X

Today, based on the experience of construction and operation, we can highlight the features, strengths and weaknesses of frame baths.

In recent years, the demand for frame baths has been steadily growing - they are increasingly preferred by those who do not want to spend money on building a log house or a brick “box”.

But just recently, frame construction was treated with a degree of distrust. However, the technology soon managed to establish itself as successfully combining practicality and low cost.

RECOMMENDED ON THE TOPIC

- Pros and cons of aerated concrete blocks

- Do-it-yourself barrel sauna: nuances...

Pros and cons of frame baths

Frame baths are of great interest due to their undoubted advantages over other structures:

- Economical . The cost of 1 m² is lower due to lower labor costs and the cost of materials (starts from 5 thousand rubles).

- Construction period . The construction of a frame bathhouse takes 3 times less time than a bathhouse made of timber (especially brick); installation (including finishing and insulation) takes 20-40 days (depending on the complexity of the work) and can take place at any time of the year.

- Exploitation . The bathhouse can be used for its intended purpose immediately after construction.

- Thermal insulation . A frame sauna heats up quickly and retains heat well at any time of the year.

- Reliability . The service life of a building erected without technological errors is from 10 to 20 years.

- Ecology . The bathhouse maintains a comfortable microclimate and is safe for health.

The frame structure pleases the owners in any weather Source it.aviarydecor.com

Features of frame bathhouse projects include:

- Lightweight foundation . The finished structure is lightweight because it requires 1.5-2 times less wood than buildings made of timber or logs. This allows the use of a columnar or shallow foundation.

- Insulation . Properly selected insulation helps save energy; A frame bath retains heat no worse than a timber bath.

- Architecture . Features of the technology allow you to create a variety of planning and facade solutions (with a veranda, attic).

- Accommodation . A frame bath can be placed in a problem area (with a high groundwater level, in a flooded area).

The negative aspects include:

- Costs for insulation and finishing . They make up a significant part of the cost of the structure, but you cannot save on them. Cheap mineral wool will not provide high-quality insulation; polystyrene foam is a fire hazard.

- Shrinkage . The shrinkage process can last up to 2 years (if wood of natural moisture was used during construction); in this case, there is a high probability of damage to the finish (plaster or decorative panels). Chamber-dried wood exhibits almost imperceptible shrinkage, but its use will be more expensive.

Photo of the frame bathhouse project - a modern interpretation of traditional construction Source artmetall.ua

Which one looks more aesthetically pleasing?

A structure made from solid logs always looks more advantageous. However, a small light bathhouse can be decorated with original finishing and decorative details. It all depends on the taste preferences of the owner.

Photo of the company ModulStroy (Tolyatti, Samara)

So which one should you choose? Each option is good in its own way. To make a choice, you need to take into account all the information presented above, calculate your own financial capabilities and preferences.

It may also be useful to you: if you are interested in which stove is best for a frame bath...

- Which stove to choose for a bath, which one is better

- Metal furnaces

- The best cast iron stoves

- How to choose the best wood stove.

In addition to frame and timber baths, a popular solution is the structure of foam blocks. The popularity of baths of this type gives rise to questions about the construction of the foundation, insulation and finishing of buildings.

Construction of baths from a frame

A cozy building will appear on the site in a few weeks, unlike a brick structure, which will take a year to build. The opportunity to provide a family with a practical steam room without spending a lot of time and money looks very attractive. The stages of construction of a frame bath are determined by technology:

Project

The success of the future structure depends entirely on careful planning and design, which is especially important on a small plot of land. Using a ready-made project (possibly with modifications) can significantly speed up the process.

The project determines the location of the steam room, shower room, and rest room; the roof structure and the installation location of the stove are outlined. Considerable attention is paid to engineering communications - safe installation of electrical cables, water supply and sewerage pipes. When drawing up a project, take into account:

- Location . The cardinal directions and the distance to the boundaries of the site are taken into account. The bathhouse is oriented so that the relaxation room faces the interior area and does not abut the neighbors’ fence.

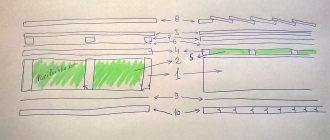

Typical design of a frame bathhouse Source remdominfo.ru

See also: Catalog of bathhouse projects presented at the “Low-Rise Country” exhibition.

- Architecture . The bathhouse may contain additional elements - a wooden staircase and a canopy at the entrance, a veranda or an attic.

- Window . Typically, one window is designed in the relaxation room (light source) and a small window in the washing room and steam room (additional ventilation). Sometimes a window is added to the roof gable.

- Convenience . A gable roof will allow you to organize a small attic, where it is convenient to store bath brooms. Warm floors must also be provided at the design stage.

Foundation

The construction of a lightweight frame bathhouse does not require a complex foundation, including digging a pit; this affects the budget in the most pleasant way. For reliable soils, the best option is a strip or columnar foundation, the depth of which is influenced by the proximity of groundwater, the type and level of soil freezing.

If the site is located in an area of regular flooding (spring floods), you can play it safe and choose a pile-screw foundation. A test screwing is first done to determine the depth of immersion of the piles. If it turns out that you need piles much longer than the calculated ones (not 3, but 5-7 meters), the foundation will become obscenely expensive, and you will have to think about another option.

Photo of a frame bath - a classic building on a columnar foundation Source kvartirnyj-remont.com

The simplest (and fastest) scheme is considered to be a columnar foundation made of asbestos-cement pipes. This foundation serves as additional protection for the walls from dampness and is laid in several stages:

- Wells are drilled along the marked contour.

- Asbestos-cement pipes are inserted into wells. The free space around the pipes is filled with coarse sand and carefully compacted.

- Concrete is poured inside the pipes, and an iron plate is installed on top of each.

If a strip or slab foundation is chosen for the construction of a bathhouse, before pouring it, it is necessary to make utility connections (water supply, sewerage, electricity).

Moisture resistance

Since frame construction has its own characteristics, the floor under the washing room needs to be done differently.

A separate foundation is required, under which the soil is removed and sand and gravel are poured. In this case, the water goes underground without causing damage to the structure.

Asbestos-cement pipes are used as floor joists and filled with concrete. An edged board is placed on top of this.

A gap of 6-7 mm and rubber gaskets are required between the board.

This design allows you to make the washing room moisture resistant.

Video description

About the process of designing a bathhouse from a frame in the video:

See also: Catalog of companies that specialize in building bathhouses using frame technology.

Frame

Before building a frame bathhouse, choose the material for the frame; Coniferous wood is most often used. Installation of the frame, which is the load-bearing element of the bathhouse, includes:

- Installation of the lower trim . For it, timber or boards pre-treated with an antiseptic are used; The logs for the future floor are attached on top. The entire structure is waterproofed with roofing felt and mastic.

- Installation of frame walls . It is done by sequentially adding vertical and horizontal elements, to which the sheathing (OSB boards, lining) is then attached. The frame takes into account openings for windows and doors in advance.

Wooden cladding of a frame bath Source remontdetskoy.ru

Floor

The floor in the bathhouse has a different design in the dressing room and the washing area. In the dressing room, the floor is a multi-layer cake, which includes a subfloor waterproofed with roofing felt, a layer of insulation (also with waterproofing) and a finished floor. A special feature of the washing room is a pourable floor, for which it is necessary to properly arrange the drainage system. The problem can be solved in different ways:

- An internal separate foundation is constructed with a concrete screed (with a slope and water discharge outside the bathhouse) and double waterproofing.

- The subfloor (with a slope towards the outer wall) remains common; the roofing material rises along the walls by 30-40 cm and is covered with cladding (lining).

In both cases, the floor is lined with an antiseptic-treated board. Wooden floorboards need to be replaced after some time (4-5 years), so sometimes plastic analogues are used instead.

Sometimes a wooden gutter is installed in the steam room, dividing the floor into 2 parts. The floorboards converge towards the gutter, allowing water to drain quickly and out. Thanks to this design, the floor dries quickly and does not rot.

Multi-layer flooring in a frame bath Source patter.ru

Roof

The elements of the truss structure are assembled on the ground and rise to the top one by one. If the bathhouse is small, soft tiles (ondulin) are optimal for roofing. If the structure (and foundation) is more serious, it is not prohibited to use metal tiles. After roofing work is completed, windows and doors are installed in the provided openings.

Which one is easier to build?

A frame bathhouse is built faster and is easier to erect. Its design gives greater freedom for interior planning and finishing. This advantage is not the only advantage inherent in frame buildings.

The construction of a structure from a solid log is a more labor-intensive process, requiring significant effort and time.

Variety of architectural forms

Baths are usually built in a regular rectangular or square shape. For this form, it does not matter what technology was used to build the structure.

Photo from the Modultron company website

If we are talking about building an original shape - polygonal, with curves, complex shapes, with decorative elements, it is better to give preference to frame technology.

Constructing buildings of unusual shapes from timber is much more difficult and expensive.

Possible defects

If all stages of construction are carried out in compliance with technology, no defects should appear. The table below shows possible defects and ways to prevent or eliminate them.

| timber | Frame |

| In a timber building, cold can come from cracks at the joints of the crowns. They appear when insulation is of poor quality, or if the lumber initially had high humidity and decreased in size as it evaporated. | When constructing walls, cavities (cold bridges) may form. In a frame building, cold bridges can run across the entire thickness of the wall. To cover them, an additional layer of insulation is applied. |

| Solid lumber can dry out over time. Cracks appear on it. If treated incorrectly or untimely, bugs may appear in the tree structure. | If the insulation was installed incorrectly and not hermetically sealed, the vapor barrier was damaged and the material began to get wet, and the room would begin to rot from the inside. To avoid such problems, you need to properly arrange the ventilation system and use only high-quality materials for insulation. |

Important! Correcting defects in the walls of a frame bath requires opening the structure and removing the finishing. This is quite an expensive process!

Turnkey frame baths

Construction companies offer projects for frame baths of various sizes and designs, containing all the necessary elements - a dressing room, a washing room and a steam room. The package may include a veranda, terrace, balcony or bay window. When ordering a turnkey frame bathhouse, you can be sure that:

- The project will be adapted to the conditions of a specific land plot: if necessary, a geological study will be carried out.

- The cost of construction includes delivery and unloading of materials.

- The foundation will be built taking into account the characteristics of the soil.

- Environmentally friendly building materials will be used during construction.

- The structure is reliably insulated and protected from moisture.

- The work will be completed within the agreed time frame (according to the contract).

Project of a frame house of a bathhouse - the attic floor of the bathhouse is suitable for arranging a rest room Source forvardplast.ru

The result of a turnkey order will be a bathhouse completely ready for use. Additional bonuses that exist in many companies include:

- Possibility of installments . Allows you to plan family expenses.

- Direct cooperation with lumber suppliers. This allows us to keep prices at an affordable level.

- Present . When ordering on a turnkey basis, some work (furnace installation, electrical wiring) is performed free of charge.

Fire hazard

Not so long ago, building a sauna with a house under the same roof was impossible, and there are some reasons for this. The first and most obvious is the increased risk of fire. Previously, bathhouses were placed away from the house, as the risk of fire was high. If you place a sauna under the same roof as your house, the risk of losing everything in a fire increases significantly, but, fortunately, this can be corrected. Effective measures are: compliance with fire safety rules, the use of special impregnations, as well as the use of fire-resistant finishing materials;

Dampening of house structures

These are the consequences of high humidity inside a bath or sauna. If you do not fight it, the wooden frame will become moldy and rot. However, any frame house, built in accordance with all construction rules, is equipped with a working ventilation system, and its operation saves from high humidity;

Well, we’ve sorted out the advantages and disadvantages, and then it’s up to you, but if you still have doubts, we advise you to contact the BUDETDOM company, where you can both choose a “sauna house under one roof” project for yourself, and find out from specialists all the specifics of such a design.

Source

Bathhouse in the house: eight categorical “no” from FORUMHOUSE participants

Should I have a sauna at home or not? The discussion of this issue by the FORUMHOUSE editors grew into a heated argument, we began to look into it and, of course, went to look at the opinions on our forum. Most of our forum members believe that a bathhouse in the house is a whim for which you will have to pay too much.

A responsible homeowner would never do this, according to our expert users, and we share their arguments with you.

2. A bathhouse in the house is a blatant contradiction of sanitary standards

The construction of a bathhouse is regulated by several documents. Fire safety standards and distances are specified in SP 4.13130.2013, and there a lot depends on the materials, although it is clear: the further the bathhouse is located from the house, the safer it is.

Sanitary standards are written down in SP 53.13330.2011 (SNiP 30-02-97), and it clearly states:

According to SNIPs from 1934, there is a bathhouse in the far corner of the yard.

Walls

The walls can be made in the form of wooden heat-saving panels, which are installed directly on the beam of the bottom trim.

The panel design looks like this:

- timber frame 50x50mm;

- vapor barrier (on the side facing the inside of the sheathed room);

- insulation made of mineral wool or other similar material;

- waterproofing to protect against rain moisture (on the side of the panel facing the street);

- paneling on both sides.

Lining made of linden, alder or aspen is perfect for cladding. You can also use cheaper pine paneling. In addition to its lower cost, many people are attracted to pine lining for its resinous smell, which saturates the bathhouse, creating a special atmosphere of a coniferous forest.

7. The quality of a built-in bathhouse is always worse than a free-standing one

A combined “house + bathhouse” object is more difficult to make efficiently, in compliance with all requirements, than two separate objects. Whatever one may say, it is impossible to fulfill all the requirements (and real sauna lovers always have a lot of them) in a built-in sauna. Any true connoisseur will tell you that a bath in the house is not only dangerous, but also frivolous.

The bathhouse should be located separately, in a pleasant place on the edge of the site next to a pond or a man-made pond - everything else is a Chinese fake.

In the end, we didn’t move out of town to be content with half measures.

8. The built-in Finnish sauna was not invented because of a good life

And, as the members of FORUMHOUSE say, they are far from new to this life, “under favorable circumstances, you don’t need to do this for yourself.”

As far as I know, the “dry sauna” was invented by the Finns in the middle of the last century solely out of poverty, during the war and after the war. Particularly because it is easier to build a dry sauna into a city house without waterproofing. Then, for the same reason, the idea was picked up by businessmen in perestroika Russia. Under favorable circumstances, there is no need to do this for yourself.

The “native” Finnish sauna is not dry at all. It is just wet enough, with brooms and a constant supply of a ladle to the heater. Of course, in a Russian bath the humidity/temperature ratio is higher, but in an authentic Finnish sauna “the water also comes in liters.”

Roof

An excellent solution for a bathhouse would be to install a pitched roof. Its equipment is somewhat cheaper and also simpler than a gable one. In the photo below you can see that the rafter system has three support points.

The rafter legs are located in increments of 60 cm from each other and are fixed to the upper elements of the wall. To achieve the required roof slope, it is necessary to calculate in advance the height of all walls so that an angle is formed between them. The roof slope angle for a bathhouse is determined individually for each project. Much depends on the meteorological conditions in a particular area, as well as the type of flooring chosen. If it is metal tiles, then the minimum slope should be 16 degrees.

In the photo above you can see that the front wall had to be raised a little. To increase its strength, jibs were installed on the sides. Roof overhangs are made at the front and back so that water flows down unhindered. Waterproofing, control sheathing and sheathing under the roof deck and the roof deck itself are attached to the rafters. A video about the construction of such a bath can be seen below.

6. A bathhouse in the house is less comfortable than a free-standing one.

This point practically eliminates the only tangible “plus” of a built-in bathhouse. Well, yes, you won’t have to go into the house with a wet head in the cold, and for some this will probably be worth a lot; but how many unpleasant “buts” appear here!

- “But” No. 1: a separate bathhouse is always more comfortable. There you can provide a spacious relaxation room, a more comfortable steam room, and a pleasant nook for storing firewood.

- “But” No. 2: a separate bathhouse is always more private. There is less risk that you will catch the eyes of guests and household members when you jump from the steam room into a snowdrift or into a swimming pool.

- “But” No. 3 : in a separate bathhouse we don’t disturb anyone!

My bathhouse starts at 6 pm and lasts until 1-2 am (guests). And this is inevitable noise. And again, after the steam room, where can you go to sit and drink tea?

Let's start with the foundation

It is precisely the foundation that least of all depends on the personal aesthetic preferences of the owner.

The combined mass of walls, ceilings and roof presses on it from above, and soil tries to push it out from below. What are the conclusions from this? To choose a suitable foundation (see here about their types), you must already know what kind of walls and roof you want to build. Some varieties will be light, others heavy.

For example: a brick bathhouse, made of foam blocks, a two-story bathhouse, made of thick logs, with ceramic tiles - there is no chance of getting by with a shallow columnar or strip foundation.

But this is on the one hand. On the other side we have soil. With its heaving (frost heaving is when water expands when it freezes, the soil increases in volume and begins to press and squeeze out everything that is in the ground, for example, the foundation), freezing depth (for critical buildings, the depth of laying the foundation should be lower than the freezing depth of the soil ), groundwater level (it is always desirable that the foundation be above their level, otherwise - drain).

BY THE WAY! After winter heaving, the ice melts and the soil begins to draw in, “drown” the foundation. Such are its seasonal fluctuations.

In addition to the above, it (soil) also has a type of soil - it determines whether the building will be stable. There are quicksand sands on which piles are placed, and deeper ones. And there are quite decent clays with decent heaving, which a slab foundation can withstand (it seems to “float” on the soil surface, like a raft on water).

The third factor is terrain. If the height difference in the designated building area is significant, and it cannot be leveled using equipment at a reasonable cost, then the best material for the foundation of a bathhouse in this case will be piles.

The fourth factor is budget. Some types of foundations are expensive, others not so much. Slab will be expensive. Steel piles for great depths also cannot be called cheap. The most budget option is or. They require little material, but the circumstances listed above should be favorable.

Useful links on the topic:

- What is the “bathhouse foundation height” and “laying depth”? What to consider?

- How to make a bathhouse foundation from blocks: what choice do we have and what does it depend on?

- Foundation for a frame bath

- With your own hands: how to make a foundation for a bathhouse? Step by step instructions here

- It's time to make a foundation for a bathhouse: which one is better will be determined by three factors

- Foundation for a bathhouse: how to make? Secrets of correct calculation, marking and creation of foundations of all types

- How to pour the foundation for a bathhouse correctly? Description of all stages of work

4. A built-in sauna increases the ventilation requirements in the house

If you want to build a bathhouse right in the house, you need to be prepared for the fact that the living and bathing areas will require separate ventilation systems (each zone has its own microclimate), but at the same time they will have to work in harmony. Obviously, this is also difficult, and also quite expensive.

There is also such a thing as the need for burst ventilation through the door and window: the steam from the steam room must go somewhere, and definitely not into the house. That is, this issue will require a separate solution.

Construction of a building

It’s easy to build a frame-panel bathhouse with your own hands. After preparing the consumables and tools, you can begin construction.

Foundation and floor

Since the frame-panel building has a small mass, it does not need to build a strip foundation. A pile foundation is suitable. Manufacturing process:

- Mark the dimensions of the building with pegs with a stretched thread.

- Clear the area of debris, level the ground from bumps and holes.

- At the corners of the building, mark the locations of future piles. Every 1.5 meters from them, mark the next holes for the pillars.

- Dig holes using a hand auger. Remove the land from the territory of the marked area. Depth - 1.5 meters.

- Fill the bottom of the holes with a layer of sand 20 cm thick. Fill the top with 20 cm of crushed stone. Compact the layers.

- Twist a tube from sheet metal into which the cement mortar will be poured.

- Stick 4 reinforcement rods inside. Mix the cement mortar in a hand-held concrete mixer. Proportions - 2 parts crushed stone, 3 parts sand, 1 part cement.

- Fill the holes with solution.

You need to wait a week until the cement hardens completely. After this, you can dismantle the metal sheets.

Floor arrangement:

- Place roofing felt on top of the posts for waterproofing.

- Place beams on the pillars and connect them together. For this purpose, a half-beam system is used. They are fixed to poles using anchors.

- After making the lower trim, you can attach the logs to it.

- Lay rough floor boards on the underside of the joists.

There is no point in starting waterproofing or thermal insulation of the finished floor before erecting walls and building a roof.

It is recommended to coat the lower trim ring with used machine oil. This way you can effectively protect it from rotting and damage by pests.

Walls

The construction of walls in a frame-panel bathhouse is a simple construction stage that consists of several actions:

- Mark the location of individual panels. Install racks between them.

- Attach the racks to metal corners to the height of the shields.

- Make the top binding crown.

All that remains is to simply attach the finished shields.

Windows and doors

When ordering panels from a specialized company, you can foresee in advance where the windows and doors will be located and inform the manufacturer about this. If the shields are solid, you can cut out window and door openings with a chainsaw.

Ceilings and roof

When the walls are ready and the top trim is secured, you can begin building the roof:

- Place the ceiling beams on top of the trim at a distance of 60 cm from each other.

- Prepare rafter spans on the ground. Secure them to the roof, resting the legs of the rafters on the hanging parts of the ceiling beams.

- Connect the rafters together with lathing. Fix a layer of vapor barrier on top, fill the counter-lattice.

- Cover the roof frame with roofing material.

The rough ceiling is made of boards on top of the ceiling beams.

Communications

You need to take care of laying communications in the first stages of construction. To do this, you need to arrange a drain for water outside the territory of the future bathhouse, install wires, supply water from a well, a well, or a central water supply system

Attention should also be paid to ventilation, which can be:

- natural;

- forced.

Harmonious union: DSP panels for exterior home decoration

Before you begin installing panels made of cement bonded particle boards, you need to decide on the thickness of the material and its dimensions. Sheet parameters according to standard:

- length from 3200 to 3600 mm;

- width – from 1200 to 1250 mm.

Dimensions and weight

The thickness of the material in the matter of exterior finishing comes to the fore due to its significance. Here it is necessary to take into account the required wind and heat protection, the load on the slab and at the same time the load created by the material on the building frame.

The following thickness is recommended for installation:

- frame house construction - 14-35 mm;

- rough floors -10 mm;

- window sills, canopies, slopes - 18 mm - 30 mm;

- permanent foundation formwork - 14 mm -20 mm;

- partitions, walls - 14 - 18 mm.

DSP of different thicknesses

On the scale of frame construction, the walls of various rooms are made mainly of slabs with a cross-sectional size from 12 to 40 mm, and on the outside they take a sheet thickness from 16 to 24-28 mm. To install a DSP on the facade of a house, it is better to take a sheet of 16, or at most 18 mm: it does not break under acceptable impact and does not create an excessive load on the frame base of the building.

Table 1. Physical and mechanical characteristics of DSP

| Planar deviation, mm | 0,8 |

| Density | 1100-1400 kg/m3 |

| Humidity | 8 +/- 2% |

| Daily swelling in cross section | 2% |

| Fire resistance | 92% |

| Bending strength of DSP 10-16 mm | 14 MPa |

| Flexural strength 24 mm | 11 MPa |

| Deviations in the cross section of the DSP 10 mm | +/- 0.8 mm |

| Deviations in the cross section of the DSP 12-16 mm | +/- 1.0 mm |

| Deviations in the cross section of the DSP 24 mm | +/- 1.0 mm |

| Maximum errors in the parameters of the CBPB board | +/- 2 mm |

| Humidity | 2% |

| Noise protection | 88% |

| Resistance to low temperatures | 12% |

| Vapor permeability | 2% |

| Daily water absorption | 15% |