Bath tub - replacement of the font. It is made of stainless steel or cast iron. It is a hemispherical bathing container. The product is placed in an area next to the bathhouse, where there is a source of water. A stove is installed below or a fire is lit to heat the water. The temperature of the latter is maintained at up to 40°. The design heats up so that the edges remain cold, so it is impossible to get burned during use. The article describes the design of the vat and provides instructions for its installation.

Where and how to buy a sauna vat?

In conclusion, some information about our partner - the Chelyabinsk company, which produces such popular “bath gadgets”.

The company supplies its products throughout the Russian Federation. It has been producing and selling sauna vats since 2013. How to make a stainless steel vat

If you have a question about how and where to buy a sauna vat, we are in a hurry to answer you. At the end of the article there is a small free test survey that will help you calculate the cost of “your desires.” Select the model, installation and heating method, and additional options if necessary. If you have any questions about delivery, custom projects, production times, etc., please ask.

They will contact you and advise you on any topic of the sauna vat that interests you. Discuss all specific issues: how many people are you planning the vat for, what steel and what thickness of metal will be optimal for you, what wood to use for finishing, delivery and payment methods

These are the main points that you should first pay attention to. These will be the cost of the “street bath”. Users of the VKontakte social network can see all the details on our VK public page in the products section

The Sauna Chan will delight you every day, give you new emotions and an unforgettable experience of steaming in the open air. It will be very useful for both private and commercial use. So, owners of camp sites, sanatoriums and holiday homes - this is “your gold mine”...

Users of the VKontakte social network can see all the details on our VK public page in the products section. The Sauna Chan will delight you every day, give you new emotions and an unforgettable experience of steaming in the open air. It will be very useful for both private and commercial use. So, owners of camp sites, sanatoriums and holiday homes - this is “your gold mine”...

That's all. If it was useful, subscribe to us in the VKontakte group, where you can find a lot of interesting and educational things for yourself. And don't forget to invite your friends. Suddenly, it is for them that the information will be very relevant. Good luck to you and peaceful bright skies above your head! Bye!

Wisdom Quote: You must find time to rest, because there is always work, but life tends to end.

Drawings, dimensions and manufacturing technology

The dimensions of the future “pot” are chosen based on your own considerations of ease of use of bath equipment. Traditionally, large sheet metal containers are made in the form of six or octagonal truncated pyramids. That is, the bath tub is not round, but in the form of a polyhedron.

One such option is shown in the drawing below.

It is known from practice that any structures whose dimensions are smaller or larger than the specified frames are not very convenient to use.

In addition, the multifaceted shape of the sauna boiler provides some advantages:

- The scheme for making patterns for individual workpieces and performing welding is simplified. Cutting rectangular elements is much simpler and easier than struggling with patterns and curved lines;

- You can easily replace any sector of the body of the bath tub if there was a defect, or a minor alteration of the design was required;

- A flat wall turns out to be more convenient as a back support than a rounded surface.

Correct installation of the sauna tank

To install an all-welded structure, you will need to level and fill with gravel a flat area measuring 2.5x3 m. The best option for installing a bathhouse would be a place under a canopy, protected from the wind and water flowing from the roof of the bathhouse.

The design turned out to be quite bulky and heavy, so the metal frame holding the bowl may not be stable enough. Therefore, under the surface of the site, a metal cross-shaped structure, 1x1 m in size, welded from a channel, is usually buried. Anchors or threaded rods are welded to the beams, after which everything is covered with gravel or concrete. With this method of fastening, the sauna vat will not tip over, even if several people try to climb inside at the same time.

Of course, for ease of handling the sauna vat, you will need a small ladder with a service platform. You can also make it yourself or buy it ready-made.

Required tools and materials

Cast iron is a difficult-to-process high-carbon metal with a large mass, so a bathing tub based on this material is manufactured only in a factory by casting in a special mold. For self-production, preference should be given to easy-to-use steel, which has a long service life, fairly quick heating and an aesthetic appearance.

Before you start work, you need to make a drawing of the future bath tub.

In addition to preparing competent and intuitive diagrams, choosing the optimal type of structure (most often in the form of a steel octagon), you also need to be able to work with a welding machine. The finished steel vat can be installed on metal supports, a durable wooden or brick base.

A good alternative would be to make a concrete font. Such a font is immediately cast in the chosen place. In this case, you will need to prepare a regular marking tool, metal reinforcing rods, wooden formwork and concrete mortar, brushes and a roller, a waterproof plaster mixture and waterproofing impregnation, a tape measure and a level.

Quality

The production employs highly qualified specialists with a narrow profile, each of whom pays maximum attention to the process.

Carpenters, welders, painters - each specialist has his own secrets that are used in his work, and, unfortunately, not everyone can become a master of even one of the crafts.

You can do everything yourself, but to achieve an impeccable result, you need to be a master of your craft!

Read also: Copper sulfate at home

Required tools and materials

Cast iron is a difficult-to-process high-carbon metal with a large mass, so a bathing tub based on this material is manufactured only in a factory by casting in a special mold. For self-production, preference should be given to easy-to-use steel, which has a long service life, fairly quick heating and an aesthetic appearance.

Before you start work, you need to make a drawing of the future bath tub.

In addition to preparing competent and intuitive diagrams, choosing the optimal type of structure (most often in the form of a steel octagon), you also need to be able to work with a welding machine. The finished steel vat can be installed on metal supports, a durable wooden or brick base.

A good alternative would be to make a concrete font. Such a font is immediately cast in the chosen place. In this case, you will need to prepare a regular marking tool, metal reinforcing rods, wooden formwork and concrete mortar, brushes and a roller, a waterproof plaster mixture and waterproofing impregnation, a tape measure and a level.

Flaws

Disadvantages of metal homemade stoves:

- the metal quickly gives off heat after the fuel has finished burning, so almost the entire time you relax in the bathhouse, the stove has to be heated;

- for a large house, one stove may not be enough for heating;

- uneven heating of the steam room - it’s hot near the stove, cool at a distance;

- You can burn yourself if you touch metal. To do this, a fence is sometimes mounted around the stove body;

- A metal sauna stove is not fireproof enough. The nearest wall must be insulated from the hot walls of the furnace;

- not very presentable appearance.

What elements do the shelves consist of?

The main ones in this design are:

- Frame. Often this is a frame made of timber into which boards of permanent or collapsible flooring are fixed. The thickness and shape of the parts resemble the legs of a bench, which are connected to each other by transverse bridges. May have a stepped structure.

- Flooring. It consists of boards that are fixed in increments of 1–2 cm. They are laid on top of the frame. Performs the function of a couch, bench. It can be removable or stationary. In the first case, it is convenient to dry it before each use of the steam room. For convenience, it is equipped with a backrest and a stand under the headboard.

There are a number of requirements for shelving in a bathhouse:

- Low level of thermal conductivity. The material should not become very hot at a constantly high temperature. Therefore, the main raw material from which shelves are usually made is wood.

- Wooden racks are designed with rounded corners to avoid injuries during operation.

- The strength of the frame is very important so that the supports can withstand significant weight loads.

- The surface of the bench must be free of any elements made of iron or other metal. Because metal heats up very quickly and can cause serious burns.

Benefits and harms

Of course, it is important to name the beneficial properties and advantages of the sauna vat. Every person experiences fatigue and needs quality and complete rest: both physical and mental.

Steaming in a sauna vat will bring great pleasure, because it is a procedure that gives strength, energy and relaxation. It is worth noting that science has long proven the benefits of this remedy, thanks to which it is possible to treat joint diseases and restore the body after severe treatment or injury.

If we talk about wood-burning bath procedures, with their help the blood is cleansed of toxins, vital energy returns, extra pounds are burned, and the skin becomes more toned. The functioning of the cardiovascular system is stabilized, and metabolism also improves.

However, despite all the benefits of sauna vats, it is worth understanding that in some cases they can be harmful, and therefore it is important to know when to refrain from the procedure. People who have high blood pressure should first consult their doctor

Serious heart disease can be aggravated by exposure to a hot sauna bath. Blood pressure increases during the procedure - this should be taken into account.

Medical contraindications

Everyone knows that in every business there are both positive and negative aspects. Our sauna vat was not left out either. Before taking hot baths with herbal infusions, it is strongly recommended to consult with your doctor. Here is a small, but not complete list of contraindications for “hot water activities”:

- Any disease that occurs in an acute form

- Increased body temperature

- Tuberculosis in open form

- Diabetes

- Cardiovascular diseases

- Cirrhosis of the liver

- Oncological diseases

- Urolithiasis disease

- Epilepsy and other diseases

Let's finish talking about contraindications here. I would like to believe that you do not have them or will not have them in the very near future. After all, health is the most valuable thing we have.

Do-it-yourself sauna vat: step-by-step instructions

Making a sauna vat with your own hands is not at all difficult. To do this, you need to decide on the material of the product and prepare the tools.

It is important to follow the step-by-step instructions given in the article

Required tools and materials

Cast iron is a difficult-to-process high-carbon metal with a large mass, so a bathing tub based on this material is manufactured only in a factory by casting in a special mold. For self-production, preference should be given to easy-to-use steel, which has a long service life, fairly quick heating and an aesthetic appearance.

Before you start work, you need to make a drawing of the future bath tub.

In addition to preparing competent and intuitive diagrams, choosing the optimal type of structure (most often in the form of a steel octagon), you also need to be able to work with a welding machine. The finished steel vat can be installed on metal supports, a durable wooden or brick base.

A good alternative would be to make a concrete font. Such a font is immediately cast in the chosen place. In this case, you will need to prepare a regular marking tool, metal reinforcing rods, wooden formwork and concrete mortar, brushes and a roller, a waterproof plaster mixture and waterproofing impregnation, a tape measure and a level.

Step-by-step instruction

Main stages of work:

- At the first stage, the dimensions of the font are determined and markings are made for digging a pit, taking into account the thickness of the walls of the concrete vat (15–18 cm). After a hole of the required depth has been dug according to the markings, the walls are leveled.

- If necessary, a relatively narrow trench is made with a slope towards the drainage pit and a plastic pipe drainage system is laid, and a sand cushion is poured into the bottom of the pit.

- After the reinforcing structure is laid on top of the sand cushion, a wooden or plywood formwork is erected, which should rise about a quarter of a meter above the ground surface.

- The internal part of the erected formwork is strengthened with bars, after which reinforcement is installed in the central part of the wooden or plywood frame and a concrete solution prepared on the basis of sand, cement (M400) and crushed stone mixed in a ratio of 3:1:5 is poured.

- After the concrete pour has hardened, the wooden formwork is removed and a standard plaster mixture is prepared, which covers the walls of the finished font. The thickness of the applied plaster layer can vary from 0.3 to 10 mm.

- The internal walls are treated with three layers of deep penetration waterproofing impregnation. The outer part of the vat can be decorated with almost any type of waterproof finishing material. Most often, standard ceramic tiles are used for this purpose.

Thanks to ancient Russian traditions, the availability and variety of construction and finishing materials, today you can independently build a bathing tub of any size and shape, and installing additional devices in the font will make bathing procedures not only very useful, but also enjoyable.

Preparation

Anyone can make a sauna vat with their own hands, although it is not as simple as it might seem at first glance. First of all, it’s worth calculating everything well to avoid semi-handicraft production.

It is also important to choose the appropriate place to install the font and determine the shape and size of its structure. The choice of material for the vat body, which must be covered with a protective layer, also plays a huge role.

At the preparatory stage, they also think through a water drainage scheme, plumbing and interior arrangement with footrests and seats.

Tools and materials

Before you start making a sauna vat at home, you need to worry about the availability of appropriate equipment, in particular, this applies to electric welding. In addition, you will need a grinder with a cutting wheel for metal and a jigsaw, which can be used to cut curved parts. As for the choice of material for the body, it is difficult to do. Thus, a cast iron vat takes several times longer to heat up than a steel one, but has a comfortable rounded shape without corners and a smooth surface.

In order for the bath tub to reliably serve for a long time, experts recommend choosing stainless steel in the form of sheet steel for its body. This material is durable and resistant to temperature changes. The only thing is that only a professional welder can assemble a stainless steel vat. If you have no experience in such work, then it is better to choose ordinary steel, which even a novice master can weld.

Drawings and dimensions

After everything has been decided with the material of manufacture and the installation location of the bath vat, the next point in the preparatory stage of construction work is the creation of drawings, according to which the vat will be made in the future. First you need to sketch out sketches and choose a more suitable shape for the future design. Most often, huge containers in the form of hexagons or octahedrons are made from metal sheets, that is, the font is not round.

As for the sizes, it is advisable to choose larger ones, since miniature structures will be inconvenient to use. Experts recommend choosing standard sizes, in which the diameter is from 220 to 260 cm, the depth is from 60 to 80 cm. In addition, when choosing sizes, you should take into account the capacity of the font (how many people can swim in it).

The final stage of preparatory work is the creation of drawings, which should provide complete information about the size and shape of the future vat. Based on the drawn up drawings, the material consumption is calculated and its purchase is carried out.

Where and in what cases can it be used

- To treat colds and activate the immune system;

- To normalize the functioning of the circulatory system, especially after suffering from colds and injuries.

- In terms of combating excess weight, to get your figure in order after the autumn-winter period of inactivity;

- For rehabilitation after limb injuries, bone fractures and soft tissue injuries;

- To improve psychological state, correct mood and relieve stress;

- As a cardiovascular workout;

- To restore the respiratory system;

- In the end, this is an excellent hygiene procedure for keeping the body in great shape.

But as for the time of use, here it is recommended to carry out treatment procedures in the morning or evening, for pleasure, there are no restrictions, the main thing is that it is safe.

Overview of species

The design of the bath tub can be different - depending on the shape, location and the presence of additional elements. There are two main categories – wall-hung and built-in installations. The vat can be placed both outside and inside; it is often installed outdoors in the fresh air.

Built-in

This design is mounted on a built pedestal, which is made of profiled pipe. In some vats it can be closed and lined with decorative material that is fire resistant. This is often brick, terracotta tiles or stone. A place for a fireplace is prepared under the structure, or a stove is built in to maintain the temperature of the water in the container. According to the rules, it should reach 45 degrees Celsius, as this is the most comfortable in winter.

The product is offered in several sizes, so first you need to decide how many people you need to accommodate. Benches made of natural wood are installed inside, they have comfortable backs, and some models have armrests.

Hanging

Such bath vats are suspended on chains and attached to tripods, which can be either metal or wood. Seven-meter logs serve as supports, as they are able to withstand the weight of the vat. This option is suitable for vaping outdoors, because it has a rejuvenating effect, and the contrast is very pleasant, especially if it is winter. The outdoor one attracts many, so if there is free space on the site, you can install the structure, heat the water over the fire and enjoy bathing procedures.

As for the size of the bathtub, there are several options, but almost every one is made with eight sides

The parameters affect the capacity, so you should pay attention to the diameter. The general depth indicator: for small, medium and large - 1 m. Maximum capacity - ten people, the diameter of such a vat reaches 2.5 meters

The medium-sized tank is suitable for six to eight people, the diameter is 2.25 m, and the small one is 1.9 m, so it will be comfortable for bathing four to six vacationers

The maximum capacity is ten people, the diameter of such a vat reaches 2.5 meters. The medium size tank is suitable for six to eight people, the diameter is 2.25 m, and the small one is 1.9 m, so it will be comfortable for four to six vacationers.

Varieties

There are a number of types of structures. The market offers hot tubs, heated sauna vats, on logs, hanging and large-sized options. When choosing a design, it is recommended to be guided by your own preferences, and in some cases, by medical indications. Hanging vats can be an original option. It must be remembered that it is almost impossible to build such a device yourself, since it requires the use of specialized equipment and tools. When constructing such a structure, basic safety rules must be observed.

To heat the bath, both wood and ordinary metal stoves are used. The safest is the second option. In the first case, you should carefully monitor the degree of heating of the structure, since burns are possible. The vats also differ in size. Here you should make your choice based on the number of people who will use this kind of open-air sauna. Fonts are a classic option.

Popular manufacturers

is one of the best in this area. The main indicator of quality is the presence of four patents and certification. The manufacturer has received the right to produce containers of a certain shape, so you can safely consider the products if you want to take bath procedures on your territory. High quality steel is used for manufacturing, which resists mechanical damage and corrosion.

Cedar wood with high moisture resistance, strength and long service life is used for components.

Wood also has a positive effect on the body and cleans the air of bacteria, which is no less important. Siberian bath vats are presented in different configurations

Sergeev Chan produces and sells products, delivering them to any region. The advantage of sauna vats is that they are made of food-grade stainless steel, the finishing is made of pine and larch. About fifty configurations are offered to buyers.

Transcarpathian cast iron vats can be ordered from, which produces containers of the highest quality in compliance with all requirements. It is worth noting that you can even choose any finishing color. A specialist consultation is provided in advance; there is also a detailed description of the products, their characteristics and parameters.

The Japanese heated sauna vat is called Furako. offers baths of this type. The range includes containers with a composite insert and a built-in or external oven. The main wood material is Altai cedar, which has beneficial properties and retains them for a long time. Such a bath can be installed in your own bathhouse or outdoors in the open air.

Tips for interior decoration of the steam room

Even at the construction stage, it is necessary to use modern impregnating compounds that can withstand high temperatures and humidity without harming human health. This way you can protect the building from fungus and rot. Those that are suitable for the ceiling cannot always be used to cover furniture.

Manufacturers of varnishes and paints (Senezh, Empils, Rogneda, Dulux, Tikkurila, Nobel, Belinka, Teknos) produce many such products with water-repellent natural substances such as paraffin, wax, oil. They are divided into those suitable for external walls, internal surfaces that a person does not touch with his body (ceiling) and furniture.

Silicone impregnation suitable for ceilings

Pyroprotective and antiseptic impregnation of logs is usually done at the timber mill, but it must be done again after construction.

The first application of the compositions to furniture is carried out immediately after its manufacture on a dry and clean surface, or even before manufacture (on wooden blanks). The product should be evenly distributed with a sponge, soft cloth or brush. Due to the thick consistency, a spray gun will not work.

Impregnation can be applied with a sponge, brush, or cloth.

Cast iron vat for bath

Cast iron is a high-carbon metal that is heavy. It is impossible to make a bath tub from it at home, so they are assembled in production by pouring into molds. Advantages of the material:

- heat capacity;

- wall thickness;

- life time.

Thanks to the thick walls, the water takes longer to heat up, but also maintains its temperature for a long time, which is important at sub-zero temperatures. There are also disadvantages:

- weight;

- price.

The weight of a vat for four people reaches 1.2 tons. Installation requires a forklift to transport it to the site. It is impossible to remove the container for storage, so a cover is built to protect the product from rusting

When choosing, pay attention to the quality of workmanship. Edges should be sanded, no flash

Porosity and wall thickness uniformity throughout the vat are analyzed. They take into account the warranty that the manufacturer is willing to provide. If the container is painted, then the composition must be fire-resistant, since the surface will be exposed to open fire.

Information! Cast iron is a fragile metal, so when using the vat, avoid strong impacts and sudden temperature changes.

Nuances of use and additions

When using, it is worth keeping in mind that the products presented in the catalog heat up differently. Or rather, the heat distribution is the same, but the larger the container, the more time it will take to heat up. The products are manufactured in such a way that the temperature of the top of the walls will always be lower than the bottom.

With intensive use, the walls and bottom will not become covered with rust. However, with rare use, such a development of events is quite possible. This problem can be prevented by plasma spraying of copper. So it is resolved once and for all. This procedure is not included in the price of the bathing product, but it can be purchased separately.

What are the health benefits

Don’t forget that you need to get regular and complete rest. If a person is constantly busy, working all the time or worried about everyday problems, if there is no time to rest at all, a feeling of psychological discomfort arises. But when you steam in such a SPA pool, you will have a wonderful rest not only with your soul, but also with your body. You will long remember the time spent in the company of friends under the aroma of hot magical water.

It has been proven by science that the chan bath is an amazing remedy for treating joint diseases, as well as for restoring the body after injuries and fractures. Many athletes, after grueling training, completely relieve fatigue and restore strength. In addition, a wood-burning sauna vat will help you:

- Cleanse the blood and remove toxins from the body

- Restore youth and vitality

- Lose excess weight and tighten your skin

- Improve the functioning of the cardiovascular system and stabilize blood pressure

- Normalize thyroid function and improve metabolism

- Cope with colds and improve the body's immunity

- Normalize the musculoskeletal system

- Strengthen the nervous system, and as a result - get rid of stress, anxiety, insomnia

- Provide a general strengthening and analgesic effect.

Of course, this list can be continued for a long time. This is probably why the vat bath is gaining more and more fans today. And it’s not in vain that many are trying to remember this long-standing tradition, regain their youth and restore precious health.

Blueprints

To simplify and speed up the process of making benches for a steam room, it is recommended to draw up a visual diagram of their structure and location.

The dimensions of each part are marked on the drawing. If necessary, sketches of shelves are made from different angles.

The figure clearly shows whether the design of the benches will be folding, stepped or removable.

The location and distance of the elements from the stove or boiler are indicated.

A separate drawing should show the overall picture of the bathhouse with the location of the steam room, shower room, and rest room (if provided).

Don't forget to indicate the height of the ceilings and the distance of the bottom shelf from the floor.

The name and consumption of material for the benches (lining, board) are indicated, and the fastening elements are noted.

Bath tub: manufacturing process

Before starting welding work, you should calculate the geometry of the workpieces that will be part of the sauna vat. To do this, you can use such a clear and proven method as building a layout.

A model of a bath tub can be made from cardboard, proportionally reducing the dimensions, for example, by a factor of 4. The model is made in the following sequence:

- Cut out the octagonal bottom of the font.

- Cut out the side wall elements in the shape of squares. The length of the sides of the blanks should be 120% of the large base of the trapezoid shown in the drawing.

- Select the desired angle of inclination of the workpieces and trim them so as to turn them into trapezoidal ones.

Provided that the cutting is carried out correctly, the entire set of parts of the layout should converge into a single integral structure. After this, sketches of the cutting of the walls are drawn up and their dimensions are transferred to the drawing.

Welding is best done on an assembly jig. It should be prepared before welding begins, using 30 mm square pipes. Welding begins by forming an octagon, the size and perimeter of which coincides with the edge of the bathhouse.

Having laid the finished polygon on level ground, the sidewall blanks are installed on it sequentially in pairs. The installed pairs of opposite walls are welded to a pre-prepared bottom. The result is a font, the bottom of which is on top.

If the font has successfully passed this test, it must be emptied, dried and prepared for protective and decorative finishing.

If ordinary steel was used to make a bath tub, then its outer surface is treated by bluing or phosphating. The inner surface of the product must be polished and then covered with silicone film.

At the final stage, seats are installed inside the font, and its upper edge is covered with protective railings. For this, oak or linden is used. The seat shelf is made of lining, which is carefully polished and impregnated with silicone varnish.

How to choose and where to place the stove?

The answer to this question is very complex. After all, in order to decide which stove to choose, you need to consider all its types, which have their pros and cons.

Metal furnace

It has small dimensions, a high degree of power, and the ability to heat the entire room. This oven heats up very quickly and cools down just as quickly. Touching it can cause burns. Therefore, when choosing such a stove, you must build a fence to avoid accidents.

Brick oven

Having chosen such a heating device, you need to know that a foundation is required for its installation. The dimensions of the oven can be selected based on the characteristics of the steam room and its dimensions. The good thing about installing a brick stove is that, unlike metal stoves, brick products heat up slowly and do not cool down very quickly. After installing such a stove, the air in the steam room will be light and dry, and besides, touching it is practically impossible to get burned. Therefore, it can be installed closer to the shelves so that it is warm for a long time.

Electric ovens

For lovers of modern technology, electric ovens are suitable. They do not need to be heated with wood. However, they also have many disadvantages. Electric stoves can heat only a small room, cool quickly, and are also expensive. In addition, the slightest fault in the insulation can lead to a short circuit. Therefore, when installing such stoves, you need to carefully check all wiring.

From soapstone

Soapstone has become popular in the modern world and is actively used to build stoves, as it is highly durable. It also has the ability to warm up the room gradually and evenly. The stone itself is expensive, but it is very economical in fuel consumption. By heating the stove for just one hour, you can enjoy the warmth all day long. Plus, such material has healing properties; steaming in such a bathhouse can not only give you pleasure, but also improve your health.

After familiarizing yourself with the types of stoves and making a choice, you can begin installing them. The base for this must be level. If it is an electric furnace or a metal furnace, you need to make a concrete base for it.

You can place the product either near the door or in the corner of the steam room, saving space. In addition, this space will be the safest place.

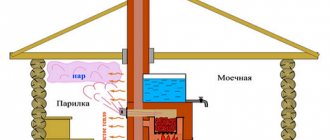

Next, a large sheet of metal is fixed in the opening on the ceiling. This is necessary to make an exit for one of the most important elements - the chimney. You need to make a hole in the metal in advance for the pipe. A water tank is installed on the stove. And through a specially made opening, a pipe is brought up, insulated with any non-combustible materials.

After installing the stove, it is necessary to conduct a test fire to see if everything is done correctly. And only then can you invite your household or friends to the steam room.

Installing a vat in a bathhouse

If the vat is installed in a bathhouse, then you can use the diagram-drawing given above. On loose soils, a pile foundation is laid. For independent construction, screw metal piles are used. They are a metal rod with a spiral at the end. The latter holds the support, preventing it from going deeper and moving. After installing the supports under the foundation, a concrete grillage is poured around the perimeter, which is tied with reinforcement to the piles.

Mark out the area for the bath tub. It will require a separate foundation, since the pressure from it is directed over a smaller area, which can deform or destroy the foundation. Select a square, the side of which exceeds the diameter of the container by 20 cm. Dig a pit to a depth of 30 cm. Screw piles into the corners so that the upper end is 10 cm below the ground level. Place river sand in a layer of 10 cm at the bottom of the pit under the bath tub. cm and compact. Medium-grain gravel is poured on top with a 10 cm layer and leveled.

Stands 5 cm high are evenly placed, on which a metal grid is placed, which will strengthen the concrete structure. Formwork is placed around the perimeter of the pit for the bath tub. Concrete is poured inside and leveled according to the rule. It takes a month to gain strength. At this time, the concrete is moistened and covered with film to prevent it from cracking. After a month, a stove is installed on the foundation and connected to a metal stand for the sauna vat. Make a conclusion for the smoke outside the structure. Use a lift to place the container in place and fix it to the frame by welding, if necessary.

Ready-made kits

Economy

- Material: steel st-3 fireproof moisture-resistant coating inside and outside

- Bath tub with drain pipe, tap and hose coupling

- vat stand

- Larch seat in a circle

- Larch footrest

- Protective cover

- Larch staircase

Standard

- Material: AISI430 stainless steel Outside: fireproof coating Inside: mirror or matte

- Bath tub with drain pipe, tap and hose coupling

- vat stand

- Larch seat in a circle

- Larch footrest

- Protective cover

- Larch staircase

- Larch all round top

Premium

Types of bath fonts

If in ancient times a bath font was a wooden barrel made of different types of wood, then modern models are distinguished by a wide variety of shapes, sizes and materials. By type of installation there are:

- bowls installed in a dug pit, reminiscent of a small pool;

- open fonts of different shapes and sizes;

- small pouring bowls shaped like buckets.

Open or recessed bowls can be purchased or made independently in a variety of shapes:

- round barrel;

- corner font for a bath;

- oval bowl;

- square or rectangular container.

There is a varied choice not only of shapes, but also of materials from which bath fonts are made:

- tree;

- plastic;

- stainless steel;

- cast iron;

- concrete.

Plastic font for a bath

Bath fonts made of polypropylene, which are cast in a variety of shapes and sizes, are in great demand. You can even order a product of individual dimensions and shape. The color range of plastic containers is varied from plain blue shades to bright bowls with a pattern. The service life of such a product can be at least several decades, and modern fiberglass bowls, according to manufacturers, will last at least 50 years without losing the brightness of their colors. Additional advantages of plastic products are:

- anti-slip, scratch-resistant coating;

- stiffening ribs provided in the structure prevent it from collapsing;

- the possibility of installing devices for heating or cooling water;

- You can install lighting and hydromassage.

Wooden font for a bath

Unlike industrial plastic, a cedar bathhouse is not only a container for bathing, but also a full-fledged health attribute. Wood resins, essential oils and minerals penetrate into the water and the pores of the body steamed after a bath, providing a rejuvenating and healing effect. In addition to cedar, other types of wood are used to make bathing bowls:

- Oak

is a durable material with antiseptic properties. Regular bathing in an oak font helps normalize sleep, strengthen the nervous system and speed up metabolic processes. - Beech structures

are also famous for their strength and reliability. This wood goes well with plastic, glass and metal. The beneficial properties of beech wood are manifested in strengthening the walls of blood vessels and the immune system. - Larch

has traditionally been used for the construction of fonts since ancient times. Its feature is an increase in hardness and strength in water.

Stainless steel bath font

A standard metal bath font is made from:

- of stainless steel;

- cast iron

Such structures are often installed outdoors and sources of open heat are supplied to them:

- A stainless steel bath font can be buried in the ground, tiled on the outside and a special wood-burning stove attached to the side.

- Another popular option is to attach the bowl to special chains attached to a special tripod. This creates an outdoor hanging bathtub for one person or a whole group. To heat the water under the bottom, you can make a fire. The container will heat up slowly and evenly. To avoid burning your feet, be sure to lay a layer of river pebbles or wooden flooring on the bottom.

Concrete font for a bath

The most expensive and difficult to install is a concrete single bathhouse. It can be installed both in the bathhouse and outdoors. Construction work may take more than one month, because the following steps need to be completed:

- digging a pit;

- summing up communications;

- installation of formwork;

- reinforcement and pouring with concrete;

- fastening waterproofing;

- finishing with finishing materials such as film, tiles or mosaics.

Additionally, a concrete bath font can be equipped with:

- equipment for hydromassage;

- LED backlight;

- chrome staircase;

- mini waterfall.

How to properly use such a bath?

There is nothing complicated here; even a beginner will quickly understand the system. You first need to fill the vat with water, then light the fire. It is best to use a stove, as it is efficient in saving fire, since almost no energy is spent on heating the environment rather than the water itself. You should light the fire after the vat is 1/3 full. Fire is not lit in a dry container; it is strictly prohibited.

After the fire is lit, you can throw several fragrant herbs that have medicinal value into the water, or simply use brooms for the bath. While the water warms up, it will begin to acquire an aroma with a useful and pleasant effect. The best option for herbs would be to use juniper or fir. You can also simply use special essential oils with the same pleasant aroma.

Only dried firewood is used; it is best to split birch wood. If the fuel is damp, then a person may simply suffocate from the smoke or the bathhouse may not heat up. Smoldering coals will be able to maintain the required temperature for a long time. If you light a fire in winter, then it will need to be maintained constantly.

242

Making a bathing bowl for a sauna: where to start

Bathing in vats attracts many people. Many people want to buy them. But the best option is to do it yourself. It will cost significantly less. If you decide to make your own, you should carefully consider the following starting points:

- choose the appropriate material. Often preference is given to sheet structural or stainless steel 2-5 mm thick;

- determine the size of the vat-sauna boiler and the method of its installation;

- choose an effective protective coating for metal;

- develop a diagram of seats and footrests.

These preliminary important points do not end there. So, in particular, you need a well-thought-out system for heating and draining water. However, in this regard, there is no point in reinventing the wheel. The best way is to borrow proven industrial circuits.

Bath tub made of steel

Bathing in a cast iron vat is, of course, great. But there is no question of making it yourself. There are quite a few obstacles to this. Therefore, when preparing to make your own, you should only consider a homemade steel bath vat.

The right choice of material for a bath tub: which one is better

In the case of stainless steel, which provides higher durability, you will have to use the services of a professional welder. With your own efforts, it is quite possible to weld only a boiler from completely ordinary steel.

Drawings, dimensions and manufacturing procedures

A homemade vat for a Transcarpathian bath should have dimensions that ensure sufficient ease of maintenance. Traditionally, they have the shape of truncated pyramids with 6 or 8 sides. In other words, the bowl is not round, but polygonal. Below is a drawing of one of these options.

As a rule, the diameter of a bath tub is selected within the range of 220-260 cm, and its depth is 60-80 cm. A multifaceted bath tub has the following advantages:

- It simplifies the edging and welding of individual elements that have straight rather than curved edges.

- It makes it easier to replace one of the structural elements if the need arises.

- Greater comfort is guaranteed for those sitting in the font, whose backs rest not on a rounded, but on a flat surface.

The right choice, which material is better

It’s worth making a reservation right away: there is no point in even trying to make a cast-iron bath tub with your own hands in makeshift conditions; you won’t be able to weld it with electric welding, much less cast it in semi-makeshift conditions without special equipment.

In addition, a cast iron vat is not the best purchase for a sauna holiday. An alloy of iron and carbon, which is cast iron, rusts and rots no worse than Chinese steel, and if you install it on a podium made of rubble or brick, then it will be quite difficult to maintain.

A cast-iron sauna vat takes 2-3 times longer to heat than a steel boiler, that is, it will need to be heated 4-5 hours before the sauna. The only advantage of this design is its very convenient rounded shape, with a smooth curved surface, without corners or welding seams.

In a garage or private house, a bath tub can be made from stainless steel sheet structural steel. It is believed that a stainless steel sauna boiler is more resistant and durable, but its assembly will require the services of a professional welder. You can easily weld a sauna boiler from ordinary steel with your own hands.