Here’s what’s interesting: despite all the intuitive clarity of the term “waterproofing,” it actually turns out that in practice there are different meanings hidden behind it.

We will try to sort out some of this issue in this article. However, it will be limited only to waterproofing the walls in the bathhouse. You can read about other parts of the building that need it in the corresponding section on our website.

Features of the interior decoration of aerated concrete baths

The bath should not only be warm, but also attractive in appearance.

The appearance and performance of the premises depends on the choice of cladding. Aerated concrete has good thermal insulation properties, but as it absorbs moisture, it will gradually deteriorate. Therefore, the finishing of walls is approached with special care. To create the effect of a thermos, the inside of the bathhouse is covered with foil. This material is able to reflect heat inside the steam room and also reliably seals the walls. Self-adhesive film is laid overlapping, ordinary foil is mounted end-to-end. The seams are taped with metal tape. A ventilation gap is created between the reflective material and the clapboard sheathing using sheathing.

Wiring

Before finishing with clapboard, it is necessary to install electricity. Aerated concrete can be easily sawed, so there will be no difficulties with gating. The wires are laid according to the diagram made at the design stage. This plan will be useful for wiring repairs. You need to take care of grounding.

Clapboard finishing

Traditionally, the bathhouse is lined with clapboard - a suitable type of wood is selected for each room. A steam room with high temperature and humidity requires the use of lining with low thermal conductivity and increased moisture resistance. These are aspen, linden, alder. The rest room can be lined with conifers; they have a beautiful structure, and the resinous aroma is good for health.

Aerated concrete allows you to build smooth walls, so the sheathing is placed directly on them. The boards in the steam room are fastened with clamps, in other rooms they are nailed. The clapboard is not attached near the stove; for fire safety purposes, this area is trimmed with stone or brick. In the shower room, if desired, the walls and floor are tiled.

Floor options

A bathhouse made of aerated concrete blocks is equipped with a wooden or concrete floor. The wooden flooring consists of a rough and finished floor. The slope of the structure ensures water drainage. Concrete flooring is a more practical option; it will not rot from moisture. Laying ceramic tiles can make the coating look attractive.

The finishing touches remain:

- collect sunbeds

- nail the baseboards

- install sockets and switches

What is the best way to decorate a bathhouse inside?

The choice of material type depends on the style direction. A modern manufacturer offers ample opportunities to create a unique interior of a bath complex.

Plastic panels

Washing area finished with plastic panels.

They are produced wide (wall panels) and narrow (lining).

The advantages of this material are as follows:

- Moisture resistance.

- Variety of colors and styles.

- Easy to install.

- Affordable price.

- Durability.

The disadvantages of panels include:

- Poor resistance to surface damage.

- High level of fire hazard.

- Low vapor absorption.

Combined wood and decorative stone finishing.

PVC siding

Siding is not susceptible to fire even when in contact with an open fire.

He is not afraid of accidental damage or scratches with sharp objects. In addition, it is plastic, thanks to this property you can successfully hide uneven walls.

Decorating walls with siding is simple and affordable, it can be easily done with your own hands, and the variety of colors available and the cost of the material will suit the taste and wallet of the most demanding buyer.

We invite you to familiarize yourself with Insulating a cinder block house - How to insulate a cinder block house from the outside with your own hands: -instructions for insulating cinder block walls from the inside, photo and price

Ceramic tile

Finishing the bath with mosaic tiles.

Tiles can be called an ideal material for covering surfaces in damp rooms, such as a sink or steam room.

Its advantages are obvious:

- Moisture resistance. The specially treated surface of the tile does not absorb moisture at all.

- Resistance to elevated temperatures. Modern technologies make it possible to produce heat-resistant tiles that are used to line fireplaces and stoves.

- Strength and durability. Properly laid material will serve for many years without changing its qualities and appearance; it is almost impossible to accidentally break a tile; in the worst case, you can break off a piece.

- Resistance to fire and aggressive chemical environments. The walls can be washed with any household cleaning products, and there is no fear of fire.

- Eco-friendly and hygienic. The tiles are made from natural materials; mold and microorganisms do not form on its surface.

Finishing with a pair of wooden clapboards.

A wide range of sizes, colors, and types of processing allows you to choose a collection for any interior.

Tree

It is generally accepted that the best bathhouse is one made of foam blocks, the walls of which are decorated with wooden slats (lining). And although wood does not have many of the advantages inherent in other materials, consumers still often prefer it.

What qualities of wood attract builders:

- Vapor permeability. In a bathhouse lined with wood, the steam is drier, the air is cleaner, and the walls “breathe.”

- Low thermal conductivity. The well-processed smooth surface of the boards is pleasant to the touch and has an ambient temperature.

- Environmental friendliness. Being in a steam room with walls decorated with natural wood is not only pleasant, but also useful. The essential oils released by wood have a beneficial effect on health.

- The beauty of wood texture.

Steam room covered with clapboard.

https://www.youtube.com/watch?v=BtA6Bqae0Qo

Aspen, linden, and alder are used for cladding the steam room. These rocks are resistant to deformation and do not crack due to temperature changes; in addition, they have healing properties that increase when heated. The sink and rest room can be decorated with larch, pine, and cedar.

Waterproofing films Ondutis

To waterproof the floor in a bathhouse made of aerated concrete blocks, a vapor barrier film Ondutis R100 or Ondutis D (RV) is used. Laying the material is carried out similarly to the processes described above

In this case, much attention is paid to waterproofing the joints, since the panels must be connected without the slightest gaps

Ondutis waterproofing films are modern materials of the highest quality. Several types of films are suitable for waterproofing work. Let's list some of them:

- Ondutis R100 is an environmentally friendly material widely used in waterproofing in aerated concrete baths. Polymer fabric has excellent performance characteristics: high tensile strength, non-decomposition. The material prevents the insulation from getting wet and causing mold;

- Ondutis D (RV) is a new generation universal film characterized by good performance characteristics. It protects structures from the harmful effects of condensation and serves for a long period of time. The gray material has high tensile strength and environmental friendliness;

- Ondutis R Thermo is a two-layer material coated with a protective coating. The heat-reflecting vapor barrier film prevents moisture from entering the enclosing structures.

Waterproofing a bathhouse made of aerated concrete, equipped with Ondutis films, is the ideal solution. The materials improve insulation performance and effectively protect walls, floors and ceilings from high humidity.

Wiring

To conduct electrical wiring in a bathhouse, you must first select a suitable cable to avoid overloads and overheating.

Since this room has high humidity, to ensure maximum safety, it is necessary to carefully insulate the wire.

It is best to mount the wire in channels that must first be hollowed out.

For complete safety, you need to place a circuit breaker at the input of electrical networks; also, it is better to equip each electrical line with a separate fuse.

Switches and sockets should be placed in the safest place possible and should not be exposed to water to prevent short circuits.

Before starting finishing work, it is necessary to install the electrical wiring. The plan for the latter should already be indicated in advance in the project documentation. In general, the speed and quality of all work performed directly depends on how well the project is drawn up. A person who does not have to invent or invent anything during construction processes works much more productively.

Recommendations for working with wiring:

- The cheapest option, of course, is to use NYM corrugated electrical cable, but firefighters recommend that wiring in the bathhouse be carried out only in metal pipes. And, to tell the truth, it is very difficult to argue with them, because, among other things, mechanical damage to the uncovered NYM power cable is possible (for example, by mice), which will negate all the reliable German technology. So if you want to play it safe and protect yourself from fire, it is better to lay the wiring through metal pipes.

- To find the wiring after a few years, you need to lay it in the walls at a distance of 150 mm from the level of the finished ceiling, and all descents are made strictly perpendicular to the floor.

- Even before creating the project, it was necessary to reservely calculate the entire load on the wiring. And, based on these data, select the required cross-section of electrically conductive wires. So during installation, check the design and lay cables only of the required cross-section.

- All non-sleeve connections of wires are soldered.

- Don't forget about such an important point as grounding. When operating modern electrical appliances, it is mandatory.

- When lighting the steam room itself, it is necessary to use step-down transformers.

Of course, with impeccable installation, standard 220 V is also quite safe. But the price of human life is too high to put on the same scale with a random mistake.

Drafting

The positive aspects of aerated concrete do not in any way affect the success of the construction process. In order for the idea to build a bathhouse from aerated concrete to be successful, it is necessary to think through each stage of the construction process. To do this, it is necessary to draw up a project. This is what you will have to focus on when carrying out activities at the construction site.

Many experts note that creating a project for such a structure from scratch is quite a serious task. Not all architects can cope with its successful implementation. Therefore, a more reasonable solution would be to use a ready-made outline plan, to which changes are made in accordance with the customer’s preferences.

When drawing up a project for a bathhouse made of aerated concrete, the following important points must be present in this document:

- Dimensions of the object.

- Layout. It is also necessary to indicate the dimensions of individual rooms. In relation to a bathhouse, the design must include the dimensions of a steam room, a rest room, as well as a vestibule and a bathroom.

- Type of foundation used.

- Method of installation of furnace equipment, its main technical characteristics and location option.

- Features of communications supply. It is necessary to describe in detail how the ventilation system and chimney will be installed.

When the design work is completed, you can proceed to the preparation of the materials necessary for construction work. Naturally, you should also think about purchasing the necessary tools that will allow you to carry out the necessary activities efficiently and quickly. The main material for the construction of such a bathhouse, of course, is aerated concrete blocks. In addition to them, you will need:

- dry cement;

- adhesive for aerated concrete;

- ladle or carriage for adhesive composition;

- reinforcing bars;

- roofing felt;

- rubber hammer;

- hacksaw;

- sand;

- grater;

- level.

When choosing a material, you should not purchase cheap blocks. You need to understand that the lower their price, the less correct the shape will be. And this affects the quality of the work performed. Of course, aerated concrete should not have defects in the form of chips and cracks. Otherwise, you can immediately forget about the dream of building a reliable structure.

The main types of bathhouse projects: standard and individual

A bathhouse made of aerated concrete blocks with an attic is now in great demand. It occupies the entire first floor, and above are guest lounges and a billiard room.

Increasingly, architects are being approached to develop an individual project for a bathhouse built from aerated block. So, below is one of them. The smallest room here (5.7 sq.m.) is the shower room, and the steam room (6 sq.m.) is designed so that it can accommodate several people at once.

Proper natural ventilation is also provided here. So, the windows in the steam room are located on the opposite side of the front door. The top point of the window opening coincides with the highest mark of the front door.

This design of a bathhouse made of foam blocks implies the presence of a vestibule, which means the possibility of using the building in winter. If it will be used exclusively in the summer, then it can be formed close to the main building.

Below is a photo of such a project.

A project with a well-thought-out ventilation system

Below is a version of a bathhouse with dimensions of 6x6 m. The dimensions written in the drawing already take into account the width of the partitions and the thickness of the walls. The vestibule is planned as a separate extension.

The resulting areas are as follows:

- dressing room and at the same time a room for storing firewood - 1.7 sq.m.;

- shower room – 7 sq.m;

- steam room – 5.3 sq.m. The placement of three tiers has been thought out here: two of them are lying down, and the top one is for seating;

- rest room – 11.2 sq.m. On its side there is a furnace firebox;

- bathroom – 1.8 sq.m.

Design of a bathhouse with dimensions 6x6 Below is a possible typical design of a 6x4 m bathhouse.

Typical design of a bathhouse with parameters 6x4

Some project customers are considering the option of placing a sauna directly in the aerated concrete house itself.

Pros and cons of the material in the design of the bath

Since aerated concrete has the highest thermal insulation properties and is not inferior in durability to stone buildings, bathhouses made from this material are widely used. Such a structure has a number of advantages that are especially appreciated by developers.

Aerated concrete bathhouse pros and cons:

- Lightweight blocks allow you to do the laying yourself; no loaders are required to move the blocks on the site.

- Strict geometric shapes make the laying process easier, even for beginners.

- Heat resistance and fire resistance are important qualities for a bathhouse where there is a possibility of a fire hazard from the stove. In terms of the level of thermal insulation of such material, they are no worse than timber.

- Possibility of use for the construction of strip foundations.

- Environmental Safety.

- Biological resistance to the formation of fungal mold and moss.

- The budget price of building a bathhouse from aerated concrete is a significant advantage in favor of developers using the material.

- Aerated blocks have virtually no shrinkage, so you can begin finishing work immediately after erecting the structure.

There are no ideal materials in nature; they all have disadvantages; for aerated concrete, this is high moisture absorption. But the masters have learned to successfully cope with this problem. In order to build a durable facility, reliable waterproofing of the walls is carried out, in this case the bathhouse will last a long time.

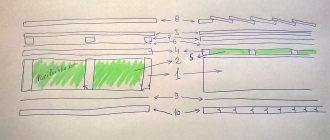

Installation of a “pie” of insulation from the inside

In addition to the very need to insulate the bathhouse from the inside (including with your own hands), it is important to make the right insulation “pie”

ATTENTION! The order of its compilation is clearly structured and should not be violated:

- lathing on a load-bearing wall;

- insulation;

- vapor protection and waterproofing;

- ventilation gap (can be arranged with a sheathing device, it is required);

- Decoration Materials.

REFERENCE: We recommend treating all finishing wooden materials with special compounds and oils to protect them from moisture and preserve their decorative properties.

For lathing, you can use wooden blocks or a metal profile. We recommend treating the former with an antiseptic to increase service life, and choosing metal profiles from the galvanized category (not subject to rust).

IMPORTANT! Try to make U-shaped lathing, this will lighten the structure, the weight of which is important for buildings made of blocks. Some fasteners can be replaced with galvanized ties. It is best to use dowels as fasteners: they will make it easier to work with blocks that have a stronger structure than wood and will provide a tighter connection

Although, in order to save money, it is permissible to use wood screws

It is best to use dowels as fasteners: they will make it easier to work with blocks, which have a stronger structure than wood, and will provide a tighter connection. Although, in order to save money, it is permissible to use wood screws.

A ventilation gap is left between the finishing materials and the layer of vapor and water protection so that condensation can flow down without affecting the insulation.

Insulation of walls in a bathhouse made of foam blocks (the diagram is suitable for all block walls of bathhouses)

Characteristics of aerated concrete blocks

Aerated concrete blocks are based on cellular concrete, made by mixing binders, fillers, additives and water. Cement is usually used for the binder; lime and quartz sand are used as fillers.

Advantages as a material for assembling a bathhouse

The blocks are large in size and light in weight, which greatly facilitates the work of builders. Assembling aerated concrete walls does not require special knowledge and experience, so even a novice master can cope with the task.

Construction of a building will cost much less than creating a brick or wooden structure.

Aerated blocks are characterized by high thermal insulation, so the bathhouse will not require serious insulation. The material is durable, fireproof, easy to process, and environmentally friendly.

It is easy to lay internal communications in a bathhouse made of aerated concrete. The blocks are easy to process by gating.

Flaws

The obvious disadvantages of aerated concrete include:

- Poor geometry, which cheap blocks suffer from;

- The need for complete waterproofing of the foundation;

- Ease of water absorption.

The last drawback calls into question the profitability of building a bathhouse from aerated concrete. But professional craftsmen say that high-quality interior finishing will help completely cope with the problem.

Small things

After installing the lining, the matter, in fact, remains small. Nail platbands, baseboards and various corners - flashings. Install sockets, boxes and switches. Finally connect the heated floor. And also eliminate all those minor imperfections and shortcomings that were left for later. All these little things, at first glance, are insignificant, but they will certainly take up more than one day of your time, and therefore, when doing work, try to leave as little as possible for later.

Vasily Molka, rmnt.ru

24.10.14

The most important thing: choose insulation

Insulating a steam room is a procedure that was performed hundreds of years ago. Then, to make this room warm, they used natural materials: moss, flax, hemp, hay, oat scraps. This is definitely super eco-friendly, but too impractical for insulation nowadays. Such materials rot too quickly, become thin and attract insects. Therefore, they need to be updated almost every season, which is too energy-consuming.

You should not choose natural materials for insulating a steam room in a bathhouse - they are short-lived and susceptible to rotting and insect attacks. Although they have no equal in environmental friendliness

In the 21st century, innovative materials are used for insulation in the steam room. They cannot be called super environmentally friendly, but:

- they are safe for people;

- do not emit harmful and dangerous substances;

- They last a really long time - about 20-30 years without annual renewal.

The pros and cons of insulation materials and prices for insulation materials are presented in the table. It will help you decide which substance to choose to update your bathhouse (specifically, for insulation).

| Insulation | pros | Minuses | Price |

| Basalt wool | Does not burn, does not deform, is not afraid of moisture, absorbs noise, does not release heat for a long time | High price | 300-600 per sheet with sides 100×50×5 millimeters (this is exactly what is needed for the steam room) |

| Expanded clay | Very light, cheap, does not deform, can fill any spaces and voids, is not afraid of high temperatures and temperature changes | Absorbs moisture and therefore requires increased waterproofing; Doesn't retain heat very well | 25-35 per liter |

| Foil mineral wool | Perfectly retains heat in the room, has the ability to reflect infrared rays; does not absorb moisture, lasts a long time | Relatively expensive | 500-600 per sheet with sides 1000×600×30 mm |

| Styrofoam | It is cheap, weighs little, does not absorb liquid, does not form condensation | Retains heat poorly, does not allow air to circulate, is afraid of exposure to high degrees - it can melt | 100-150 rubles per sheet with dimensions 1000×500×30 mm |

| Expanded polystyrene | Lightweight, not afraid of elevated temperatures and moisture | Cannot be used near open fire, does not allow air to pass through | 150-200 rubles per sheet 1000×600×30 mm |

| Foil polyethylene | It is inexpensive, retains heat well, is not afraid of water and steam, and reflects infrared radiation | Does not breathe, melts under increased load, can release corrosive substances at very high temperatures (150-200 degrees Celsius) | 1,500 rubles for a 25-meter roll one meter high (this is more than enough for insulation measures) |

| Foil cardboard | Costs little, light weight, small sheet thickness, it is not afraid of water, steam, high loads, reflects infrared rays | Does not allow air to circulate freely, does not retain heat well | 200-250 rubles per sheet 100×50×5 millimeters |

Important: experts advise not to skimp and purchase basalt insulation for insulation measures. It is considered the most durable and reliable for insulation

No analogues have yet been invented. If your budget does not allow, opt for expanded clay or foil mineral wool.

If you want to enjoy the time spent in the steam room in the bathhouse, insulate the walls, floor and ceiling with basalt - nothing better has been invented yet

If basalt, expanded clay or foiled mineral wool are unavailable, use any other insulation presented above for its intended purpose.

The video will show you how to choose an insulating material.

Watch this video on YouTube

Lining for room cladding

You should take a responsible approach to choosing wood for cladding. The greatest resistance to decay is inherent in coniferous species, but when heated they are capable of releasing resin. Therefore, it is better to use them when covering a dressing room or washing room. Of the deciduous species, oak has the optimal resistance; however, when wet, it becomes slippery. An important factor when choosing lining is the aesthetic side of the issue. Cedar, oak, and alder have rich, dark colors, while larch, hornbeam, and spruce are lighter in color.

Windows and doors in the bathhouse

It is advisable to make them wooden, for which pine or ash are suitable, and varnishing is allowed only on the outside, otherwise harmful fumes cannot be avoided. For the same reasons, it is not recommended to use polyurethane foam as a sealant; it is better to use natural materials, such as felt.

The windows in the bathhouse serve only for lighting, therefore, in order to reduce heat loss, they are made small and placed low.

Special attention should be paid to the door to the steam room - it should open exclusively outward and close only with a ball latch, so that it can swing open simply from a push or under the weight of the body if one of the visitors becomes ill. Dimensions are smaller than standard (to avoid waste of heat).

Electrical wiring in the bathhouse

When installing the electrical network yourself, you should not forget that in aerated concrete walls the cable, wound into a corrugated tube, is laid along grooves cut into the blocks. It is first recommended to carefully develop a layout of electrical appliances, as well as lighting points, sockets and switches inside the room.

According to the calculated power of lamps and other electricity consumers, it is necessary to select a cable of a suitable cross-section in order to avoid overloads and heating of the wire. Since the bathhouse is a room with high humidity, the insulation of the electrical network should ensure maximum safety, and sockets should not be located too close to the floor.

It is recommended to install a circuit breaker at the entrance of the electrical network to the bathhouse. It is also advisable to provide each wiring branch, in accordance with the diagram, with a separate fuse. This is a fairly important part of the work in installing electrical equipment, so if you can’t do it yourself, it’s better to invite specialists.

Is it possible to build a bathhouse from aerated concrete?

Many steam room lovers are interested in the possibility of building their own bathhouse, reducing the cost of its construction. One of the options for relatively inexpensive construction is the use of aerated concrete. When asked whether it is possible to build a bathhouse from aerated concrete, all professionals answer in the affirmative. The main thing is to carefully study the specifics of the material. Knowing the conditions in which construction with aerated blocks is expected, you will build a beautiful and durable bathhouse.

Aerated concrete intended for the construction of steam rooms has:

- porous structure;

- rectangular or U-shaped;

- optimal dimensions 625 x 240 x 250 mm or 600 x 300 x 250 mm;

- frost resistance, which is indicated by the marking, from F35 and above.

The thickness of the walls of a bathhouse made of foam concrete or aerated concrete usually depends on the region of location. In the northern parts of the country, it is recommended to erect walls whose thickness reaches 60 cm. For the middle zone of the country, thinner walls are suitable - with a width of 250 to 400 mm.

In terms of hardness and density, the blocks are not inferior to brick and wood, and they are easier to work with

When purchasing material, it is important to choose products from a trusted manufacturer. One of the well-known brands on the modern market is “Aeroc” - this type of aerated concrete is characterized by high quality, and the percentage of defects is minimal

Main characteristics of the material

Aerated concrete blocks produced for sale, intended specifically for the construction of baths, are determined by the following indicators:

- frost resistance marking not lower than F 35;

- elements in the form of a P symbol (U-shaped) or rectangular. The first type is used to form door and window openings, ceilings;

- porous structure. It is typical for foam concrete, since when it is created, gas is added to the mixture of cement, water and sand;

- wall blocks have a heat-insulating layer applied;

- standard dimensions of elements are 60x30x25 cm or 62.5x24x25 cm. For laying external walls, blocks with a thickness of 20 cm are used, and partitions - up to 15 cm.

Appearance of aerated blocks A bathhouse built from aerated block in the middle zone should have walls with a width of 25-40 cm. For the northern regions, this value increases to 60 cm.

Finishing

The walls of aerated concrete baths must be lined both outside and inside. There are different types of decorative materials that can be used to finish surfaces.

Internal

Features of the interior decoration of aerated concrete baths:

- To waterproof walls under a decorative coating, you can use liquid glass or foil film.

- The material with which the walls will be sheathed from the inside must be resistant to constant temperature changes and prolonged exposure to moisture.

- Finishing work must begin with the floors. They can be covered with wooden flooring - continuous or with intervals to drain water. You can cover the floor with ceramic tiles.

For interior wall cladding you can use:

- Siding. Plastic is not suitable for a steam room, but can be used for a washing room.

- Lining made from different types of wood.

- Ceramic tiles.

Surfaces near the stove must be covered with heat-resistant material. To do this, you can use basalt slabs, on top of which reflective metal sheets should be fixed.

External

Before fixing decorative materials, you need to coat them with a hydrophobic primer. For cladding you can use:

Environmentally resistant plaster.

Block house. Can be metal, wood, vinyl. Plastic or metal siding. Facing brick, decorative stone.

Lining made from different types of wood

It is important to cover it in advance with a protective composition against moisture and insects. Facade putty.

A bathhouse can be built from different materials - timber, unedged boards, bricks, foam and gas blocks. The latter option is popular due to its ease of installation and low price. Anyone without practical skills can assemble a bathhouse from aerated blocks.

Floor decoration

The next step after finishing the steam room is working with the flooring. Tile is used as a finishing material. To perform the work as efficiently as possible, you must adhere to several recommendations:

The first step is to install a drainage system. To do this, you need to install ladders. To finish the floor, you can use any tile without exception. It is used only to ensure that sanitary standards are met in the room. Sloping plums must be trimmed with special attention

It is important to avoid the formation of counterslopes. You can buy tiles cheaper, but you shouldn’t skimp on grout. High-quality grout will help ensure that moisture does not seep through the seams. It is strictly forbidden to lay tiles on so-called slips. The temperature inside the room will constantly change

As a result, moisture will collect under the tile, which can tear it off at the first sharp cold snap and frost.

You will also have to tinker with the floor in the dressing room. You need to lay the tiles there after the “warm floor” system is installed. Many do not see the need for it, believing that the heat from the steam room is enough to heat this room. But this is not so, and heated floors are a completely reasonable solution.

Installing a heated floor is not difficult. The work is carried out in several stages:

- First of all, you need to do the marking. The detailed plan marks the location of the grooves, sensor and other elements.

- Next comes the manufacture of grooves - recesses in the floor. There will be a temperature sensor inside. After the wires are routed from it to the thermostat, the groove can be covered with a solution of cement and sand.

- The next stage is cleaning and priming the working surface. It is better to choose a deep penetration primer.

- Now, strictly adhering to the markings, you need to lay out the heating mats.

- Next, to check the correct connection and functionality, you need to connect the system to the network.

- After checking, you can lay out the tiles.

The finishing of the floor in the dressing room is carried out using a special technology, different from that used in other rooms

Particular attention should be paid to the thickness of the adhesive layer - it should be at least 1 cm. Because of this, the floor will take a little longer to dry than in other cases

Object cost

Those who have decided to acquire their own bathhouse made of aerated concrete are, of course, concerned about the issue of cost. Here everything largely depends on how complex the project was chosen for implementation. The simplest bathhouse made of this material will cost 10,000 rubles per 1 sq. m. m.

It is possible to arrange a more complex structure on the site. However, in this case you need to be prepared for serious financial costs. After all, the cost of constructing a large facility with a complex layout increases significantly.

You can do the construction of a bathhouse on your own site yourself. This will significantly reduce the budget for the construction of the facility. In this case, the main expense item will be the purchase of building materials.

The construction of a bathhouse made of aerated concrete is a cheaper measure compared to the construction of a building for steam procedures made of wood. An object for rest and relaxation can be obtained subject to the correct choice of aerated concrete blocks. The building material from has proven itself well. The blocks of this manufacturer are characterized by a homogeneous composition, have the same geometric dimensions, and their surface is absolutely flat.

Aerated concrete is an excellent material for building a bathhouse. It has many advantages and very few disadvantages. This structure can be easily erected with your own hands. When performing work, you must act in accordance with the developed project. In this case, many mistakes that novice builders often make can be eliminated.

If the main points of construction technology from aerated concrete blocks are observed, it becomes possible to construct a reliable bathhouse.

For its long-term operation, it is necessary to correctly approach the issue of interior decoration. In this case, the procedures in it will bring joy, and the need for repairs will not arise soon.

Advantages of this construction technology

Do-it-yourself technology for laying a wall of foam blocks.

Undoubtedly, bathhouses made of aerated blocks will delight their owners for many years. Installation of gas blocks does not require much effort and they are easy to install into the required structure. Aerated blocks are moisture resistant, so you don’t have to worry that the walls will absorb all the moisture, which is more than enough in the steam room.

The constructed baths do not require additional vapor and waterproofing. But if you wish, you can make the interior decoration with wooden lining. In this case, a gap of 10 mm must be left between the gas block and the lining. This will provide additional ventilation. In this case, the lining does not serve for waterproofing, but is rather of an aesthetic nature, because since time immemorial we have become accustomed to the fact that the walls in the bathhouse are made of wood.

Another advantage of aerated concrete, which manifests itself during the operation of the room, is its low thermal conductivity. This property allows you to retain heat for a long time, while the air in the room will be clean and safe, since the aerated block has a cellular structure and is 80% air. The bathhouse is either not insulated at all, or lightweight material is used. Aerated blocks are easy to cut; for drilling walls, almost the same set of tools is suitable as for woodworking.

Therefore, when all construction work reaches its final stage, you will receive a bathhouse in which it will be pleasant to relax after a busy day at work.

Aerated concrete can be used to build not only a one-story building, but also a two-story building. If your project includes openings whose width is more than 2.5 meters, then it is necessary to strengthen the structure using lintels made of reinforced aerated concrete. Building a bathhouse from aerated concrete involves construction tools for processing the blocks. All blocks are mostly the same size, but if a block does not fit, it can be easily reduced using a hacksaw.

An aerated block is easier to lay than a brick, due to the large size and comparatively lighter weight of the blocks. There are cases when other materials are used to build a bathhouse, and aerated concrete is used to install internal partitions for its good sound insulation. The foundation of the bathhouse should not be powerful, since aerated concrete is light in weight. If the soil is not unstable or mobile, a strip foundation with a sand base is used. Waterproofing material is laid on top of the foundation. Most often, rubyroid is used for such purposes; it protects the structure well from moisture penetration. The size of the waterproofing material must be greater than the width of the gas blocks.

Construction of walls from foam blocks.

If you are thinking about how to insulate a bathhouse, remember that aerated concrete is a warm material, so insulation should be minimal. In aerated concrete, unlike brick, it is much easier to drill a hole for hidden wiring with a hammer drill. In addition, electrical wiring does not require additional insulation, such as in wood. Facing the facades with bricks for such a bath will be very useful - ordinary aerated concrete looks unaesthetic.

To finish the bath, it is necessary to paint the walls of the steam room and washing compartment with a hydrophobic primer. After this, you can apply a small layer of plaster. First add dissolved tile adhesive to the cement mixture. Even beginners can use a bathhouse made from this material, provided they follow the construction technology.

Bathhouse made of aerated concrete: pros and cons

Choosing a material for construction is an important step; the heat in the steam room and the durability of the building will depend on its correctness. Aerated concrete baths have high thermal insulation properties and are comparable in durability to stone buildings. What kind of building material is this?

Aerated concrete is an artificial stone, which is a type of cellular concrete. During the manufacturing process, dry ingredients (cement, sand, lime, aluminum powder or paste, special gas generators) are mixed with water. A reaction occurs due to which the mixture increases in volume.

After drying in an autoclave, a porous material is obtained having the following properties:

- light weight

- heat transfer resistance

- exact geometric dimensions

- Ease of processing is comparable to wood - easy to cut, saw and drill

- affordable price

A bathhouse made of aerated concrete has a whole list of advantages that builders appreciate:

The light weight of the blocks allows you to lay the walls yourself. No need to use machinery to move material on site

Another advantage of a lightweight material is the possibility of constructing a strip foundation. Artificial stone is environmentally friendly. A clear geometric shape simplifies the work, allowing even a novice in construction to cope with it. Aerated concrete does not burn, this is an important property for buildings where there is a possibility of a fire from a hot stove. The level of thermal insulation of aerated concrete the blocks are not inferior to the timber. Biological resistance will not allow fungus and mold to appear on the walls Affordable cost is a significant argument in favor of the building material Aerated concrete does not shrink - this allows you to begin interior and exterior decoration immediately after the construction of the building

But there are no products without drawbacks; the disadvantage of aerated concrete is its high moisture absorption. In order for the building to be used for a long time, high-quality waterproofing and wall finishing will be required.

Insulation of a steam room made of foam blocks

You should take the most responsible approach to the choice of materials and insulation design in the steam room.

The insulation material should not emit toxic substances and withstand high temperatures well. Mineral wool can be an excellent choice.

Its advantages as insulation for a steam room include the following qualities:

- high value of heat transfer resistance;

- mineral wool does not burn;

- does not emit odor or harmful substances;

- does not support the spread of mold and mildew;

- not susceptible to being eaten by rodents and woodworms.

Mineral wool materials are perfect for insulating walls and ceilings in a steam room.

To lay heat-insulating material on the walls, wooden blocks with a thickness equal to the thickness of the insulation layer are hammered at intervals equal to its width.

Thermal insulation is rolled out between the bars, covered on top with a layer of vapor-waterproofing material (foil) and sewn up with clapboard.

In general, the layers of the thermal insulation “pie” of foam block walls look like this:

Thickness and layering of walls

The bathhouse is not a living space and is heated only periodically, so there is no need to build massive walls in it. Excessive thickness only increases warm-up time, forcing you to waste more fuel. It’s not for nothing that standard designs provide for a wall thickness of 300 mm - it is the most optimal.

Taking blocks of greater width (375 mm) or laying a wall one and a half blocks long makes sense only in the northern regions. In a relatively warm climate zone, walls can be made no more than 200 mm, for which the same block with dimensions 60*20*30 cm can simply be laid on its edge.

A lot here also depends on the size of the building - a small bathhouse definitely doesn’t need thick walls. Moreover, the facade is also insulated.

A little about masonry

Work begins with preparing the foundation surface, which is most often uneven. When installing gas blocks, manufacturers recommend using special adhesive mixtures. This is more profitable, since glue, although more expensive, is consumed much more economically.

However, the first row of blocks is placed on a regular solution of cement and sand, and the foundation is also leveled with it. A screed is made, waterproofing is laid on top of it with mastic (to cut off the possibility of capillary suction of moisture), and then the bed for the first row of masonry is laid out.

Laying the first row of waterproofing

- All other rows are mounted with glue - with it the thickness of the seams is thinner, and accordingly, there are practically no cold bridges. Like any building mixture, dry glue is mixed with water, mixed, and swells for 5-10 minutes. Then it is mixed again and goes to work.

- Laying begins from the highest point of the foundation, determined by the water level. In the corners of the wall, ordering slats are placed, a mooring cord is pulled between them, which will make it possible to control the position of the blocks and the thickness of the seams.

- There should be no differences between the upper planes of neighboring blocks, as this can cause cracks to appear. They are sanded - like the block halves, which need to be sawn to complete the laying of the row. The next row begins to be laid on the side where the extension is installed - this will ensure the necessary displacement of the vertical seams.

About reinforcement

If the length of the bathhouse walls does not exceed 6 meters, there is no need to reinforce them in every 4th row.

It is enough that you provide reinforcement:

- On the sides of the openings on top, where the lintels will rest.

- In the penultimate row of masonry in front of the window opening.

- Make an armored belt in the area of the ceiling or support of the roof rafters.

Reinforcement of a number of gas blocks with rods

The masonry can be reinforced either with rod reinforcement: on walls with a thickness of 250 mm or more - in two rows with a diameter of 8-10 mm (on thinner ones, one rod with a diameter of 12 mm is taken). The reinforcement is placed in pre-cut grooves and embedded in glue. You can also use punched tape, steel or basalt mesh to strengthen the masonry.

Interior decoration

After laying the walls, they arrange the ceiling and try to quickly install the roof - to protect the construction site from precipitation. Then they begin to form the floor and only then begin to line the walls. First from the inside.

Traditionally, the walls of the washing compartment of the bathhouse are covered with wooden lining - a profiled board with a tongue and groove on one side and a groove on the other. It is mounted on a wooden sheathing, between the belts of which they lay, for example, foam plastic, covered with sheet foil on top.

Cladding made of clapboard in the steam room

- We have already mentioned the ease of use of materials such as Penofol and Tepofol. They have a great advantage over all known insulation materials, since with the same thermal conductivity they have a vapor permeability coefficient of only 0.001 mg/m*h*Pa. We can say the figure is zero.

- That is, such a material best protects against the penetration of vapors into the wall, while at the same time being a thermal insulator. Thanks to the foil layer, which must face the inside of the room during installation, it perfectly reflects heat.

- A vapor-waterproofing membrane is first installed under the polyethylene foam, making overlaps between the sheets, leading them to the foundation and to the ceiling, and fastening them with double-sided tape. Next, Penofol sheets are mounted end-to-end, gluing the seams with aluminum tape.

- Mechanical fastenings are made with dowels only along the top line, since the sheathing bars installed at the next stage will perfectly fix the rolled insulation. If the lining is mounted vertically, the bars are placed in a horizontal position - and vice versa.

Installation of insulation on walls

For insulation you need to have a set of necessary tools and materials:

- thermal insulation material;

- special glue that will attach the sheets to the walls;

- dowels (“umbrellas”) – if you need to attach mineral wool mats;

- fiberglass mesh;

- any container for preparing the adhesive mixture;

- building level;

- notched spatula;

- perforator;

- perforated corners.

To insulate with foam plastic, you must:

- clean the walls from dirt;

- level with cement mortar or special plaster mixtures;

- at the level of the base, install a frame that will become a support;

- glue the fiberglass wall for reinforcement (fixed so that 10 cm is under the insulation).

After this, special glue is applied to the foam and walls using a spatula with teeth. A sheet of glue is applied to the wall, secured with dowels in the corners and in the middle. Be sure to coat the foam joints with glue.

Please note that the sheets must be laid offset, as when laying blocks

When working with mineral wool, do not forget that the material has good vapor permeability and the walls will “breathe”.

Getting started with mineral wool is the same as with polystyrene foam. The sheets are fastened at intervals, and a fiberglass mesh is placed on a layer of wool. This will help prevent cracks in paint and plaster. An additional layer of glue is applied on top of the mesh. After the glue has dried, vapor-permeable plaster is applied.

To summarize, I can say that internal and external insulation of aerated concrete walls will require time and attention from you, but the end result will pleasantly surprise and delight.

Why were gas silicate blocks chosen?

When I just started construction, many neighbors in the dacha community asked me a question about why I chose gas silicate blocks. Somehow everyone got used to either wood or brick. And my arguments are:

- Quick installation. Gas silicate blocks are larger in size than bricks, so the construction of walls from them is much faster.

- High thermal insulation. Gas silicate belongs to cellular concrete, that is, it has many air cells inside. They play the role of heat insulators. Therefore, a bathhouse made of gas silicate blocks, in comparison with a brick one, warms up faster and retains heat longer. In terms of thermal insulation qualities, gas silicate is not inferior to wood.

- Fire resistance. Gas silicate blocks do not burn, unlike wooden structures.

- Impossibility of rotting.

- Low cost compared to brick, timber or logs.

In addition, I have good bricklaying skills, so I decided that I could handle gas silicate blocks.

I'll start in order.

Third stage: erection of walls

Aerated concrete blocks begin to be laid in the corners of the building, and a thread is pulled between them - this is a kind of guideline that will prevent uneven laying of the walls.

Professionals recommend that at the stage of laying the first row of blocks, using a building level, get rid of all the shortcomings that arose during the construction of the foundation itself

The first row is laid on the mortar and manually leveled so that the blocks do not move to the side in the future. Once the cement has completely dried, all dust is blown off, the blocks are cleaned and floated. The second, like all other rows, is laid on a special construction adhesive. The layer thickness should not exceed 7 mm.

Use the solution to secure the first row. For others, an adhesive solution is better

*If the bath area is up to 20 square meters, then the thickness of the walls is half a block; in other cases, the thickness of one block is sufficient.

The blocks are laid edgewise, try to make the joints as small as possible, because the thermal conductivity of the bath directly depends on this. Constantly check the evenness of the walls horizontally and vertically, if necessary, level the blocks using a rubber hammer.

A reinforced belt is laid on every fourth row. Using a hand cutter, a small trench is cut out in the blocks around the perimeter, the depth of which corresponds to the diameter of the metal rods. They must be completely immersed in the recess and filled with solution.

Laying is carried out with bandaging on the floor of the block using a glue carriage or ladle. And the installation itself must be done in such a way that the vertical seams of the previous row do not coincide with the next one. To arrange window and door openings I use a concrete belt made of U-shaped blocks. First, temporary support structures are installed under the openings, and then reinforcement is installed in the product tray and poured with concrete.

A wall chaser will help you easily cut grooves in blocks to create a reinforced belt

The last row of aerated concrete blocks is reinforced with a monolithic stiffening belt, which helps to more reliably fix the Mauerlat and other components of the rafter system.

A couple of tips for insulation

As I already wrote above, not only the floor in the steam room should be insulated, but also all other rooms of the bathhouse. But here you should carefully consider the choice of material used. For example, only materials with a closed cell structure (foam plastic, extruded polystyrene foam, etc.) are suitable for steam rooms and sinks. Due to the peculiarities of the microclimate created in these rooms, the use of mineral insulation is not recommended!

But the rest room or dressing room can be safely insulated with mineral wool and even construction felt (no one has canceled polystyrene foam either). In these rooms, the humidity is not so high, and therefore these materials will not be subject to strong influence and will help create a cozy atmosphere.

Well, that’s probably all I wanted to share with you in this article. I hope it will be useful to some readers. See you again, friends. And warm floors to you... Bye!

Lining for room cladding

You should take a responsible approach to choosing wood for cladding. The greatest resistance to decay is inherent in coniferous species, but when heated they are capable of releasing resin. Therefore, it is better to use them when covering a dressing room or washing room. Of the deciduous species, oak has the optimal resistance; however, when wet, it becomes slippery. An important factor when choosing lining is the aesthetic side of the issue. Cedar, oak, and alder have rich, dark colors, while larch, hornbeam, and spruce are lighter in color.

Windows and doors in the bathhouse

It is advisable to make them wooden, for which pine or ash are suitable, and varnishing is allowed only on the outside, otherwise harmful fumes cannot be avoided. For the same reasons, it is not recommended to use polyurethane foam as a sealant; it is better to use natural materials, such as felt.

The windows in the bathhouse serve only for lighting, therefore, in order to reduce heat loss, they are made small and placed low.

Special attention should be paid to the door to the steam room - it should open exclusively outward and close only with a ball latch, so that it can swing open simply from a push or under the weight of the body if one of the visitors becomes ill. Dimensions are smaller than standard (to avoid waste of heat).

Electrical wiring in the bathhouse

When installing the electrical network yourself, you should not forget that in aerated concrete walls the cable, wound into a corrugated tube, is laid along grooves cut into the blocks. It is first recommended to carefully develop a layout of electrical appliances, as well as lighting points, sockets and switches inside the room.

According to the calculated power of lamps and other electricity consumers, it is necessary to select a cable of a suitable cross-section in order to avoid overloads and heating of the wire. Since the bathhouse is a room with high humidity, the insulation of the electrical network should ensure maximum safety, and sockets should not be located too close to the floor.

It is recommended to install a circuit breaker at the entrance of the electrical network to the bathhouse. It is also advisable to provide each wiring branch, in accordance with the diagram, with a separate fuse. This is a fairly important part of the work in installing electrical equipment, so if you can’t do it yourself, it’s better to invite specialists.

Finishing is the final stage of building a bathhouse made of aerated concrete

For interior cladding, you need to use environmentally friendly, natural materials. They must have excellent thermal insulation characteristics and be resistant to moisture.

The quality of finishing of a bathhouse is directly related to the comfort of its further operation.

The material that meets all the criteria is the following wood species:

- ash;

- coniferous species (spruce, pine) without resin;

- alder.

The bathroom or sink surface is tiled with ceramic tiles. To improve hydro- and thermal insulation, surfaces are insulated from the inside after the building has completely shrinked. Typically, a support beam is used for this, on which a wooden lining is attached. The free space formed between the wooden sheathing is filled with insulation – glass mineral wool. To make the microclimate as favorable as possible, lay a warm concrete floor in the bathhouse.

For exterior decoration it is not necessary to use expensive wood - these days vinyl siding, artificial timber or block house have proven themselves well. Decorative stone and facing brick will look good in combination with a metal tile roof.

What is needed for the job?

To do the work yourself, prepare the following materials and tools:

- ingredients for preparing concrete mortar (cement, crushed stone, sand, water) necessary for the foundation;

- gas silicate blocks, the number of which is determined at the design stage;

- concrete mixer necessary for preparing the solution;

- shovels and buckets used in the construction process;

- reinforcing bars to strengthen the concrete base;

- pegs and cord for marking the site.

After marking the site, removing vegetation, planning the surface, proceed to further work.

Waterproofing with films

Waterproofing a bathhouse built from aerated concrete blocks is a complex of works that cannot be avoided. Insulation materials (stone and mineral wool) are rightfully considered effective materials. But if they are not protected by reliable and high-quality waterproofing, destructive processes begin. Moisture gets into the insulation, thereby reducing its properties. Also, increased humidity has a negative effect on aerated concrete blocks, since the structure becomes less durable. As a result, the risk of cracks and other unpleasant consequences increases, which lead to additional costs for restoration work.

Waterproofing film is best suited for protecting aerated concrete blocks from the negative effects of moisture. It is manufactured in accordance with the standards and has excellent performance characteristics. Film waterproofing is widely used because the materials fully fulfill their purpose. They do not rot over time and provide long-term use.

Waterproofing film has a number of fundamental advantages. These include:

- high strength;

- reliable protection of insulation and aerated concrete blocks from the harmful effects of moisture;

- resistance to the influence of negative factors;

- long service life;

- ease of installation.

Comparison of insulation materials

The choice of insulators for insulating bathhouse walls made of expanded clay concrete blocks is based on the following criteria:

- ease of installation, quick assembly;

- functionality;

- heat resistance;

- heat saving;

- hygroscopicity.

The most popular thermal fiber is its safety and versatility - it can be used both inside and outside. Before installation, preliminary preparation of the walls is necessary - cleaning them from dust, dirt, plastering. The latter measure also serves as additional insulation.

Natural jute felt is easy to install and does not impose specific requirements on conditions. This is an effective, environmentally friendly option. Polystyrene foam and mineral wool have good insulating characteristics and are attractive due to their low cost, low dead weight, and ease of installation. Mineral wool is more preferable here, since it does not arouse interest among rodents.

Expanded clay insulation is used to insulate block baths

Expanded clay insulation is still relevant, since it is free-flowing and can only be used to strengthen the ceiling and floor. Basalt wool is fireproof, mold and fungi do not grow in it, it is durable and environmentally friendly. Foamed polypropylene is used in tandem with foil; this combination can withstand heating up to 150°C.

Characteristics of aerated concrete products

This building material has many advantages:

- Ease. Despite the fact that the blocks are large in size, they are very light, which greatly simplifies the work. Even an inexperienced builder can build a bathhouse from an aerated block with his own hands.

- Thermal insulation. Due to its porous structure, aerated concrete has good thermal insulation properties. If you build a bathhouse from aerated concrete, it will need less insulation.

- Durability and fire safety. This is a durable material that is resistant to rot, mold and attack by small rodents, and resistant to fire. Such properties ensure a long service life of aerated concrete products.

- Compliance. Aerated concrete blocks lend themselves well to manual processing. This allows you to build any complex structure with virtually no waste.

- Harmlessness. From an environmental point of view, aerated concrete is completely safe, which is confirmed by leading experts in this field.

- Affordability. Compared to other building materials, aerated concrete is low in cost.

In addition to its positive properties, aerated concrete material has one drawback - moisture absorption, and therefore requires external finishing.

Features of the work depending on the type of blocks

When designing the cladding structure and selecting thermal insulation, it is necessary to take into account the properties of the bathhouse caused by the material used for its construction.

Foam blocks

The specificity of the resource is its porous structure, since the production technology involves foaming a concrete mixture with protein additives and sand. Therefore, during insulation, the foaminess of the raw material leads to the fact that the blocks need to be protected from moisture as best as possible. Otherwise, excessive dampness will lead to a decrease in the thermal insulation parameters of the structure and its service life. You should not use polyethylene here; membrane films are more appropriate.

When insulating with foam blocks, you need to use membrane filmsExpanded clay concrete

In the process of insulating a bathhouse made of expanded clay concrete blocks from the inside, the porous contents of the workpieces are also taken into account; they are made on a vibropress. This is an environmentally friendly and easy-to-build material; it absorbs moisture abundantly. When arranging the “pie,” you need to provide waterproofing from kraft paper and a foil screen.

Cinder blocks

The budget resource can have different standard sizes, and the low price is explained by the use of waste from the coal and metallurgical industries as raw materials. Products vary in size, weight, and thermal conductivity.

As in the case of expanded clay concrete blocks, a ventilated gap should be maintained during the assembly of internal insulation. For cladding, you can use wood in the form of a block house or lining; it must be impregnated with compounds intended for use in hot, humid microclimates. The boards should be sewn horizontally so that as the lower segment wears out, local replacement can be made.

Gas silicate

The insulation of a bath made of gas silicate blocks is carried out in accordance with the type of base material. If this is a category from D800, it means that the structures are characterized by insufficient thermal insulation and high strength. The gap between D500-D800 is characterized by average parameters in both respects, while blocks of grades below D500 have excellent insulating properties and low strength.

When insulated, aerated concrete products need to protect air cells from moisture penetration and contact with high temperatures, otherwise the raw material will lose durability and strength.

Bathhouse made of aerated concrete: photo

Let's look at the most common bathhouse designs. In most cases, land owners have to save space. Therefore, a bathhouse is often combined with a summer kitchen. You can also combine a bathhouse with a terrace or outdoor barbecue area.

If space allows, the relaxation room is made as spacious as possible. Here you can not only relax after the steam room, but also receive guests. It would be great if the design of an aerated concrete bathhouse (see photo) includes a bathroom and a small utility room.

Advice! You should not leave walls unfinished for a long time - the thermal insulation properties of wet material will decrease.

To protect against precipitation, it is also advisable to immediately prepare the roof and install windows.

Sunbeds

Now it’s time to arrange the sun loungers. To make them from lumber you will need: oak beams 60x50 mm and planed linden boards 40–45 mm thick.

First of all, according to the drawing, load-bearing trusses are made. Two of them are rigidly anchored to the opposite walls of the bathhouse.

The rest are installed between them in increments of 600–700 mm and screwed to the floor and rear wall.

During installation of the frame, it is necessary to ensure that similar elements of the support trusses are in the same planes. The resulting wooden frame is covered with linden boards. In this case, the boards of the horizontal planes of the sunbed must first be planed in a surface planer to the same thickness, and the joints of the boards must be processed with a special cutter.

The vertical planes are hammered in such a way that there are ventilation gaps of 3–5 cm between the boards. We also remember that there should always be space between the floor tiles and the first lowest board. Moisture should flow freely into the sewer.

For all self-tapping screws used during the installation process, “sunk holes” about 10 mm deep are pre-drilled, which are then closed with wooden plugs.

After assembly, the entire deck chair is sanded with sandpaper.

This is the design of the simplest two-tier lounger. Perhaps some people won't like it. But you can always design the one that suits you best. You just need to follow some rules:

- The horizontal plane intended for steaming with brooms must have a width of at least 750 mm and be at a height of at least 800 mm.

- There must be good access to the sun lounger on which steaming with brooms takes place so that the bathhouse attendant can easily do his job.

- Inside, the structural space of the sunbeds should be well ventilated to avoid the accumulation of dampness and mold formation.

- The distance from the top shelf of the sunbed to the ceiling should be at least a meter.

- All metal parts or fastening elements of the structure must be securely hidden so that they cannot be touched even by accident.

- The entire structure of the lounger must be rigid and reliable enough to withstand the weight of all steaming people.