, the dust that is formed when cutting the lining, with a small amount of PVA glue until it becomes a thick paste. Use this mixture to cover all the grooves.

Finishing nails for lining

It is better to take finishing nails for lining in a bathhouse with a copper, brass or chrome coating. They will withstand high humidity and will not collapse prematurely.

The first board is installed in the same way as when installing lining using nails. It's all about how it is fixed. Clamps are put on the tenon, which are attached to the sheathing using nails/staples/screws. There are three holes for fasteners, but you choose whether to use all or only two (it is dangerous to fasten the paneling in a bathhouse with one nail/screw - it can tear it out). Nails or screws are supplied with the clamps. If you are going to “mount” it on self-tapping screws, it is better to have a screwdriver - this will speed up the process significantly.

You can also use a construction stapler to attach the clamps, but you also need to know how to use it. It all depends on how hard you pull the trigger. If you press weakly, the staple will not completely enter the wood; you will have to either shoot another staple, or “finish off” this one with a hammer.

In any case, the fixation scheme is no different from fastening with nails: first fasten the clamp in the middle, then along the edges, and, after checking the vertical/horizontal installation, to all other intermediate lathing strips.

The lining is attached to the ceiling according to the same principles as on the walls: first, a wooden frame is assembled, adjusted to the level. The lining is attached to it - with clamps or nails - it’s your choice. Both methods have a right to exist.

It is more convenient to lay the lining with the tenon facing towards you. The principle is the same: you lay the first board of the lining, retreating 1-2 cm from the wall. It can be fixed along the wall with nails - then a corner or plinth will be attached to the top. Then, on the tenon side, at the intersection of the lining with the sheathing, you either install clamps or drive nails in at an angle.

Conclusion: You can fix the lining yourself. There is nothing super complicated about this. It takes time, accuracy and patience (except for the lining and fasteners).

Nuances of assembling various designs

When it comes to assembling furniture, you need to take into account that it will not be possible to connect elements of different products in the same way - the installation of furniture structures requires special fasteners, fittings and a set of tools.

There are certain nuances in the assembly process itself - you need to know them in order to work quickly, accurately and accurately. Floor installation of a bed is significantly different from the assembly of wall cabinets; the connection of upholstered furniture parts and the installation of a built-in compartment are carried out completely differently. Some nuances and recommendations for assembling various furniture: a chest of drawers with drawers is an example of simple prefabricated furniture with a minimum number of fasteners. You need to install drawer guides on the side panels. Pour a little glue into the blind holes in the sidewalls and ends of the stiffener flanges, insert the dowels and easily hammer them in, connecting the elements, and then attach the confirmations. The top cover is fixed with dowels and minifixes - a pin in the cover, an eccentric in the sidewall, then the confirmations are screwed in until they stop. The next stage is to nail the back wall, having previously checked the diagonal, assemble the drawers, install guides on them, screw the handles into the prepared holes; standard sleeping bed. After checking the presence of all structural parts, the base is assembled - the transverse and longitudinal beams of the frame are connected with euroscrews (confirmations) or self-tapping screws. A cross beam is fixed in the center, the lamellas are installed in specially prepared grooves. The side walls of the frame are secured with dowels and plugs. The remaining elements of the bed are fixed with bolts, the legs are screwed in, if there are any, and the mattress is placed in the base box. The double model is assembled according to the same principle; bed with lifting mechanism. The standard model consists of a frame (base), a lifting mechanism, a mattress and internal drawers. You will need a screwdriver with a full set of attachments, a screwdriver, a wrench, euro screws with countersunk heads and an internal hexagon, a tape measure and a level. Assembly diagram: connecting three drawers and headboard parts with brackets, corners or ties with screws. In the upper part of the drawers, shelves, corners, a lifting mechanism are mounted - a gas shock absorber (cylinder upwards) is secured with nuts with a stopper, handles and a limiter for the mattress are installed; Stationary cabinets are the easiest furniture to assemble. Sequence of actions: connecting the shelves with the side panels using confirmations and screwdrivers, installing the back wall made of fiberboard, for which furniture nails or a furniture stapler with staples are used. After assembling the box, check the same level of diagonals and compliance with the right angle between the elements. The next step is hanging, adjusting the facades, then all that remains is to install the shelves. If the model has drawers or roll-out shelves, guides for them are installed first; sliding body - a stationary sliding wardrobe with a plinth begins to be assembled by screwing the plinth to the bottom with minifixes and dowels, and then driving in support nails

The body is also assembled on minifixes and duplicate dowels; it is important to check the correspondence of opposite holes. Next, fix the back wall (nails, staples, installation in a groove), check the diagonal and angle

After this, you need to install shelf supports, guides for drawers, install shelves and a bar. If the cabinet is without a base and trim in the lower rear part, the plinth is dismantled; sliding door system – used for all coupe models. Built-in products do not have side walls and are often made without a roof or bottom. Installation consists of attaching shelves to the walls of the room and installing a sliding system. First, install stoppers and limiters, secure the upper guide rail, there is no need to screw the lower one. The door panel is inserted into both guides into the far grooves, the second leaf into the near grooves, and adjustments are made. After this, you can fix the bottom rail and glue the sealing brushes; elements of a kitchen set are complex installation; a full set of tools, diverse fasteners, and special fittings are required. Assembly begins with the preparation of the lower sections - the bottom is connected to the side walls with euroscrews, the planks are installed under the tabletop, the back wall made of fiberboard is secured (stapler, nails in increments of up to 10 mm), and the legs are fixed with self-tapping screws. This is followed by installation of hinges in the mounting slots, hanging of hinged facades, and adjustment. Drawers are assembled using the same principle. After screeding the “bottoms,” the tabletop is installed, checking the horizontal level with a building level.

Claymers, their features and characteristics

In modern construction, lining as a finishing material today enjoys very wide popularity. This is due to many different factors. This material is distinguished by its reliability and quality, and its installation does not cause any particular difficulties for builders. When carrying out external finishing work, hardware for lining, as a rule, is nails and self-tapping screws. However, if it is necessary to perform a neat installation, with the ability to hide all fasteners, clamps become almost irreplaceable. That is why they are used with equal success for both external and internal finishing work.

A house trimmed with “block house” clapboards with fasteners using clamps

What is a kleimer?

A clamp is a special fastening element in the form of a bracket, mounted with nails or self-tapping screws on a prepared base - lathing, or directly on the wall. The clamp hook firmly fixes the lining, while allowing all fasteners to be hidden. This type of hardware is used for the installation of not only lining, but also plastic PVC panels and MDF elements.

Kleimer

Advantages of using clamps

Hidden fastening of lining with clamps has become so popular for many reasons:

- It allows you to significantly speed up the installation process.

- Eliminates all risks of damage to materials, splits or cracks associated with the use of standard hardware - nails and self-tapping screws.

- Individual and precise selection of fasteners corresponding to the type of lining used.

- High reliability of fixation. Boards secured with staples will not begin to play and become loose over time.

- Claimers do not require the purchase of additional components. All that is needed for installation are the staples themselves and nails with self-tapping screws.

- Coating with an anti-corrosion layer ensures durability and a high degree of reliability of fasteners.

- Low cost and availability of clamps, excellent combination of price and quality.

Clamps fixed into the groove of the lining

How to choose the right mounting brackets for lining?

Claypers must be selected based on the type of lining used in finishing the room. It comes in different thicknesses and weights, so the mounting brackets must have the appropriate size and tongue height.

- Plastic products and MDF elements can be fixed with clamps 1-2 millimeters high.

- Fasteners with a tongue of 3 millimeters are used for finishing materials made of chipboard.

- Eurolining is mounted using clamps 4 millimeters high.

- When decorating a house with ordinary wooden paneling, 5 mm staples are used.

- A block house requires the most powerful fasteners. Here you will need six millimeter clamps.

Claymers of different types

Calculation of the number of clamps required for work

As for the consumption of fasteners, as practice shows, to securely fasten a square meter of lining you will need about two dozen staples. But it’s still better to buy them with a reserve, since the cost of clamps is low.

The exact calculation of the required number of fasteners is carried out using the following algorithm:

- We measure the length of one panel of the lining.

- Determine the pitch of the sheathing frame. As a rule, standard values vary from 40 to 60 centimeters.

- Divide the first number by the second, adding one to the result.

- We multiply the result by the total number of lining panels that are planned to be used for finishing work.

- We calculate the number of packages with fasteners based on the number of staples in one. As a standard, each box contains 100 clamps.

What should you consider during installation?

To successfully install lining using clamps, the following nuances must be taken into account:

- The boards should not be in direct contact with the surfaces of the floor, ceiling or wall. That is, a tight fit to them should be avoided in order to ensure ventilation;

- It is quite possible that you will have to sheathe a surface on which there are niches for an outlet or other electrical devices. In such a situation, you should also carry out installation, and then cut out the corresponding holes with a flared saw - as a rule, a diameter of 5.5 cm is enough;

- The free space between the floor and the casing can be hidden with a skirting board that matches the texture.

Return to content

How to calculate clamps for fasteners

You can correctly calculate the number of clamps needed as follows:

- Measure the length of the lining with a tape measure.

- The location of the clamps is usually calculated at a distance of 40-60 cm. 5 cm is possible. It is better not to do less or more.

- The division works like this: the length is divided by the distance, plus one. Visually: 200 cm: 40 cm 1 = 6 clamps per lining.

- Then you can calculate how many of them will be needed for all the linings and work.

- Example: 10 linings X 6 clamps = 60 clamps.

- Usually 100 staples are sold per package, but you can also find them sold individually in regular hardware stores.

It is very easy and quick to calculate how many clamps are needed for the job.

Tips for use

A few simple tips will help extend the life of the lining and preserve its attractive external characteristics for a long time:

- Buy hardware from trusted construction stores with quality products and good reviews.

- Do not use liquid sealants for joints, so as not to cause corrosion of hardware.

- After installation is completed, treat the lining with varnish or oil composition.

Clamps are easy to install, inexpensive, provide high structural stability and long service life. For these reasons, fastening lining with clamps has become so popular in our time.

How to cover a wall with laminated panels

The process of covering walls with panels is simple and does not require high qualifications from the performer. Anyone who knows how to hold a hacksaw, hammer and screwdriver in their hands can do this job without much difficulty.

Required Tools

What tools the installer may need depends on how he plans to install the laminate on the wall, but in any case the following will be required:

- building level;

- tool for cutting panels (metal hacksaw, jigsaw);

- block for padding panels during installation;

- wooden or rubber mallet;

- metal square and tape measure.

To cover a wall on a wooden frame, you will additionally need a stapler with the ability to use nails, and to attach it to a metal frame, a screwdriver. To glue the laminate to the wall, you will need a glue gun.

Wall mounting methods

Two methods of covering walls with laminated panels are used - adhesive and frame.

The first requires careful leveling, puttying and priming of the wall before starting installation.

The frame method does not require leveling the surface of the walls - the slats are laid on a sheathing mounted from a metal profile or wooden blocks.

When you plan to install laminate flooring on a wall with your own hands, it is advisable to carefully consider which option will be less labor-intensive and make the optimal decision.

Laying panels

If you choose the method of attaching the laminate to the wall using lathing, the sheathing process begins with its manufacture. To make a wooden one, you need to attach bars 20 - 40 mm wide to the wall with self-tapping screws at a distance of 300 - 400 mm from one another perpendicular to the direction of the strips. To assemble the metal sheathing, a profile designed for gypsum boards is used.

Before you start installing the laminate on the wall, you need to place spacer wedges under the bottom strip to ensure a deformation gap of 5 - 10 mm (cuts of the laminate will do). You can start installation from any corner, but it is more convenient from the bottom left.

Laminated panels are attached to the sheathing using special staples called clamps, or nails. Clippers are the best fastener for laminate flooring when laying it on a wall, but the process itself is more labor-intensive.

Due to the fact that laminated panels have the ability to expand and contract, the clamping method of their installation is the most reliable.

The clamps press the protruding part of the lamella lock, securely fixing it and not interfering with the docking of the next laminated panel laid on the wall. The clamps themselves are secured to the sheathing either with self-tapping screws or nails.

A simpler, but less reliable way of attaching lamellas is with finishing nails through the groove of the lock. For stronger adhesion, strips of glue can be applied to the bars before installation.

With the adhesive method, before starting to lay the laminate on uneven walls, first of all, it is necessary to remove these irregularities. Then the wall needs to be plastered, and after drying it must be covered with a primer. The glue must be chosen taking into account the fact that the material tends to “walk” when humidity and temperature change. To securely fix the laminate to the wall, “liquid nails” or special glue designed for this purpose are best suited.

The technological process of installation is extremely simple - you need to apply glue to the first panel (or wall) in a zigzag pattern and press it firmly against the wall at the point where installation begins. All other slats are attached in a similar way. To ensure maximum strength of the coating, they are laid with a “comb”, for which the required number of panels should be cut in half. Start laying each next row alternately with a whole strip or with its half.

To complete the work, the corners and edges of the sheathing should be covered with corners and decorative plinths.

Installation of sheathing

Do-it-yourself installation of the lining begins with the installation of the sheathing.

If the room has smooth wooden walls and ceilings, then the lining can be attached directly to them, but in 99% of cases this is not the case. Therefore, it is impossible to do without installing the sheathing, which will become the supporting structure.

First you need to choose the direction in which the panels will be mounted. In the frame, the beam should be located perpendicular to this direction. Horizontal installation will visually expand the room, and vertical installation will raise the ceiling.

The lathing can be made of metal profiles or wood. For lathing, slats with a cross section of 20x40 or 25x50 mm are used; they can be easily purchased at specialized retail outlets or, if you have one-inch wooden boards, you can make them yourself by cutting them using an electric saw.

It is better to use coniferous wood; it is not so affected by changes in humidity and temperature.

We proceed directly to creating the supporting frame. If the wall is sheathed vertically, we fix the first beam horizontally under the ceiling:

- using a level, draw a line parallel to it; mounting brackets will be installed along it;

- using an impact drill and anchor screws, we install brackets at a distance of half a meter;

- we form a connector under the beam, bending part of the fastening inward;

- We fasten the timber, fixing it with wood screws in the side holes of the brackets, and screw the rest of the fastenings to the wall.

All beams in the frame must lie in the same plane and be set strictly level. To do this, having installed the first beam, plumb lines are attached to it, which will help determine the location of the remaining slats.

Insulation

Before installing the lining, you can additionally insulate the wall.

Most often, mineral wool in rolls is used for this. It is cut into segments of the required size, which are then placed under or between the sheathing beams.

For additional fixation of the insulation, you can use mounting fasteners or glue.

After laying the insulation, the joints of the segments need to be filled with polyurethane foam (do not use “extra” foam, it can deform the insulation).

There is a second option, in which the insulation is laid before the frame is installed, it is strung on fasteners for the slats, after which the sheathing is completely installed.

Video - insulating a balcony with penoplex under the sheathing:

Installation

The first thing you need to do is choose one of 5 ways to attach the lining.

- This method is characterized by its simplicity, high strength of fixation and the possibility of dismantling if necessary. Installing the lining on the clamps is easy to do yourself: they are inserted into the internal projections of the grooves on one side, and the other is attached to the wooden frame.

- A hole equal to ½ the diameter of the screw is drilled in the panel, after which, using a screwdriver, the screws are screwed in until they are completely immersed in the wood. The holes are closed with a wooden pin and sanded. The method is often used in cladding rooms in bathhouses.

- A method for professionals: a nail is carefully driven into the groove at an angle of 45º, then driven into the sheathing. To fix a 2.5 m panel, at least 6 nails are used.

- A hole for a screw is drilled in the panel tenon, and then the board is screwed to the slats. The process must be carried out flush with the board.

- Using a construction stapler, the staples are installed diagonally into the groove of the panels and secured to the sheathing.

Video - a non-standard, but proven method of fastening:

We begin to install wooden lining with our own hands. Vertical cladding is made from the corner of the room.

Horizontal cladding involves fastening the panels from above, and the groove should be directed downwards, so moisture and debris will not get into the grooves, therefore, it will last much longer.

If the panel is not tightly pressed to the previous one, it can be tacked using a piece of lining, so as not to damage the connecting system.

Before fixing it on the sheathing, the last panel is adjusted with a hacksaw, the gap between it and the floor is closed with a plinth, and the joints and corners are decorated with special slats and corners.

Video - DIY installation:

How to attach?

Before starting work, you need to decide how exactly the boards will be fixed: in a horizontal or vertical position.

In any case, you first need to take measurements and outline the approximate location of the products with a simple pencil. After this, the wood is immediately sawed according to the intended instructions and the necessary tools are prepared for installation.

To make a reliable and durable frame structure from the clamps, they should be properly secured to the surface. You can attach the parts either to a flat, cleaned wall, or to a prepared sheathing.

If you plan to fix the clamps with nails, then you should use a building level and a hammer. If you are attaching them with screws, you will need to take a screwdriver and a screwdriver.

Fixation of fasteners and the wooden panels themselves is carried out alternately. During the work, it is necessary to maintain accuracy when calculating the position of fasteners

In this case, special attention should be paid to the very first part, because it is this that determines the position of further planks

Remember that nails to secure the clamps can only be used if the sheathing has been installed in advance. It can be mounted using dowels or self-tapping screws.

To make the sheathing, use small blocks of wood. They must provide a gap of at least 5 centimeters. Only after this the clampers themselves are installed.

Each clamp is attached in such a way that the board can lie on it as evenly as possible. If you used self-tapping screws, then it is also recommended to make the sheathing from the bars in advance. It can greatly simplify fixation.

After this, you should prepare small holes (their diameter should be less than the diameter of the screw), you can also gradually screw the screws into the base at the designated points. When the first part is attached, you should begin installing the first board and at the same time you need to fix the remaining brackets.

The first sheet is always mounted in the hook of the latch; subsequent elements will be installed with a groove in the tenon. After joining, the coating must be carefully inspected. It should be smooth, not deviate from the surface, and press tightly against the wall. When several boards are secured, knots will form. They can be fixed using ordinary nails.

If necessary, decorative corners can be used during installation. They make it possible to hide all imperfections after installation work and give a beautiful and neat appearance to the finished coating.

For information on how to use the clamper, watch the video below.

Frame structure

Installation diagram of MDF panels.

If the rough ceiling in the room is made of prefabricated reinforced concrete panels, you must first carry out preparatory work. The rustles between the slabs are cleaned of everything that does not hold well. The aesthetic properties of the rough base are not important, so the easiest way to fill the seams is with polyurethane foam. For wooden plastered floors, it is enough to ensure strong adhesion of the finishing material to the base. If the strength of the plaster is in doubt, it is better to knock it down. After all, during the installation of suspensions, the quality of adhesion will further deteriorate. And this already threatens the strength of the future structure.

Next, you need to apply horizon marks at the corners of the room, i.e. serifs that will be located strictly at the same level. The easiest way to do this is with a laser level. But a regular water level with a tube of sufficient length will work just fine. It is not advisable to use a bubble level on the staff for this; this can lead to significant errors.

Related article: Mint-colored wallpaper in the interior

Scheme of an open slatted ceiling.

Using the marks obtained, we determine the lowest corner of the ceiling of the room. The rough base is rarely horizontal; the discrepancies usually reach several centimeters. We retreat 5 cm from the level of the lowest point of the rough ceiling. At this mark we will make the base of the finished ceiling. Using horizon marks and a tape measure, we transfer the mark for the placement of the future frame to all corners of the room. Using a construction cord, draw a horizontal line around the perimeter of the room at the selected height.

Then you need to make sure that there is no electrical wiring in the room at this level. There are special devices for this. If they are not available, you will have to carefully look for grooves covered by builders using a hammer and chisel. An indirect indication of the position of the electrical wiring is the placement of wiring boxes. It's easiest to start from them.

We fasten the UD profile around the perimeter of the room so that its bottom shelf is flush with the horizontal line. It is attached to a concrete or plaster base with “quick installation” dowels into holes drilled with a hammer drill. For walls with a wooden base, “press washer” screws are suitable for this. Their length is chosen so that the thread enters the wooden base by at least 25 mm.

Next, you need to decide on the direction of installation of the MDF panels. Because The panels have a finite length; it is advisable to choose a direction in which they would not have to be extended. In addition, keep in mind that placing panels along the long side of the room visually lengthens it, and across it shortens it.

Marking of suspended ceiling.

At the locations of future load-bearing rails, draw straight lines on the ceiling. Along the lines, perpendicular to them, we attach straight hangers, also in increments of 30 cm. They are attached to concrete bases with driven dowels, and to wooden bases - with press washers of sufficient length. It is selected in the same way as for attaching the UD profile to the wall.

Related article: Beautiful and comfortable living room 30 sq m: design of a combined space

CD profiles or 25*50 mm wooden slats are inserted across the grooves on the UD profile. They are fixed to the bent legs of straight hangers with LN 9.5 mm self-tapping screws. The extra length of the paws is simply bent upward. It is convenient to lay sheets of polystyrene foam insulation on the bent legs if insulation is being carried out. If necessary, profiles or slats need to be extended using connectors. All lightweight galvanized profiles can be easily cut with metal scissors. If you use wooden slats instead of galvanized profiles, try to find ones that are even and dry, which is not at all easy. Before cladding, you need to lay all the necessary electrical wiring along the frame.