Despite the growing popularity of wooden/frame and monolithic housing construction, various blocks still have a lot of adherents. They are attractive to private owners both because of their large dimensions, which allow them to speed up masonry processes, and because of their impressive characteristics. And the wide variety allows you to choose a material that fully suits your needs and capabilities. Our portal contains construction experience from almost everything that is produced or made independently; in this material we will consider the popular types of wall blocks:

- Ceramic blocks.

- Aerated concrete.

- Arbolit.

How to choose the right blocks for construction

When choosing blocks, you should focus on the specific purpose of the building or structure being erected: a permanent house, a cottage or summer house, an outbuilding or a garage.

Main criteria for selecting blocks for construction:

- the use of lighter weight building materials will allow significant savings on the foundation;

- the use of large blocks with good geometric characteristics significantly reduces time and labor costs for the construction of buildings;

- the correct choice of building materials for thermal insulation properties will avoid additional costs for insulation;

- Most types of building blocks do not require finishing work, which reduces overall costs and construction time.

Facial building blocks made of expanded clay concrete Source ro.decorexpro.com

Main technical parameters for choosing the right material:

- density;

- compressive strength;

- thermal conductivity;

- frost resistance;

- bending strength for earthquake-prone areas.

Wall building blocks Source beton-house.com

Recommendations

Experts advise:

- correctly calculate the amount of material to reduce the cost of constructing a structure. A smaller quantity will lead to the need for re-purchase, and a larger quantity will result in useless ballast. It is important to take into account all the parameters of the formula, since the blocks for the wall should be calculated taking into account the stock, destruction, defects, size of seams, etc.;

- When choosing aerated concrete and foam blocks, it is important to lay it correctly, since reinforcing aerated concrete blocks is a mandatory measure to increase the strength of the structure. The difference between a foam block and a gas block is hardly noticeable to an amateur, but before determining a specific type, it is worth finding out about the differences;

- at home you can prepare blocks from sawdust; they are almost as good as industrial materials and are suitable for building residential premises;

- To retain heat in a room, it is better to choose cellular blocks. Warm blocks for building a house will help you save on additional insulation and payments for energy resources;

- The choice of material is influenced by the area of use: load-bearing structure or partition. Blocks for partitions must provide sound insulation, but are not designed to withstand heavy loads; hollow options are suitable. Load-bearing walls are made exclusively from solid elements.

Clear prioritization and understanding of the differences between materials will help you make the right, solid choice. The priority should be in terms of economy, thermal insulation or strength. Each material is good, but in its own way.

What are the building blocks?

Building blocks are a good alternative to other materials for constructing buildings, such as brick. Blocks are suitable for the construction of structures of any type and purpose, since they are larger in size than bricks, buildings from them can be erected faster.

Building blocks come in different types. To choose the right material for construction, you need to compare all the varieties and choose the best option based on the purpose of the block, its characteristics and quality.

All building blocks are divided into wall, partition and foundation.

Hollow building blocks Source kabel-house.ru

The main types of building blocks are:

- reinforced concrete;

- tongue-and-groove;

- expanded clay concrete;

- foam concrete;

- gas silicate.

This is not the entire list of building blocks; there are also adobe, cinder blocks, sawdust concrete products and others.

Cement blocks Source bettermetaltech.com

Earthbiting

Earth is the oldest building material. In Europe, building houses from earthen blocks is still quite popular today. This is caused not only by the fashion for ecological construction, but also by the unlimited service life of properly built houses made of earthen blocks, which over the years turn into the strongest concrete and do not shrink.

By adding straw or pine needles to the earth breaker, its thermal conductivity properties are significantly improved.

The most famous building made from this material is located in Russia. This is the Priory Palace in Gatchina.

Priory Palace in Gatchina Source xxx.artfile.ru

Original earthen house Source rumahku.com

Small round house made of earthenware Source stroysam.news

Adobe blocks

One of the varieties of earth breakers with identical technology for making blocks is considered to be adobe. Making adobe blocks is a fairly simple process, mostly done by hand. Water is added to the clay, the clay soil is kneaded and various components, mostly organic, are added to it.

Additives used:

- straw, firewood, manure, shavings - increase strength;

- crushed stone, sand, expanded clay - reduce shrinkage;

- cement, lime - accelerate hardening and increase moisture resistance;

- bone glue, casein, starch, molasses and other plasticizers.

The mixed components are stuffed into wooden formworks and dried naturally. As a result, after drying, adobe blocks are obtained; their dimensions are usually identical to cinder blocks: 40x20x20 cm.

Making adobe blocks Source domvpavlino.ru

Today, the technologies for making adobe blocks have been significantly improved, sometimes they are called clay concrete, clay fiber concrete.

Advantages of adobe house:

- The hygroscopicity of the building material creates a good microclimate in the house. Adobe acts as a humidity stabilizer; walls made of this material can replace air conditioners and humidifiers.

- An adobe house is always warm and cozy due to the thermal inertia of the material.

- Excellent soundproofing qualities of adobe walls.

- High fire resistance of building material.

- The aluminum contained in the clay gives the walls the properties of a protective screen from electromagnetic radiation.

- The price of adobe blocks is very affordable due to the low cost of raw materials.

Building a house from adobe Source pinterest.com

Disadvantages of housing made from adobe blocks:

- Low moisture resistance, the need for external protective finishing materials, at least lime whitewash.

- Organic fillers can lead to the appearance of unwanted insects and rodents in the walls; protective means and technologies are available, but this will lead to a slight increase in the cost of adobe blocks.

- It is necessary for the adobe to dry completely; in an under-dried state, the material loses all its advantages.

An adobe house with an original shape Source oooarsenal.ru

An adobe house, properly built and from high-quality materials, is reliable and durable in low-rise construction.

Historical examples can serve as clear evidence:

- tens of thousands of English adobe houses have remained decent and comfortable housing for more than five centuries;

- the earthen buildings of Jericho are usable after 9,000 years;

- houses in Yemen, built using adobe, 10 floors high, have been inhabited by people and have served them well for 900 years.

Can you be sure that houses made from modern super materials will last for so many years?

Shibam: Yemen's multi-story masterpiece Source mapio.net

See also: Catalog of companies that specialize in the design and construction of turnkey country houses.

Concrete blocks: foundation and wall

Products made from classical concrete are the only type of standardized blocks; all others are produced on the basis of technical specifications.

Cement, crushed stone, sand, water in various proportions to impart certain properties, voids are possible to reduce weight. The generally accepted dimensions of wall blocks (usually 390x190x190) - this is the general characteristic.

The price range for concrete blocks for building a house of standard size 390x190x190 is from 40 to 55 rubles, partition blocks 390x90x190 cost from 30 rubles. for 1 piece

The main use of concrete building blocks is the construction of foundations and load-bearing main walls.

Four-hollow wall concrete blocks Source festima.ru

The use of concrete blocks in the foundation significantly reduces the labor intensity of monolithic concreting and eliminates some technological processes, for example, the installation of formwork. Construction time is reduced both when constructing foundations and when replacing small-piece products (bricks) with blocks.

Foundation concrete blocks Source remdek.ru

cinder block

Slag is the material obtained after the combustion of solid fuel, mainly coal. Slag is an alloy of oxides. To be used as a raw material in the production of blocks, the slag must be kept in open areas for at least six months. Exposure to atmospheric precipitation allows you to naturally clean the slag from residual sulfur and phenol.

When producing cinder blocks, no additional chemical compounds are added.

Cinder block has two advantages over other wall stones: light weight and the lowest price in the wall block category, since slag is considered waste.

Types of cinder blocks Source banya-expert.com

The most common size is 390x190x190, it can have voids or be produced in a monolithic design, the average cost is around 35 rubles per piece.

Expanded clay block

Expanded clay concrete is a block made by vibrocompression, which contains: cement, sand, expanded clay, and water. Expanded clay has replaced slag in the composition of blocks, as it is an environmentally friendly, lightweight, inexpensive, accessible material.

An expanded clay concrete block made in industrial conditions has good geometric characteristics, different strength characteristics depending on the composition of the grade, which ranges from M25 to M100, and frost resistance from F15 to F100. The volumetric weight of expanded clay concrete block is from 800 kg/m3 to 1500 kg/m3.

Blocks that correspond in density to SNiPs have a smooth surface, do not require expensive finishing, and are quite consistent with the price-quality ratio.

Expanded clay concrete blocks Source domvpavlino.ru

Comparative characteristics

The table below contains technical indicators of the types of blocks described in the previous section, which will help you decide on the choice of the most suitable products for the construction of a particular building, as well as understand how foam blocks differ from concrete, gas silicate, gas blocks and other types.

| Block type | Strength B (kg/m3, MPa) | Frost resistance (F) | Density (D) | Weight 1 piece (kg) | Thermal conductivity λ (W/m2) | Moisture absorption | Shrinkage | Reinforcement | Construction speed months | Average price (RUB) | Features of appearance |

| Foam concrete | 7,7-90 | 35 | 1000-1200 500-900150-400 | 11-25 | 0,05-0,38 | 14 | 28 days | Yes | 1,5-2 | 25 | Gray Cellular Stone |

| Aerated concrete | 1,5 | 15-25 | 700 | 17-40 | 0,08-0,1 | 20 | Yes | Yes | 1,5 | 31 | Light grey, cellular, smooth |

| Gas silicate | 20-35 | 10-30 | 400-600 | 11,7-48,7 | 0,11-0,16 | 100 | Yes | 1,3-2 | 30-206 | Grayish white, smooth | |

| Concrete (monolithic) | 250 | 15-50 | 2500 | 16-17,5 | 2,55-3,24 | 0,7-5 | 90 days | No | 3-4 | 21-60 | Smooth, light gray |

| Ceramic | 125-135 | 35-50 | 830-1350 | up to 31 | 0,21-0,56 | 12-13 | No | No | 3 | 12-113 | Porous or regular, over 60 shades |

| Expanded clay concrete | 3,5-7,5 | 15-100 | 900-1200 | 13-17 | 0,5-0,7 | 18 | No | Yes | 3-4 | 12-65 | Various shades of gray, from dark to light, pronounced porosity |

| Polystyrene concrete | 15-35 | 75-150 | 150-600 | 13 | 0,1-0,145 | up to 4 | Yes | 2 | 33-200 | Light gray with whitish inclusions in the form of small balls | |

| Arbolite | 20-50 | 25-100 | 500-900 | 16-24 | 0,20-0,30 | 60-80 | Yes | Yes | 1,5 | 50-165 | All shades of grey, sawdust visible on the porous surface |

| Plaster | 4,4 | 1000 | 27 | 0,30 | 5-25 | No | No | 1,5 | 39 | Smooth, light green or blue stone | |

| cinder block | 35-125 | 15-50 | 28-40 | 18-23 | 0,27-0,65 | 75 | No | Yes | 3 | 35 | Gray tint, slight roughness |

Building blocks made of cellular concrete

Pore cells are formed in concrete as a result of foaming. This can be achieved in different ways, but the result is quite similar building materials: aerated concrete and foam concrete.

Building blocks made of cellular concrete Source emupauto.ru

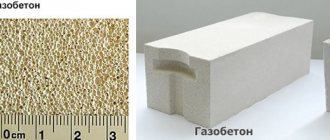

Aerated concrete blocks

When aluminum powder is added to the building mixture and interacts with lime, a reaction occurs that resembles the fermentation of dough, as a result of which a porous structure is formed. The powder acts in the reaction as a gas-forming agent, and the resulting porous building material after hardening is called aerated concrete. The aerated concrete block gains strength in an autoclave.

The legislation does not require certification of aerated concrete blocks, but voluntary certification of those produced in a building materials plant is ubiquitous.

Construction from aerated concrete blocks Source interteam.com.ua

Dimensions of aerated concrete blocks:

- length – 600 mm;

- width – 250 mm;

- height – 100, 200, 250, 350, 450, 500 mm.

The blocks can withstand 100 freezing cycles.

Industrial production of aerated concrete began in 1929 in Sweden, in the USSR - in the 30s of the last century.

Aerated concrete blocks are connected using a special glue; this is facilitated by their ideal geometric shape with an error tolerance of no more than 2 mm. There are tongue-and-groove and smooth blocks, with a special recess for the hand.

The excellent heat-insulating properties of the gas block allow the house not to overheat even in hot weather.

Qualities of aerated concrete block Source nadoremont.com

Foam concrete: optimal price-quality ratio

Concrete block is a cellular type of building material. All their qualities are inherent in him. It is made from a mixture of concrete and foaming agent. The foam is prepared in a special generator and then poured directly into the cement. It envelops and thereby closes all cells in the structure. Afterwards, the mixture enters special cassettes and remains to solidify at natural ambient temperature. There is no special thermal effect on this material.

Note! Foam concrete needs to “stand” for an average of 28 days from the date of manufacture in order to finally harden and obtain the necessary strength.

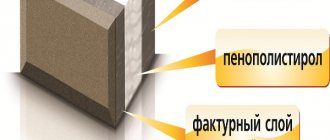

Foam concrete block with facing side

Many developers note the favorable price of blocks for building a house: any private developer can buy foam concrete products. At the same time, they make it possible to easily display, for example, any figured arches or partitions.

When considering the question of which blocks are better for building a house: gas and foam concrete are often compared. There is no clear answer to this question, but there are a few things to consider:

- aerated concrete blocks look like a sponge. Their pore cells are not closed, as a result they actively absorb and retain moisture that gets into them. In this regard, foam blocks with cells that are completely closed and concentrated exclusively inside are in a more advantageous position;

- if we apply sub-zero ambient temperature to the absorbed moisture, we will get a disappointing result for the aerated block: it will crack and shrink;

- Foam concrete has a lower density; it contains more cells that are filled with air. Therefore, it retains heat much better;

- For the production of aerated concrete blocks, more professional equipment is used, which makes it possible to have clear dimensions and correct edges of the products.

The most popular size of foam concrete block is 600x300x200 mm

A foam concrete block, depending on its density in the most popular size 600x300x200 mm, costs from 95 to 120 rubles/piece. Naturally, high-density material has the highest price. If you increase at least one of the dimensional parameters, for example, to 600x400x200 mm, then the price will be 120-170 rubles/piece.

Video description

For more information about aerated concrete blocks, watch the video:

Gas blocks Source eurohouse.ua

Foam concrete blocks

Foam concrete in the Czech Republic is called “bioblocks”; it is extremely popular in Germany, Sweden, and Finland. In Russia, according to the most conservative estimates, there are approximately 1,200 foam concrete producers.

The difference between foam concrete and aerated concrete is that the former hardens under natural atmospheric conditions; otherwise, the characteristics of building materials are similar.

Foam concrete blocks Source kladka-penoblokov.ru

Advantages of aerated concrete building blocks:

- not flammable;

- does not rot;

- easy to process;

- has a wide range of sizes;

- does not mold;

- not afraid of water;

- relatively low price.

Advantages of foam concrete block Source pt.decoratex.biz

Disadvantages of aerated concrete building blocks:

- unstable density and weight;

- heterogeneity of pores due to the use of foam;

- a large number of uncontrolled producers.

In case of proper production and adherence to manufacturing technology, the properties of foam concrete are almost identical to aerated concrete, but the price of the latter is significantly higher.

House made of foam concrete Source remontik.org

Gas blocks

These are briquettes made from aerated concrete, a material from the cellular concrete family. It consists of the same materials as traditional concrete:

- Portland cement;

- sand;

- lime;

- water.

The fundamental difference of this material is the porous structure that arises as a result of the chemical reaction of the working solution with a gas-forming agent - aluminum paste. It is added after mixing the base components. A reaction begins with the release of gas, during which the material is placed in molds and kept for a certain time. Aerated concrete rises like yeast dough, acquiring its porous structure. When the reaction is complete, the raw material is cut into blocks and sent to an autoclave for 12 hours, where they are treated with hot steam under pressure.

Advantages of aerated concrete:

- light weight, no excess load on the foundation;

- low heat transfer coefficient, allowing you to save thermal energy;

- smooth and precise shape of the blocks, allowing you to make thin seams (2-4 mm);

- high laying speed, the work can be performed by unqualified builders.

Minuses:

- high hygroscopicity, walls must be protected with moisture-impermeable sheathing;

- low strength, there is a restriction on the height of buildings (up to 3 floors);

- the material does not withstand bending loads (multidirectional loads), as well as pressure.

These properties differ significantly from the parameters of traditional concrete, which caused a wave of criticism from builders. Many people try to approach new material with old, familiar standards. However, subject to technological requirements and construction rules, aerated concrete allows you to save on heating and reduce costs during the construction of the foundation.

Ceramic building blocks

Ceramic blocks, according to their production technology, are ceramic bricks of large volumes and attractive shapes. Ceramic blocks have excellent performance in all physical and chemical characteristics:

- good thermal efficiency;

- environmental friendliness;

- high sound insulation properties;

- ease of installation;

- suitable for performing any architectural and design tasks;

- does not require additional insulation;

- The blocks are laid using a special glue.

Ceramic blocks Source kamin-best.ru

Sand blocks

This is one of the simplest and most discussed materials. Sand blocks consist of common components:

- cement;

- sand;

- water.

To increase strength, various additives are added to the composition. Curing and drying are carried out by vibration pressing followed by treatment with a UV lamp. The material does not have a generally accepted standardized technology or established composition. This has given rise to many different modifications with different parameters due to additives and additions to the technology. The advantages of sand blocks are considered to be:

- strength, ability to withstand high pressure;

- hollow universal blocks have good heat-saving abilities;

- resistance to moisture;

- durability (up to 100 years);

- the blocks do not burn or rot, and are not susceptible to mold or mildew;

- have the ability to muffle sounds;

- sand blocks are 2 times cheaper (or more) than bricks.

Disadvantages of sand blocks:

- solid sand blocks have low thermal insulation;

- heavy weight, load on the foundation;

- low vapor permeability, resulting in an uncomfortable microclimate in the house;

- There are many low quality products on the market.

Sand blocks are often produced by unknown companies, so they should only be purchased from trusted sellers.

Polystyrene concrete blocks

Building blocks made of polystyrene concrete are lightweight concrete using cement binder and foamed polystyrene as filler.

Advantages of polystyrene concrete building blocks:

- does not rot, does not mold;

- thermal conductivity is similar to wood;

- easy to process;

- a large selection of products of various shapes and sizes;

- light weight;

- high elasticity.

Advantages of polystyrene concrete block Source kassot.com

Disadvantages of polystyrene concrete building blocks:

- there is no data on the possible release of harmful substances during combustion;

- rapid destruction when exposed to ultraviolet radiation, additional timely protection is necessary;

- cold bridges appear at the junctions of blocks and lintels, window and door structures;

- long time to achieve design strength;

- significant shrinkage.

Polystyrene concrete block is produced in a classic form, in accordance with the requirements for building materials. It is used in the construction of non-load-bearing walls and partitions, for thermal insulation and sound insulation.

Polystyrene concrete block Source brick-66.ru

Arbolit

Belongs to the group of lightweight concrete.

Raw material base, production technology, characteristics

Wood concrete is made from a mixture of cement and organic fillers, mainly wood chips, although it is technologically possible to replace wood chips with firewood (flax, hemp). In addition to the binder and filler, modifiers are added to the mixture to improve the characteristics of the blocks. The optimal species for wood concrete are coniferous, and deciduous species are aspen, birch, poplar or beech. To obtain homogeneous and durable blocks, the wood chips must be crushed to a certain fraction - 40x10x5 mm. If the technology for preparing raw materials and mixing components is standard, as is the mixture recipe, then the method of forming blocks depends on the specific manufacturer. This can be instant formwork, permanent formwork or vibrating with a weight. It is believed that with instant formwork it is more difficult to obtain blocks with decent characteristics, while blocks laid in a mold are of higher quality.

The density of structural wood concrete varies from 500 to 850 kg/m³, strength class B1.5-B3.5. Unlike ceramic and aerated concrete blocks, it is possible to make wood concrete yourself, but obtaining D500 and B1.5 in homemade products is quite problematic.

a991ru

As the practice of wood concrete production shows, when producing a block with a density of 500 kg/m³, achieving a minimum structural strength of 21 kg/cm² (strength class B 1.5) is very, very difficult. This ratio of strength and density is obtained only in the manufacture of very high-quality wood concrete using pure wood chips and absolute adherence to the wood concrete production technology without the slightest deviation.

Wood concrete has the following most important characteristics:

- density (dried to constant weight) – 500-850 kg/m³;

- strength – B1.5-B3.5;

- frost resistance – F25-F50;

- thermal conductivity (in a dried to constant weight state) – 0.09-0.14 W/(m·C).

Dimensions

According to standards, wood concrete has three sizes:

- 500x200x250 mm;

- 500x300x250 mm;

- 500x400x250 mm.

But in practice, manufacturers produce products with a variety of dimensions. The universal block size is 500×370×160 mm. Such wood concrete can be used both for laying walls and for laying partitions, if the region of residence allows.

Heat blocks

Combined type blocks are gaining popularity, for example, heat block, heat wall, polyblock, porotherm.

Manufacturers declare heat blocks and its analogues as an ideal solution not only as the main wall material. Heat blocks are considered universal, made in the form of a multi-layer cake with additional insulation properties.

Heat block Source bizorg.su

In addition, heat blocks can be used as a decorative material for external and internal use.

Frame houses

SIP panels, SIP panels, sandwich panels are the names of the same material that is used for the construction of buildings using frame-panel construction technology. The house is assembled according to the principle of a designer from ready-made elements of a certain standard size. The panels themselves are a “sandwich” of chipboard/OSB sheets between which insulation is located. Frame houses are rightfully considered one of the most rapidly erected and budget-friendly housing options.

Advantages

- low cost of materials

- minimal costs for building a “box”

- high construction speed

- high thermal insulation

- buildings are not subject to shrinkage

- savings on foundation

Flaws

- extremely high flammability of the structure

- almost complete lack of sound insulation in the rooms

- poor resistance to pests and parasites

- fragility of construction

Permanent formwork blocks

Small-piece blocks used as permanent formwork can, to some extent, also be classified as building blocks.

When using them, it is possible that better performance is possible in comparison with traditional blocks, but the share of permanent formwork materials in construction is still small, there are technological difficulties in using them, and their effectiveness has not yet been confirmed in practice.

Main brands and brands: Simprolit, Izodom, Durisol, Thermoblock, Mosstroy-31.

Permanent formwork blocks Source ko.decorexpro.com

Log

Rounded logs are a traditional material for constructing walls of wooden houses. The log has precise geometric shapes (same diameter), high strength, reliability, environmental friendliness, provides natural ventilation of the room, and does not require significant foundation costs. The material has become widespread due to its availability and high speed of construction - the “box” of a house can be assembled in just a couple of days. Also, we must not forget about the high aesthetics of a log house.

Advantages:

- positive natural qualities of the material

- pleasant microclimate

- high material strength

- high speed of house assembly

- attractive appearance

Flaws:

- significant shrinkage during the first year

- susceptibility to parasites

- fire hazard

- the need for constant processing of the material

Conclusion

Everyone is looking for the ideal wall material that would have high strength, good thermal insulation, environmental friendliness and low cost. Modern technologies make it possible to work wonders by combining many characteristics in a particular material. However, it is impossible to say unequivocally which block is better to build a house from; each has certain pros and cons, and the final choice depends on the budget, climatic features, and the quality of the site.

You can always use a block calculator if you need to calculate the amount of materials, their cost, find out the total cubic capacity and weight.

Comparison of moisture resistance

There is so much conflicting information on porous concrete that it is easy to get confused. If you doubt the moisture resistance of the material, experts advise conducting your own experiment:

- Pour equal amounts of water into 2 glasses.

- Break off a piece of aerated concrete and foam concrete and lower them into the liquid.

- Wait 2-3 days.

The standard results of such an experiment prove that foam concrete does not absorb moisture. It floats on the surface for several days, while aerated concrete sinks quite quickly.

If when using gas blocks it is necessary to protect them from moisture with a special coating, then it is enough to protect foam blocks with external finishing.

Ceramic blocks

It is a worthy alternative to the usual brick. Ceramic-based wall blocks have appeared recently, but are gaining popularity in the private construction sector. The basis of the block is baked clay with a hollow, cellular structure of the finished products.

Advantages and disadvantages

| Advantages | Flaws |

| Complete environmental safety | Low level of thermal insulation/td> |

| Increased degree of vapor permeability | Large weight of blocks |

| Resistance to static loads | The ends are not very reliable |

| Reliable sound insulation of premises | Fragility makes transportation problematic |

| Convenient installation with joints of elements using a tongue-and-groove connection using a lock. The price is a little high | Dependence on the installation technology followed |

| Difficulties in finishing from the inside, since the hollow structure does not “hold” screws and nails |

There may be difficulties in the process of additional processing: it will not be possible to split a ceramic block like an ordinary brick. It is necessary to use a grinder.