The idea of building a bathhouse from a container looks quite unusual. It would seem, why equip a bathhouse in a metal box if you can build a light frame building and arrange the bathhouse according to all the rules. Perhaps the idea is worth trying to put it into practice. Well-appointed houses and cottages are built from container structures, why not at least try to plan how to make a bathhouse from a container.

What is the value of a container bath

Making a bathhouse from a container box is relatively easy. All you need to do is develop and plan:

- A system of powerful insulation of metal walls, otherwise in winter the sauna from a container will turn into a glacier covered with condensation, and in summer in the sun the temperature will easily reach 70 ° C;

- Ventilation diagram of the internal space and auxiliary insulation cavities;

- Water supply for shower and steam room;

- Installation of a stove or electrical heating connection for lamps and fan drives.

All this is not difficult to do, if not for one “but”. On the one hand, it is possible to sheathe or cover a metal box with bricks, SIP panels, aerated concrete slabs, and problems with room insulation and corrosion protection would be solved. But why then fence a garden with a heavy metal body? Offhand it turns out that it is cheaper to build a bathhouse without a container insert.

Most owners choose to build a bathhouse from a container, photo, if they require:

- Build a bathhouse with a strong frame for installation on heaving loams or sandy quicksand. Buying and building a full-fledged bathhouse from a 20 English foot container will cost less than the hassle of rearranging timber or log crowns;

- Make a small-sized steam room on wheels, which can be taken for a season to a vacation spot, to a country house, or to a full-scale construction site. A bathhouse made from a 5-ton container can easily fit in the back of a Bull or a Ford truck.

Important!

A container bathhouse does not require a full foundation, regardless of whether it is a bathhouse made from a 20-foot container, or whether it is planned to use several 5-ton boxes. A flat area filled with sand and gravel is sufficient. Several container boxes, one of which is allocated for a dacha, after finishing and connecting communications, can easily serve as a full-fledged country house.

If the five-ton truck is used as an extension to an ordinary country house, the task can be simplified. For example, make only a steam room out of a container, and use the premises of a country house for relaxation and washing.

After trimming the side walls, the container body can become a frame for arranging an ordinary stationary bathhouse, built in accordance with all the rules and laws of heating engineering.

To do this, you don’t need to purchase a new or a whole container; you can buy a box with holes in the walls literally for the price of scrap metal, and it will be cheaper than:

- Pour the foundation;

- Spend half a cube of high-quality timber on the arrangement of racks and the upper and lower frame of the frame of the future bathhouse.

It will only be necessary to insulate the bathhouse on a container frame and veneer it both on the inside and on the outside of the building.

Layout

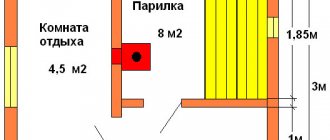

Everything is standard here. If a 20-foot container is chosen as the basis, then the bathhouse is usually divided into two sections: a dressing room and a shower room (often combined with a steam room). The 40-foot configurations are more like the usual options - a waiting room, separate shower and steam room. It is clear that with a compact footage, each section will hardly accommodate more than one person.

For compact compartments, it is recommended to use electric ovens, which take up little space but use stones to generate heat. In 40-foot baths, you can use a regular “wood stove” with a small boiler.

Container bath problems

Most developers planning to build their own bathhouse on a suburban site pay increased attention to container-based steam rooms and sauna projects. Often, three factors, which many private owners are familiar with only through rumors, keep them from building a bathhouse from a container with their own hands:

- Significant cost of implementing a bathhouse project from a container;

- The metal of the case is subject to severe corrosion;

- In the summer, the interior of the steel container turns into a stove.

The main argument of opponents of the idea of building a steam room from a container is the rather small number of offers of a ready-made bathhouse from a 20-foot container on the real estate market. This is not entirely true. Firstly, most specialized construction companies offer custom-made bathhouses from a container according to a standard design. One of the options, costing about 500 thousand rubles, is given below.

Such a bathhouse made from a 20-foot container photo is divided into three rooms with an area of 10-12 m2:

- Steam room with electric stove;

- The second box is a dressing room and a wash room with a shower;

- The third room is reserved for a locker room and a rest room.

The internal space, 6 m long and 2.2 m wide, is lined with clapboard, the external walls can be finished with siding or block house. The price for a finished bathhouse from a 20-foot container is clearly too high, which limits the mass demand for the product.

Secondly, there is a certain shortage of sea containers on the market. Companies involved in the production of premises from sea containers buy them in small quantities from carriers. A new or three-year-old box in good condition will cost at least 40-50 thousand rubles. If you set a goal and build a bathhouse from a 20-foot container for yourself, then with some patience you can find a single box in good condition for 25-30 thousand rubles.

Container finishing and insulation work

After installing and securing the container on the supports, work is carried out to bring the module into proper form:

- Clean surfaces from rust and treat them with anti-corrosion compounds. All existing cracks are filled with putty.

- The inside of the walls is sheathed with thermal insulation, then with foil material.

- A bathhouse made from a 20-foot sea container is usually lined with wooden beams on the outside; examples are shown in the photo. Modern options are profiled or laminated timber. It is treated with compounds to increase moisture and fire resistance.

- Installation of flooring. It is usually made from boards laid on joists. Thermal insulation material is laid between the metal bottom and the boards.

- Installation of double-glazed windows. For this purpose, double-glazed windows are recommended, providing good heat-saving characteristics.

- Installation of partitions. To make the frame, timber is usually used, which is then sheathed with boards. Finishing material – lining. Aspen is traditionally used for finishing interior surfaces. The use of coniferous wood in the steam room is not recommended, since at high temperatures resinous substances are released from it.

- Furnace installation. A modern option for heating a bathhouse is an electric stove. All surfaces adjacent to the heating unit are covered with non-flammable materials. If there is no hot water supply from a centralized pipeline, then a large storage tank is installed in the bathhouse.

How to prevent corrosion

The metal of most container models has practically no special properties. To protect steel walls from moisture and salts, the surface is phosphated and treated with special primers. If you already have plans to build a bath complex, then it is best to equip the bathhouse with your own hands from a sea container.

Such a building will easily last a couple of decades, while ordinary container boxes can be subject to corrosion due to improper ventilation of the steam room and insulation.

Advice! The simplest way to protect a steel body from corrosion is to use zinc or magnesium anodes. The rods are buried in the ground to a depth of 50-70 cm, and the leads are soldered to the metal walls of the room.

Subtleties of finishing work

When deciding how to build a bathhouse from a container, you need to rely on the essence of the base material. The metal base requires a special approach when selecting and assembling the skin.

Interior decoration

Wood is considered the most suitable solution for decorating a bathhouse from a container with your own hands; there are no special requirements for the species, you just need to avoid coniferous materials. Construction using wooden lining allows you to avoid the release of toxic substances and unpleasant odors during heating; the surface retains heat and has an aesthetic appearance.

To increase the resistance of the material to moisture, fire, and damage by microorganisms, it is advisable to impregnate the skin with protective compounds. Please note: you cannot paint the inside of the bathhouse.

Facade cladding

Exterior cladding can be made using a wide range of materials. Bathhouses built from containers and decorated with clapboard look neat and presentable. It is customary to use aspen here, since as a result of drying it acquires special strength and the ability to serve for a long time. Also in demand are oak and pine variations, glassine and heat-resistant plastic.

Decoration of the facade of a container bath

The rectangular shape of the steel box simplifies the task somewhat. In the most budget-friendly option, the bathhouse body can simply be painted in a pleasant color, white or red. Light colors are very popular among developers in the southern regions, where it is important to combat the heat of the sun, which heats any metal in the summer. White paint reduces heat by 30-35%. If we add foil thermal insulation to this, then the problem of overheating can be considered solved.

The second most popular finishing method is wall cladding with a block house, wall paneling or regular siding.

If you add a roof and a wooden porch to the wooden cladding, you can successfully hide the very fact of using a container in the construction of a bathhouse under the outer cladding.

If the bathhouse is attached to the house, then it would be quite logical to line it with the same material as the main building. For country and mobile bathhouse options, it is best to limit yourself to painting the external walls. If the container is new, with factory paint, then such a three-layer coating will last much longer than a semi-handicraft repainting with automotive enamel.

Interior decoration

Internal work begins with the electrical connection and installation of water supply lines. The wiring is routed and hidden in protected boxes and cable channels. Next, you need to lay thermal insulation, vapor barrier and waterproofing in several layers over each floor. It goes without saying that the walls of the container must initially be cleaned with an anti-corrosion compound and treated with protective liquids. The “insides” of the bathhouse are finished with clapboard or timber. The owner determines the configuration of the sunbeds himself. The dressing room is also used to decorate the waiting room.

How to properly build a sauna from a sea container

Immediately after purchasing a 20-foot container, the first thing you need to do is check for damage to the walls and places with painted over, putty, rusty holes. A rusty hull costs half the price of a container in good condition, so owners widely use automotive putty and marine paints to mask problem areas. You can identify a hole in the wall with a magnet or a special device.

Which foundation to choose for a bathhouse - container

Despite the fact that a bathhouse can stand for many years even on a simple platform with crushed stone, most owners prefer to install it on a foundation.

A lightweight five-ton container for a steam room is usually installed on columnar supports cast in concrete formwork or built of brick. If the place for the bathhouse is chosen in the forest, or on the shore of a reservoir, then it is recommended to make a crushed stone cushion under the supports. To do this, dig mini-pits according to the number of pillars to a depth of 60-70 cm, fill them with a mixture of fine sand and gravel screenings. Such a foundation will support even a forty-foot container.

Often, the owners of a future bathhouse pour a slab foundation under the container block, motivating their decision with insurance against sagging of the building and the desire to install a second floor in the future. This is not the best option for a bathhouse. The container body is so strong that it will withstand even the collapse of 40% of the supports, and the concrete under the floor will require serious insulation of the bathhouse subfloor.

Insulation of container walls and ceilings

The main issue in building a bathhouse is always the choice of insulation method. At the first stage, the walls and ceiling are sheathed with wooden slats, providing a ventilation gap. Next, the material is selected.

Metal walls can be insulated in three ways:

- A multi-layer sandwich made of foamed foil polyethylene with an additional layer of aluminum foil laid on the crate;

- Stone fiber mats with a glued layer of foil film. This type of insulation is used exclusively in saunas;

- A “pie” of polyurethane foam from the inside of the container and polystyrene foam on the outer surface.

Thermal insulation based on polyethylene foam and stone fiber must be sheathed with a vapor barrier. A 20-foot container will require at least one and a half rolls of film.

The insulation layer is sewn up with a wooden lath; for a three-room bathhouse you will need at least 80 m2 of linden or ash finishing. The gap between the container wall and the fiber must be ventilated after each visit to the bathhouse.

You can insulate the container space by spraying polyurethane foam directly onto the metal and sheathing slats. Next, a layer of vapor barrier, film and decorative finishing are laid. In this case, the dew point moves to the metal surface of the container.

The most optimal insulation option is considered to be the internal lining of the steam room compartment of the container with stone fiber with an aluminum screen. Layer thickness is at least 50 mm. Next, the outer walls of the bathhouse are covered with penoplex, at least 50 mm thick. The facade of the container is plastered or covered with clapboard.

Arrangement of the bathhouse floor in a container version

Expanded polystyrene insulation is laid on the floor of the bathhouse, over which a screed with a thickness of at least 100 mm is poured. In shipping containers, the floor is almost always made of thick, moisture-resistant plywood; polystyrene foam and concrete screed can be laid directly on the plywood base.

The next step is to lay a layer of mastic waterproofing over the concrete, install larch logs and install a ventilation system for the underground space. A wooden floor is laid on the joists. Most of the water and condensation that gets on the floorboards will be removed from the subfloor by the ventilation system.

The floor in the dressing room is arranged in a similar way; in the locker room or rest room, you can lay tiles directly on the concrete screed, and a lower level of flooring will make cleaning the premises easier.

How to deal with condensation inside a bathhouse

The steel walls of a container can become a source of serious problems, primarily due to the metal’s impermeability to water vapor. Even with special treatment of metal parts under conditions of warm condensation and detergent vapors, pitting corrosion can form on the walls of the container. Especially if window openings were cut out, holes were drilled for screwing in self-tapping screws, and laying communications.

Wherever the protective coating has been damaged, the metal will rust. In addition, the wooden sheathing on which the entire internal lining is supported easily absorbs moisture even under a layer of varnish or oil impregnation.

There is only one way to prevent container corrosion - by providing effective ventilation. In fact, each room of the container is equipped with its own supply and exhaust ventilation, plus one system for ventilating the subfloor and places where condensation accumulates. Ventilation should be turned on every time lovers of light steam leave the bathhouse and the stove is extinguished. Due to the accumulated heat, the air accelerated by the fans effectively expels condensation at any air temperature outside the container.

Finishing the interior of the bathhouse

According to the standards, the requirements for cladding with wooden slats apply only to the steam room or sauna. In the Turkish bath, the walls of the hot compartment can be finished with ceramic tiles.

The dressing room with shower compartment is lined with wooden panels, clapboard or board. The space for the shower can be separated by a wall and tiled with ceramic tiles. The shower floor is equipped with a drain without a tray, or a plastic shower cabin is simply installed. All parts of the wooden finishing of the bathhouse must be treated with impregnation with fire-retardant additives.

How to properly install a stove in a steam room

Regardless of what type of heater, wood-burning or electric, will be used to heat the container sauna, it is necessary to measure or calculate the volume of the steam room. Based on the resulting cubic capacity, the thermal power of the heater required for the bath and its location are determined.

For a sauna built in a container, the most preferable option would be a wood-burning steel or cast iron heater. It will be difficult to heat the huge steel body of the bathhouse using electricity.

The location for installing the stove is selected next to the partition separating the rooms of the dressing room and the steam room of the bath. The housing is mounted closer to the wall of the container so as not to block the passage and simplify the removal of the pipe. In this case, part of the wooden cladding of the wall behind the stove is removed and replaced with heat-resistant tiles, and the base is laid out of it. A ventilation window is cut out in the wall next to the stove. The second window is cut into the opposite side of the bathhouse wall.

Features of choosing and installing a stove

Unlike traditional baths, where dozens of types of devices can be used, a compact steam room based on a metal frame can only function with a wood-burning or electric stove. In conditions of cramped free space, many install a compact metal tank. The easiest way is to buy a factory boiler: on the specialized market you can find small, convenient domestic and foreign models.

When choosing a place to install heating equipment, you need to take into account an important condition: heat under the influence of natural air movement must first be directed to the steam room. Therefore, it is recommended to install the stove in the area of the partition separating the washing room from the steam room. A gap of 20 cm must be left between the heating apparatus and the wall in order to comply with fire safety standards.

Start

A “Soviet-hardened” container made in 1985 was purchased from a friend at a reasonable price. Despite the presence of technical and not so technical holes that appeared over the years of use for other purposes, the design pleased me with its good condition, which made it possible to use it as a basis.

Navyrom

I watched people swear over trifles, looked at advertisements for the sale of cabins and sandwich houses, looked at the design and made it my own way. Let them criticize me, justify what I did wrong, but I will say right away that I will not pay attention to this and respond to various attacks directed at me. What's done is done, especially since the house will be used in the future as a summer guest house or for children's games. Or maybe I’ll sell it.

First of all, Navyrom installed windows and a door in the container, having previously studied topics on containers and cabins on the forum. I cut out the openings with a grinder with an allowance of 3 cm, welded a frame from a metal angle (60 mm) into the openings, secured the profile into the frame with self-tapping screws and centered it. Reinforcement for the doorway follows the same principle, only the side posts are extended from floor to ceiling and welded to the load-bearing beams of the container. All seams were sealed with foam. I made the roof a simple one, temporary - to practice and protect several welded seams from possible leaks.

What containers are used to build houses?

For the construction of houses, any models designed for transporting goods are used. Some are suitable for organizing living rooms, others for arranging passages, hallways, and bathrooms. However, the choice is limited. Manufacturers produce a certain range of products regulated by the ISO 668 standard. Existing options are shown in the table:

| ISO classification | 1 EE | 1 EEE | 1A | 1AA | 1AAA | 1B | 1BB | 1BBB | 1C | 1CC |

| Standard title, foot, Standard (S), High cub (hc) | 45 | 40 | 30 | 20 | ||||||

| S | hc | S | hc | S | hc | S | ||||

| External dimensions | ||||||||||

| Length, m | 13.716 | 12.192 | 9.125 | 6.058 | ||||||

| Length, inches | 45’0” | 40’ 0” | 29’ 11.25” | 19’ 10.5” | ||||||

| Width, m | 2,438 | |||||||||

| Width, inches | 8’ 0” | |||||||||

| Height, m | 2.591 | 2.896 | 2.438 | 2.591 | 2.896 | 2.438 | 2.591 | 2.896 | 2.438 | 2.591 |

| Height, inches | 8’ 6” | 9’ 6” | 8’ 0” | 8’ 6” | 9’ 6” | 8’ 0” | 8’ 6” | 9’ 6” | 8’ 0” | 8’ 6” |

| Inner dimensions | ||||||||||

| Length, m | 13.542 | 11.998 | 8.931 | 5.867 | ||||||

| Length, inches | 44’ 5.15” | 39’ 4.375” | 29’ 3.6” | 19’ 3” | ||||||

| Width, m | 2.330 | |||||||||

| Width, inches | 7’ 73” | |||||||||

| Height, m | 2.350 | 2.655 | 2.197 | 2.350 | 2.655 | 2.197 | 2.350 | 2.655 | 2.197 | 2.350 |

| Height, inches | 7’ 8.5” | 8’ 8.5” | 7’ 2.5” | 7’ 8.5” | 8’ 8.5” | 7’ 2.5” | 7’ 8.5” | 8’ 8.5” | 7’ 2.5” | 7’ 8.5” |

Conversion into a garage

The procedure for converting a container container into a garage includes several main stages.

Foundation preparation

It is best to use a screw foundation. It has the following advantages:

- reliability;

- there is no need to carry out earthworks;

- the ability to install piles into the ground - both using tools and by hand;

- Possibility of installation on any soil.

Installation

The algorithm for installing a container container is as follows:

- Installation of the container on the foundation using a crane.

- Roof installation.

- Laying cement slabs or sheet metal on the floor.

Entry device

The entrance to the premises can be arranged in the form of:

- A ramp is a gently sloping platform made from concrete or asphalt material. Sides are usually created on the sides (to prevent the car from leaving the ramp).

- Blind area - a concrete/asphalt layer that has a slope to drain rainwater.

- Screeds – sand-cement/concrete layer. Allows you to level and stiffen the surface on which the car will drive into the room.

Making a gate

The front door does not need to be changed. Typically, tanks have swing gates, which are quite convenient to use.

Interior arrangement

Install electrical wiring in the garage. Cover the ceiling and wall surfaces with plastic panels. You don’t have to do any finishing, but then the garage won’t look very aesthetically pleasing.

Step-by-step instruction

Converting a twenty-foot container into a country bathhouse begins with the preparation stage and includes the following steps:

- If the construction option without a foundation is used, then it is necessary to clean and mark the area and thoroughly compact the area. It is also necessary to equip a timber frame on a brick foundation.

- A waterproofing sand and gravel layer 150–200 mm high is poured onto the prepared area according to the markings, which is carefully compacted and moistened with water.

- For the installation of a sea container, a columnar foundation made of concrete or brick is built. The monolithic type of foundation is erected using formwork and reinforcement cage.

- After checking, the entire foundation is leveled using special pads. The container can be mounted using professional equipment and special equipment.

- Wall, ceiling and floor surfaces require insulation; they must first be cleaned and leveled as thoroughly as possible. Reliable thermal insulation is basalt wool, polyurethane foam or foam sheets, which are laid on top of the waterproofing layer. Thermal insulation work is not carried out on surfaces where heating equipment is supposed to be installed.

- The final stage of construction and installation activities is the internal arrangement of the bath structure. Installation of an electrical network involves the installation of lighting fixtures and sockets, a machine in the box, as well as fixing the corrugation to bring power out. For this purpose, cables with double insulation and a copper core, which has waterproof protection, are used.

- The issue of organizing a reliable ventilation system in the form of supply and exhaust openings in all rooms is being resolved.

For the interior lining of the bathhouse, it is recommended to use only natural wood (except coniferous trees). This finishing material is not capable of releasing toxic substances and unpleasant odors during heating. It has an aesthetic appearance and can also retain heat perfectly.

To give the wood sufficient fire resistance and to minimize the risk of fungus appearing under the influence of high moisture, the material must be treated with special protective compounds. The floor covering in the steam room is tilted towards the drain flange.

Bathhouses made from twenty-foot containers are today the simplest and most economical way to arrange a full-fledged structure for water procedures in a suburban area. This design is not only an excellent option to significantly save on building materials and attract workers, but also an opportunity to obtain a safe and all-weather building.

The idea of building a bathhouse from a container looks quite unusual. It would seem, why equip a bathhouse in a metal box if you can build a light frame building and arrange the bathhouse according to all the rules. Perhaps the idea is worth trying to put it into practice. Well-appointed houses and cottages are built from container structures, why not at least try to plan how to make a bathhouse from a container.

Zoning

When building a bathhouse from a block container, for maximum comfortable use, it is important to divide it into several zones.

It would be logical to provide them with the following arrangement:

- Locker room (aka rest room).

- Washing compartment (shower).

- Steam room.

In this case, the boiler installed to the internal partition of the steam room will heat two adjacent rooms, except the locker room. It is very convenient and practical.

Next, we will tell you how to select and install a suitable stove in a container bath.

What to pay attention to

At first glance, you can build a bathhouse from a construction trailer with your own hands in a couple of days. The rigid frame of the cabin does not require additional measures to strengthen the walls and floor. The trailer room is already insulated during the manufacture of the box.

In theory, you will need to make only small additional equipment for a bathhouse with your own hands:

- Lay electrical wiring to connect lighting and ventilation systems, heating, if an electric heater will be used in the steam room of the bathhouse instead of a wood-burning stove;

- Supply water, make a drain for the shower and steam room, connect communications to the septic tank or sewer;

- Finish and install the stove.

Important! In practice, everything turns out to be more complicated. Before making a bathhouse from an iron trailer, you will need to solve the problem of arranging steam and thermal insulation

The problem is that the steel or aluminum walls of the trailer, as well as modern sandwich panels based on bakelite plywood, do not allow water vapor to pass through at all.

The task is not even how to make a bathhouse from a change house, it is important to ensure maximum comfort and durability of the building

In such a situation, you have to choose - either build a bathhouse from a construction trailer with metal walls, durable and reliable, capable of standing for 20 years in the middle of a swamp, but at the same time rack your brains and look for the best insulation option. Or look for a ready-made change house assembled from timber. In this case, the construction and insulation of the bathhouse is no different from the arrangement of a conventional frame steam room.

Extension

To prevent the house from looking “scrappy”, and also to provide the family with comfort, Navyrom made an extension to the container - an open veranda and a closed sanitary unit. To do this, I lifted the container onto FBS blocks and welded a frame from a metal profile with dimensions of 2x4 m. Although there is a crushed stone cushion under the blocks, in order to prevent possible problems associated with the difference in the movements of a heavy container and a light extension, I made a bolted connection. Also, such fasteners, if necessary, will allow you to disassemble the structure if you have to transport it.

The sewer system was organized on the basis of a two-chamber plastic septic tank with a volume of 3 m³ and a drain well made from used truck tires. The well was dug to a depth of 3.5 m - at this depth the sandy soil begins, and the wastewater is absorbed without stagnating. I immediately laid a sewer pipe to the bathroom to simplify the installation of plumbing equipment in the future.

The floor on the veranda is made of bakelite plywood, 18 mm thick, the outer cladding of the bathroom is OSB, the internal cladding is spruce plywood, 12 mm thick. From the inside there is a vapor barrier using OSB, a lathing made of timber to match the size of the OSB boards. Since there were no plastic windows of the required size on sale, I installed wooden windows purchased at a bathhouse store. Finishing with plastic panels, linoleum on the floor, on top of an electric film heated floor. Amenities include not only a sink and compact, but also a walk-in shower.

Initially, I planned to use a gable roof for the toilet, but as a result, I dismantled one side and extended the slope to the required size.

The facade was covered with thermal panels (polyurethane foam/metal/protective and decorative layer), the problem arose due to the dimensions - instead of the stated 3800 mm, they came across shorter sheets, I had to buy two more pieces and wait for delivery.

Heating device

At the bathhouse design stage, it is worth considering what energy source we will use. This is an important point, because you will need to think about how energy will be supplied and by what methods. Bath boilers are of the following types, namely:

- Electrical.

- Woody.

Depending on the size of the container, 5-20 or 40 pounds, the actual heat source is selected. I would recommend a wood-burning stove, it warms up faster and is more efficient. Well, you should choose the size based on the size of the steel container that will be used as the frame of the building.

In order to provide the bathroom with hot water, it is worth considering in advance the plumbing methods for wiring from the boiler.