These small structures have their own unexpected plus. When it has been decided exactly what is required, when the estimate has been determined and it is felt that you can add a little and the price will not suffer, this is where the initial small sizes come to the rescue. A 3x4 bathhouse with an attic easily turns into a 4x5.

Moreover, this transformation has practically no effect even on the project drawings, the dimensions are simply rewritten. It will be easy to manipulate the numbers, knowing that the original idea - enjoying the “communication” with the steam room - is not at risk.

In the photo - the most common design of a 4 by 4 bathhouse with an attic

Furnace installation

For a bathhouse with a 4x5 attic, you can choose a metal or brick stove.

Metal stove

A metal stove heats up faster and provides quick heating of the room. However, it also cools down within a short time. Installation of a metal furnace does not take much time and is carried out as follows:

- The selected oven is installed on the prepared surface. Its power must correspond to the volume of rooms that are planned to be heated.

- a tank is connected to the stove, then a damper, then there is an adapter for a sandwich and an insulated sandwich pipe, which will go to the second floor;

- a ceiling groove is installed in the interfloor ceiling, through which a sandwich pipe passes;

- the pipes are routed through the roof through a special master flash, which will ensure sealing of the passage opening;

- in total, the chimney is mounted at least 4 meters in height.

Furnace installation

The wall near the stove should be lined with bricks or sheathed with asbestos and thick sheets of iron. If you plan to install a firebox inside the partition between the steam room and the dressing room, then it should be lined with refractory bricks. All pipe connections between each other should be sealed.

Brick oven

Brick sauna stove

A brick stove takes longer to heat up than an iron stove, but it retains heat for a long time. You can fold it yourself or seek help from specialists.

For independent masonry you will need:

- fire bricks;

- mortar for laying stoves;

- cast iron grates, valves, doors;

- row masonry diagram;

- metal sheets;

- trowel;

- wire.

Each row of bricks should be laid according to the chosen pattern, and they should be arranged in a checkerboard pattern. Coincidence of vertical seams between bricks is not allowed. Fastening the doors and installing smoke ducts must be carried out strictly according to the instructions, then the finished stove will serve for many years without any problems. Do not forget about installing cleaning doors and valves.

Roof

In a bathhouse with an attic, special attention should be paid to waterproofing the ceiling of the first floor. The steam room and washroom should be protected especially carefully.

After installing the floor joists and subfloor of the second floor, foil insulation should be attached to them from below using a stapler. Tape all joints between strips with aluminum tape. Then put a layer of insulation and another layer of waterproofing on top of the subfloor. And only then install the floorboards on the second floor.

Video - Ceiling in the bathhouse

https://youtube.com/watch?v=Xbn0i3smn0A

The roof in a bathhouse with an attic can be single-pitch or gable. However, a pitched roof will significantly reduce the area of the room on the second floor. Therefore, in a bathhouse with an area of only 20 sq.m. It is more expedient to make a gable roof.

Bathhouse with attic - construction features

Gable mansard roof

Gable mansard roof design

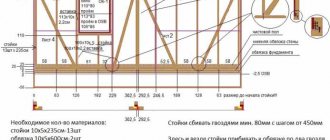

The rafter system is calculated in advance. Racks are installed on the floor joists, to which the attic floor beams, as well as side and ridge rafters, are attached. The distances and angle of inclination must correspond to the length of the rafters and ensure structural rigidity.

Rafter system

Then the sheathing and waterproofing are attached to the rafters. The roof covering is already screwed onto it. This can be slate, ondulin, metal tiles, etc. After this, insulation, vapor barrier and wooden slats are installed between the rafters from the inside. Finishing materials are installed on them. The thickness of the insulation in the attic room must be at least 200 mm.

Roofing pie

This freedom of choice - 4 by 4 or 3-5 by 4 - has its advantage

4x4 bathhouse with attic - two in one: first floor - bathhouse; the second, in the attic - a full-fledged living room-bedroom

In this area - small compact baths with an attic in the form of a rest room - it turns out that there are their own detailed “top projects”. The above 3D computer sketch and drawing of two floors is one of them.

There are only 4 rooms, but they fully correspond to the purpose of such a “house”:

- A – entrance hall on the first floor and living room-bedroom, occupying the entire area, on the second;

- B – washing-steam room; Note that there are no windows, which means this solution eliminates the need for additional care about insulating the bathhouse openings;

- C – kitchen; everything is very functional, and it is reasonable to provide an exit from the steam room to the kitchen, and not to the hallway, which can be found in some projects.

Some important nuances

Don’t be fooled by its “matchbox”-level simplicity of a 4 by 5 bathhouse with an attic.

This is a serious building, which has its own strict mandatory requirements:

Firstly, regardless of the building material, be sure to provide reliable window openings. You can’t do without insulation and waterproofing here.

If round logs or timber with a rounded profile are used, pay special attention to the processing of joints

Regardless of the size - whether it is a bathhouse with an attic 4 by 5 by 4 by 5 - utmost attention must be paid to the design and insulation of window openings

Secondly, the interior decoration must be made of a safe material from the point of view of the theory of bathhouse construction - no tiles or slippery materials, only friendly wood;

Projects of 4 by 4 bathhouses with an attic may not be particularly cozy. They take others - functionality, simplicity, price, and, of course, constant pleasure for connoisseurs of this type of recreation

Thirdly, there is still no escape from creating a stove, so give it the highest priority. We can say, without fear of making a big mistake, that the success of the whole undertaking will depend on the quality of the water heating device, whether it will be a stove or even a boiler

Whatever the size of a self-made sauna, there should always be room in it for a boiler or stove

Number of floors and their layout

A 4x4 house can have more than two tiers. Japanese architect Tadao Ando developed the layout of a 4-story building with an upper block on remote consoles. Such a project makes it possible to provide all amenities in a limited space.

Frame technology is used for construction. Total area, m2 – 64. Each floor plays the role of a separate area: dining, sleeping, dressing room. The main stages of planning a 4 by 4 building include the construction of a plinth. It is used as a storage room.

You may be interested in: Layout of a house with an attic: advantages and important points

Single storey

A one-story 4 by 4 house has several layout options:

- One-room;

- Five-wall building with two rooms;

- Second light.

The “Second Light” project eliminates the attic floor. Under the roof there is a mezzanine, to which a compact staircase leads. Upstairs there is a sleeping place or an office for work. In this case, it is not practical to divide the area of the first floor with partitions.

Stages of construction of a 4 by 4 building with a second light:

- Project development, planning;

- Laying the foundation;

- Wall installation;

- Installation of rafter legs without tightening;

- Roof insulation.

An example of a one-story building 4 by 4, equipped with all amenities for permanent residence, is located in the Republic of Belarus. The owner of the building took the idea for the layout from German architects. The kitchen, hallway and sleeping area are located on different levels. The bathroom is located on an area of 1 m2, there is also a shower. The drain is provided by a drain in the floor. Examples of the layout of such bathrooms can be found in Japan and Hong Kong.

Double decker

The design of a 4x4 house with two floors includes calculation of the foundation and rafter system, selection of material for the construction of walls. The layout provides for two rooms with an area of 14.4 m2. For a comfortable stay, additional buildings are “added” to the main house. The living rooms are spacious enough and are suitable for three people.

The second floor increases the load on the base. To save on the foundation, light wall materials are used - frame or foam block.

Tsokolny

The plinth increases the usable area and reduces the cost of heating the first floor. However, this requires large construction costs, especially if it is planned to be installed as a two-story house. The project must include calculation of the load on the walls of the basement. In case of construction in an area with a high groundwater level, the base needs reliable waterproofing.

Why do you need a bathhouse with an attic?

The very first attics were inhabited by people leading a bohemian lifestyle - poets, artists, and so on, and this is not without reason. After all, in such a bright and quiet place it is pleasant not only to relax, but also to socialize, especially after taking hot bath procedures.

Cozy view inside the attic

A 4x6 bathhouse with an attic can have a very different design; it is not at all necessary that it will be presented in the form of a table and benches.

The attic in the bathhouse is:

- living room with wicker furniture;

- billiard room with refrigerator;

Design options

- SPA salon with modern hydromassage or aromatherapy technology;

- an eastern corner with luxurious pillows that will be on the floor instead of furniture, rugs.

Great view of the room

In general terms, the advantages of the attic can be identified as follows:

- an aesthetic appearance of the bathhouse, which will resemble not a steam room, but a cozy country house;

- in comparison with a two-story bathhouse, in this case you do not necessarily need to build a strong foundation;

- thanks to its presence, heat loss is significantly reduced;

- Thanks to the heat that comes from below, there is no need to install additional heating sources in it.

Frame bathhouse with attic

The frame construction method came to us from Canada and Europe. Undoubtedly, building a bathhouse with an attic using this technology is the fastest and cheapest process, since the price of such a structure, unlike other types, is several times lower.

Frame sheathing

Stages of construction of a frame bath:

- construction of the foundation;

- frame construction;

Frame diagram

- frame covering;

- installation of bath insulation;

- interior decoration of room walls;

- additional façade finishing.

- Typically, the frame of a bathhouse is built in increments of 95 cm, the material for this is usually timber or boards with dimensions of 150 by 50 cm. The frame structure is quite light, both in terms of assembly and the load on the foundation;

Getting started with the frame

- But in the case of the construction of such a structure, you must remember - in this case you will have to use insulation from a special film with vapor barrier capabilities, and good ventilation must also be ensured. Otherwise, your building will not last long;

- A frame building with a 6 by 4 attic provides for a washing room and a steam room on the ground floor, and a dressing room or dressing room will also be located there. An internal staircase will lead from this room to the attic. In the attic room you can arrange a terrace or veranda.

Timber bath

A 6x4 bathhouse made of timber with an attic is preferable to a frame one. Although such a structure will cost you more, it will be much more pleasant to steam in it, since the material from which the structure will be built retains all the positive properties of wood.

Timber bath project

As a rule, such baths are built from timber with dimensions of 110 by 135 cm or more. Each row of timber must be laid with a special fabric made of flax and jute. This is necessary so that your structure maintains its tightness.

Finished timber structure with a simple roof

In addition, it is best to make a bathhouse with a veranda in order to place a staircase in it leading to the attic. Stairs are usually single-flight, but it is also possible to create a rotary or multi-flight staircase.

You can insulate an attic in such a structure with mineral wool or use any other type of insulation for these purposes. This recreation room can be made with a balcony, this will give it more comfort.

Log sauna and sauna house

The best bathhouse, no matter what they say, is a 4x6 log bathhouse with an attic. The thickness of the walls of such a room makes it possible not to use insulation. It will be enough to cover them with a biological protective composition to protect your building from external factors. The attic of such a building is not built under a sloping roof, but under a half-hip or hip roof.

Log building

You can build a bath house with a terrace or attic from a log. In this case, on the ground floor you can place a room for bathing procedures, and in the attic you can arrange several living spaces.

The size of the plot is not the main thing

Why a frame house?

It is difficult to imagine faster construction than frame construction. The construction of a house measuring 4x4 meters will be more like building a bathhouse, and if we talk about a house made of timber, then you will have to wait for shrinkage even for such a small structure. Building a house made of brick or foam block is associated with an increase in costs for the house itself and its foundation. We decided that our house would be cozy, but at the same time you would not cause significant damage to the family budget. In these conditions, frame house construction is the best choice. In addition, the availability of materials for this technology, ease of construction and undemanding requirements for special equipment and tools will allow you to carry out all the work yourself.

Excluding the costs of paying for the work of builders, we can build a 4x4 meter house in the shortest possible time and almost 2 times cheaper than a similar project implemented by construction companies.

Another option

We offer another implementation option, when a 4x5 bathhouse with an attic does not contain a kitchen on the ground floor - everything is given over to “bath” pleasures. Although, if desired, the kitchen can be equipped on the second floor.

Focus again on the foundation

In the proposed layout, the approach to presenting the design result is very attractive - a three-dimensional sketch with the roof removed is so visual that it gives a comprehensive idea of the entire further progress of the work.

Please note how carefully the area around the piles is finished, 8 of which are located around the perimeter of the house and one in the center. This elevated position of the bathhouse is an ideal protection against the influence of wet soil on materials and an excellent solution to the problem of base ventilation

A three-dimensional view from above, without a roof, removes all questions - a 5x4 bathhouse with an attic appears in full view

So, here we also limit ourselves to four rooms - 3 on the first floor and one large one on the second:

- A – hallway and, at the same time, dressing room;

- B – washing room, note, with one small window;

- C – steam room, no windows;

- D – attic on the second floor; As a small drawback, we note the small attic windows. This is due to the triangular roof included in the project, although this part of the project can be safely changed to a version of the previous project. It provides more space for the attic and, as a result, the opportunity to increase the width of the window openings.

Selection of material for construction

A 4*5 bathhouse with an attic can be built from:

- timber;

- logs;

- heat blocks or foam blocks.

The choice of material depends solely on personal preference.

Most often, site owners purchase a ready-made log house from rounded or regular logs. Each part in it is numbered; during construction, you just need to stack them on top of each other, observing the correct sequence.

Log sauna

Stages of constructing a bathhouse from logs:

waterproofing material and lining boards are laid on the foundation; The first crown of the log house

First crown

First rows of logs

- install the lower crowns of the log house according to the diagram;

- check diagonals, compliance of angles and level;

- treat the lower logs with an antiseptic;

- install logs;

- carry out further laying of logs, installing inter-crown insulation between them;

- The logs are connected to each other by drilling holes with a diameter of 30-40 mm into them and driving in dowels. The distance between the fastenings is from 50 to 100 cm; in adjacent logs they are placed in a checkerboard pattern. When chopping into the paw, an additional dowel is installed in each corner joint;

- install the rafter system and install the roof.

Bathhouse made of timber

You can build a bathhouse with a 4*5 attic from timber yourself. This will require approximately 10 cubic meters. timber 200*200. The result is a high-quality, warm and durable structure. There are many ways to connect timber to each other. One of the most reliable is the “dovetail”. In addition to this, there is also a main tenon, a locking groove and many others.

The choice of method should be made depending on the design features of the building being constructed.

The sequence of construction of a bathhouse made of timber:

- foundation waterproofing;

- antiseptic treatment of timber intended for installation of the bottom row;

- cutting out tenons or locking joints;

- laying the first row;

- installation of logs;

- fastening inter-crown insulation using a stapler;

- laying the second row;

- drilling holes and inserting dowels;

- laying insulation and installing the third row, etc.

Bathhouse made of timber with an attic

Bathhouse made of blocks

Blocks are used much less frequently for the construction of bathhouses, although their thermal insulating properties are often not inferior to wood. In addition, they do not burn, allow steam to pass through well and do not rot. However, not every block is suitable for a bathhouse. It must have high vapor permeability and not contain harmful substances.

Bathhouse made of blocks

The construction of bathhouse walls from blocks (main stages of work) is reflected in the table.

| Illustration | Description |

| Preparing for the construction of walls | Using a level, determine the highest corner of the foundation from which to begin laying the blocks |

| Cement mortar | Prepare a cement-sand mixture |

| Pulling shoelaces | Pull the string level from one corner of the structure to the other |

| Laying the first row | Begin laying the first row on cement mortar, constantly monitoring the evenness of the surface |

| Leveling masonry with a hammer | Tap each block with a rubber hammer, adjusting it to the desired level. Check the evenness of each row of masonry using a laser level |

| Technique for applying glue to blocks | Subsequent rows are laid on special glue for blocks, which is diluted immediately before starting work and applied to blocks no more than 5 mm thick |

| Fastening the Mauerlat with metal studs Fastening the maueralat using an anchor with a washer and nut | The Mauerlat is installed on the top row |

Bathhouse walls made of blocks require additional insulation. From the inside, it will be possible to attach foil material to them, which will reflect heat and retain it indoors for a long time, and on the outside it is best to install a ventilated façade with mineral wool insulation.

Houses made of SIP panels

The same panel house, but the walls are made using special technology in production. They are a sandwich of outer and inner cladding with insulation based on polystyrene foam. Installation is carried out identically to the construction of a panel house. The main disadvantage is the limited availability of SIP panels. Not in every region you can find a manufacturer of this material, although technology is developing very quickly.

Houses made of mini-timber or double timber. The technology is more reminiscent of construction from profiled timber. However, its Scandinavian origins made this technology closer to frame technology. This is another rarely used technology: it is difficult to find a supplier, it is not easy to build walls correctly without additional knowledge.

Floor installation

Before you start installing the floor, you should decide on its type. It can be either wooden or concrete.

Wooden floors in the bathhouse

Wooden floors in the bathhouse

Wooden floors in a bathhouse can be built to leak or not. The choice of method should be made depending on the frequency of operation of the structure and the climatic conditions of the region in which it is located. Leaking floors are usually built in bathhouses, which are used only in the warm season. In winter, they will emit extreme cold due to the lack of insulation. To arrange this structure, it will be enough to lay logs in the washroom and nail boards to them on top. In this case, gaps of several mm should be left between the boards so that water can drain into them. Since a drain with a drainage pipe was already prepared in advance at the lower level of the floor, the water will simply go into it.

Leak-resistant wood floors are a more complex design. They are laid out as follows:

- install logs;

- install subfloor boards;

- insulation is laid between the joists;

- nail the waterproofing with staples;

- lay the top layer of floorboards 40 mm thick tightly, ensuring a slope towards the drain hole;

- a gap of 2 cm is left between the wall and the boards;

Concrete floors in the bathhouse

Floor construction

Concrete floors are less warm, but more durable than wood floors. To set them up you need:

- level the area inside the bathhouse;

- cover it with fine gravel and sand, compact it;

- pour a thin layer of concrete;

- lay insulation;

- install the waterproofing layer;

- lay the reinforcing mesh;

- install level beacons;

- attach damper tape along the walls and partitions;

- pour concrete solution;

- perform the finishing screed device.

Video - Installation of floors in a bathhouse

Electric or water heated floors should be installed immediately inside the screed.

Infrared heating elements can be laid directly under the floor covering.

Construction of the foundation

For such a lightweight structure, it is not worth investing in a capital foundation. The best option would be a columnar foundation, and modern technologies have given us an excellent solution for a frame house - a foundation on screw piles. Each option has its own advantages and disadvantages.

A column foundation is the cheapest option. You can assemble wooden boxes yourself from scrap lumber or plywood, tie together the reinforcement and fill the resulting structure with concrete that you made yourself on site. After the concrete has hardened, you will receive ready-made piles, which will need to be installed in pre-dug holes. A sand cushion must be poured into the bottom of the holes under the concrete piles.

An even simpler option may be to purchase stubs of piles from the construction of multi-story buildings, where the piles are driven in and the excess length is cut down. You may even be allowed to pick up this construction waste for free. But in fact, these “stumps” will be even more durable than piles made independently.

It is very difficult to make homemade screw piles. But perhaps this is not such a big minus. Self-produced concrete piles may have geometric defects, or low-quality cement will affect the durability and reliability of the foundation. Factory screw piles do not have these disadvantages. The strict geometry of the pipe and the correct blades will allow you to screw the piles strictly vertically.

Sergey Yurievich

Construction of houses, extensions, terraces and verandas.

Ask a Question

A set of screw piles will cost you a little more, but the work of installing them is also quite affordable for you to do it yourself. Even attracting specialists will not become a “hole” in your budget. Screw piles are a godsend for prefabricated structures. You only need to mark the location of the piles and screw them in. All work is completed in 1 working day, if we are talking about a 4x4 m frame house.

conclusions

If you intend to build a bathhouse with an attic on your country plot, you will be faced with a huge number of proposals. But, oddly enough, if your goal is a small two-story bathhouse with an area of no more than 20 square meters, difficulties in choosing will arise - it (the choice) will not be rich. But everything that will be offered has been tested by time and practice.

Focus your efforts on the quality of the foundation, a reliable boiler and insulation of the walls of the washing room and steam room. If these issues are resolved successfully, the proposed designs will last a very long time.

Then the plan of each floor becomes an empty formality, only the dimensions are important here, the construction instructions are perfectly readable from a three-dimensional sketch

Despite the fact that the dimensions simply “scream” - everything is clear, we advise you to watch the additional video in this article, perhaps it will be able to eliminate some of the remaining questions.

Frame house 4x4 from the developer

Unlike the construction of large residential buildings, a huge number of construction companies and private teams of carpenters are engaged in the construction of low-budget frame country houses. How not to be deceived? How to choose a reliable construction team or company?

First of all, you should not chase the lowest price. The best option would be to take the advice of relatives or friends who have already encountered the construction of a house. Subjective opinion can tell you a lot. If there are no advisors in your close circle, start studying reviews on the Internet. Any self-respecting builder should have a set of proposals and a portfolio of finished projects. It’s great if the developer invites you to visit current or completed projects. Even if your country house does not cost too much money, you should still require the preparation of an agreement describing all the structures and the guarantee for them. Even a country house will be covered by a warranty of at least 1 year, and load-bearing structures – up to 3 years.

A 4x4 frame house is not difficult to design, but working with such an object is no different from constructing a larger structure: you will encounter the same operations and difficulties, you will need the same materials and tools. Such houses can become for you a training ground for the construction of a more serious building, and maybe even a spacious residential cottage based on frame technology.

You can ask your question to our author: