Steam generators are widely used for arranging baths, steam rooms, cleaning all kinds of equipment and in the production of alcoholic beverages. Such units allow you to effectively warm frozen pipes and car engines in winter. A homemade unit will function no worse than a purchased analogue if it is properly made at home. Together with the editors of Seti.guru, in today’s review we will look at how to make a steam generator with your own hands for various household needs, and we will also analyze in detail the features of installation, assembly and testing the operation of the unit.

Homemade solid fuel steam generator

Types of steam generators and their use in the household

Regardless of the purpose, the design of steam generators contains a reservoir - a boiler, in which steam is generated and supplied to an external consumer. Based on the type of supply of working fluid (water), it is customary to distinguish between manual types of units and automatic units. Depending on the amount of power consumed, steam generators can be industrial or domestic. For household units, this figure, as a rule, does not exceed 9 kW, and they are connected to a 220 V power supply (industrial units - to 380 V).

Industrial steam generating plant

Depending on the method of heating the working fluid (water), steam generators can be induction, with electrode installations, furnace and electric. The table shows the main features of each type of unit.

Table 1. Types of steam generators and their features

| Type of unit | Image | Description |

| Induction | The water in the device’s tank is heated due to the influence of an electromagnetic field. The equipment allows you to obtain purified and light steam at the output. | |

| Electrode | Inside the reservoir there is an electrode, which is the heating element of the device. The units operate from the mains. As a result of heating water, steam is obtained that is free of harmful impurities and mineral deposits. | |

| Electric | The units are equipped with heating elements of various powers (from 4 kW). Such devices are used for steam rooms. In large areas, steam generators for baths and saunas are used, the power of which exceeds 12 kW. | |

| Pechnoy | Stove heating heats water and releases steam. Coal or wood is used as an energy source. |

In households, factory-made and home-made steam generators are used in arranging steam rooms, as cleaning equipment (washing various surfaces with steam under pressure), and in the manufacture of moonshine stills. The units are also used to heat water pipes and car engines. Watch the video to understand how the steam generator works.

Video “The principle of operation of the steam generator”:

To humidify the air in residential premises, you can make your own ultrasonic steam generator. This device is installed on the surface of the water and generates vibrations of a certain frequency, resulting in the formation of many small drops that rise into the air.

Where it all begins

At one time, I had a desire to equip an individual microbath, or phyto-barrel as it is also called, in my city apartment; my wife really liked it.

There were no problems with the barrel itself; knocking down a wooden structure made of planed tongue-and-groove boards doesn’t require a lot of intelligence or special skill, but the steam room requires a steam generator. My first thought was to buy a production model.

A modern steam generator for a bath is a reliable and durable device, and most of these devices have many operating modes, they are equipped with sophisticated protection and control systems, but at that time I was not ready to pay that kind of money for them.

Wall-mounted steam generator "Harvia".

For those who are interested, below I have tabulated popular models and also placed a diagram that clearly shows the operating principle of an industrial steam generator.

| Serial models of steam generators | |||

| Model name | Power consumption | Dimensions | Price |

| Harvia Helix HGX11L | 10.8kW | 155x320x600 mm | 57 t/rub |

| Harvia Helix Pro HGP30 | 30kW | 320x490x560 mm | 166.5 t/rub |

| Helo HNS 60 T1 | 6kW | 160x380x520 mm | 60 t/rub |

| Helo HNS 140 T1 | 14kW | 160x380x520 mm | 70.5 t/rub |

| TYLO Steam 2/4/6 | 2 – 6kW | 445x130x415 mm | 74 t/rub |

| TYLO Steam 12 | 12kW | 570x224x485 mm | 135.5 t/rub |

Scheme of operation of one of the serial models of the steam generator.

Having studied the structure of the steam generator, I realized that it is not so difficult to make it with my own hands, moreover, such a device would not be superfluous in a real wood-burning sauna, plus in my case it could be useful in the apiary for melting wax out of frames.

Unfortunately, I was not able to make a universal homemade steam generator that would be suitable for all occasions; instead, I assembled several steam generators, each of which was “tailored” for a specific purpose.

Details of one of the serial models of the steam generator.

Steam generator design

A steam generator is a power plant made of a metal casing, inside of which there is a water tank. To make a steam gun for a bath with your own hands, you will need a steam and water pump. In addition, the design of the steam generator must include:

- evaporation chamber;

- temperature sensor;

- heating installation;

- nozzle.

To make a home steam generator with automatic liquid supply, it is necessary to install a pipe outside the structure. This element will be required to connect the unit to the water supply system. You also need to install a valve to drain the liquid.

Advice! The manufacture of such a structural element as an evaporation chamber must be made from materials with high heat resistance. For example, to make a home electric sauna stove with a steam generator, you can use steel or copper.

Testing is a mandatory stage

Testing is necessary to check the tightness of both containers, the liquid level, and the electrical connection. But the main thing is whether the installation produces a sufficient amount of steam.

Any unit that works with water requires maintenance, descaling, and efficiency testing. It is necessary to test the unit in case of such unpleasant situations as:

- lack of water;

- voltage drop;

- overflow of water.

If this does not happen, the steam generator works for a long time without creating problems. It would be a good idea to install a filter, especially if the water contains a high content of salts and sand.

There are some well-known tricks and devices that protect against overflow. Pressure gauges are installed to monitor the pressure in the housing, and thermometers to record the temperature.

It is important to know that a homemade steam generator is not only useful, but also dangerous. Incorrect assembly or incorrect calculation can lead to electrical injuries and burns. You should think a hundred times before you start assembling the device. And if it is not possible to purchase good quality equipment, which includes HARIVA, TYLO, SAVO, it may be better to steam the old-fashioned way, splashing water from a wooden ladle onto the stones of a wood-burning stove.

How to make a steam generator for a bath from a gas cylinder with your own hands

A steam generator from a gas cylinder is one of the most popular variations for self-assembly of a steam generator. The metal body is strong enough to withstand high temperatures and steam pressure.

Tools and consumables used in work

When manufacturing a steam generating unit, materials that are resistant to high thermal loads should be used. Among them, stainless steel has proven itself well. The best option for creating a steam generator design is a gas cylinder, since it is made of durable metal and the welds can withstand high pressure. Before starting assembly and installation work, you should prepare plumbing tools. For these purposes you will need:

- electric drill and set of drills;

- roulette;

- fastening elements (screws, bolts);

- circular cutting machine (grinder);

- insulating tape;

- metal scissors;

- a set of keys.

In addition to the listed tools, you will need a welding machine. This equipment is used to ensure strong seams, as well as installation of metal pipes. Consumables should also include sensors for measuring pressure and operating temperature, as well as ball valves. Households often use low-power installations that can be made independently from old household appliances or household items. For example, it could be a steam generator from a flask, an old electric kettle or a pressure cooker.

Selection and preparation of a container for a steam generator

To make your own steam generator for defrosting pipes and other household needs, you should choose a reliable tank for the design. A gas cylinder is ideal for these purposes. As for the size of the container, they should be selected in accordance with the purpose of using the equipment (the amount of steam generated was sufficient to heat the room, clean the car engine, etc.).

Gas cylinder for steam generator

Before starting installation work, for safety reasons, the cylinder should be prepared accordingly. To do this, you need to get rid of its contents by bleeding off the remaining gas. It can be easily removed from the container by unscrewing the valve.

The next step in preparing the tank is to wash the inner surface of the tank (you can use regular dishwashing detergent). The container should be processed until the characteristic smell of propane (gas) disappears. After the cylinder has completely dried, they begin installing the heating elements.

Installation of heating elements

Before you install the heating elements yourself, you should develop a drawing of the steam generator (an example can be seen in the figure). As you can see, a heating element should be installed in the upper part of the tank, which is permanently mounted on a removable lid.

Steam generator heating element

Please note that the heating element must be installed in such a way that if it burns out, replacement can be done without effort. For this reason, it is not recommended to weld heating elements to the structure body.

Expert opinion

Artyom Krikunov

Tool selection consultant at VseInstrumenty.ru LLC

Ask a specialist

“When choosing a heater, it should be taken into account that this structural element must withstand fairly high loads during operation of the unit - from 6.079 Bar. The choice of device based on power should be based on the calculation of 3 kW heating element for every 10 liters of liquid.”

Steam generator connection diagram

As for the assembly of a solid fuel unit, there is no need to make special calculations or install heating elements. Watch the video about the steam generator - it’s quite easy to assemble such equipment yourself, and the cost of consumables will be minimal.

Installation of additional elements

The next stage of self-manufacturing of a steam generator is the installation of additional structural elements that are installed in the upper part of the unit. To secure the automation, as well as the relief (pressure) and filling valve, you should weld small sections of pipes - pipes, in the amount of 4 pieces with threads.

Steam generator pressure gauge

A ball valve is mounted on the side of the structure, which is essentially a liquid level. It opens as soon as the tank is filled with a certain volume of water, and closes when it flows out. This element is installed at a distance of 100 mm from the top point of the unit body.

Features of valve modification

As we have already said, the gas cylinder has a valve made of brass, which should be divided in half. After this, you need to remove the rod and cut the thread to install the ball valve. This design will be required to select steam flows.

Checking the safety of the steam generator

When making a steam generator for hamam, baths and other needs with your own hands, you should check the operation of the unit. For these purposes, at the final stage of assembling the structure, an automatic safety unit should be installed, consisting of pressure gauges that allow monitoring temperature and pressure indicators (they must be connected). The safety unit works as follows: as soon as the internal pressure or operating temperature reaches the limit values, the heating will automatically turn off. A magnetic starter should be included in the electrical circuit of the unit (the retractor coil will be the load). After checking the performance indicators and triggering the safety automatics, the steam generator can be installed for subsequent operation. Below is an approximate diagram of connecting the unit for the steam room.

What about the sauna, is it not popular now?

Well why? To each his own! Some people prefer dry steam, others prefer wet steam. Most saunas are powered by an electric stove with an internal and external heating element - stones! And steam from such bath stones will only be produced if you use liquid for steam generation. Most often it is simple water with oils diluted in it. But such steam quickly evaporates due to the high temperatures in the steam room itself.

You can also use a more modernized bathhouse solution by installing a multifunctional installation in the steam room using a stove with a steam generator. Or you can buy a ready-made cool unit, but that’s a completely different story.

That's probably all. Until next time, dear readers. I hope you liked the article, and we will definitely meet again on the pages of this blog! If you rate this information positively, you can share it with your friends on social networks.

Comment, criticize, like. In a word, everything is as usual. Have a nice steam!

Wisdom Quote: Years teach many things that days do not know.

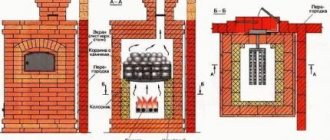

Features of assembling a solid fuel steam generator for a home using wood or coal

Assembly of a solid fuel steam generator is much simpler compared to its electric counterpart, and less expensive. The design will require pipes of various diameters. First you need to make a loading tank, for which you can use a pipe with a diameter of 300 mm. It burns coal or wood. It is also necessary to weld a water container that is installed above the firebox. A register pipe and an adapter should be welded to it, through which the steam will be discharged outside. For more information on how to make a steam generator with your own hands, watch the video.

Video “Features of assembling a solid fuel steam generator with your own hands”:

And then?

We perforate a metal-plastic water pipe with a drill or screwdriver. The holes should be a maximum of 5 millimeters in diameter, and the distance between them should preferably be 5-8 cm. Then the plastic pipe must be rolled into a ring corresponding to a slightly smaller diameter than the diameter of the bottom of the wooden barrel. We place the pipe blank inside the barrel, on its bottom, with the holes facing up.

Almost everything! We have reached the final stage of work. Now you need to drill a hole inside the barrel that matches the diameter of the flexible metal hose. Thread the hose into this hole and connect it through a tee fitting to a metal-plastic water pipe. That's almost all, all that remains is to secure the thermometer inside the barrel and install the electronic thermometer display outside.

We install a steam generator

For obvious reasons, it is not practical to use solid fuel steam generators indoors in bathhouses or steam rooms. For these purposes, electrical units will be required. When installing equipment, you should pay attention to the condition of the hoses - they should be without kinks and have a slight slope. This is necessary for free drainage of condensate.

Welding of bends on the installation

When connecting the power plant to the electrical network, a residual current device should be used. The power of the RCD will be 10-30 mA depending on the type of load and type of room. Please note that the steam generator is a powerful, traumatic electrical installation. For this reason, its installation must be accompanied by the mandatory connection of a grounding loop.

Steam generator installation diagram

When can you start enjoying?

Patience! Very little left! Our design is 99% ready, all that remains is to pour water into the canister, plug in the plug, wait for the water to boil and steam to enter the barrel. Then climb inside, close it with a special shelf on top and a door on the side.

Now enjoy! Just remember to keep an eye on the thermometer so as not to overheat. And be sure to monitor the water level in the canister. Otherwise, there will be no luck! Let me note that this is the most basic way to make a homemade sauna steam generator, which can be done without straining.

This is the kind of country mini-hamam we got. And what? We can safely call the phyto-barrel that way. After all, steam baths, including the Turkish bath, are all built according to a similar principle - their design is based on a closed room and steam supply through a steam generator!

How to make a steam generator for a moonshine still – nuances

For this type of steam generator, enameled or galvanized deep dishes are suitable. It is better to use a pressure cooker to make the unit because a heating element is already built inside it, and it is also characterized by excellent tightness. When creating a steam installation for a moonshine still, the unit should be equipped with a safety valve. This element is necessary to relieve pressure inside the container. In addition, you will need to secure the fitting, which is necessary to discharge steam flows.

To control the water level inside the container, you need to install a tube (corrugated metal hose). It is recommended to use a thermometer to control the heating temperature. As for the distillation cube, you also need to install a fitting into this structural element, having previously drilled a hole in its lower part. A steam outlet and a perforated tube twisted in a spiral should be connected to it. Streams of steam are released through it. How to make a steam generator for a moonshine still with your own hands can be seen in the diagram.

Scheme of operation of the moonshine still

What is needed for making

1. First of all, the steam generator needs a container with a capacity of 5 liters (for a distillation cube up to 20 liters). It could be:

- a pressure cooker or steamer that will require minimal modification. This is almost an ideal option, since the lid is sealed and already has a safety valve;

- a milk flask, which will have to be processed more thoroughly;

- beer keg. You will also have to work hard on it;

- pot. A container suitable only if there are no other options. Here, in addition to installing valves, you will have to come up with a reliable option for sealing the lid with the pan.

2. Bubbler. This can be a plumbing bellows from a store or one made by hand from a tube with a cross-section of 15–22 mm and a length of 20–40 cm. Cuts are made in the tube every centimeter or holes are drilled.

This is necessary so that steam can escape from these cracks and heat the mash evenly along the entire perimeter of the tank. The tube is twisted into a half ring, placing the open end approximately in the middle of the cube at a height of 4-5 cm from the bottom.

Attention. The longer the bubbler, the faster the mash will heat up.

3 Fittings: for securing the bubbler in the distillation cube - with a check valve; for connecting the steam outlet hose - normal.

4. Safety valve fixed in the steam generator cover.

5. Electronic or bimetallic thermometer and a capsule for it (a piece of tube welded into the lid).

6. Steam supply hose. The thickness is selected in the given parameters of the fittings, the length is calculated so that it is enough to connect the cube bubbler to the steam generator.

7. Insulation for the cube, steam generator and steam supply hose.

Advice. Choose insulation from what plumbing stores offer. You can take, for example, heat-resistant foil insulation made of basalt or mineral wool with the designation “for saunas” or another of your choice.

8. If you plan to heat the steam generator using a heating element, also take care of purchasing a thermostat, which will greatly simplify the management of moonshine production.

We make our own steam generator for heating pipes

As in the previous case, the steam generator must be mobile so that the installation can be moved over a considerable distance. In addition to flexible hoses, electrical cables of similar length will be required to connect the installation to the water supply.

Using a steam generator to defrost pipes

Let's take a closer look at how to make a steam generator for universal purposes out of trash with your own hands. This generator can be used to wash parts of household appliances that cannot be dismantled, for example, air conditioner radiators.

| Illustration | Description of action |

| To work, we will need the simplest things that you probably have lying around in your garage. One of them is an old electric kettle. We take away the most valuable thing from it - the heating element. | |

| We grind the 150 pipe to the required size and trim the edges. | |

| And we insert our “device”. | |

| We grind out an adapter for attaching the heating element. | |

| We attach the rim to the plastic base. | |

| We fix it inside the pipe with ordinary bolts, and make a hole for the electrical wires. Instead of legs, we use hoses. | |

| We weld a sheet on top of the structure, weld a fitting, attach a tee and a tap for filling water, a boiler valve with adjustment and a steam outlet tap with a plug. | |

| We supplement the design with a regular water hose and a gun (we used a regular one for foam). | |

| The steam generator operates from a power outlet and is equipped with a handle like this for mobility. |

Build process

When choosing a method for attaching heating elements, you need to make sure that the tubes do not touch the bottom, much less the walls.

Therefore, it is necessary to drill a through hole of the appropriate size in the wall so that the heating element can be mounted there. At the same time, the distance of the heating elements from the surface should be approximately 1 cm. This will ensure proper heating without damaging the container itself.

It is best to use insulating washers, which should be installed both outside and inside the container. To seal the fasteners, silicone gaskets are used (it is important that these are heat-resistant options). They can be purchased at the store or made yourself.

The main reasons for the breakdown of steam generators

Since steam generators are characterized by a simple design and high strength of the materials used, breakdowns of such equipment are quite rare. The main reason for the failure of units is the poor quality of the water used, which causes scale to form. To avoid its formation, appropriate filtering equipment is installed in the water supply circuit. If the water is hard, it is recommended to drain the remaining water from the tank, and also wash the internal surfaces of the structure with acetic or citric acid. After treatment, the unit should be thoroughly rinsed with running water.

Before using the steam generator, it is imperative to check the unit for the presence of working fluid in it. Its absence may lead to burnout of the heating element. Dear readers of the online magazine Seti.guru! Share your experience in the manufacture of steam-generating equipment in discussions with other visitors to our resource, and also offer solutions for its improvement.

Safety precautions

When operating a homemade steam generator, it is important to follow safety rules.

All heating elements used in creating such a device must be insulated and the circuit must be grounded.

To prevent generator failure when operating without water, you should rely on the readings of the cylinder filling control sensor.

Making a steam generator with your own hands is quite simple; the main thing is to have the necessary equipment at your disposal and know the basic principles of the device’s operation. Thanks to the useful recommendations in our article, you can assemble a simple device for household needs.

Video instructions for assembling the steam generator:

- Author of the material

- Other materials

Recommendations for use

- It is preferable to install the steam generator in the room adjacent to the steam room, since it is an electrical appliance that is dangerous in conditions of high humidity.

- The steam supply tube must be positioned at an angle so that the condensate can drain without forming a plug.

- It is better to pre-purify ordinary tap water with a filter. To descale the liquid, you can add acetic acid.

- When performing various health procedures, herbal infusions or essential oils are added directly to the water.

Important: To ensure electrical safety, the metal body of the steam generator is grounded. An RCD should be used for connection.

Preparation of equipment and materials

What you will need for manufacturing and installation:

- ball valves that can withstand elevated temperatures;

- heating elements (heating elements);

- gaskets for heating elements (they must be heat-resistant);

- safety valve;

- a hose is used for the steam line;

- bends with corresponding connecting diameters;

- a container that can withstand high pressure (for example, an old gas cylinder);

- pressure gauge

Important: The volume of the tank is selected based on the size of the steam room. General rule: for a 10-liter container, the power of the heating elements should be 3 kW.

The gas cylinder is prepared before use:

- The integrity of the walls is checked for the absence of defects.

- The top valve is carefully removed.

- Water is poured into the cylinder to completely displace gas residues.

- The upper part of the cylinder is cut off at the welding seam.

- The inner surface of the container is thoroughly washed using detergents.

Step by Step Actions

- The funnel is prepared (take a ready-made one or make it from a stainless steel sheet)

- A check valve is mounted and a corrugated pipe is connected using a fitting. It can also be regular tap water.

- Using connecting elements, a device is manufactured in a shape that is suitable for placement in a stove-heater.

- Sections of corrugated pipe will serve as steam diffusers. A series of holes up to 2 mm in diameter are drilled onto them. If water evaporates at an accelerated rate during testing, some holes can be closed with self-tapping screws.

- The finished steam gun is placed in the oven and laid on top with stones.

During the first tests, the homemade device is filled with liquid in a limited amount, and the oven does not heat up completely. If the tests are successful, then you can test it in operating mode.

A homemade generator is easy to make, and a craftsman can make it within one day. It is impossible to completely replace the factory device, but as a result, a more comfortable atmosphere and better conditions for healing will be created in the bathhouse.