Advantages of a timber bath

It is worth knowing what qualities distinguish this model from other known options:

- Natural materials.

- Good environmental performance.

- Ease of operation.

- With high-quality pre-treatment, the construction is safe.

- Relatively low cost.

- Save time. The construction of this model will take much less time, thanks to the use of shaped blanks and the absence of frame structures.

- Sufficient thermal insulation. The timber has a good thickness, which allows you to retain heat indoors.

Due to the presence of so many advantages of practical application, bathhouses made of timber have gained particular popularity among owners of summer cottages.

Why wood

The environmentally friendly natural material will release beneficial resin during use - the heated bathhouse is filled with evaporations of soothing essential oils. Pine wood also helps disinfect the room - it prevents the proliferation of microorganisms and viruses.

Wood is optimal from the point of view of natural ventilation; such walls establish natural air and moisture exchange. As a result, a microclimate that has a beneficial effect on health and an ideal ratio of oxygen and steam is formed. Baths made from the material in question are able to retain heat for a long time; their thermal conductivity is much lower than that of concrete and brick structures.

Another significant advantage of timber is the complete pre-processing of the material, so that builders do not need to waste time bringing surfaces to the required state for assembly.

The walls look neat, do not warp during use, and exhibit high sound insulation rates.

High-quality finishing gives the bathhouse a simply chic look Source mebel-go.ru

Features of material selection

When purchasing material, you should consider the following characteristics:

- Timber harvesting season. Ideally, the material should be prepared in winter. This indicator may affect the quality of construction.

- Storage period before use. This characteristic has the same basis as the harvesting season. You can check this information with the seller of the materials.

- Appearance. You should definitely evaluate the condition of the workpieces: stains, dampness, and traces of pests may alert you. The quality of trimming and the degree of alignment of the cuts are also assessed.

- Type of raw material.

- Wood species. The best options for building a bathhouse are hardwoods. It is better not to use raw materials from pine needles due to the presence of various resins in the structure.

Assessing these parameters is mandatory, as it will help avoid possible problems during the construction process.

Treatment with antiseptics

It is very important that only high-quality consumables are used in construction. It is imperative that the timber be pre-treated with specialized compounds that increase the fire protection and moisture resistance of the building. Special, safe antiseptics protect it from insects and rodents, natural elements, and allow you to preserve and improve the properties of wood.

It is also extremely necessary to treat materials adjacent to heating objects with fire-fighting components. Materials such as wood, without being treated with antiseptics, quickly deteriorate and become a fire hazard. The material processed with special means has a good level of fire safety and is reliably protected from fire. The use of high-quality antiseptics does not in any way reduce the environmental purity of wood.

Choosing a timber model

The material for the construction of baths differs not only in its species and quality characteristics, but also in its manufacturing technology. Today, manufacturers offer their customers the following types of timber:

- Profiled option.

- One-piece models.

Each of the presented models differs in the method of formation, finishing features, and methods of practical work with the material.

Profiled version

Structures made from profiled timber are durable and resistant to moisture.

During manufacturing, additional surface grinding is used due to the presence of tenons and grooves. But in terms of safety, the material is inferior to the second model, so before construction, the workpieces are treated with an antipyretic.

Profiled timber as a material for the construction of a bathhouse

Profiled timber is considered one of the most environmentally friendly building materials. It began to be used in construction more than 15 years ago; this technology came to Russia from the Finns.

A sauna made from profiled timber has both its pros and cons. Positive aspects include ease of assembly. Indeed, using this technology, you can assemble a bathhouse like a children's construction set.

Also, such a bath has good thermal insulation. This is due to the locking connections. Another advantage is the correct geometric shape.

The disadvantages of this design include natural humidity. Possible cracking of walls and distortion of the structure.

It is better to take building material in winter, as it has a moisture content that is similar to chamber drying.

Additional materials for construction

Any construction process requires auxiliary materials and a certain set of tools. Before starting work you should prepare:

- Foundation materials: cement, sand, gravel.

- Brick for the stove.

- Lining for interior decoration.

- Roofing material.

- Tool sets: nails, hammers, screws.

- Insulation materials.

- Lighting fixtures and cable.

Construction of a bathhouse

For a novice master, the main question is: how to make a sauna with your own hands correctly and for a long time. The construction process itself consists of several stages:

- Drawing up a bathhouse project.

- Foundation construction.

- Laying a waterproofing layer.

- Walling.

- Hiding cracks.

- Formation of the roof.

- Finishing.

Each stage requires certain efforts and skills from the master. If you wish, you can familiarize yourself with photos and video tutorials on building a bathhouse from timber.

Drawing up a bathhouse project

Any construction process requires a clear drawing or diagram. Preparation of the project includes sketching the following details on paper:

- Bath box dimensions.

- Indication of the location of doors, windows, stove, rooms (steam room, dressing room, shower).

- Electrical wiring indicating the location of sockets and lamps.

After drawing up the diagram, you should definitely calculate the required amount of material in order to avoid unnecessary financial costs.

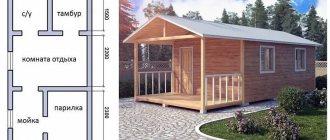

Bathhouse layout

If there are opportunities, a bathhouse complex can include a couple of floors, guest rooms with balconies, and billiard rooms with a swimming pool, and in the absence of these, they manage to enjoy the bathhouse in one room “for everything.” A typical bathhouse layout includes the following rooms:

- steam room;

- washing (soap);

- dressing room

Initially, in Rus' they made do with one room in which they both steamed and washed, but in today’s baths the steam room and washing room are separated. This is due both to the possibility of using various modes in the steam room, as well as to convenience and safety. Modern detergents are far from being so harmless as to risk using them at elevated temperatures.

The dimensions of a typical washing room with shelves and basins are also tied to the number of visitors - from 1.5 m² per person, that is, the washing room is half the size of the steam room. But given that today many people prefer to rinse under a shower head or install shower stalls, this room can be made smaller by adjusting it to the dimensions of the equipment. In this case, 1.8 × 1.8 m will be sufficient. However, possible does not mean necessary.

ZYBYFORUMHOUSE Member

Wet procedures are done in a soap bar. It is optimal to have the same number of beds in the soap room as in the steam room, according to the number of people steaming! Better yet, have a table in the middle where you can do massages and walk around! This is why you need a large soapy bowl, and keeping it warm during the procedures won’t hurt! Anyone who does not take this into account loses a lot! This is the main part of the sauna process, just like steaming! It's a shame that people have lost everything!

Not everyone can afford a full-fledged relaxation room in a bathhouse - for some, finances do not allow them to “go wild”, while for others, due to the size of the site, they only have room for the basic minimum. In these cases, the functions of the rest room are performed by the dressing room, which is also a locker room and vestibule. Naturally, the larger the room, the more comfortable you can stay in it, arranging a place for gatherings over a glass of whatever you like best. If you plan to relax after the bath in the house, and the dressing room has only direct functionality, a width of 1.2 m is enough to make it convenient to undress.

Foundation structure

The choice of foundation models is quite extensive and depends on the weight of the structure and soil characteristics. The most famous options for filling the base:

- Tape type.

- Pile type.

- Slab option.

- Columnar model.

For a structure such as a timber bathhouse, a columnar foundation is perfect. To lay the support, you should use the instructions:

- First of all, you need to mark the site. To do this, install pegs and pull the string.

- Additional marks are placed in the places of future support pillars.

- Niches are dug in the ground for filling.

- At the bottom of the pits, make a sand cushion of at least 20 cm, then fill it with water.

- The next layer is crushed stone and formwork is formed.

- A bunch of metal reinforcement acts as supporting structures.

- After installing the support column, the empty spaces in the pits are filled with cement mortar.

Experts advise making additional concrete inserts to increase the strength of the supporting structure.

Bathhouse 3x4 m: basic information about the project

The construction of a dacha mini-complex is classified as the construction of outbuildings on a private plot and is regulated by the state-approved document SNiP 30-02-97. Study building and sanitary standards before choosing a place to build a structure to ensure fire and hygienic safety.

You need to build your own bathhouse on the most suitable territory. To do this, you need to analyze the following aspects:

- soil type. Choose non-swampy, flat areas for construction. The choice of type of foundation layer depends on the nature of the soil;

- depth of the aquifer. Assess the area after snow melts and when groundwater levels drop. The foundation must not be washed away;

- climatic features of your region. Analyze the freezing depth of the soil substrate, the threat of flooding and seismic activity to select a reliable foundation for construction that will ensure long-term operation of the building;

- location relative to other objects on a summer cottage or private plot. Draining water from a bathhouse, drawing water, heating requires compliance with sanitary and fire safety;

- electrification. The supply of electricity must be carried out from a common panel that supplies a residential or country house and other objects on your territory;

- harmony with the overall landscape of the site. Ensure that the building fits organically into the overall appearance of the territory, its appearance is combined with neighboring objects.

The architectural aspect of construction in the area where your site is located plays a big role. When constructing a bathhouse on residential land, it is necessary to coordinate the upcoming construction activities and obtain permission from state administrative bodies before the construction process.

Laying a layer of waterproofing

This stage should not be ignored, since laying an additional protective layer will significantly increase the service life of the structure. The step-by-step scheme looks like this:

- After the concrete has hardened, a layer of bitumen is laid on top of the foundation.

- Next comes a layer in the form of roofing material.

This procedure is repeated several times.

Walling

The first step in construction is laying the strapping crown. The closest attention is paid to this layer, since the even laying of subsequent rows depends specifically on the first row. You can check the laying direction using a building level.

A layer of insulation can be laid on top of the first row. Next, proceed to assembly, depending on the type of fastening structures:

- Metal pins. The advantage is the strength of the connection.

- Wooden dowels.

There are features regarding the frequency of screeding: when building a bathhouse from laminated timber, the screeding is done after every 5th row.

Roof assembly

The assembly process depends on the covering model, material and shape (single or gable roof). Regardless of the type chosen, the entire process will consist of a number of steps:

- Preparation and fastening of rafters.

- Laying the covering.

Very often, tiles are used as a material, but the final choice is made by the owner of the bathhouse, based on personal wishes and financial capabilities.

Optimal steam room sizes

There are quite a large number of projects and layouts of bathhouses of all sizes available on the Internet, ranging from mini-houses to full-fledged complexes with a swimming pool.

There is plenty to choose from, but it’s not so problematic to independently develop a layout to suit your “wants”, rather than deal with adjustments.

unforgivenFORUMHOUSE Member

It is much wiser to take a pencil and paper (or the appropriate program) and, having thought it through, draw a PLAN of the bathhouse than to cram all the necessary premises into the general dimensions taken from the ceiling.

The starting point when designing a bathhouse is the dimensions of the main room - the steam room, the calculation of which takes into account several factors.

- Average number of visitors at the same time.

- What type of oven will it be?

- Operating mode.

The area of a steam room, as well as a private bath, in general, is not regulated by standards, solely by common sense and one’s own capabilities. But it is believed that comfortable bath procedures are possible if at least 1 m² is allocated for each person in the steam room. Again, if the household is large, the square footage is clearly not enough for them, and it is better to allocate 1.5 or 2 m² per visitor.

In addition to the number of steamers, the dimensions of the furnace equipment are also taken into account. Modern sauna stoves are mostly compact, but there must be a safety zone around, the size of which depends on the type of structure. This is 500 mm on each side for a brick stove (metal in a brick frame) and 1 m for a metal stove.

The operating mode refers not only to the intensity of use of the bath, although this factor is also important, but also to the preferences of the steamers. If sitting three people can take a steam bath in a 2x1.5 m room, then lying down, and even with a broom, you won’t fit in a three-meter steam room, and it will be at least 2.4x2 m. As for the ceiling height, it varies in within 2-2.5 m, the optimal height is considered to be 2.1 m. This value is enough for the majority of visitors, with the expectation of swinging a broom, if there is no “Uncle Styopa” among the household members or friends who may come to the bathhouse.

Bath decoration

The whole process is divided into two options: interior and exterior finishing. The external design of the building plays only an aesthetic role, and therefore is not a mandatory stage. But the same cannot be said about the interior design, which includes:

- Wall covering with decorative materials.

- Conducting electricity, installing sockets and lamps.

- Construction of the stove and installation of a shower cabin or washing room.

There are a lot of options and ideas for interior decoration, and the choice is individual for each style.

Original author's ideas

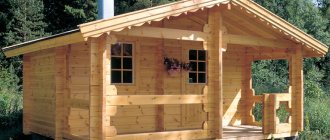

For those who have not yet decided on a timber bathhouse model, here is a selection of the most original options:

- Bathhouse with terrace.

- Unusual shaped baths. One of the most famous and original models is a steam room in the shape of a horizontal barrel.

Non-standard sizes and shapes, as well as interesting approaches to design, are great for construction when there is a shortage of free space.

Photos of finished baths can be found on landscape design websites, where it is easy to choose a unique option for every taste.

Types of modern baths

Today there are a variety of types of modern baths, namely:

With attic

This is one of the common options for a steam room with an attic roof and a veranda. At the top of the structure there is a bedroom where you can relax comfortably after taking a bath.

And the veranda is a great place where you can drink a cup of aromatic tea.

With terrace

Are you planning to build a barbecue in your country house? Then build a steam room with a terrace where you can install a stove directly. After time, you can create a pond in front of the steam room.

With veranda

A bathhouse with a spacious veranda is considered one of the simplest structures.

How to obtain permits for construction: list of documentsModern Bluetooth headphones

Construction services for business

In this case, it is preferable to glaze the veranda and use it as a summer recreation area or kitchen space.

With porch

Are you a fan of the true Russian bathhouse? Then build it with a spacious porch, which is not just beautiful, but also as practical as possible.

A small table, a traditional samovar and the splendor of the surrounding nature.

Photo of a bathhouse made of timber

Total

Category: Gazebos and baths