The consequence of long-term use of a wooden house is the wood turning blue. The reason for the appearance of blue is certain types of fungus, which forms over time on the surface of an old wooden house, especially in cases where the wooden structure has not been periodically treated with protective agents. However, a healthy tree can have multi-colored spots if the natural pigment is unevenly distributed. Darkened and unevenly colored wood greatly spoils the appearance of the house; in addition, fungi can cause rot and destruction of the wood structure. An effective way to combat blue stains is to bleach wood. What means and how to whiten the walls of a wooden house will be discussed in the article.

Why bleach wood - reasons

It is necessary to bleach wooden objects if they have lost their former beauty and become darker over time. A yellowish or grayish tint may appear; this happens to the material under the influence of natural phenomena.

Wood bleach works by starting the oxidation process, as a result of which the substance present in the structure of the material loses color. And external qualities become more pleasant.

It is necessary to bleach wooden objects if they have lost their former beauty and become darker over time.

Why does wood change its natural color?

Wood is an organic material, for this reason insects are interested in it, fungal and microbial formations appear. The appearance and spread of such microorganisms is typical under conditions of high humidity, when temperatures are elevated.

Sometimes more serious lesions spread, in the form of moss and lichen. Such formations are typical for baths, where high temperature exposure and humidity are normal.

But there are other factors that can cause blackening of the wood surface:

- The logs were transported incorrectly;

- The material was stored in inappropriate conditions;

- The tree was hit by sediment;

- Long exposure to ultraviolet radiation.

The appearance of fungal plaque is typical for any type of wooden material. What shade you end up with depends on the type of wood. The sooner you bleach the wood, the easier it will be to deal with the problem, otherwise you may end up with a stain that cannot be completely removed.

The appearance of fungal plaque is typical for any type of wooden material.

Expert advice

More than once I have come across the opinion that damage to lumber 1 mm thick does not threaten the lumber, log, or beam at all and therefore they are in no hurry to deal with this problem.

Indeed, wood-staining fungi and mold at the initial stage of development will not be able to cause significant harm to the wooden material, they will not impair its strength, and will not destroy the structure in the coming months.

But do not forget that they will prepare the wooden surface for the appearance of other, more dangerous wood-destroying fungi, which will begin to rapidly destroy the wood.

It will be much more difficult to destroy these pests, and the damage caused to the wooden material cannot be eliminated, it will no longer be possible to restore its former strength or improve its appearance.

Therefore, the appearance of wood-staining fungi on logs, beams and lumber should be an alarming signal for owners and they should immediately begin to eliminate them.

In addition, if wood in a residential area is contaminated with them (for example, crowns in a house), then residents, inhaling their spores, cause great harm to their health. Allergic diseases, serious respiratory problems, constant headaches, etc. may appear.

How can you bleach wood that has changed color?

Unwanted stains that appear on the surface of the wood can be removed by exposure to oxidizing substances. The return of color occurs through exposure to chlorine and oxygen. Wood bleach includes components that help activate the process of chlorine formation, and the darkening disappears, returning the original shade of the material.

Unwanted stains that appear on the surface of the wood can be removed by exposure to oxidizing substances.

What functions does bleach perform?

The use of special bleaching preparations allows not only to refresh the color of the surface, but there are also other properties that can be obtained from their application. The following functions are distinguished:

- Mold and fungal formations that caused these changes in the material are destroyed;

- Drying from the inside of a wooden base, surrounding factors can affect the material's absorption of moisture. And an increase in humidity leads to fungi; the compositions are able to remove excess moisture from the base;

- A good uniform shade of the base is created, which is necessary to obtain a beautiful shade after coating with varnish or paint. And they sometimes resort to the process even without detecting the affected areas.

It is advisable to bleach sawn and planed surfaces at home periodically, this will extend their service life.

A good uniform shade of the base is created, which is necessary to obtain a beautiful shade after coating with varnish or paint.

Composition of wood bleach

The construction market offers a wide range of bleaching agents; they can be divided into two large groups:

- Contains chlorine. Used for the production of potassium or sodium hypochlorite, chlorine dioxide, bleach;

- Does not include chlorine substances. Hydrogen peroxide, ammonia, alkali and oxalic acid are used.

The construction market offers a wide range of bleaching products.

Review of ready-made products: brand, instructions for use

The fight against the appearance of stains from biological formations is easier if you choose ready-made types of bleaches. Which wood bleach is best to choose is up to everyone to decide for themselves, but there are several brands that are popular among buyers. This happens due to the high-quality results obtained after application.

The fight against the appearance of stains from biological formations is easier if you choose ready-made types of bleaches.

Sagus

Sagus can be used for interior and exterior work. Suitable for processing any type of wooden structures, copes with color changes caused by natural factors. It can also get rid of microbial biological formations.

It is an effective product, can withstand low temperatures, and does not have a negative effect on the material. It is distinguished by deep impregnation of the base; small containers of 10 liters are available for sale.

It is an effective product, can withstand low temperatures, and does not have a negative effect on the material.

Zerwood

Zerwood quickly copes with bleaching the base. Can remove darkening caused by various reasons. Suitable for use on painted substrates, as well as on fresh wood. Can also be used for concrete, brick, stone, tile materials.

Can remove darkening caused by various reasons.

VGT

VGT does not adversely affect the material and copes with a variety of darkening on the surface. As a result, the natural shade returns. Can be used on a cleaned base, old materials are removed. Available in containers of 0.5 kg, 1 kg, 5 kg.

VGT does not adversely affect the material and copes with a variety of darkening on the surface.

Neomid

Neomid 500 is distinguished by its affordable price and high quality. Can be used inside a building, but provides good ventilation. During the cleaning process, when salt appears, it is simply washed with water. If coniferous substrates are processed, the resin must first be removed.

Neomid 500 is distinguished by its affordable price and high quality.

Yaroslavl antiseptic

is engaged in the production of various products for wood, producing products in accordance with GOST. Penetrates deeply into the material without violating its integrity and allows the wood to breathe. The product can be applied at temperatures not lower than +5 degrees.

Also popular are Senezh Effo and Fongifluid Alpa.

Penetrates deeply into the material without violating its integrity and allows the wood to breathe.

Preventive action

To prevent the development of fungus before shipping, it is advisable to coat them with transport antiseptics, which protect the wood for 10-15 days. Even despite these measures, blue discoloration (the result of fungal activity) often appears even after treatment. Then the question arises: how to bleach a log?

Here everything is much worse: white mold has been added to the blue, and it must be fought mercilessly: it destroys the structure of the tree. Therefore, it definitely requires treatment with bleach and then a powerful bioprotective impregnation.

To prevent or stop/slow down the development of fungus, it is important to properly store lumber until the construction of the log house begins. It is not always possible to lay a frame straight from the wheels. Even if it was planned this way, in most cases there are hiccups. And an incorrectly folded log is quickly damaged by fungus.

Therefore, immediately make ventilated stacks. They should be located on a dry area of soil, preferably in the shade. But questions of light and shadow are not fundamental. It is much more important to find a dry area.

It is equally advisable to protect the logs from precipitation: install a temporary canopy. At the same time, do not close the sides. In this case, good ventilation is more important than inaccessibility to droplets.

Folk remedies for whitening

Traditional methods are also widely used, although their results are not always smooth. And if appearance is important for the surface, then it is better not to resort to them. Pre-prepared solutions are tested in an inconspicuous place.

Traditional methods are also widely used, although their results are not always smooth.

Chlorine-containing bleach products

First get rid of tar deposits; for this purpose, you can use potassium carbonate or soda ash. The following actions are followed:

- 10 liters of water are poured into the container;

- Pour in 2 kilograms of bleach and 0.25 kg of soda ash;

- Mix the ingredients well and wait to cool;

- The product is applied to the surface;

- After 5 minutes, treat the material with 9% vinegar.

If paint is applied afterwards, wash the base with soapy water. For heavy stains, you can apply the treatment twice.

Mix the ingredients well and wait to cool.

Whitening with hydrogen peroxide

A concentrated form is required for processing - perhydrol. Without dilution, the product is applied to the surface using a sponge material. After some time, it is treated with 4% vinegar.

Before bleaching, you need to apply a 10% ammonia solution. This method is not suitable for oak wood.

Without dilution, the product is applied to the surface using a sponge material.

Treatment with calcium hypochlorite

Calcium hypochlorite dissolves in a ratio of 8 to 100. Application is done with a sponge, after which it is necessary to neutralize with 2% vinegar. The effect will appear in about half an hour.

Calcium hypochlorite dissolves in a ratio of 8 to 100.

Lightening with oxalic acid solution

For 100 ml of water, take 5 mm of element. This solution is applied to the material. When the light has returned to the same level, treat the surface with a prepared solution of 100 milliliters of water, 15 grams of bleach, three grams of soda ash. Dissolution is carried out in hot water, soda is poured in first, followed by lime. The surface can be rinsed with plain water after 60 minutes.

This solution is applied to the material.

Video description

You can see how a special bleach and whiteness for wood works in this video:

As you can see, the effectiveness of professional products is noticeably higher, since in addition to the main active compounds they contain additives to improve bleaching and other properties.

- Catalysts promote better penetration of bleaching substances deep into the wood.

- Stabilizers prolong their effect time.

- Surfactants make rinsing easier.

- Fungicides disinfect and antiseptic wood, destroying pathogenic flora.

In addition, bleaches are usually available in concentrated form; they are diluted with water in a certain proportion, which is selected depending on the degree of damage. Therefore, their consumption is relatively small, and instructions for use are detailed on the packaging.

It is more difficult to use home remedies precisely because it is impossible to determine the required concentration of the active substance. For example, bleaching wood with hydrogen peroxide is ineffective; instead, it is better to use a more concentrated perhydrol, and after exposure, be sure to neutralize it with a 4% solution of acetic acid. This means extra time and extra labor.

Regular 3% peroxide will not cope with bleaching; it is better to take a concentrated solution for swimming pools Source oknakr.dp.ua

For reference! All professional bleaches are washed off with plain water, with the exception of acidic ones. To neutralize them, soda is added to the water.

Whitening instructions

Pre-clean the wood, it is necessary to remove all contaminants, if possible, then a smooth surface is created. Sand warps to get better impregnation.

If there is glass or aluminum nearby, they need to be covered so that the bleach does not destroy them.

The prepared solution is applied according to the manufacturer's recommendations. They also look at the time when it will be possible to wash off the remaining solution. When washing, they move from top to bottom, spraying water from a hose is suitable. For moldy areas, it is better to clean with a metal brush or spatula.

Pre-clean the wood, it is necessary to remove all contaminants, if possible, then a smooth surface is created.

Required tools and materials

You can bleach wood yourself using chlorine. To do this, you should prepare the necessary components:

- water;

- sodium hydroxide;

- salt in crystals;

- bleaching powder;

- work gloves;

- container for diluting the bleaching agent;

- brushes for application.

Prices for caustic soda

sodium hydroxide

The surface itself must be sanded, completely free of uneven surfaces and wood fibers, so that the bleach penetrates well inside.

To work, you need to prepare the actual bleach, gloves, water, a container for diluting the drug, brushes, and sponges for application. You can also use a sprayer to irrigate wood with the solution.

Is it possible to bleach wood after using Pinotex, firing, brushing?

Pinotex is an impregnating agent for wooden products, there are different shades of the product. But sometimes the color in the catalog turns out darker than desired on the surface. The composition penetrates deeply into the structure of the wood, and it is difficult to lighten it. You can sand the base, lightening it somewhat in this way. But you should not choose whitening products for this purpose. In practice, we found out that dark spots may eventually remain, which worsens the decorative effect.

The composition penetrates deeply into the structure of the wood, and it is difficult to lighten it.

Brushing is carried out to emphasize the natural grain of the wood; the top layer is removed. But mold and fungi can also appear in such material. Bleaching solutions are suitable for removing stains.

Brushing is carried out to emphasize the natural grain of the wood; the top layer is removed.

Firing involves exposure to fire in order to obtain softer layers, the color becomes darker in tone. To obtain a light tone, do not use bleaching; it is necessary to act mechanically. Applying treatment with a stiff brush.

Firing involves exposure to fire in order to obtain softer layers, the color becomes darker in tone.

Briefly about the main thing

Products that bleach wood surfaces are divided into chlorine and non-chlorine. The former cope better with fungi, the latter are more often used to restore the color of old wood. But they do not protect it from discoloration in the future. The wood may darken again from ultraviolet rays or wood-staining bacteria. To prevent this from happening, darkened structures need to be treated as early as possible, before the fungus goes deeper, then antiseptically carry out and a protective coating is applied.

Ratings 0

Recommendations for whitening at home

To carry out a successful repair, you need to carry out the technology step by step. Start by preparing the base, then carefully prepare the solution and apply it for the required period. After the composition is washed off, you can use a solution with soda ash. Alternatively, diluting baking soda in water is suitable.

You cannot combine different solutions; the result is unknown. Such mixing is allowed only if the manufacturer has indicated the possibility of action.

After the composition is washed off, you can use a solution with soda ash.

How to avoid repeated defeats

Almost all wood pests cannot reproduce in a dry environment. They need moisture. Therefore, your main task is to ensure:

- good waterproofing (necessarily horizontal from the foundation, as well as the roof);

- when installing the roof, make the overhangs long enough so that they protect the upper crowns from precipitation;

- properly drain water from wet rooms;

- effective ventilation.

Moreover, ventilation is not only indoors. This is also the airflow of the facade, if there is external finishing, and the space behind the internal finishing (nailing the clapboard onto the sheathing). It is equally important to ensure proper drainage of water in wet areas.

With the right approach, the log house looks amazing

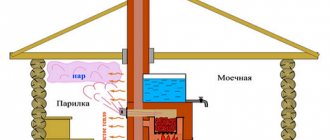

For Russian baths, it is very important to dry everything well after the procedures. To do this, create a draft and throw a couple of logs into the firebox. After a couple of hours, most of the moisture will evaporate. Only after this can the bathhouse be closed.

Caution when working with wood bleaches

You need to know that getting the composition on the fabric leads to the formation of white spots. For this reason, it is better to wear clothes that can be thrown away later. The master is protected by a respirator, gloves and safety glasses. During interior work, high-quality ventilation is ensured.

If drops get on the skin, wash the area with water. Contact with eyes is dangerous, wash the eye with water and seek immediate medical attention.

Solutions should be stored in a place where children and animals will not find them. The container should not be exposed to sunlight; choose a dark place. The container is hermetically sealed. After work, tools should be washed in water to eliminate any residue on the surface, otherwise contact with the skin may occur.

During interior work, high-quality ventilation is ensured.

The article described how to bleach wood so that it regains its beautiful appearance. It is always better to prevent darkening by creating optimal conditions and using wood preservatives. It is more effective to use ready-made bleach, but the choice should be made at the discretion of buyers. You must work in compliance with safety rules, without violating work technology. Then they will get uniform whitening, and the structure will look like new again.

Sequencing

Specific actions depend on what stage the construction of your bathhouse (house) is at.

Before construction starts

If the logs have just been delivered, and some are already affected by blue staining, they need to be treated with bleach before being placed in the log house. If only part of the materials is affected and there are absolutely clean logs or beams, then it is better to coat only the affected ones, leaving the rest as is.

After treatment with bleach, the surface is treated with an antiseptic (after drying the bleach). Don't forget to process the bowls as well as the ends.

Just don’t get it mixed up: after bleaching, treat not with a finishing film-forming composition, but with a water-based or solvent-based antiseptic (they are not very popular because they are not environmentally friendly). Precisely an antiseptic, preferably of deep penetration, which does not form a film.

If the log did not need bleaching, it is not coated with an antiseptic. The fact is that after drying you will have to sand the frame. And wood treated with an antiseptic does not sand well. If the log is clean, and there is a season ahead with minimal precipitation or low temperatures, then without moisture or heat, fungi will not develop without any treatment.

After drying, the logs or beams are sanded. There is a high probability that all the blue will be removed

After installing the log house, it is covered with a roof and in this state is left to dry out/shrink. There is one point: during this period, you should not cover the cut window and door openings with film. You can fill it with boards, but with cracks so that moisture can escape freely. You can also use vapor-permeable films (if the film has one-sided conductivity, do not confuse which side should be nailed - the rough side facing the street). If the openings are closed tightly, there is a high chance of getting mold or white fungus in addition to the blue. Therefore, take care of ventilation.

Blue of dried logs (timber)

After drying and shrinking, it’s time to polish the frame . This is where the need for bleaching may arise again. If there is blueness, bleach, if not, you don’t need to. Then comes the grinding of the frame. In the process, many minor lesions that the bleach did not remove can be removed mechanically: you will still have to remove the darkened layer of wood, so this may also remove fungus-affected wood.

After the first pass with a grinding machine, the condition of the treated logs is assessed. If there are dark spots, they are treated with bleach again. Only this time you need to act carefully: light spots on wood are no less pleasing than dark ones. Therefore, the sequence is as follows: first, generously moisten the darkened area, and then rub it with a brush, “blurring” the boundaries of the treated area. After the bleach has dried, the frame is sanded with a fine-grain abrasive until smooth.

In case of deep damage, simply sanding is not enough: no one will remove two or three centimeters of wood

Then, they are immediately coated with an antiseptic, fire retardant and finishing composition (for example, Senezh wood protection compositions). You can use combined products, or you can use three different ones. You just need to select compatible compounds.

If it works, take all the products from the same brand: there will be no compatibility problems. If this does not work out, before purchasing a large batch, buy the selected products in small packaging. Use them on some unnecessary piece of wood (cover it with a layer of the last compound applied to the walls) and try how they behave in combination. It is necessary that they do not react and do not stain the wood. For example, some antiseptics in combination with chlorine give a pink color. Also check whether the product lays evenly, does not roll down and how well it is absorbed.

Using the same test, determine how much you like the selected topcoat tone, and how many layers you will need to apply to achieve the desired result.

Before buying a large batch of bleach, antiseptic and paint, test them all on an unnecessary (or invisible) piece of wood

Unfortunately, it is impossible to determine the effectiveness of the protection. Unless you can see if the water will be repelled. After the topcoat has dried, spray the board and see what happens. Drops should roll off but not be absorbed.