Have you thought about installing water heating in your home? It is not surprising, because a single-pipe heating system for a private house can be traditional and completely energy-independent or, on the contrary, very modern and fully automatic.

But you still have doubts about the reliability of this option - you don’t know which scheme to choose and what pitfalls await you? We will help clarify these issues - the article discusses schemes for arranging a single-pipe system, the pros and cons that await the owner of a house with such a heating system.

The article is provided with detailed diagrams and visual photographs depicting individual elements used in heating assembly. In addition, a video has been selected with an analysis of the nuances of installing a single-pipe system with heated floors.

General information about single-pipe heating schemes

The main areas of application of single-pipe schemes are houses of different heights with a small number of radiators in one circuit. For example, in high-rise buildings no more than three radiators per floor extend from the riser. In the private sector, such systems are most effective in one- and two-story private houses with an area of up to 150 m2.

Advantages and disadvantages

You can choose the right heating system only based on operating conditions, taking into account the positive and negative aspects of all types of construction.

| Advantages | Flaws |

| Material savings and lower labor costs compared to two-pipe options | Uneven heating of radiators - the last batteries in the circuit warm up worse than the first (see photo below the table), since the coolant arrives to them already cooled |

| Compact – pipes are easier to hide in the floor or walls | Complex hydraulic calculations, requiring a thorough study of the methodology |

| Hydraulic stability, constant heat transfer of elements | Difficulties with arranging a gravity coolant supply circuit (without installing a circulation pump) |

| Low inertia - filling the lines requires less coolant, which warms up faster | Difficulty in balancing during commissioning - even with accurate hydraulic calculations, sometimes you have to adjust the system |

| Installation of thermostatic fittings on each radiator is allowed | |

| Shut-off valves and battery bypasses allow you to replace the radiator without stopping the system | |

| Simple design, accessible for self-installation with proper hydraulic calculations available |

Cooling of the coolant when moving through a single-pipe heating system.

The negative aspects can be minimized by installing radiators with a large number of sections at the end of the circuit, mandatory installation of bypasses, and dividing the system into several branches.

Design Features

The main distinguishing feature of single-pipe wiring is that all batteries in the circuit are connected in series, and the outlet pipe from the previous battery is connected to the input of the next one. After the last radiator in the circuit, the coolant returns to the boiler.

A pictorial diagram of a typical single-pipe heating system.

In a more competent system, a jumper (bypass) is installed of each

Scheme of a single-pipe heating system with bypass.

It allows:

- balance the system, achieving approximately equal battery temperatures;

- turn off the radiator in case of malfunction or accident;

- regulate the temperature - even with minimal opening of the thermostat tap, the coolant will flow into the next convector.

Heating systems are classified according to several criteria:

- contact between coolant and indoor air – open and closed;

- method of organizing coolant circulation - natural, forced, combined;

- type of coolant supply to radiators - top or bottom;

- layout - horizontal or vertical.

Each of the characteristics and their combinations affect the heating efficiency under specific operating conditions.

Open and closed systems

As it heats up, the volume of the coolant increases. Excess fluid appears that must remain in the system. For heated coolant, expansion tanks are installed. Their volume is chosen at the rate of 10-15% of the total capacity of the boiler, pipes, radiators.

The design determines the type: closed or open.

Open type

Ready-made expansion tank for open-type CO.

In open versions, any container that is resistant to corrosion and temperatures of about 80 ° C is used as a tank. This can be a tank made of stainless steel or corrosion-resistant ferrous metal. The device is installed at the highest point, which prevents the coolant from leaking under the influence of the liquid column.

Important! Open systems are filled only with clean water. When antifreeze evaporates (boils), it releases dangerous or even toxic substances that can be harmful to health.

At the bottom there is a pipe for connection to the pipeline. A hatch is left at the top for adding water.

In other options, topping up the evaporated water is carried out by connecting to the water supply network (see diagram below) and organizing the drainage of the excess into the sewer.

Scheme of an open-type single-pipe system.

To prevent overflow and automatically remove air, the tank is often made airtight, and an automatic bleeder valve is installed in the upper part of the tank. This option is preferable if the tank is located in the attic and access to it is difficult.

Open system tank with automatic air vent.

Closed systems

Design of a membrane expansion tank.

In closed circuits, two types of sealed expansion tanks are used: with a diaphragm or balloon membrane.

Before filling the system, pressure is injected through the nipple in the air chamber to 1.5 atm. Then fill the system with coolant until the pressure gauge reads 1.8-2 atm.

Then the tank operates in automatic mode:

- When heated, the liquid expands.

- The pressure increases, and excess coolant enters the working cavity of the tank through the pipe.

- The separating membrane is elastic, so the working area increases. At the same time, the air pressure in the second compartment of the tank increases.

- After cooling, the coolant decreases in volume and the membrane, straightening under the action of compressed air, squeezes the coolant into the heating system.

There is no contact between the working fluid and room air, so in closed systems you can use any antifreeze and glycols approved by the heating equipment manufacturer.

In closed systems, the expansion tank can be installed anywhere, but preference is given to installation near the boiler: the tank does not spoil the appearance of living quarters, and maintenance is easier.

Scheme of a closed-type single-pipe heating system.

Principle of operation

The functioning of a single-pipe main is carried out by constant circulation of coolant through the branches of the system. As it moves from the boiler to the radiators, it releases heat and warms the room, and then returns to the original tank to repeat the cycle.

The coolant can be steam, antifreeze, air or water. The last option is the most common.

The operating principle of a classic heating system consists of several stages:

- The boiler heats the liquid, causing it to expand and create pressure in the pipes.

- The density of the coolant decreases and it loses weight.

- Cold, heavier water pushes the heated liquid upward. To ensure this process, the pipes coming from the boiler are always installed in the upward direction.

- Under the influence of the resulting pressure, gravity and convection, the liquid flows to the batteries and heats them up.

- Cooling down, the coolant returns to the heating source, repeating the process.

In gravity heating systems, a certain angle of inclination of the horizontal branches is required (per 1 linear meter - 2-3 mm) to ensure stable flow movement.

Heating water increases its volume, which creates hydraulic pressure in the system. But even a slight increase in pressure above normal due to lack of fluid compression can cause pipeline failure. To compensate for the pressure in such schemes, a special expansion tank is installed.

Coolant circulation options

In single-pipe networks, there are three ways to move coolant:

- gravitational;

- using a circulation pump;

- combined.

The option is chosen depending on the configuration of the house and wiring.

Gravity systems

In the case of constructing such networks, the laws of physics are used:

- Thermodynamics - a heated liquid is less dense (light), the greater the difference, the stronger the heating.

- Convection and gravity - light liquid in a closed circuit rises, displacing cooled liquid down.

Heating boilers are used for heating. The organization diagram does not differ from the scheme of an open CO with an expansion tank. Large-diameter pipes are installed in the lifting section (acceleration section), usually 2 times larger than the main distribution. The coolant is cooled in the radiators and enters the boiler.

(Repeat) diagram of an open-type single-pipe system.

Important! Gravity systems can only be open, the coolant is in contact with the air in the expansion tank.

| Advantages | Flaws |

| Energy independence | Large pipe diameters to minimize hydraulic resistance |

| No expensive components - a sealed tank and pump | Complex hydraulic calculations |

| Reliability. Fewer parts means less chance of failure | Complex balancing and adjustment at the commissioning stage. |

| Can be used with a solid fuel boiler without a circulation pump | Long warm-up due to slow coolant movement speed |

There is a limitation on the use of gravity circuits - they do not work if the height of the house is more than 7-9 meters and the contour length is more than 30 meters.

Forced circulation circuits

(Repeat) diagram of a closed-type single-pipe heating system.

In closed and spatially distributed open heating systems, pumps are installed to circulate the coolant.

| Advantages | Flaws |

| Suitable for long pipelines | Energy dependence |

| Fast warm-up after switching on | If the pump is turned off or broken, circulation stops |

| Easy installation, which does not take into account the slope angles of the connecting pipes | Without reliable power backup it is unacceptable to use with solid fuel boilers |

| Possibility to use different types of wiring | High costs to replace the pump if necessary |

The pump capacity is selected based on hydraulic calculations, allowing for a margin of up to 20%.

Important! Most of the pumps used are built according to the “wet rotor” design. The coolant lubricates and cools the electric motor. Based on this, the pump is installed in the rupture of the “return” pipe, where the coolant is in a cooled state.

Water or antifreeze should not be drained in the summer; the engine must remain filled.

Combined systems

In open types of heating, a combined method of organizing the movement of coolant is often used. To do this, set

Scheme of bypass organization in a single-pipe combined heating system.

There are several options for using the device:

- In mild frosts, when gravity circulation is sufficient to warm up the radiators, open the tap; in this case, the pump is not used.

- If there is insufficient circulation, turn off the tap and turn on the pump.

- When the power supply is turned off, circulation occurs through an open pipe without the use of a pump.

A bypass is required in systems with solid fuel boilers that cannot be stopped quickly. When circulation stops, the working fluid in the heat exchanger quickly heats up, boils, and an explosion due to increased pressure and destruction of the boiler is possible.

Do-it-yourself installation

When installing heating from polypropylene pipes, it is initially necessary to calculate the laying diagrams. With this installation, it is necessary to maintain the slope level to the lowest point of the system, because a tap or valve for draining is installed in this place. The length of pipe sections must be calculated for each section of communication. If the pipeline is divided into sectors that can be shut off individually at any time, the operation of the communication system will become significantly safer. All tools and installation parts must be at room temperature, for which they must be brought into the room immediately before the installation process. This action is necessary to prevent the material from cracking during operation. Using a felt-tip pen, it is necessary to apply marks according to the calculations performed on the measured pipe sections.

You need to cut the polypropylene with your own hands evenly and perpendicular to the surface with special scissors or a pipe cutter, after which the cut edges of the pipe are treated with an alcohol solution, and the rest of the dirt is removed with a dry rag. A nozzle with the appropriate cross-sectional diameter is installed on the soldering apparatus, which must first be degreased, the apparatus is installed horizontally and heated to 260 °C. Pre-prepared parts (pipe and fitting) are placed in the heater holes in a horizontal position, then the time is determined from the table and the parts are heated.

http:

Then the parts are removed, the pipe is inserted into the fitting and a certain period of time is maintained for the elements to completely harden; twisting the parts during the hardening process is prohibited. This method of welding (soldering) parts is reliable and the most durable. Communication parts must be dry and clean when carrying out soldering work; if installation is carried out in a working (operating) system, then the water must be drained from the heating systems. To conduct trial tests of the heating system, you should not purchase water meters; instruments that show the deaeration of pipes are quite sufficient.

Vertical and horizontal wiring

When constructing networks, there are two options for distribution and delivery of coolant: vertical and horizontal.

Scheme of a vertical single-pipe heating system with upper and lower wiring.

The vertical type is installed in houses of two floors and above. In this case, the upper or lower coolant supply to the radiators is used.

For overhead wiring, a horizontal pipe with bends into each riser is placed under the ceiling of the last floor or on the technical floor. The flowing coolant warms up the radiators and collects in the return pipe.

| Advantages | Flaws |

| Low pipe consumption | Low coolant temperature in the radiators on the first floor |

| Easy to install | Mandatory installation of bypasses on each radiator so as not to stop heating when replacing or removing the battery |

| Applicability for gravity system | It is impossible to install individual heat metering devices in apartments |

| Possibility to hide pipes in the floor with bottom connections | Visible pipes with top connections |

| By installing collectors, you can organize a “warm floor” system |

Vertical wiring allows you to organize a gravity-flow open heating system, independent of the power supply.

Bottom wiring is used in modern multi-apartment and individual residential buildings with forced circulation of coolant. This allows you to hide pipes in the basement or basement, reduces installation costs, and does not spoil the appearance of residential premises.

Hiding the heating pipeline in the basement of the house.

The main disadvantage of this method, as with all single-pipe systems, is the cool coolant in the last radiators of the circuit.

Horizontal wiring is standard and simple; it is used mainly in one-story buildings or on each floor. In the latter case, collectors are installed.

Pipe soldering

In order for the pipeline connections to be reliable, installation work must not be carried out at room temperatures below 5 C. All components (pipes, fittings, valves) must be free of contamination and damage. Therefore, it is important to observe safety precautions when transporting and storing the material. It is important to keep open flames away from the material. Otherwise, the pipes and fittings will become deformed and will be unusable. If it is necessary to intersect pipes, you need to use special (triple, cross) fittings. Threaded fittings are installed where there should be a threaded connection. It is unacceptable to cut threads on polypropylene pipes with your own hands. To ensure the tightness and tightness of the threaded connection, use flax tow or FUM tape.

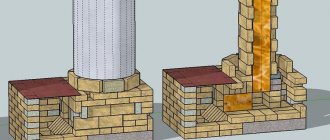

Leningradka

One of the popular and easy-to-implement schemes began to be widely used in Leningrad, hence the name. Its peculiarity is the way the radiators are connected - in series with bypasses for each battery.

Leningradka open type.

Leningradka closed type.

The scheme is suitable for open and closed systems, with natural and forced coolant circulation. The design can be implemented in vertical and horizontal layout.

Thus, Leningradka is a universal scheme for constructing single-pipe heating systems. It has all the described advantages, but its disadvantages limit its use in large houses.

Possible Solution! In branched networks, several heating branches are made with 3-5 radiators in each. For example, they separate the heating circuits of the first and second floors. For houses with a large area, it is more advisable to use two-pipe systems.

Practical calculation example

A residential building requires a single-pipe system controlled by a thermostat.

The nominal throughput of the device at the maximum setting limit is 0.6 m3/h/bar (k1). The maximum possible flow rate for this setting value is 0.9 m3/h/bar (k2).

The maximum possible differential pressure of the TR (at a noise level of 30 dB) is no more than 27 kPa (ΔР1). Pump pressure 25 kPa (ΔР2) Operating pressure for the heating system – 20 kPa (ΔР).

It is necessary to determine the pressure loss range for the TR (ΔР1).

The internal heat transfer value is calculated as follows: Atr = 1 – k1/k2 (1 – 06/09) = 0.56. From here the required range of pressure losses at the TR is calculated: ΔР1 = ΔР * Atr (20 * 0.56...1) = 11.2...20 kPa.

If independent calculations lead to unexpected results, it is better to contact a specialist or use a computer calculator to check.

Methods for connecting radiators

The manufacturer indicates the preferred method of connecting radiators to the pipeline in the battery data sheet.

They can be divided into three types:

- diagonal;

- side;

- lower.

The diagonal option is the most effective in terms of heat transfer. However, in single-pipe systems, the method causes increased material consumption and does not look the best.

The side method is suitable for a vertical scheme, when the coolant enters the upper radiator manifold and is removed through the lower one.

For bottom connections, the radiator fittings should be located at the bottom of the device; such products are 10-20% more expensive.

The lower connection reduces the radiator performance by 15-20%, this must be taken into account when calculating the system. At the same time, the bottom connection allows you to hide the wiring as much as possible by pouring pipes into the floor or leading them out through the ceiling of the lower floor. How to actually choose the cheapest heating radiators on the market

Understanding the popularity of aluminum radiators

The main advantages of polypropylene pipes

If we list all the advantages of polypropylene pipes, it is worth noting their high level of quality, as well as their affordable cost. Heating systems created from these elements will serve their owners well for decades. The use of unique technologies in the manufacture of polypropylene pipes allows us to speak with complete confidence about the high strength of the products.

Polypropylene pipes do not succumb to the negative effects of corrosion during operation, and also perfectly resist mechanical influences from the outside. Dirt and impurities will not accumulate on the pipe walls. Consequently, the water will be clean and transparent for a long period of time.

As for installation, this is another advantage inherent in polypropylene pipes. Installing polypropylene heating with your own hands is not difficult.

Choosing an effective option

Design decisions are influenced by the configuration and area of the house, number of storeys, design requirements, and quality of power supply.

Taking into account the features, we can recommend:

- For one-story houses with a small area - Leningradka with horizontal wiring.

- Two-story buildings in places with intermittent power supplies should be equipped with an open, vertical, gravity system with bypasses and circulation pumps.

- Systems with boilers using coal, wood and pallets should be built using an open circuit with natural circulation.

- Divide the heating into sections with no more than 5 radiators in each.

Before design begins, local conditions are studied and only after that decisions are made on choosing the type of heating system.

Hydraulic calculation of a single-pipe system

Hydraulic calculations are carried out to determine the diameter of the connecting pipes in each section of the circuit and the performance of the circulation pump.

Sequence of calculations:

- Determination of heat loss through building structures.

- Calculation of the required heat transfer from radiators for each room.

- Selecting a boiler of the required power.

- Calculation of the diameter of the supply pipes, taking into account the circulation rate of the coolant in the coldest time of the year.

- Selecting a circulation pump if you need a remote option.

Determination of heat loss and calculation of radiators

The heat generated by the boiler is dissipated through the floor, walls and ceiling of the building. They take into account the material of the walls, the number and area of windows and doors, and the quality of insulation.

You can use the calculator on our website:

For small houses, an approximate option is used. It is believed that in the northern regions, to heat 10 m2 of area, 1.5-2 kW of boiler power and radiator heat transfer performance are required. In the middle zone the figure is 1-1.5 kW, in the southern regions - 0.6-1 kW. The data is correct for houses with solid walls and medium or high-quality thermal insulation.

Knowing the dimensions of the house, they obtain the necessary data for subsequent calculations. It is important to determine the required number of radiators for each room. Aluminum and bimetallic radiators in most cases emit from 120 to 210 W per section. By dividing the power required for the room by the performance of the section, the battery dimensions are obtained.

Boiler selection

The heating boiler will work much longer if it does not heat the coolant at maximum mode. In this regard, equipment is chosen that is 10-20% more powerful than the heat loss obtained in the calculations. For example, with a loss of 10 kW, a boiler designed for 12-14 kW is purchased.

Determination of pipe cross-section

The optimal speed of coolant movement through the pipes is from 0.3 to 0.7 m/s. If the parameter is lower, then at low temperatures the radiators may not warm up sufficiently. At higher speeds, the radiators often become airy and noise is heard. Based on the flow rate, pipes with the required internal cross-section are selected.

The required coolant flow is determined by the formula: G=860* q/ΔT , in which:

- G—flow rate kg/h;

- q is the thermal power in the circuit section (kW);

- ΔT is the difference in temperature of the coolant at the inlet and outlet of the radiator, usually taken to be 20 °C.

For example, to ensure heat transfer from a circuit of 2 kW, we obtain the coolant flow rate: 860*2/20=85 kg/h.

Next, special tables compare the flow rate and the generated thermal performance. In our example, for 2 kW radiators, a pipe with an internal cross-section of 8 to 12 mm is sufficient. Highlighted in the table with a red frame.

Table for determining the diameter of pipes of a gravity heating system

Data for each circuit is plotted on a general diagram. By summing up the data obtained, they determine which pipe diameter to choose for connecting to a group of circuits or for each riser.

Pump selection

Modern gas and electric boilers are equipped with a built-in pump. Its performance is selected by the manufacturer based on the boiler power.

The required performance of the remote pump is determined by summing the coolant flows in each circuit. They provide a reserve of 15-20% in performance so that the pump operates in a gentle mode.