When choosing the thickness of timber for the walls of a bathhouse, you can focus on several criteria, for example, the climate in the region, the presence of insulation, and others. The available budget for construction is also important. Maybe the bathhouse will not be used in winter, which often happens in the case of dachas. It would also be a good idea to take advantage of the experience of other people who have already built a timber bathhouse and used it for at least one full year.

If you don’t want to bother, and you need some kind of average solution to the problem, then you can resort to the standard, time-tested option. If the beam is profiled, with a cross-section of 150 mm, then this option will be the best for the money, and you will not freeze in the bathhouse, even if it is frosty outside -30°C.

If the average option is not for you, it’s worth spending two minutes of time and considering all the criteria described below for choosing the thickness of a beam for a bathhouse.

Generally accepted standards

Today, in the vast majority of cases, timber with a thickness of 90 mm to 200 mm is used for the construction of baths. The spread is considerable, and it is especially acute in terms of the price of lumber. For example, a 6x8 m bathhouse made of timber with a cross-section of 90 mm will cost about 500 thousand rubles (spacious, with an attic, bedrooms, a balcony and other amenities). If for its construction we take timber 200 mm thick, then approximately another 100 thousand rubles will be added to the indicated amount.

Naturally, the larger the cross-section of the walls, the warmer it will be inside. However, if you additionally insulate walls from relatively thin timber, then, in general, the costs will be slightly lower than if you achieve high thermal insulation characteristics by increasing the thickness of the timber. It is also worth considering that a bathhouse made from 200 mm timber is much heavier than one made from 90 mm timber. And this will require strengthening the foundation, which is not cheap.

Comparison of materials

There are many materials that can be used to build a bathhouse. You need to evaluate the advantages and disadvantages of each option.

Beam or log

The joints between the logs must be caulked with felt or tow.

The log is a traditional material for the Russian bath. Such wood fully retains the advantages of the material: the highest heat conservation, the ability to regulate the microclimate by removing moisture out, exceptional durability and beauty.

However, the log shrinks greatly: the bathhouse can be finished and glazed no earlier than 1 year after construction. And after that, she sits down a little every year. Laying the log is very difficult. This requires high qualifications and experience. Periodically, the walls of the bathhouse need to be caulked.

A log building is inferior to a log house in terms of durability and comfort, but is erected much faster. Many builders believe that it is easier to insulate a building from timber than to build it from logs.

Timber or brick

It is difficult to compare these materials because they have different properties. In general, brick and stone are not the best option for a bathhouse, since brick is much heavier, has low vapor permeability and retains heat much worse.

But if a bath complex with guest rooms and a swimming pool is being built, brick may be the best solution.

Beam or blocks

A bathhouse made of blocks can be built faster and cheaper.

Cellular concrete is the most budget option for construction. The blocks are much larger than ordinary bricks, the building is built much faster, the surface of most foam concrete is smooth, which allows the stone to be joined very tightly. Their thermal conductivity is much lower than that of ordinary concrete.

The disadvantage of cellular concrete is hygroscopicity. It is less for non-autoclaved foam concrete, for example, and more for aerated concrete. Nevertheless, such walls need to be carefully waterproofed and finished both inside and outside. As a result, construction becomes more complicated, although it is cheaper than construction from laminated veneer lumber.

Type of timber

If you use the most common timber today - profiled timber, then its thickness can be calculated to a minimum. Since the crowns are connected to each other using the tongue-and-groove system, the overall thermal insulation properties of the log house are increased when compared with planed timber.

The moisture content of lumber has no effect on the choice of its cross-section, contrary to popular opinions. So, even if a 150-mm profiled timber is kiln-dried or atmospheric-drying, there is absolutely no difference for the thermal insulation properties.

Types of logs

For the construction of houses, rounded logs or timber are used

Despite the development of new technologies for the construction of residential buildings, their architecture and layout, the emergence of innovative building materials, log houses do not lose their attractiveness and popularity.

The following types of logs are used in construction:

- Rounded. It is a trunk that undergoes precise processing on machines, during which part of the wood is removed from it, and then sanded and polished. The result is products with precise geometric shapes. There are logs with completely rounded walls and their modifications with semicircular grooves. The diameter of the finished product is 15-25 cm with a length of up to 600 cm.

- Solid. The process of their production is not complicated, hence the lower cost. During the manufacturing process, only the bark is removed from the tree by hand or on a machine, and a layer impregnated with resin remains on the surface, protecting the log from dampness and insects. Installation from such material is more complex, but the end result is worth it.

Climate

You need to navigate this criterion based on the lowest air temperature in the region. Many people make the mistake of looking at the peak temperature, which lasts for only a few hours per year. It is more rational and correct to take the most severe frosts, which last for at least five days. This will allow you to save a lot, since you won’t have to “thicken” the walls in order to “not freeze” on the very day when the frost outside is at its peak. On this day you don’t have to take a steam bath.

Usually, if no additional insulation of the walls is provided, and the most severe frosts (prolonged) in the region reach -30°C, then for the construction of a warm bath a profiled beam with a cross-section of 150 mm is sufficient. If the conditions are different, you can focus on the specified starting point, not forgetting about the other criteria described below.

Undeniable advantages and annoying disadvantages of frame baths

Frame bathhouse covered with a block house

The frame bath pampers its followers with beauty and comfort. For a dacha, it is impeccable: neat, attractive and ergonomic. In addition, she demonstrates a colossal number of undeniable advantages.

- Long service life. Thanks to innovative technology and modern raw materials, the bathhouse is durable. In addition, it does not require frequent repair work.

- Wear resistance. A cozy steam room, built using modern frame technology, is generously treated with special substances that make it resistant to the harmful effects of negative environmental factors. Namely: it is not afraid of the action of chemical, biological, climatic, thermal factors. And it is not afraid of mechanical factors (within reason), since it is built using the strongest materials - the same OSB boards or plywood.

- Environmental friendliness. The bathhouse is not capable of harming people's health, as it is constructed from environmentally friendly raw materials that have passed the strictest testing by experts.

- Aesthetics. Frame steam rooms look avant-garde, solid and noble.

- Comfortable. Structures built using modern frame technology are easy to use and easy to maintain.

- Economical. The cost of a frame structure varies within reasonable limits. Well, at least it won’t leave the owner of the steam room “without pants” (although depending on how you look at it, it’s inconvenient to wash while dressed). The construction will cost approximately $80 per square meter.

- Lightning speed of construction. Construction of the structure lasts from two weeks to a month.

- Possibility of finishing work. The surface of the bathhouse can be combined with any facing raw material, allowing you to make your wildest dreams come true. Do you want to have a magical house, like in fairy tales? Maybe you dream of a mansion? Perhaps you are dreaming of a hut on chicken legs? Although, maybe you want to have a super innovative building? No problem! For a frame bath, “all outfits” are good.

- There is no bad weather. And even if there is, the frame bath doesn’t care. Construction can be carried out at any time of the year.

- Heat capacity. The steam room heats up very quickly, so you won’t have to wait long for the optimal temperature to be reached.

- Non-shrinkability. The design does not shrink, which is simply wonderful. After all, you don’t need to wait a lot of time to do the exterior and interior decoration.

So-so. A worthy competitor, to say the least. Maybe she has no flaws? The advantages are painfully good. How? Yes, of course.

- Expensive. How so? Construction is inexpensive. That's how it is. But facing work will cost a pretty penny. In addition, a capricious steam room requires high-quality insulation, which is also not cheap, alas.

- High thermal conductivity. Yes, undoubtedly, the baths warm up in a short time, but, unfortunately, they are not able to retain heat for a long time.

- Possible harm. What is it? It was said that the frame structure is safe. This is true. The structure, which is usually built from wood, cannot harm human health. But thermal insulation material, especially if the owner has saved on it, can release toxic substances under the influence of high temperature and humidity (take the same polystyrene foam).

That's all. The frame bathhouse has no more negative aspects. In principle, if you want, you can read reviews from the owners of such objects and make sure that the design deserves attention.

Availability of additional insulation

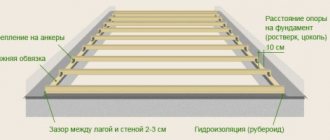

You can make a warm bathhouse from the most inexpensive profiled timber with a cross-section of 90 mm. To do this, simply insulate the walls. Outside, as a rule, a so-called ventilated façade with mineral wool up to 100 mm is installed. If this is not enough, then you can insulate the building from the inside, using the same mineral wool, but no more than 50 mm thick.

Insulation of the floor and interfloor ceilings should be by default, regardless of what kind of timber is used and whether the walls are insulated.

Regarding the experiences of real people. In fact, almost all of the above is the very experience of people who have had a bathhouse made of profiled timber for more than one season.

Frame bathhouse and its features

In deciding whether a frame or timber bath is better, consideration of the key features of each of them is not least important. The main criterion in this is the design differences. So, in the first version, the structure is a set of posts, beams and crossbars connected into a single architectural form.

The frame can have any base - metal, plastic, but often preference is given to wood - boards or bars. The skeleton of the structure is built on a primitive foundation. Then, depending on the required characteristics, it is sheathed on the outside and inside with sheet material - chipboard, plywood and others. If necessary, cavities formed in the walls are filled with inexpensive insulation, for example, polystyrene foam or mineral wool.

Start of construction of a frame bath Source pikabu.ru

The main advantages of such a structure include:

- Speed and ease of construction without the use of complex equipment and special equipment.

- Light weight and the ability to install without a foundation or with its basic modification.

- There is no shrinkage of the walls, which allows for interior and exterior finishing immediately after construction.

- Versatility in the choice of building materials.

- A wide selection of design projects - by size, interior design, architecture, type of materials, facade.

- Sufficient resistance and durability.

At the same time, the frame structure is not without its disadvantages:

- The latest heat-insulating materials are quite expensive, despite the fact that the construction of the frame itself can be cheap.

- In terms of composition, not all insulation materials are environmentally safe, especially under operating conditions at elevated temperatures and humidity.

- The operation of a frame bath in winter is limited or requires significant modification. For use in severe frosts, the structure must be well insulated.

Small frame bathhouse covered with boardsSource okarkasnih.ru

Video description

In this video, a lawyer talks about how a bathhouse should be located in accordance with the law:

There should be 8 m of free space between your residential building and the building - this is what SanPiN norms say.

During the preparation of the project, it is necessary to determine the size of the bathhouse. Wood supplied to production is no longer than 6 m long, and in some cases there are blanks for 4 m, therefore, 7-8 m timber will cost much more. Therefore, the most optimal and budget sizes are 4x4, 3x4, 6x4, 6x3, in some cases they choose an area of 4x5 and 5x3.

The entire space is usually divided into a steam room and a small relaxation room. In addition, they can also accommodate a sink with a size of at least 1.4 m. But for the above sizes, such a division is not entirely comfortable, since it will result in 3 small rooms, where it is difficult for even one person to stay. The main thing in planning is to follow the principle - the smaller the bath area, the fewer rooms there should be.

Already during the design process, you can find out exactly how much timber is needed for a 3 by 3, 5 by 4, and other non-standard size bathhouse.

An example of the layout of a spacious and comfortable 8x6 bathhouse Source par-torg.com

After the location has been chosen taking into account all the rules and regulations, and the project has been drawn up correctly, it is necessary to order the timber. You can find out what points you need to pay attention to when choosing, in the first half of the article.

Frame bath: features

Concept

Frame technology for building baths in our country is considered know-how, but in other countries it has been used for centuries. Its essence is the construction of a frame - a post-and-beam structure from high-strength materials and filling the walls with inexpensive but high-quality raw materials.

The technology for constructing walls is as follows: assembling and installing the frame on a finished base - the foundation, laying insulation into the frame, installing steam and waterproofing, cladding the frame both from the inside and from the outside.

Frame baths are in enormous demand in Finland, Germany, the USA and Scandinavia. But recently, they are well winning their place in the sun in our country.

Advantages and disadvantages

Structures erected using frame technology, of course, have advantages and disadvantages. First, let's examine the undeniable advantages.

- Durability. Frame structures are durable and reliable, and therefore have a long service life.

- Environmental friendliness. Baths are built from environmentally friendly raw materials.

- Safety. Frame structures do not harm human health.

- Aesthetics. The designs are attractive.

- Ergonomics. The steam rooms are comfortable.

- Economical. The construction of a bathhouse will cost approximately 5,000 rubles per square meter.

- Speed of construction. The steam room has been under construction for about a month. But a good professional construction company will do its job much faster.

- Lightweight design. The frame is known for its low weight, so it is installed on a lightweight foundation.

- Seismic resistance. The structure can withstand vibrations of up to 5 points.

- All-season. The steam room is built not only in summer, but also in winter, but at a temperature not lower than -15°C (not comfortable to work).

- Non-shrinkability. The structure is not subject to shrinkage, which is why facing work is carried out immediately after the construction of the facility.

- Versatility. The surface of the bath goes well with any finishing raw material.

Now let's deal with the negative aspects.

- Money spendings. The construction of a bathhouse using frame technology is inexpensive, but insulation and finishing require large financial investments.

- Harm. As a rule, the frame for baths is made of wood, and it is, of course, absolutely safe, but the insulation, especially the cheap one, may contain harmful substances that become very “toxic” when heated, for example, polystyrene foam.

- Deterioration of performance characteristics in the cold season. Frame baths heat up quickly, but also cool down at lightning speed.

In principle, if you choose high-quality insulation and stock up on a lot of firewood, then a frame bathhouse is a pretty good option. And reviews from steam room owners are positive.